Upsetting method and upsetting device

A processing method and processing device technology, applied in metal processing equipment, engine components, mechanical equipment, etc., can solve problems such as poor, wrinkled surface properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

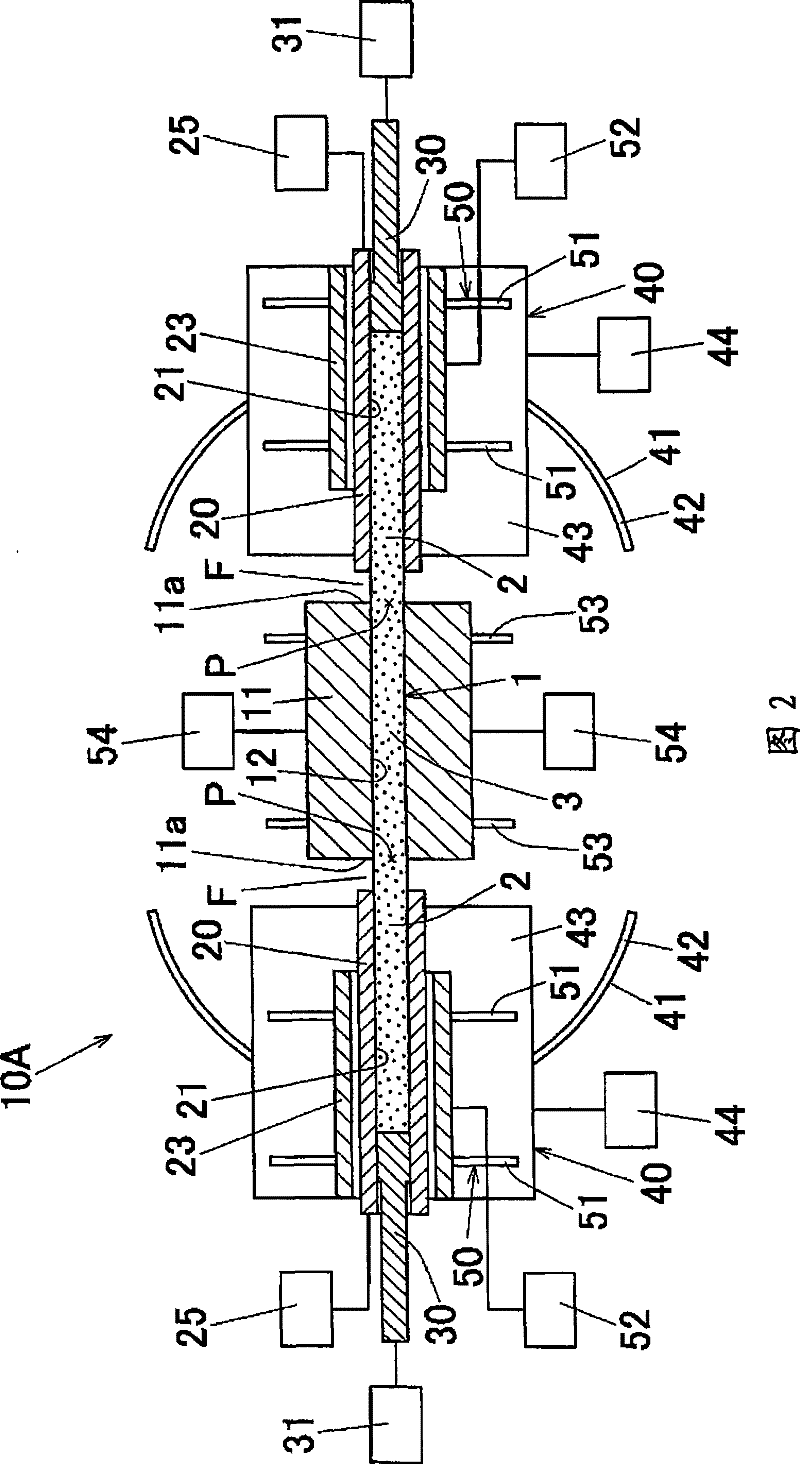

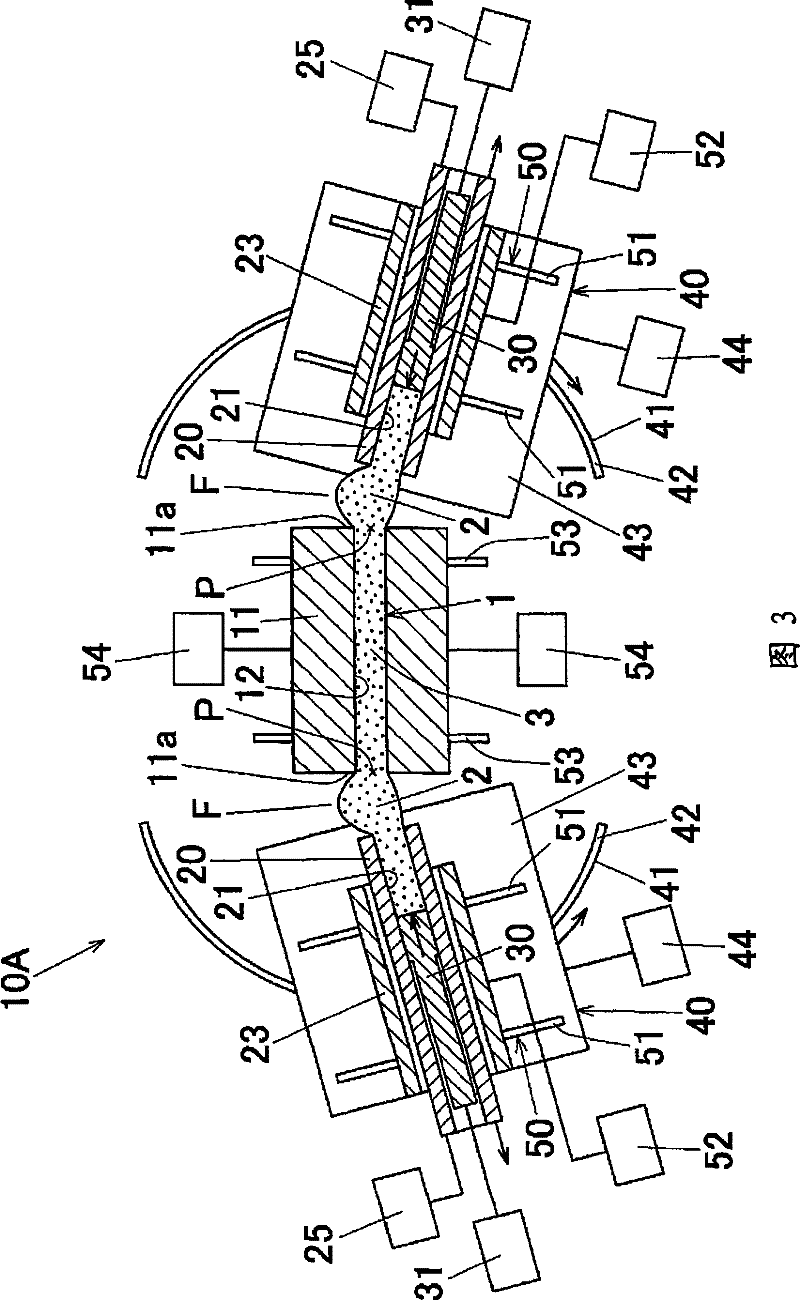

[0235] Next, several embodiments of the present invention will be described with reference to the drawings.

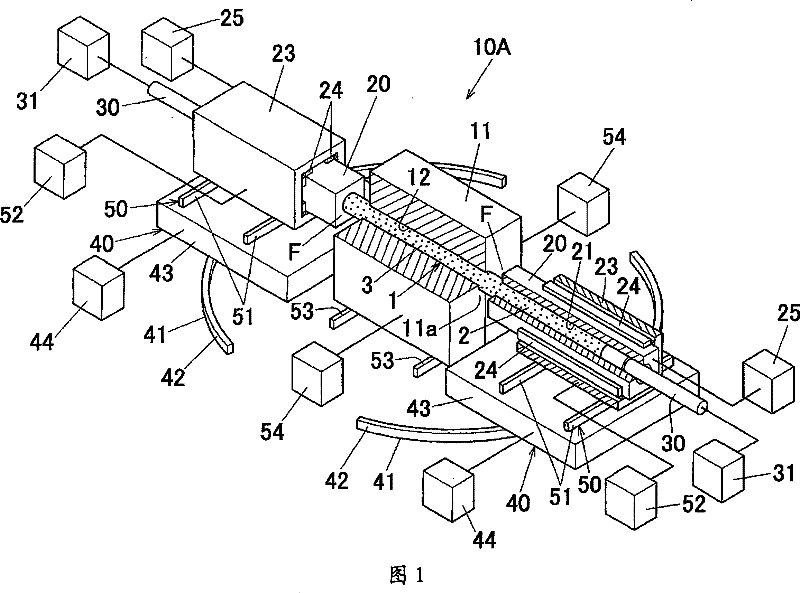

[0236] Figure 1 to Figure 5 It is a figure for demonstrating 1st Embodiment of this invention.

[0237] exist figure 1 Among them, 10A is the upset processing device according to the first embodiment. The upsetting device 10A is a free upsetting device in detail. In addition, 1 is a rod-shaped blank.

[0238] exist Figure 5 Among them, 5 is an upset processed product processed by the upset processing apparatus 10A. In this upset-forged product 5 , bulged portions 6 (diameter-enlarged portions) bulging (diameter-enlarged) outward in the radial direction over the entire circumference are formed at both ends of the straight shaft portion 7 . Each bulge 6 is bent in the axial direction. To describe in detail, the bulging portion 6 itself is bent, and the bulging portion 6 bulges unevenly in the circumferential direction. In more detail, the bulging amount of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com