Tilting system for a flanging device

A technology of flanging and flanging, applied in the field of operation of workpieces, can solve problems such as complex and expensive structures, and achieve the effect of improving flanging, low cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

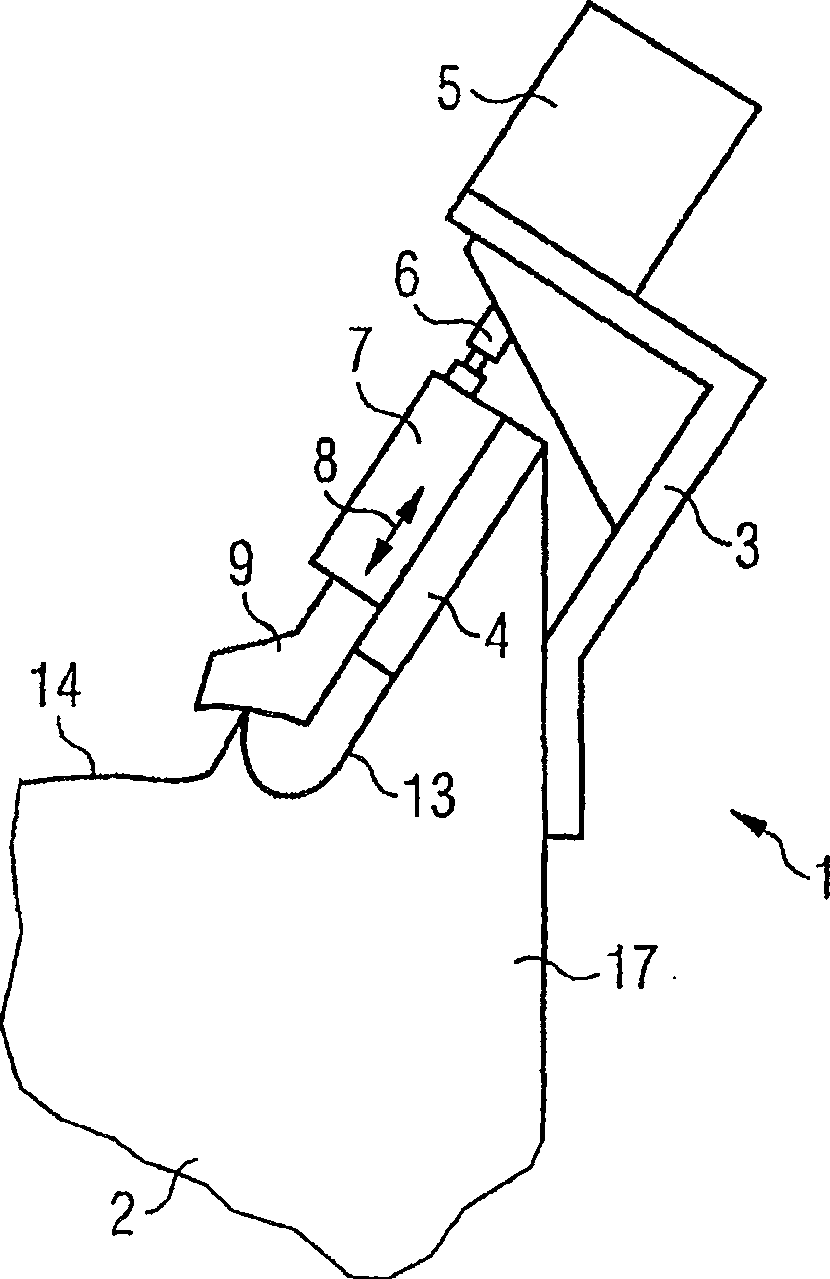

[0034] figure 1 A side view of the bending device 1 according to the invention is shown. The flanging device 1 is divided into a crimping machine base 2 with a cast-on slider 7 bracket 17, a welded structure 3 for mounting a pneumatic cylinder 5, a molded part 9, a guide device 4 and a piston rod 6 with an adjustment device .

[0035] A thin steel panel 14 rests on the crimping stand 2 . The welded structure 3 is meant to be the carrier of the pneumatic cylinder 5 and fastened to a bracket 17 designed as a cast part.

[0036] The machined upper side 13 of the bracket 17 serves here as a support for the guide 4 of the slide 7 which is connected to the piston rod 6 of the pneumatic cylinder 5 . A forming pincer 9 is provided on the front side of the slider 7 .

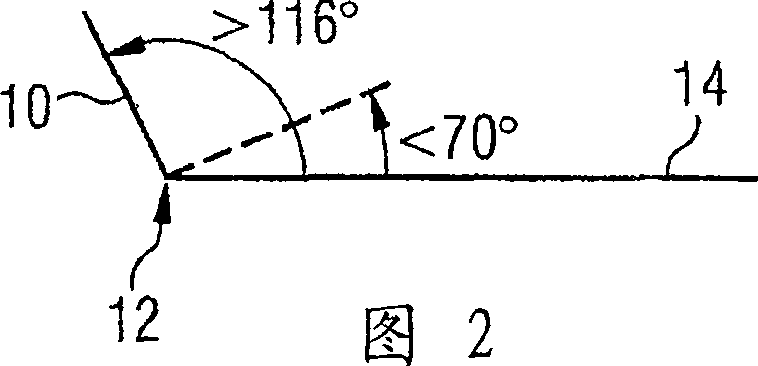

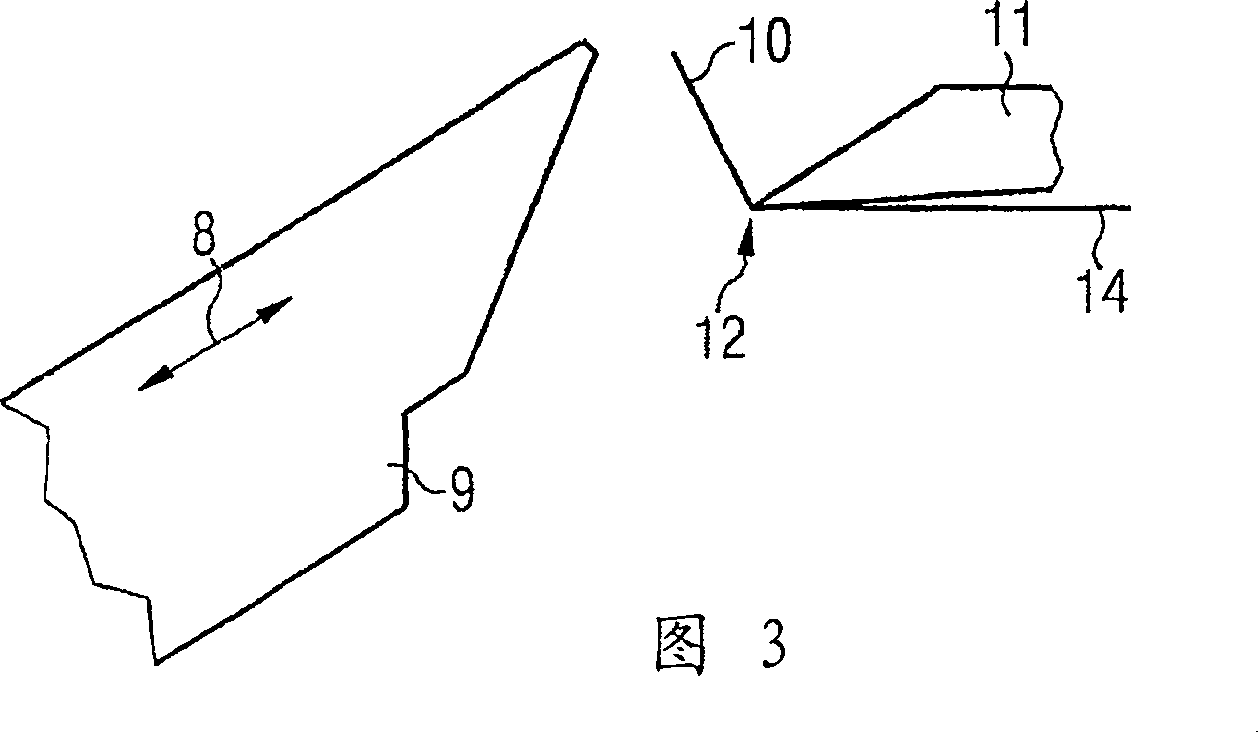

[0037] 2 and 3 show the deformation of the beading flange 10 of the thin steel panel 14 .

[0038] It can be seen from FIG. 2 that the beading flange 10 of the thin steel panel 14 is bent at a bending angle larger t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com