Patents

Literature

33results about How to "Reliable bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible optical waveguide, process for its production, and epoxy resin composition for flexible optical waveguides

InactiveUS20100150510A1Excellent in flexibility and durable to bendingReliable bendingCladded optical fibreCoatingsChemistryWaveguide

The present invention provides a flexible optical waveguide in which at least one of a lower cladding layer, a core layer, and an upper cladding layer is composed of an epoxy film formed using an epoxy resin composition containing a polyglycidyl compound having a polyalkylene glycol chain(s) and at least two glycidyl groups or an epoxy film having a glass transition temperature (Tg) of 100° C. or lower, a process for its production, and an epoxy resin composition for flexible optical waveguides.

Owner:NIPPON SHOKUBAI CO LTD

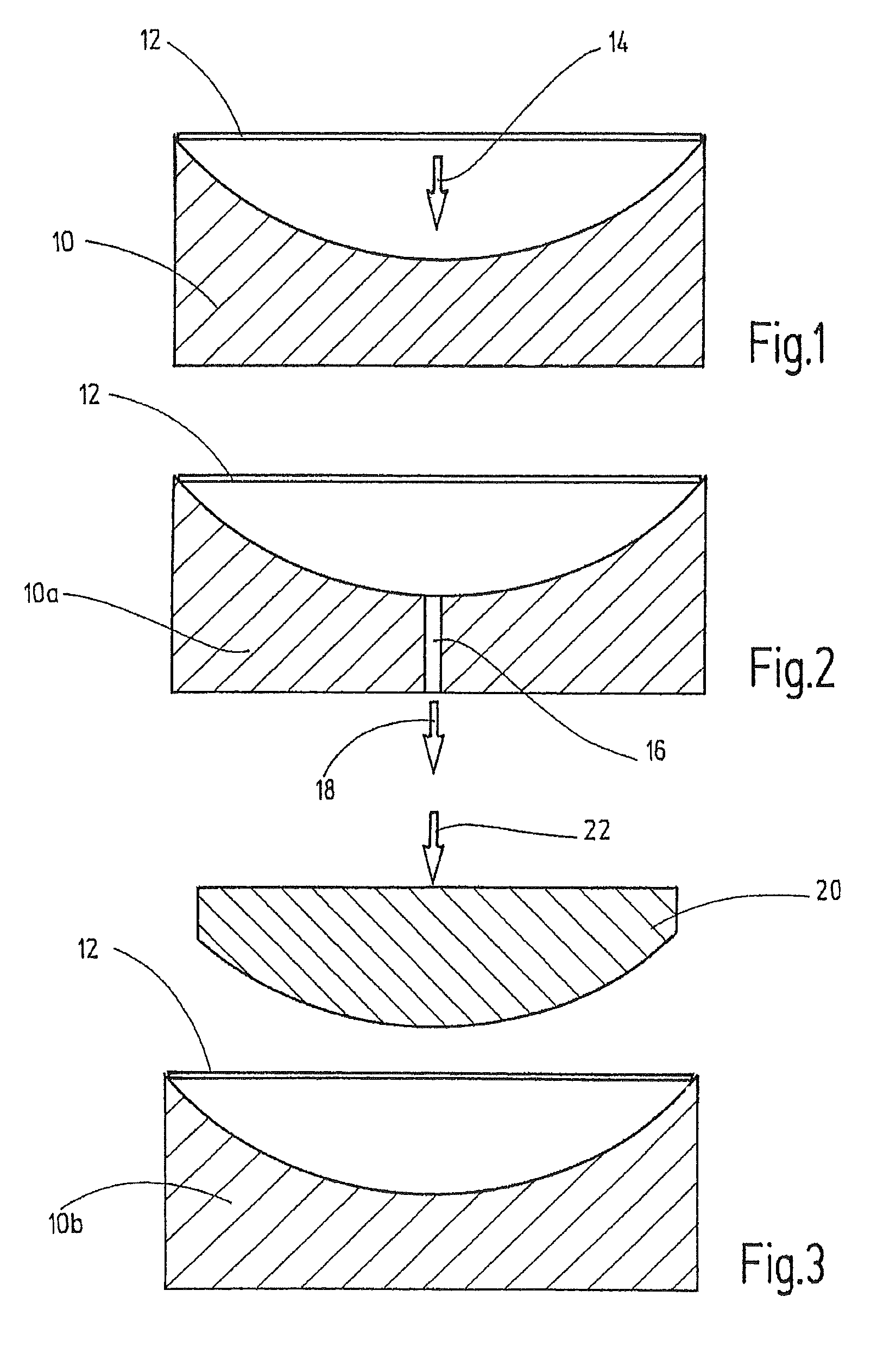

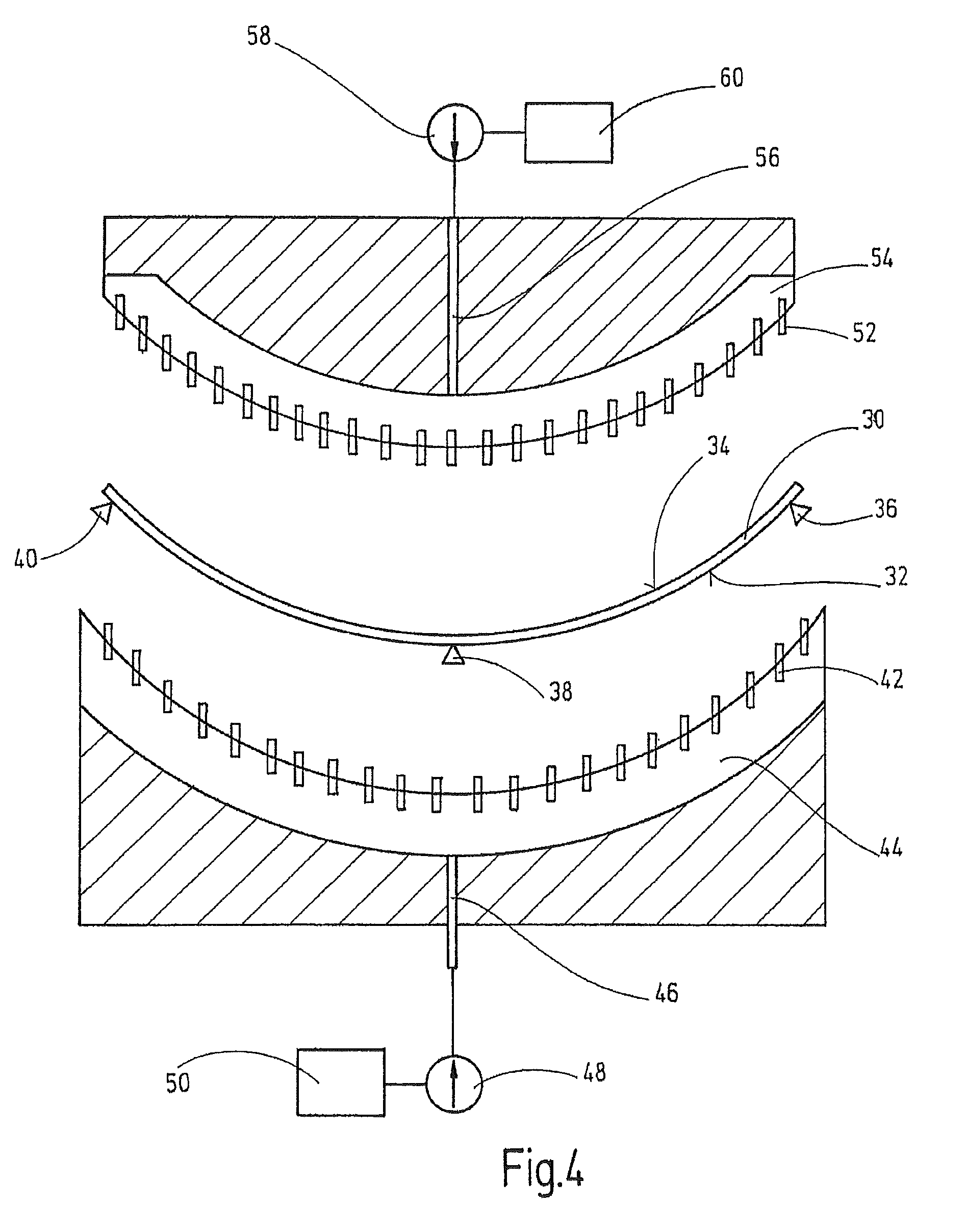

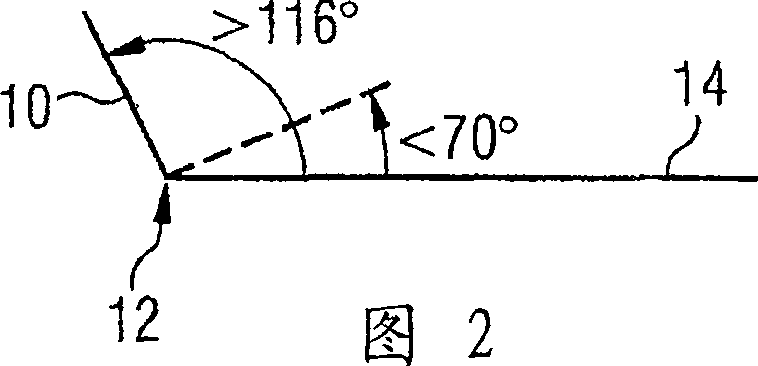

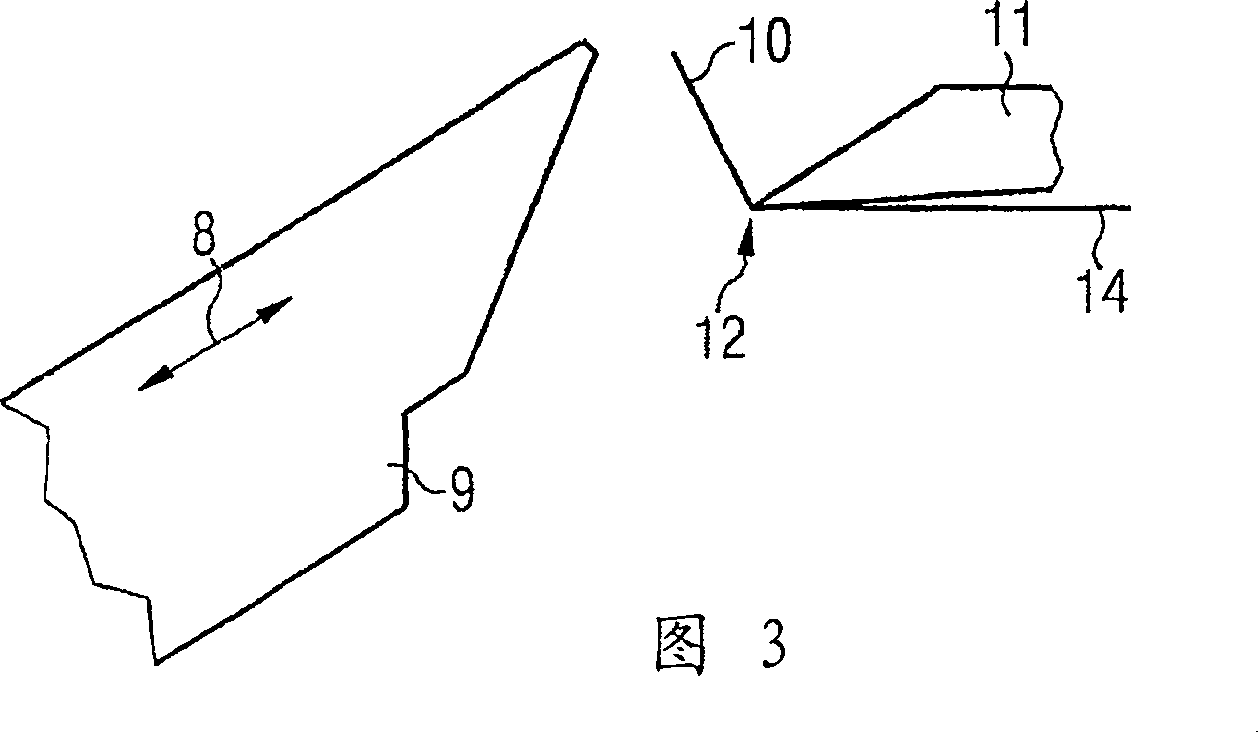

Method for bending and thermally prestressing radiation shielding glass

ActiveUS8783065B2Quality improvementReliable bendingGlass reforming apparatusGlass severing apparatusCold airHeating time

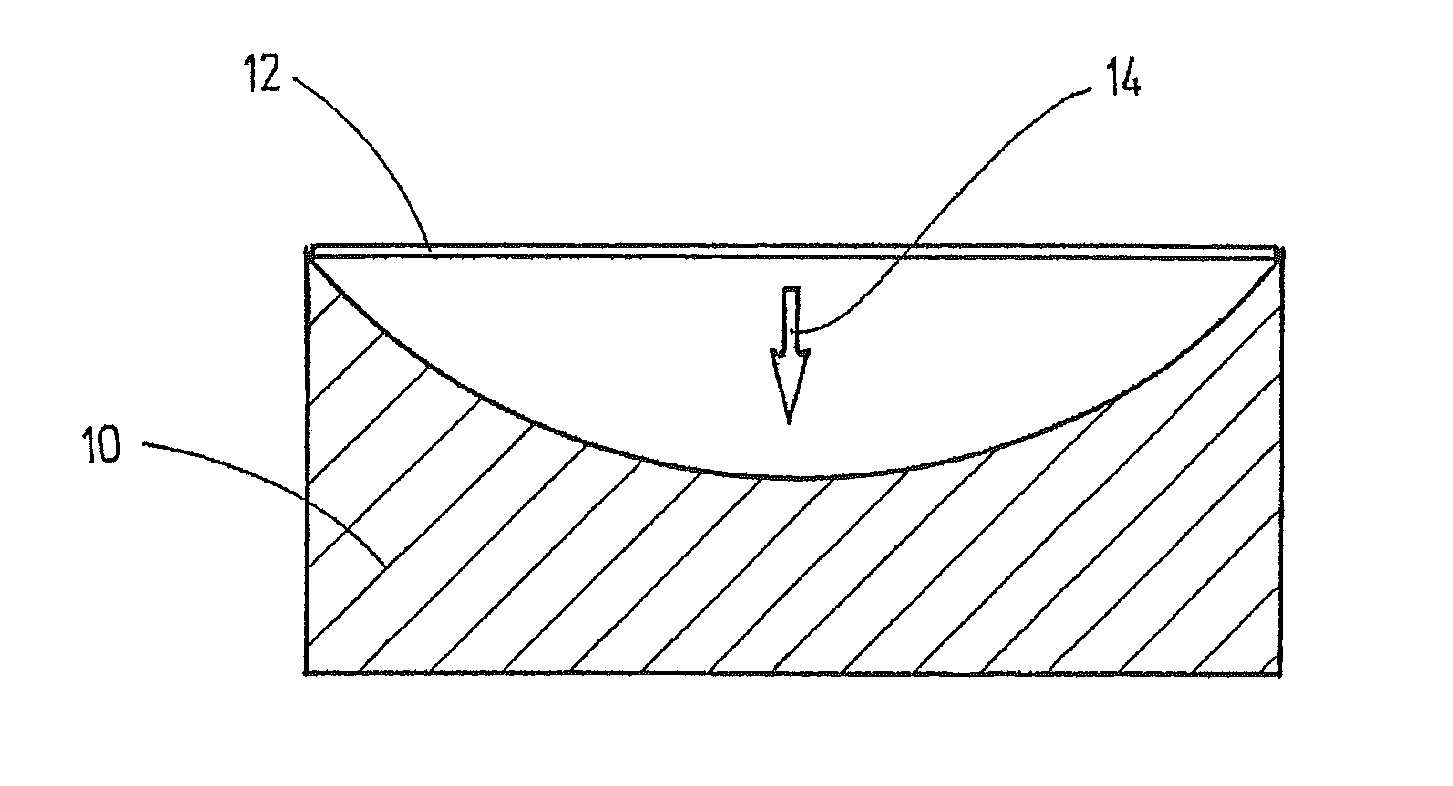

A method for bending radiation shielding glass which has a heavy metal oxide content of at least 50% by weight is provided, wherein first a mold is provided, a glass plate comprising a radiation shielding glass is then provided, the mold is preheated to a temperature of 300 to 400° C., the glass plate is placed on the mold, the glass plate and the mold are heated in a furnace to a temperature of 370 to 430° C., then heated together to a temperature of 400° C. to 500° C., preferably to 440 to 500° C., the total heating time being at least 30 minutes, preferably at least 60 minutes, the glass plate is then molded and finally the molded glass is cooled by means of a cooling program over a period of at least 60 minutes. For thermal prestressing, the glass body is supported at least at its outer periphery at a number of support points, introduced into a preheated furnace, heated to 400 to 500° C. and then removed, and cold air is blown onto both sides from a multiplicity of nozzles, preferably until cooling to about 100° C. has taken place.

Owner:SCHOTT AG

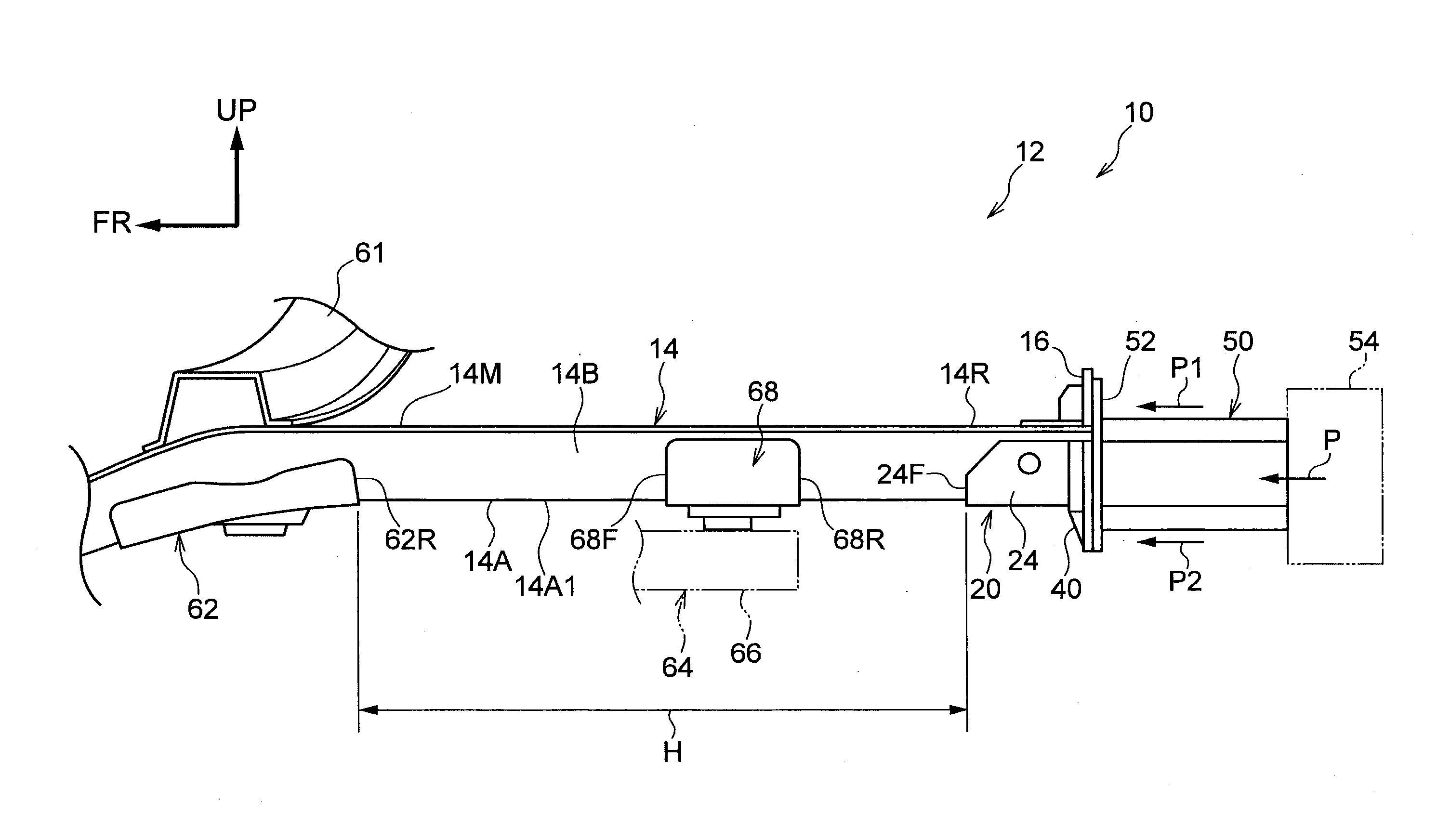

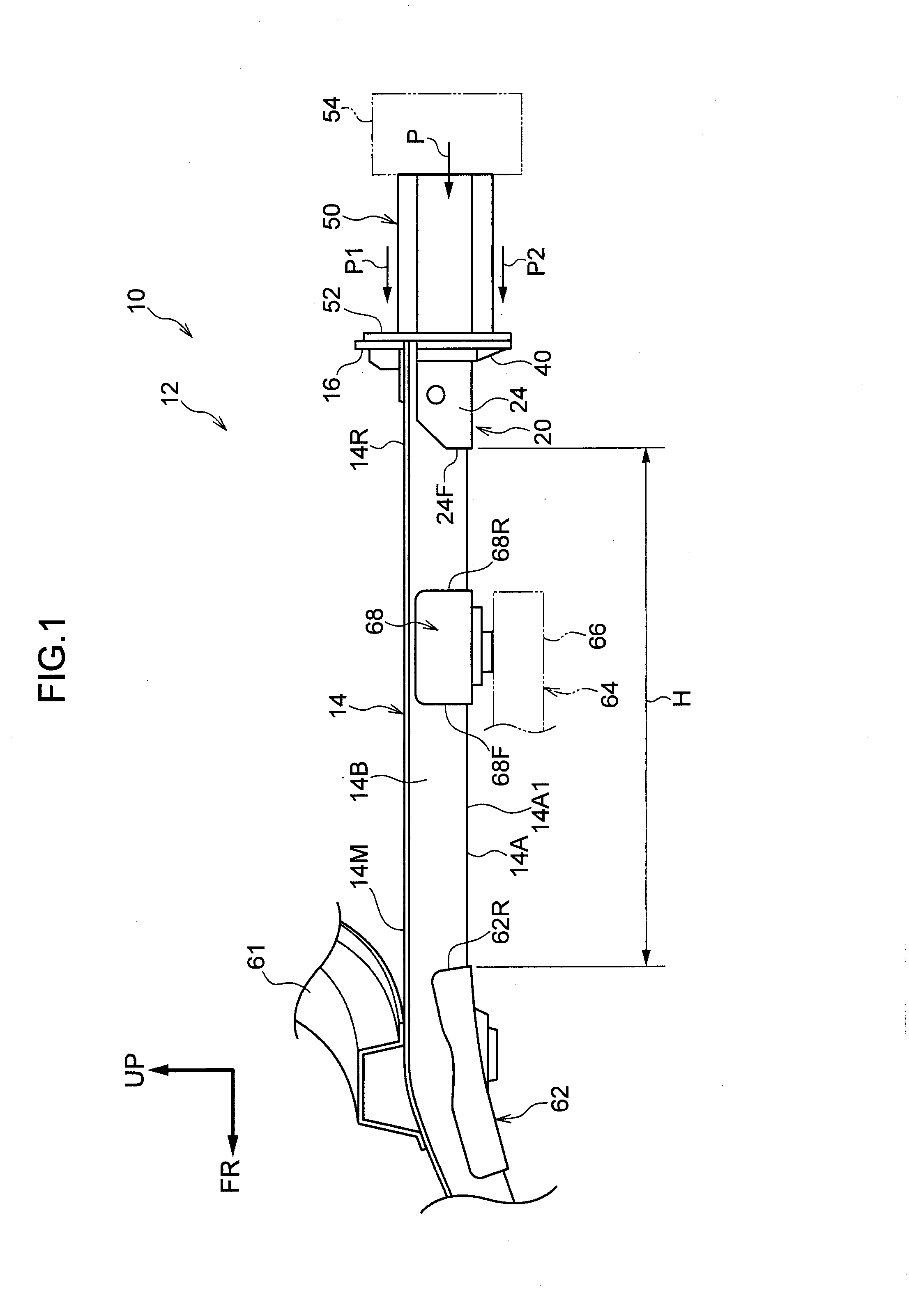

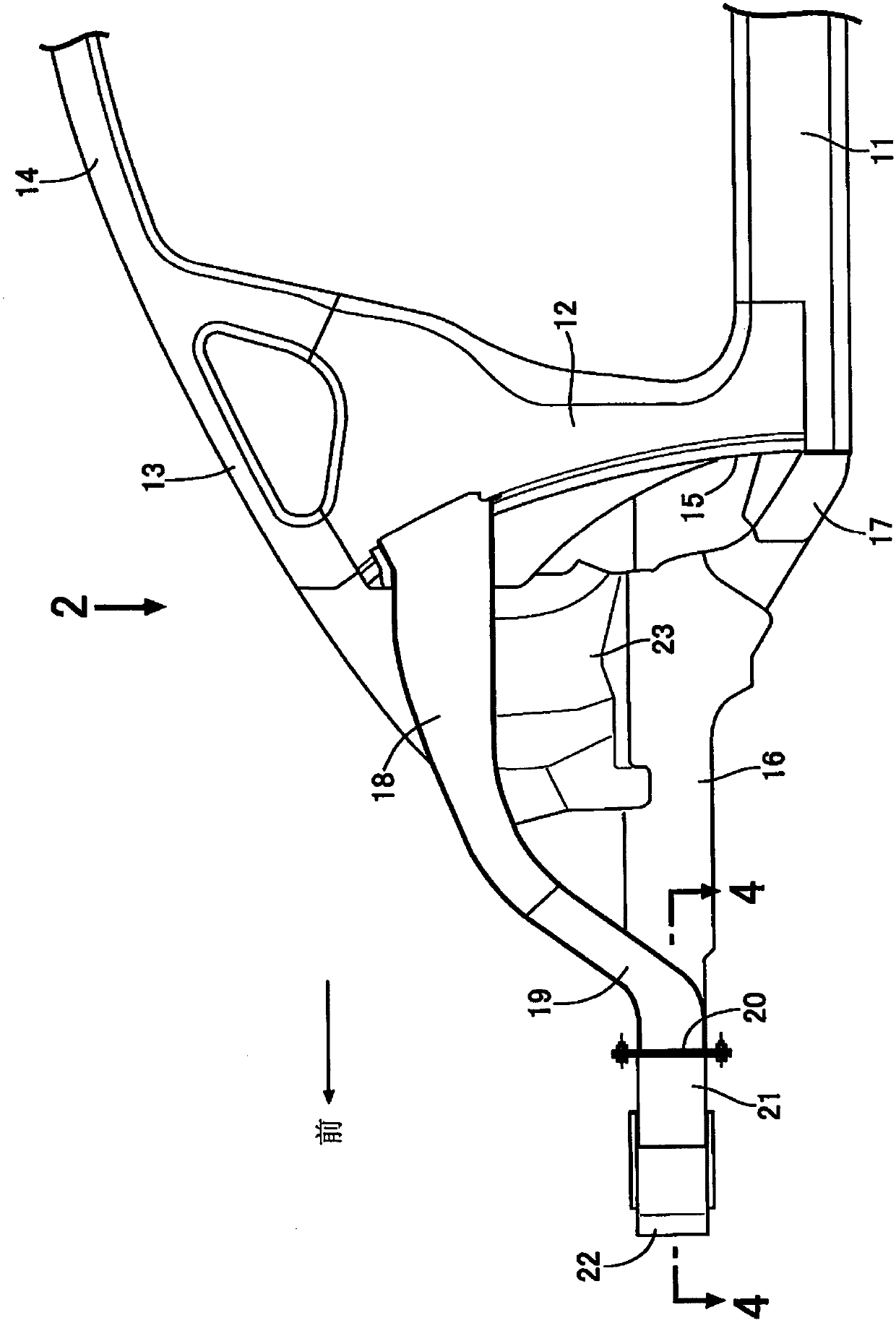

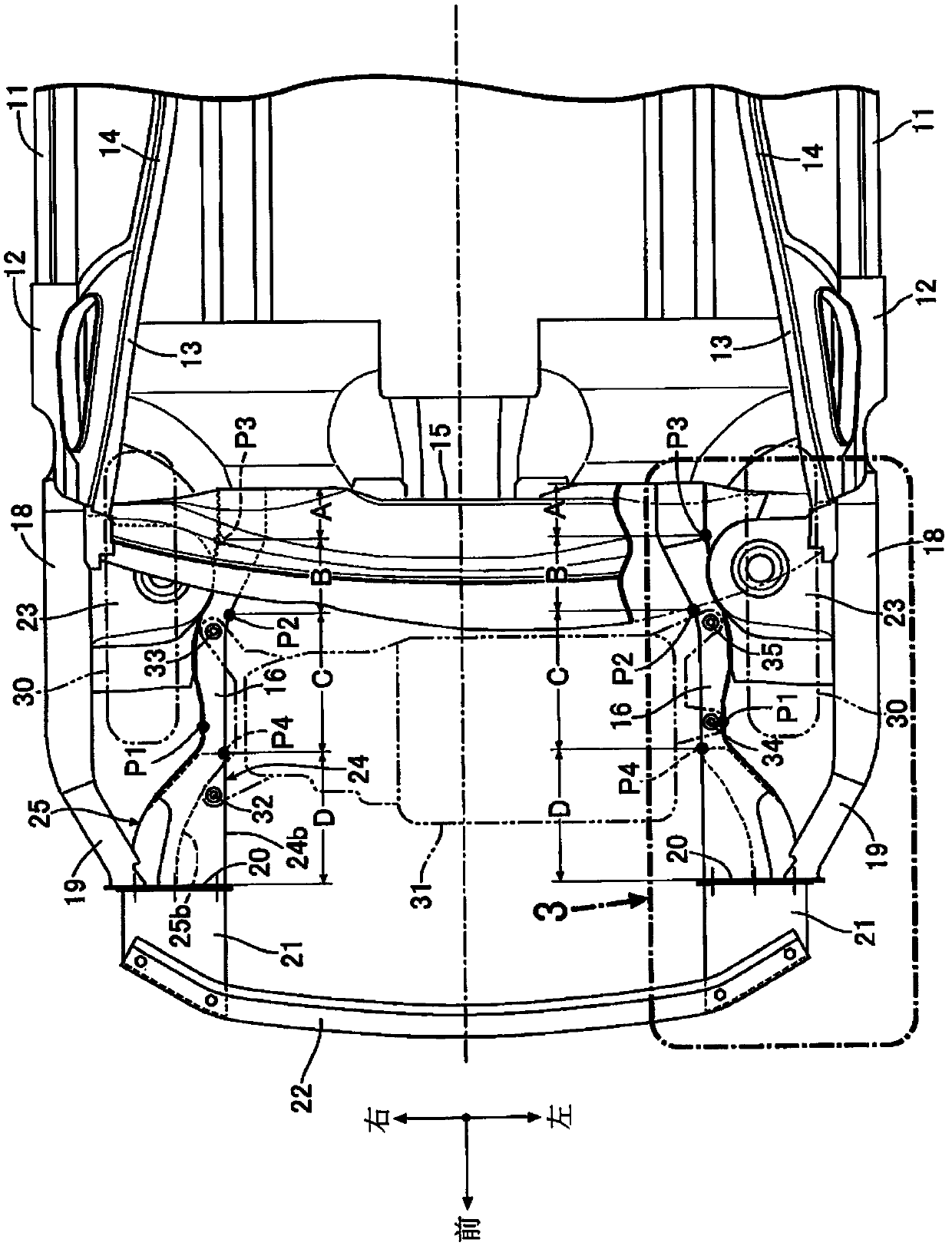

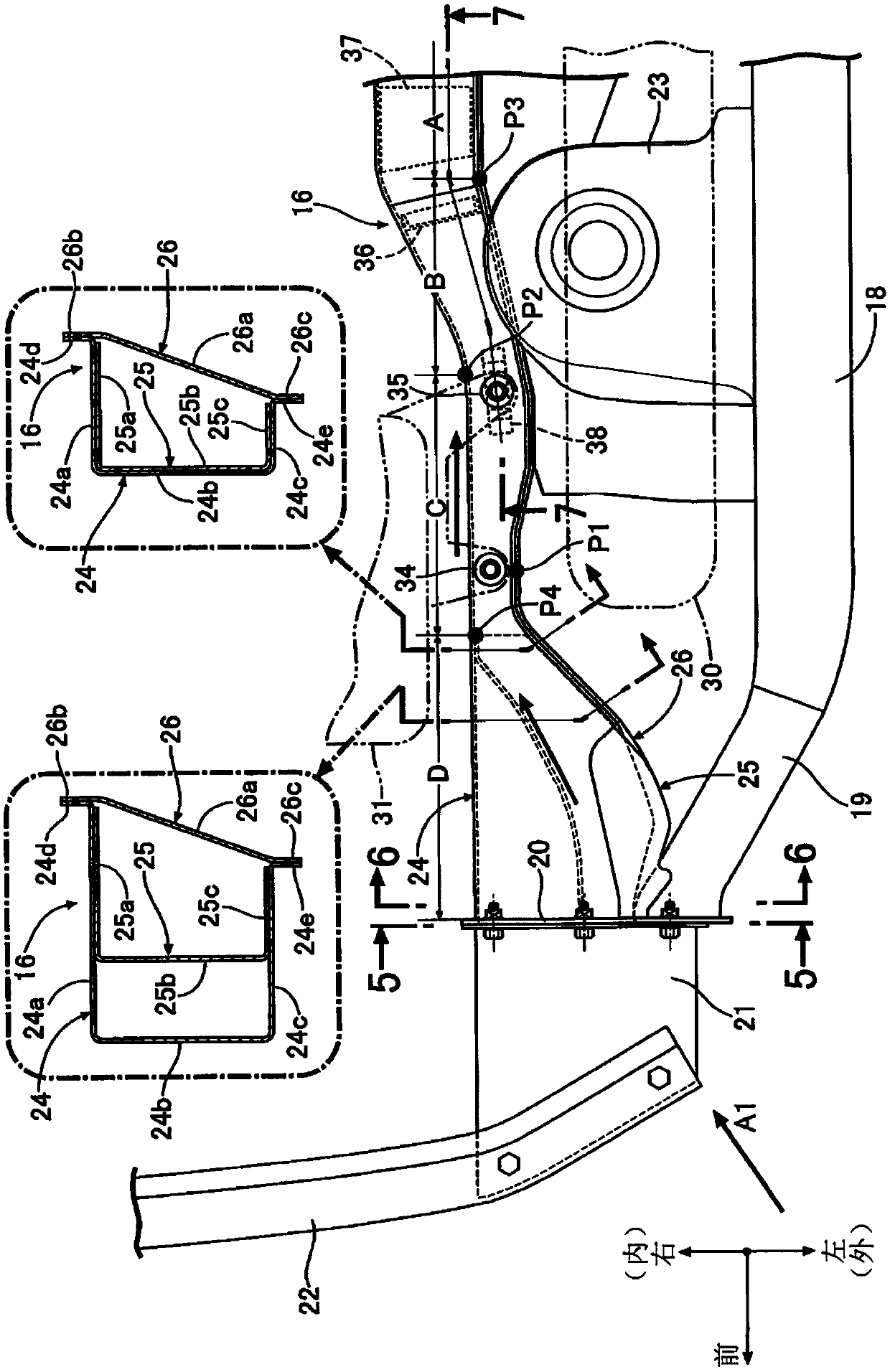

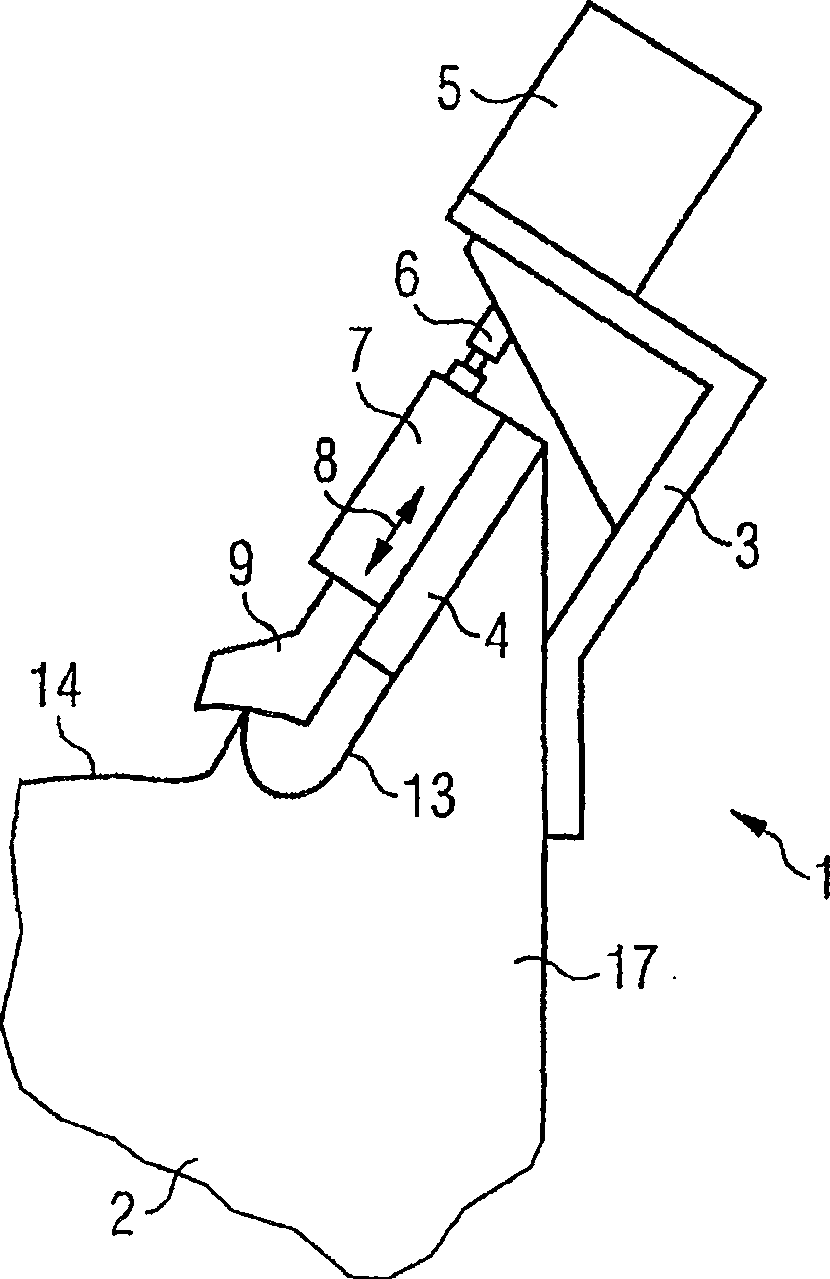

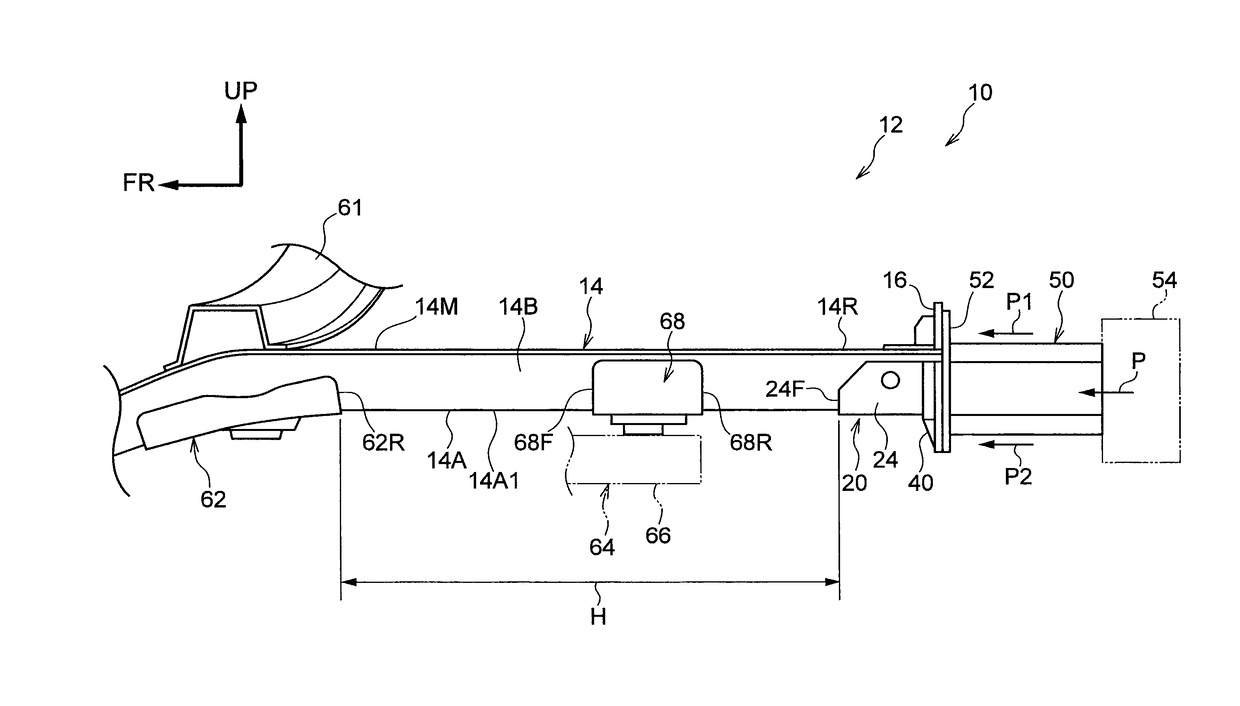

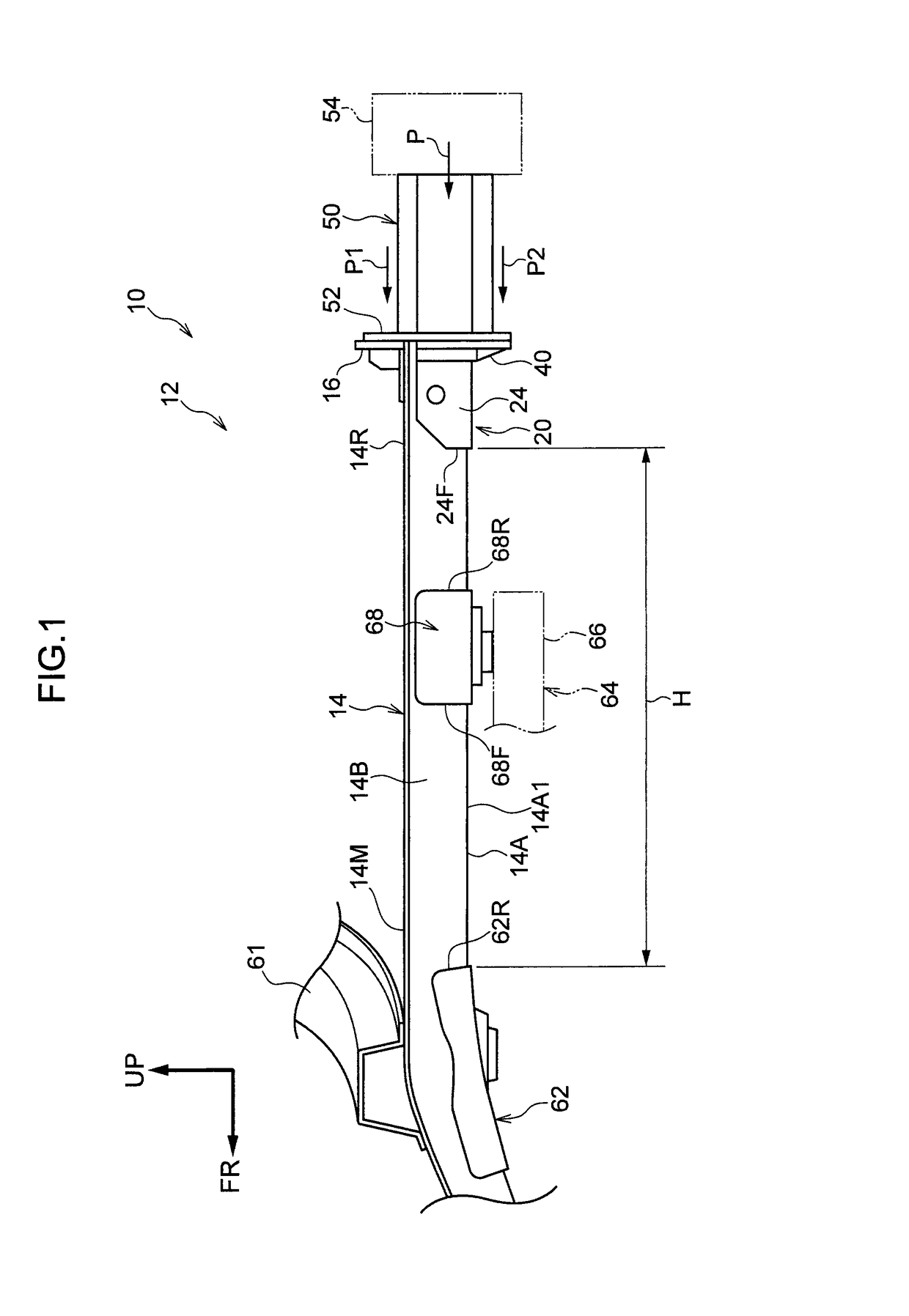

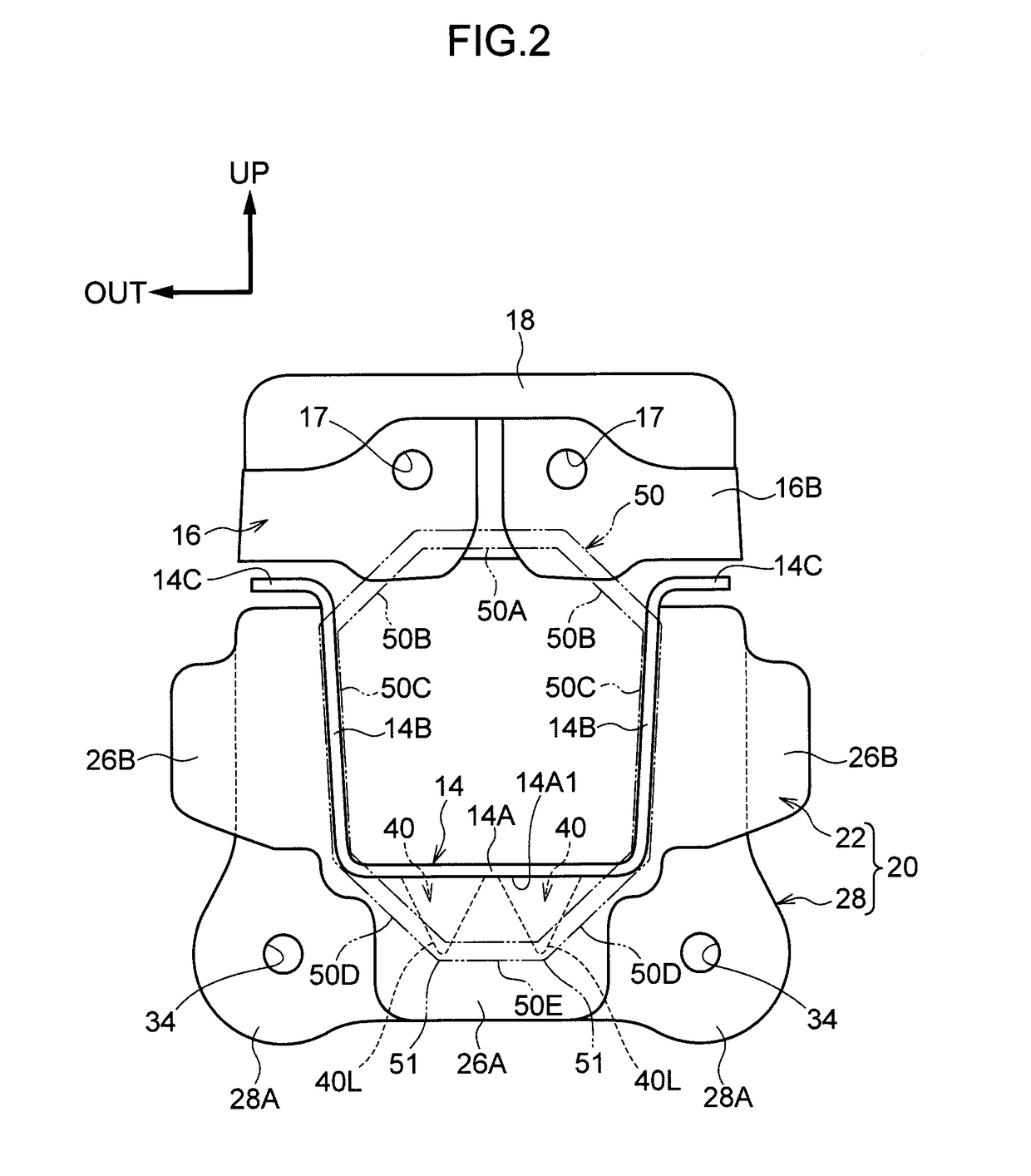

Vehicle rear portion structure

ActiveUS20160185391A1Improve transmission efficiencyReliable bendingVehicle seatsUnderstructuresMechanical engineering

Owner:TOYOTA JIDOSHA KK

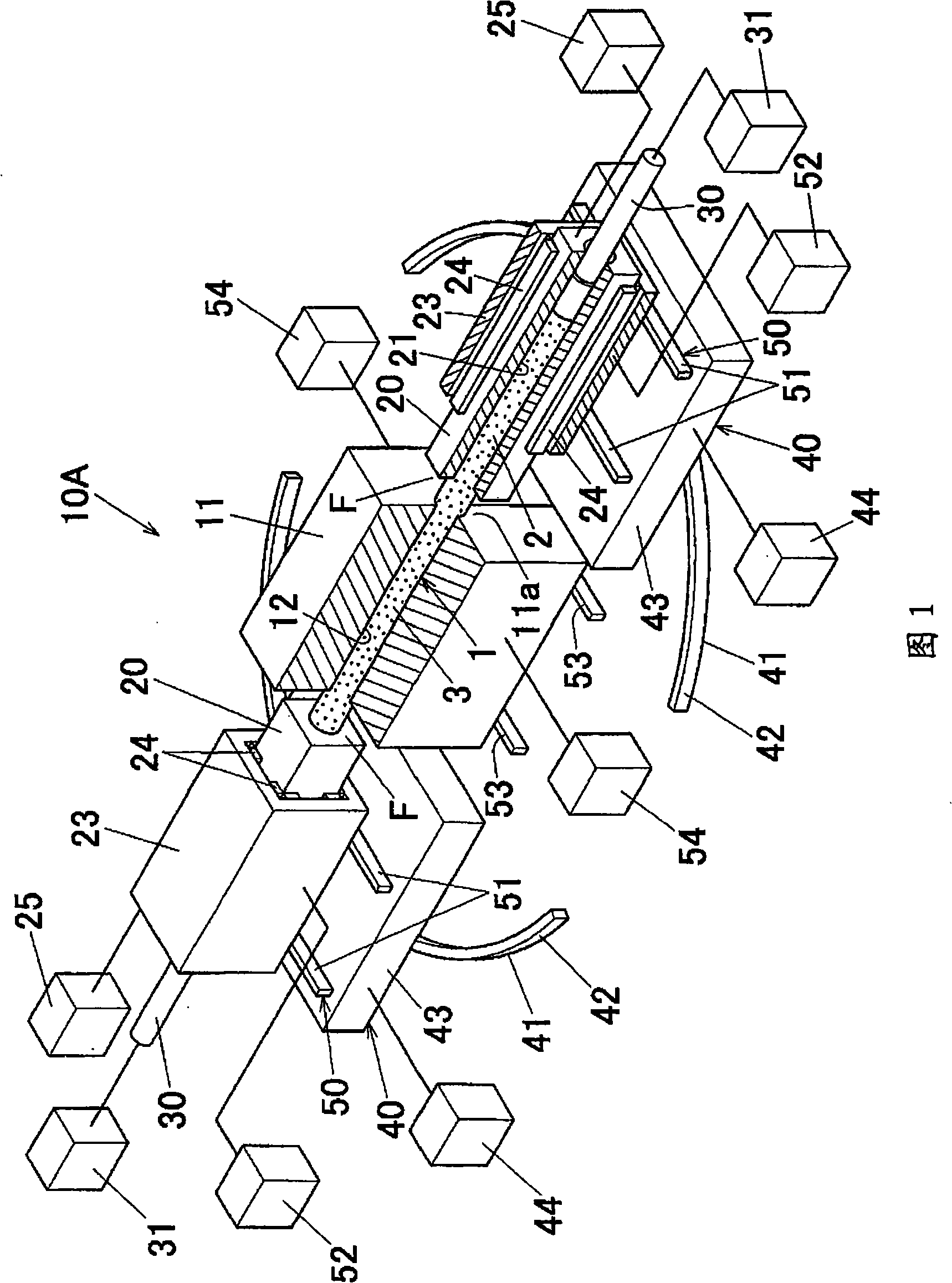

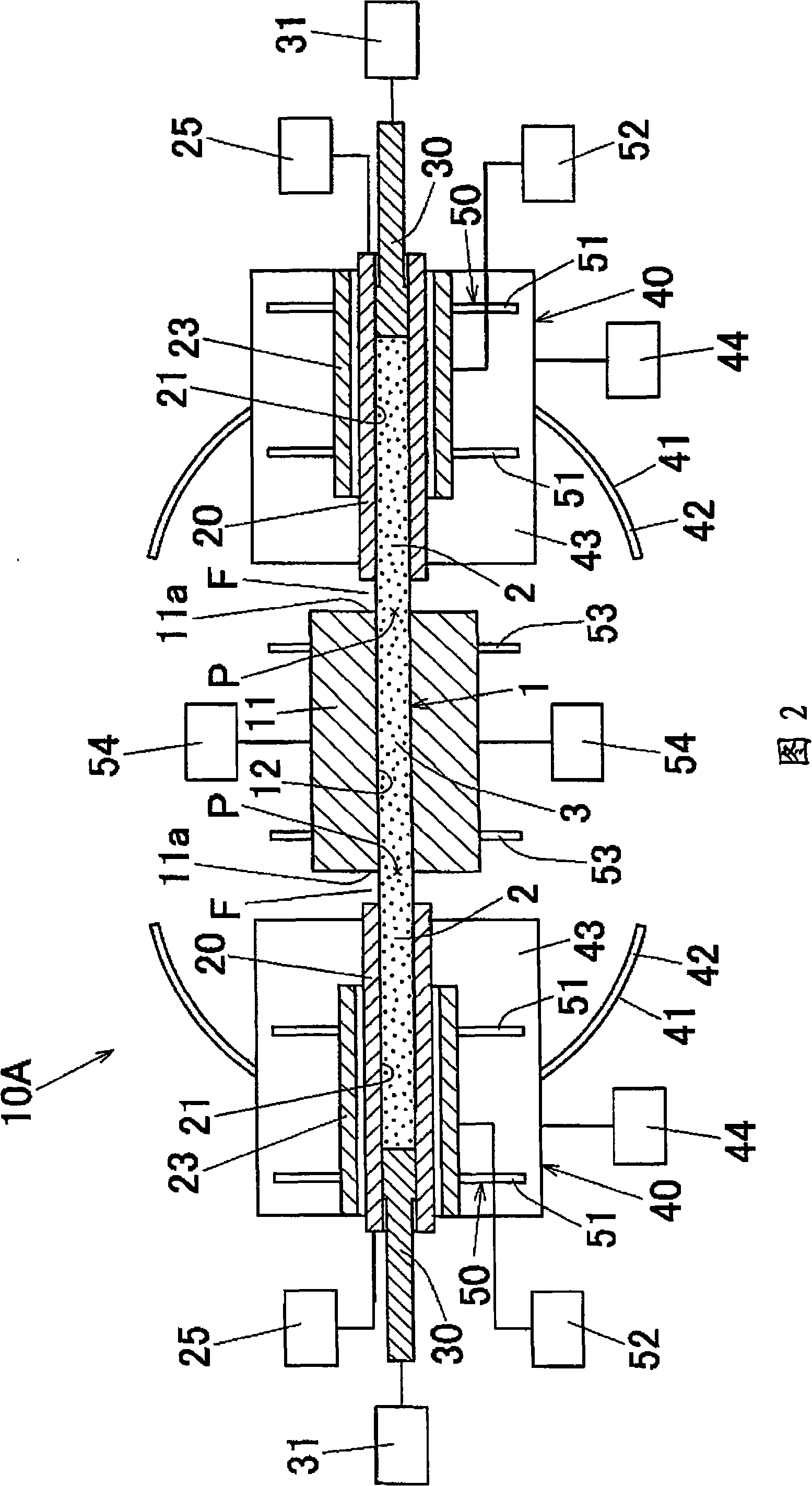

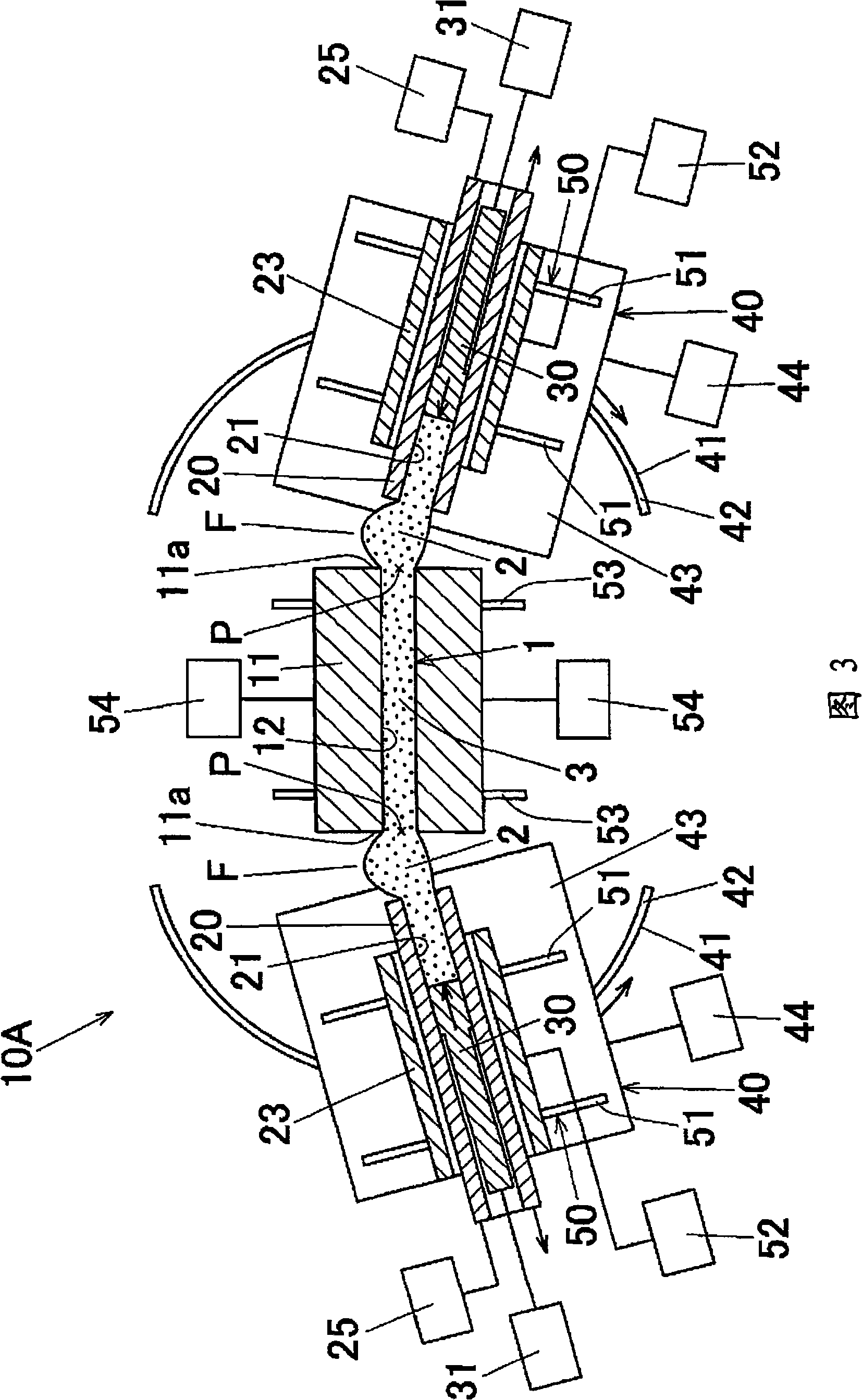

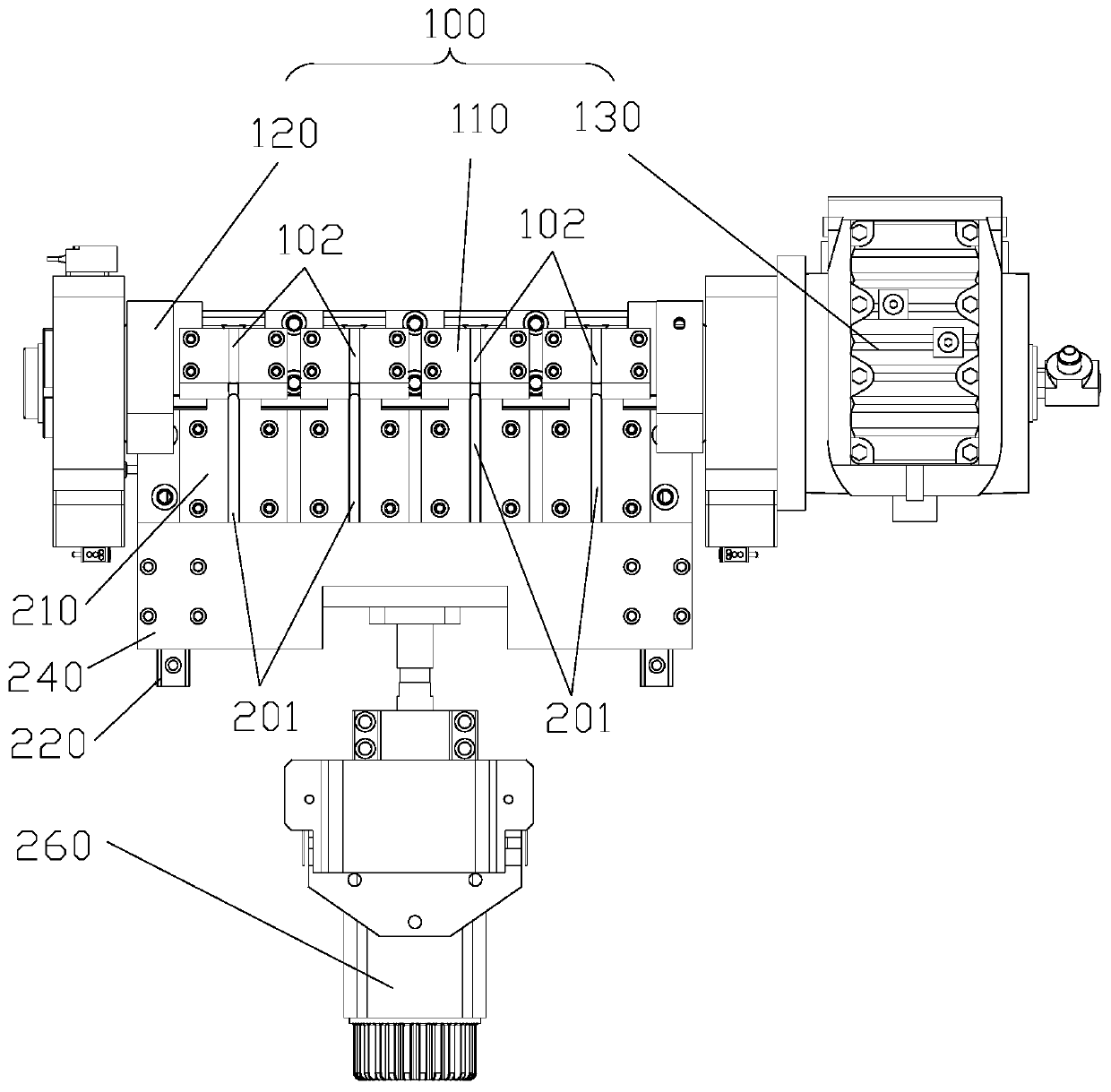

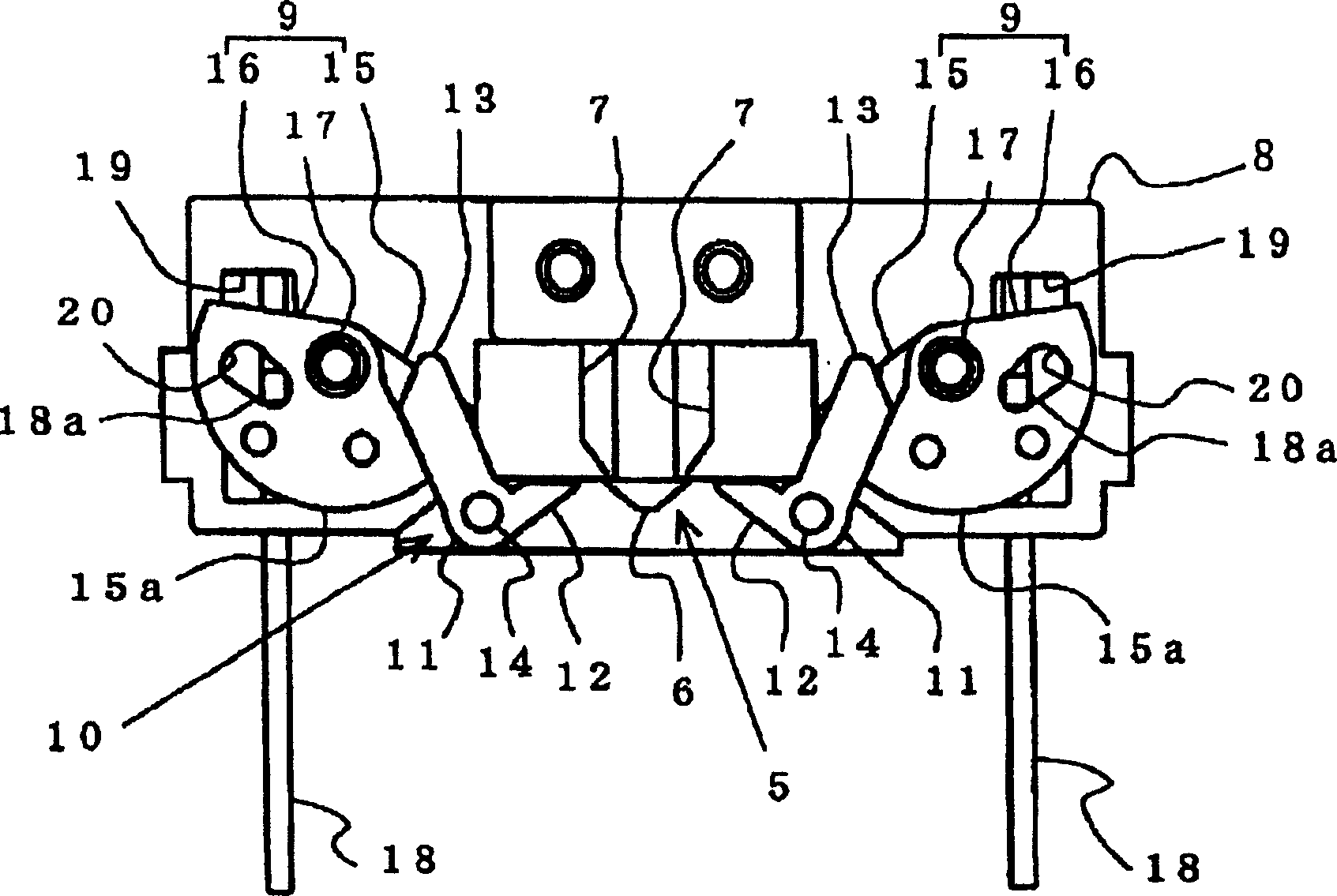

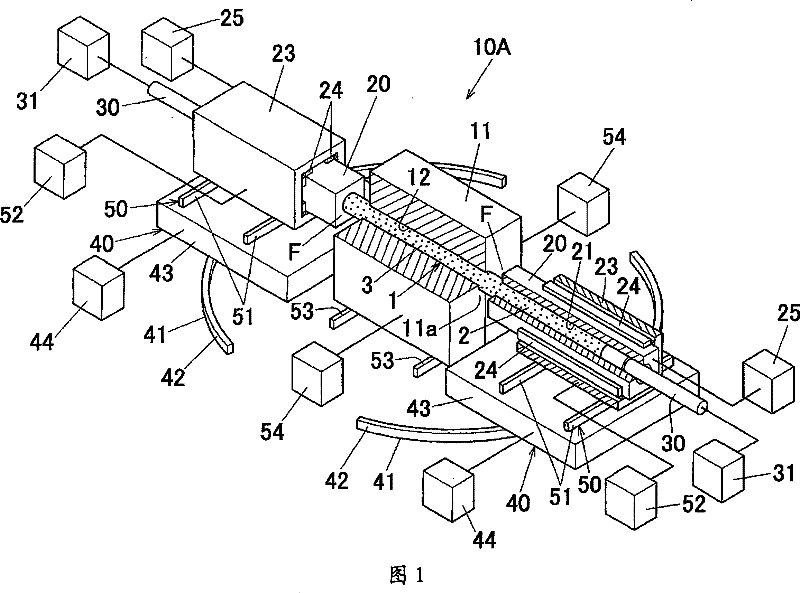

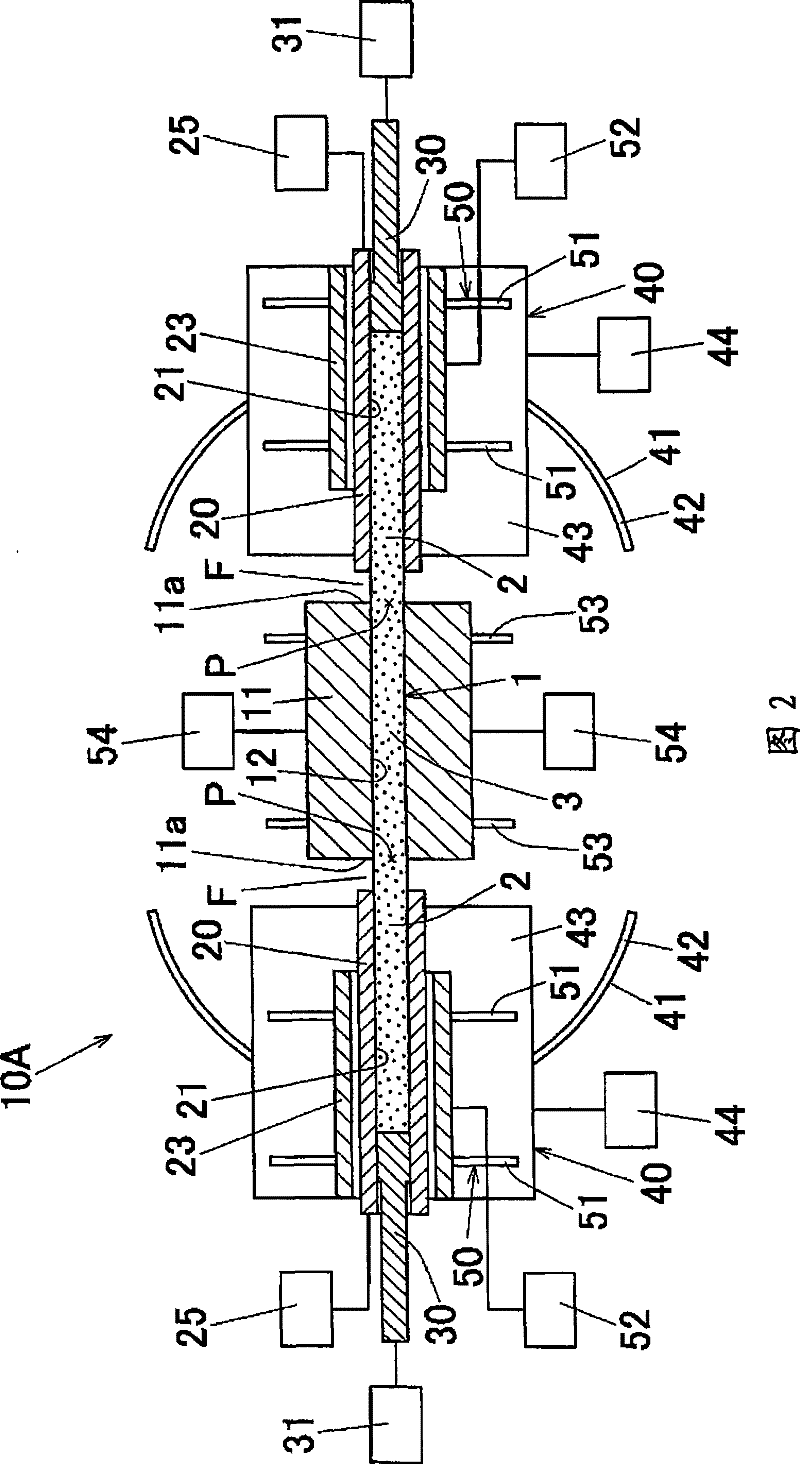

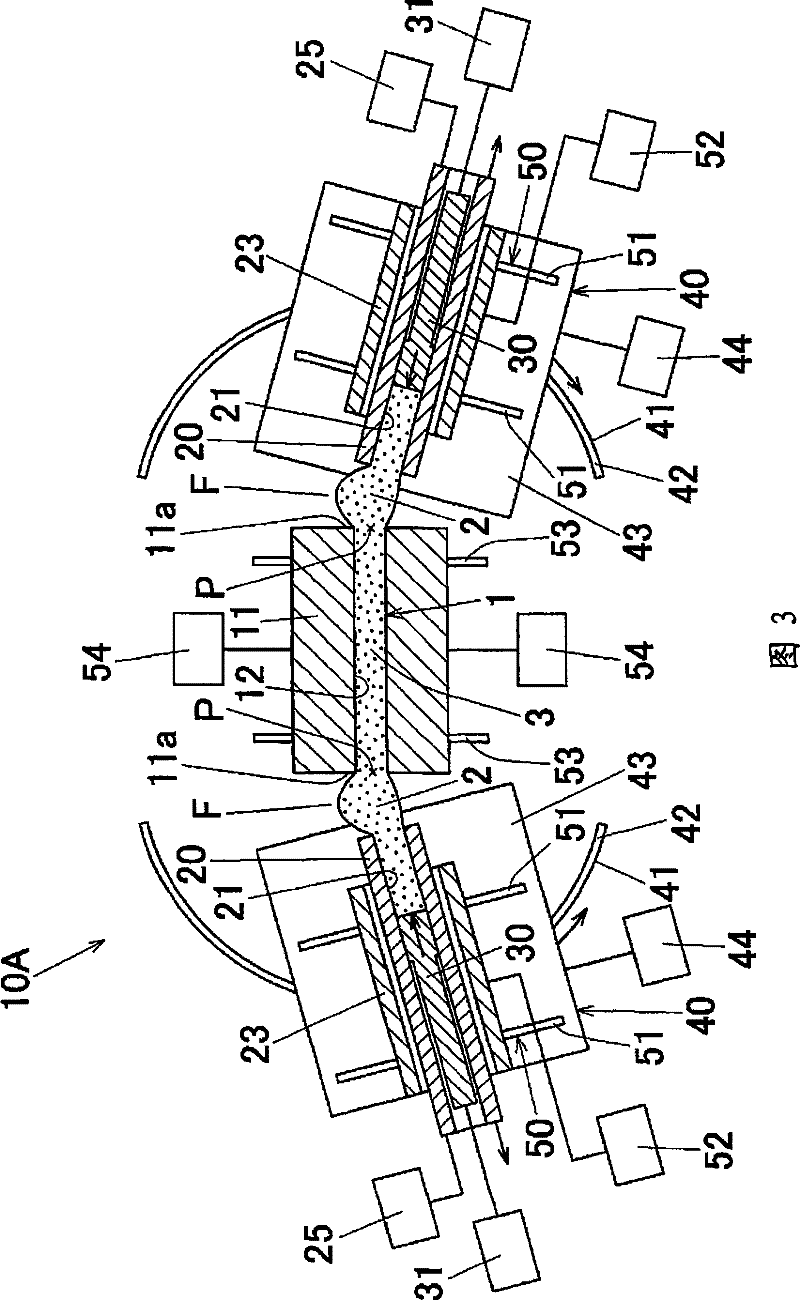

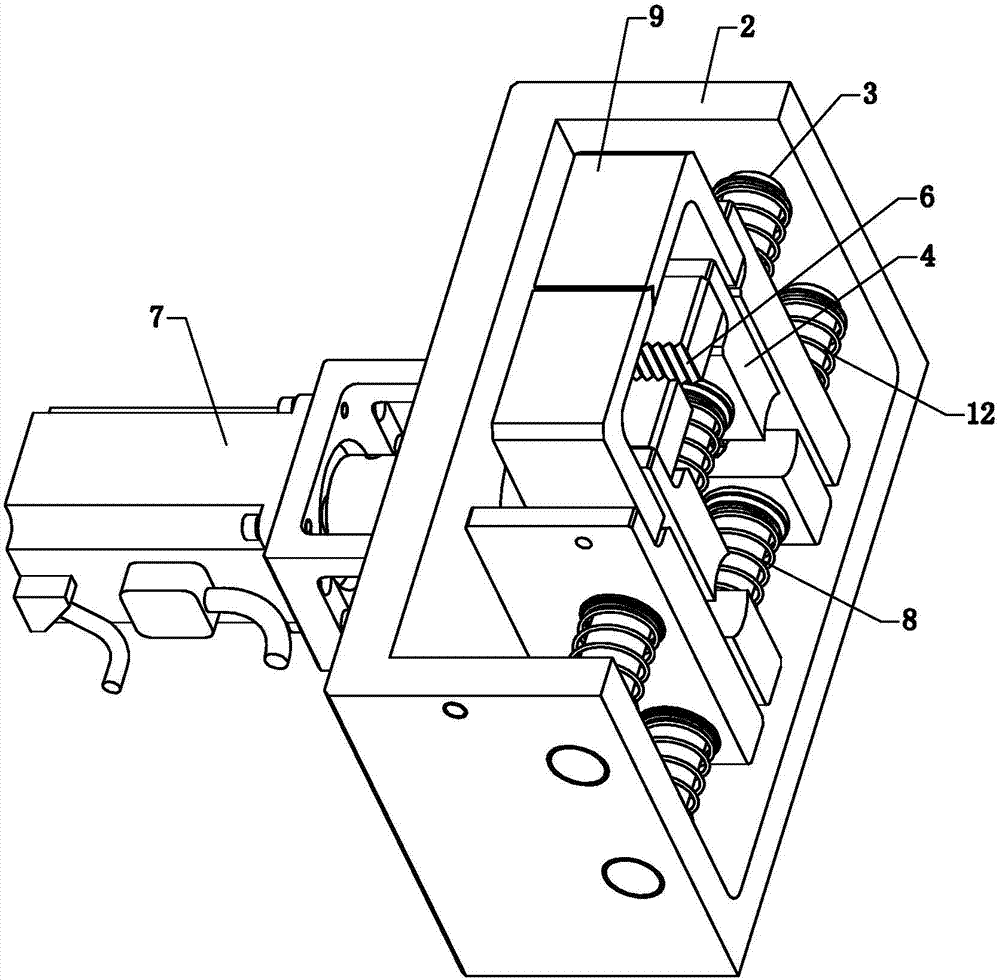

Upsetting method and upsetting apparatus

InactiveCN101257984ALongitudinal bending stopReliable bendingMetal-working apparatusEngine componentsEngineeringMechanical engineering

The present invention provides an upsetting method capable of manufacturing, by a minimum load, an upset article having swelled parts formed in a bent shape. A bar-like material (1) is mounted on a receiving die (11) so as not to move in the axial direction, the parts (2) of the material (1) are disposed in insertion holes (21) formed in guides (20) and holding the planned swelling parts (2) of the material (1) in the inserted state so as not to buckle. Next, the planned swelling parts (2) of the material (1) exposed to spaces between the heads of the guides (20) and the receiving die (11) are swelled to radially outward by moving the guides (20) in directions opposite to the moving directions of punches (30) while the planned swelling parts (2) of the material (1) are axially pressed by the punches (30). In the upsetting method, the planned swelling parts (2) of the material (1) are bent while the planned swelling parts (2) are being swelled.

Owner:SHOWA DENKO KK

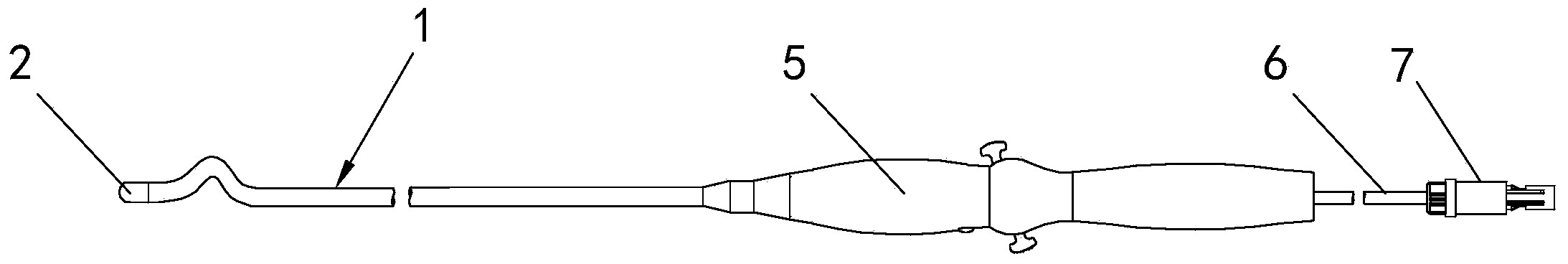

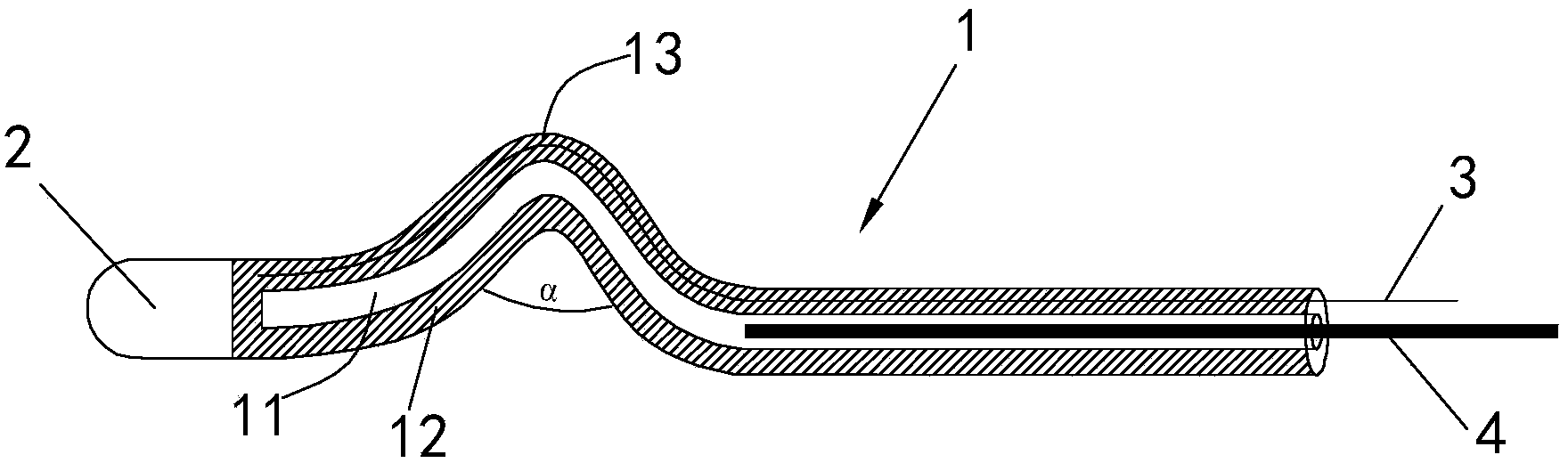

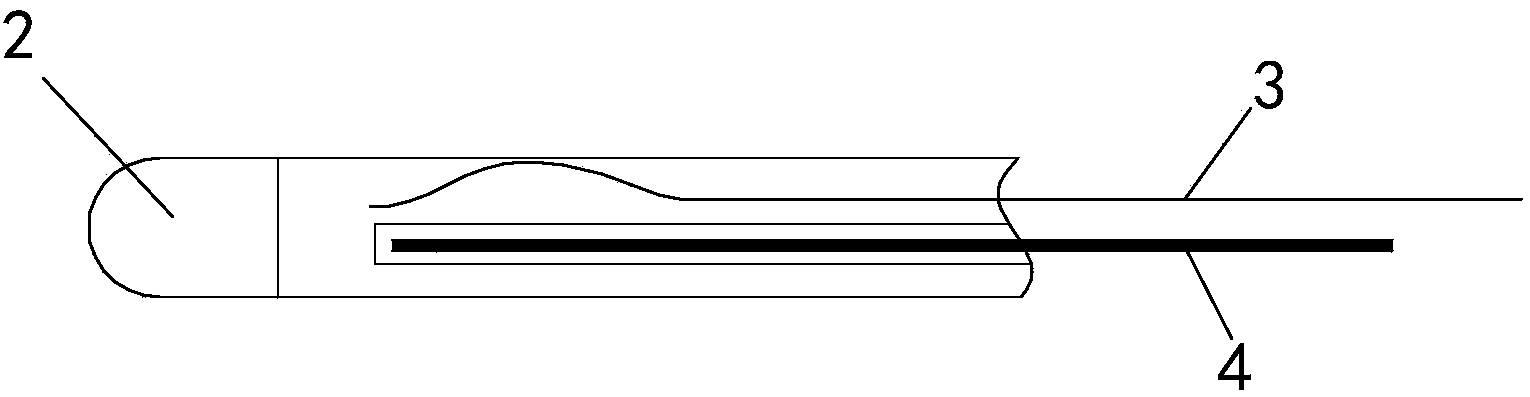

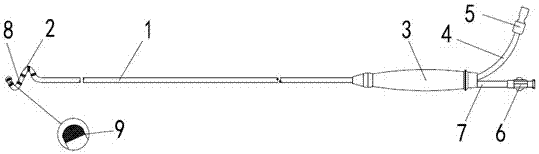

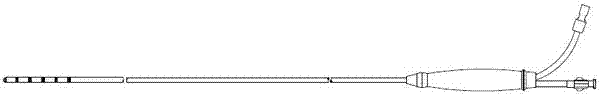

Renal denervation ablation catheter with pre-bent catheter body

InactiveCN104068930AReliable bendingSimple structureSurgical instruments for heatingDenervationElectric wire

The invention discloses a renal denervation ablation catheter with a pre-bent catheter body. The ablation catheter comprises a main catheter body, an electrode, a handle, an electric wire and an electric terminal; the two ends of the main catheter body are connected with the electrode and the handle, respectively; the main catheter body is provided with a tubular cavity and a tubular wall; the electric wire goes through the tubular cavity of the catheter body, and one end of the electric wire is electrically connected with the electrode, while the other end of the electric wire is electrically connected with the electric wire of the electric terminal after going through the handle; one end, close to the electrode, of the main catheter body is a far end of the main catheter body, and an in-catheter shape memory metal wire is inserted in the tubular wall of the far end in the axial direction of the main catheter body and provided with a bent part; after the in-catheter shape memory metal wire is inserted in the tubular wall so that the far end of the main catheter body is provided with a bent far-end pre-bent catheter section, and the bent far-end pre-bent catheter section is capable of providing reliable and controllable curvature. The ablation catheter is simple to operate, easy to manufacture, and capable of providing reliable curvature.

Owner:远见企业有限公司

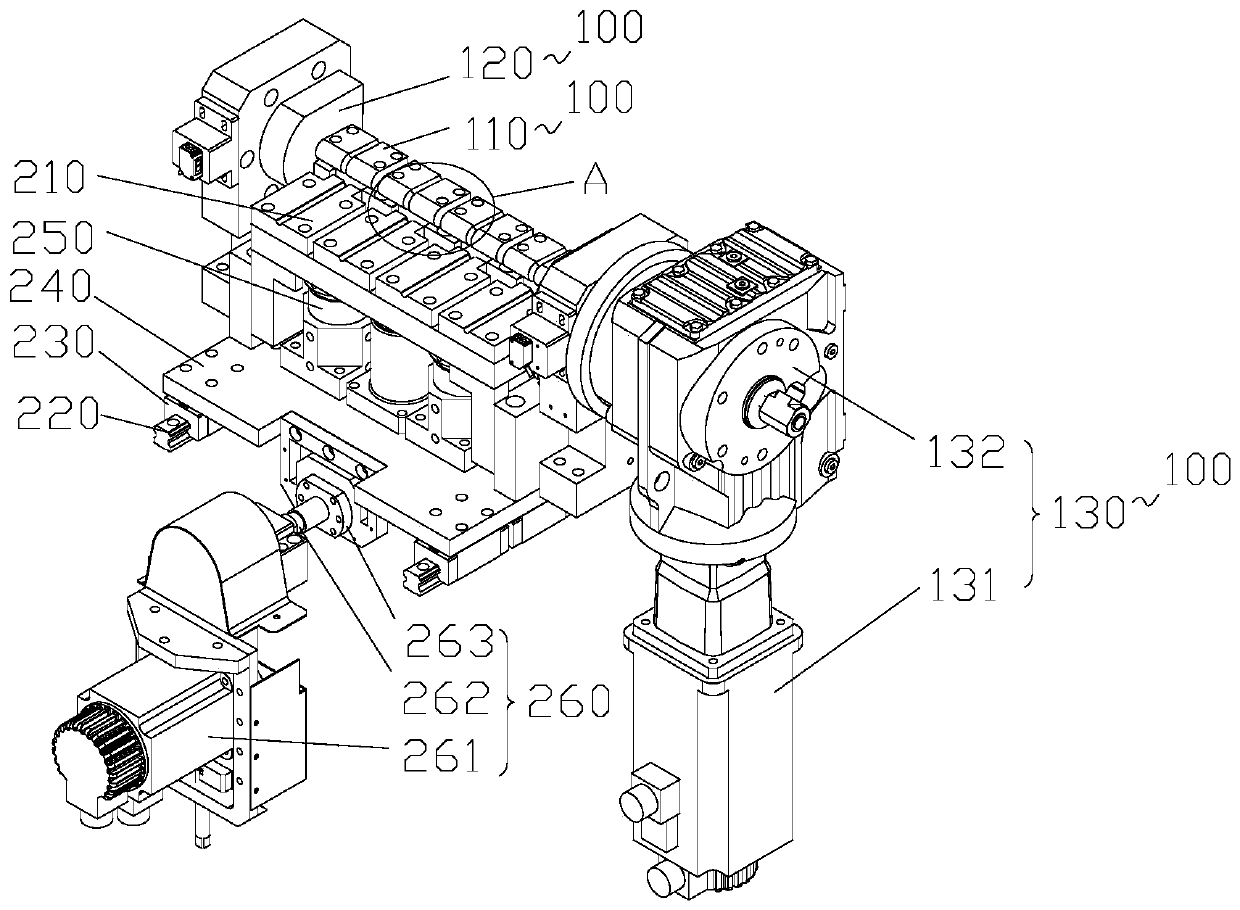

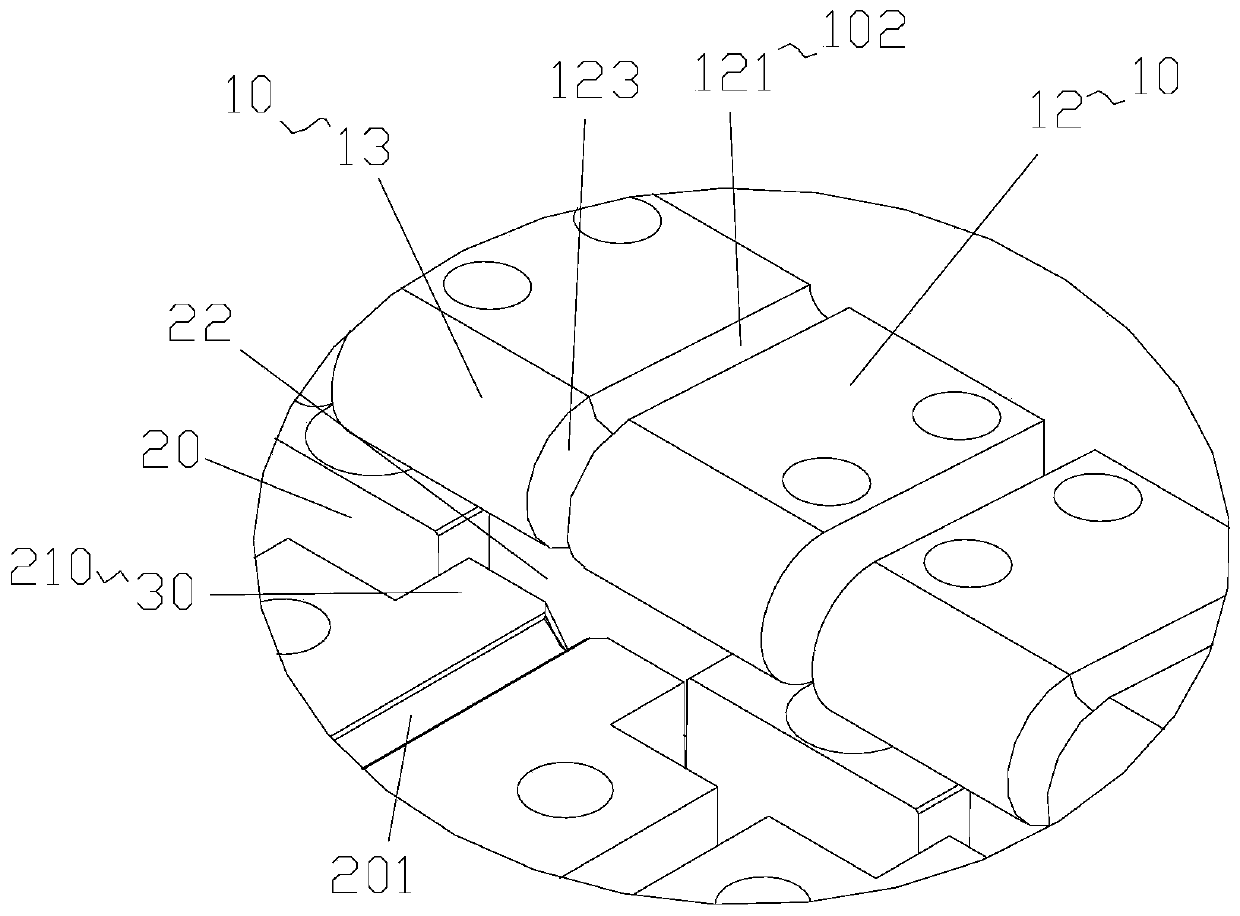

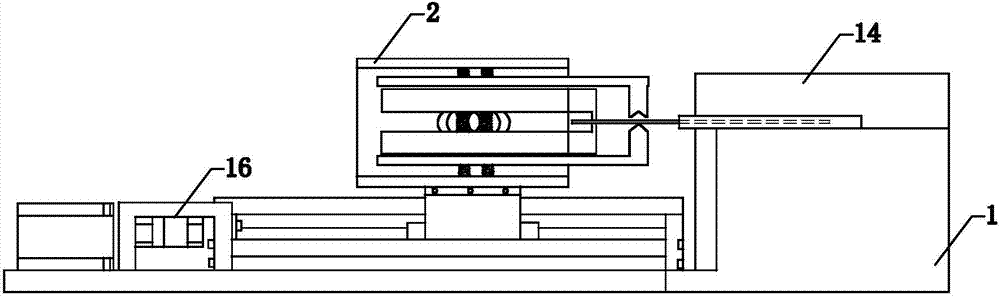

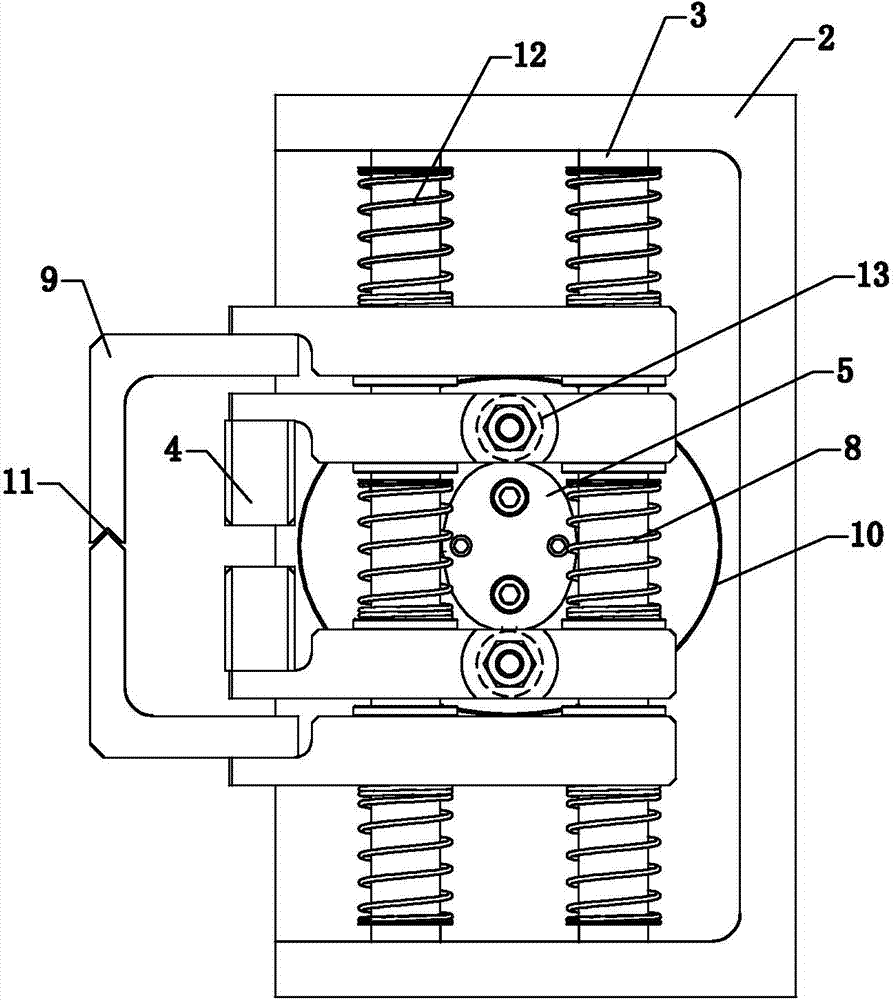

Bending device and U-shaped pipe machining equipment

ActiveCN110666011AReliable bendingReliable bending and formingMetal-working feeding devicesPositioning devicesPipe fittingStructural engineering

The invention provides a bending device and U-shaped pipe machining equipment. The bending device comprises a bending mechanism and a contact pattern mechanism, wherein the bending mechanism comprisesclamping portions, and the clamping portions comprise clamping spaces for containing pipe parts and first position-limiting grooves, are rotatably arranged and are provided with feeding positions andbending positions; the contact pattern mechanism comprises position-limiting portions, and the position-limiting portions are provided with second position-limiting grooves for containing the pipe parts, are movably arranged both in a first direction and a second direction and are provided with first position-limiting positions, second position-limiting positions and third position-limiting positions; and in the process of the clamping portions rotating from the feeding positions to the bending positions, the position-limiting portions move from the first position-limiting positions to the second position-limiting positions in the second direction and move from the second position-limiting positions to the third position-limiting positions in the first direction to make the first position-limiting grooves and the second position-limiting grooves be butted and clamp the pipe parts. By means of the bending device and the U-shaped pipe machining equipment, the problem of the poor qualityof U-shaped pipes produced and obtained by a bending device in the prior art is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

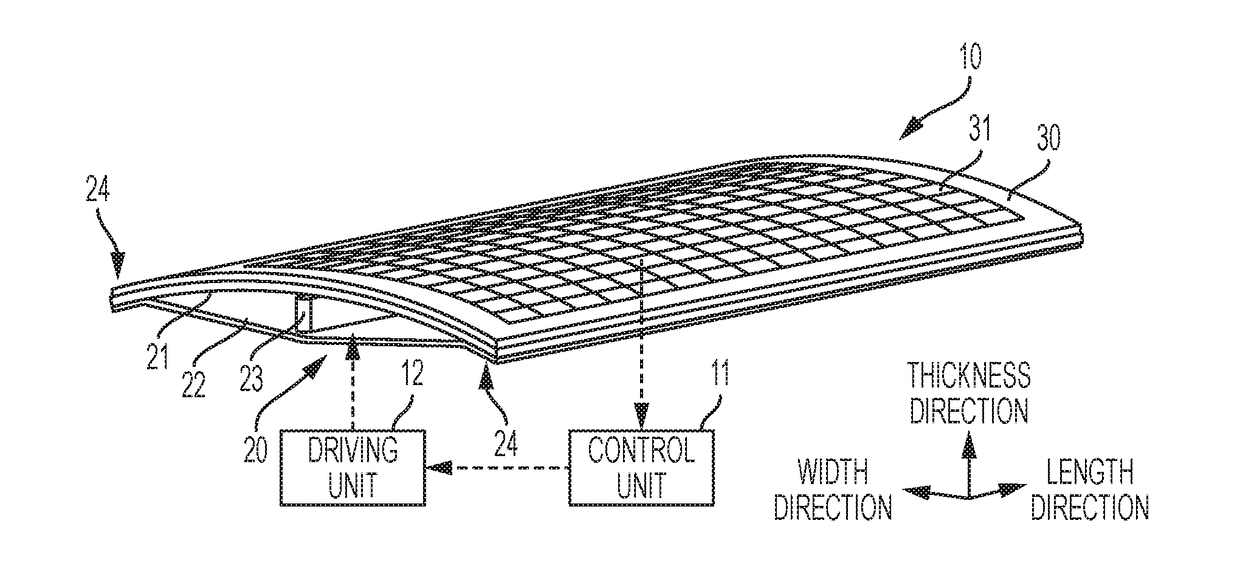

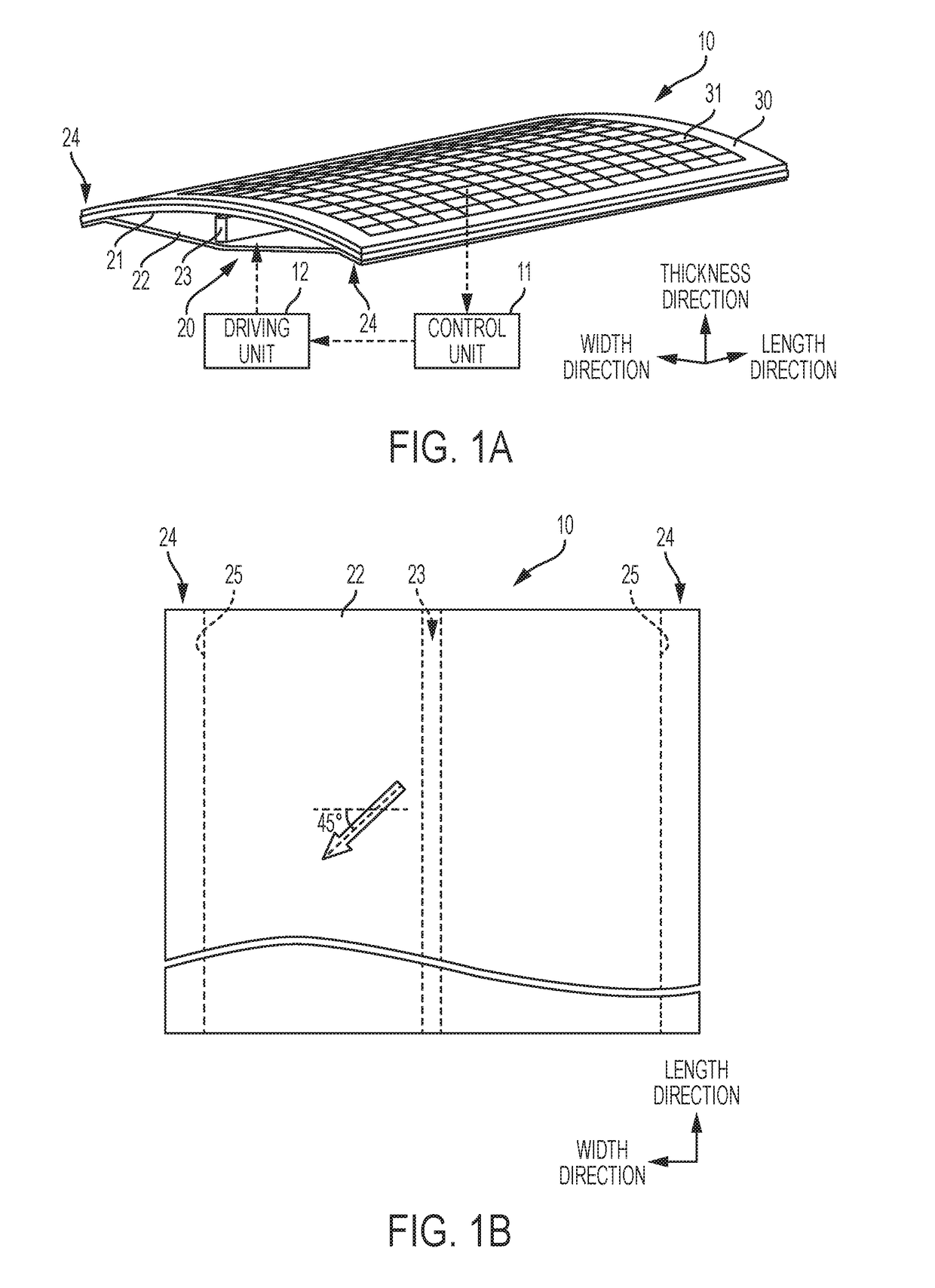

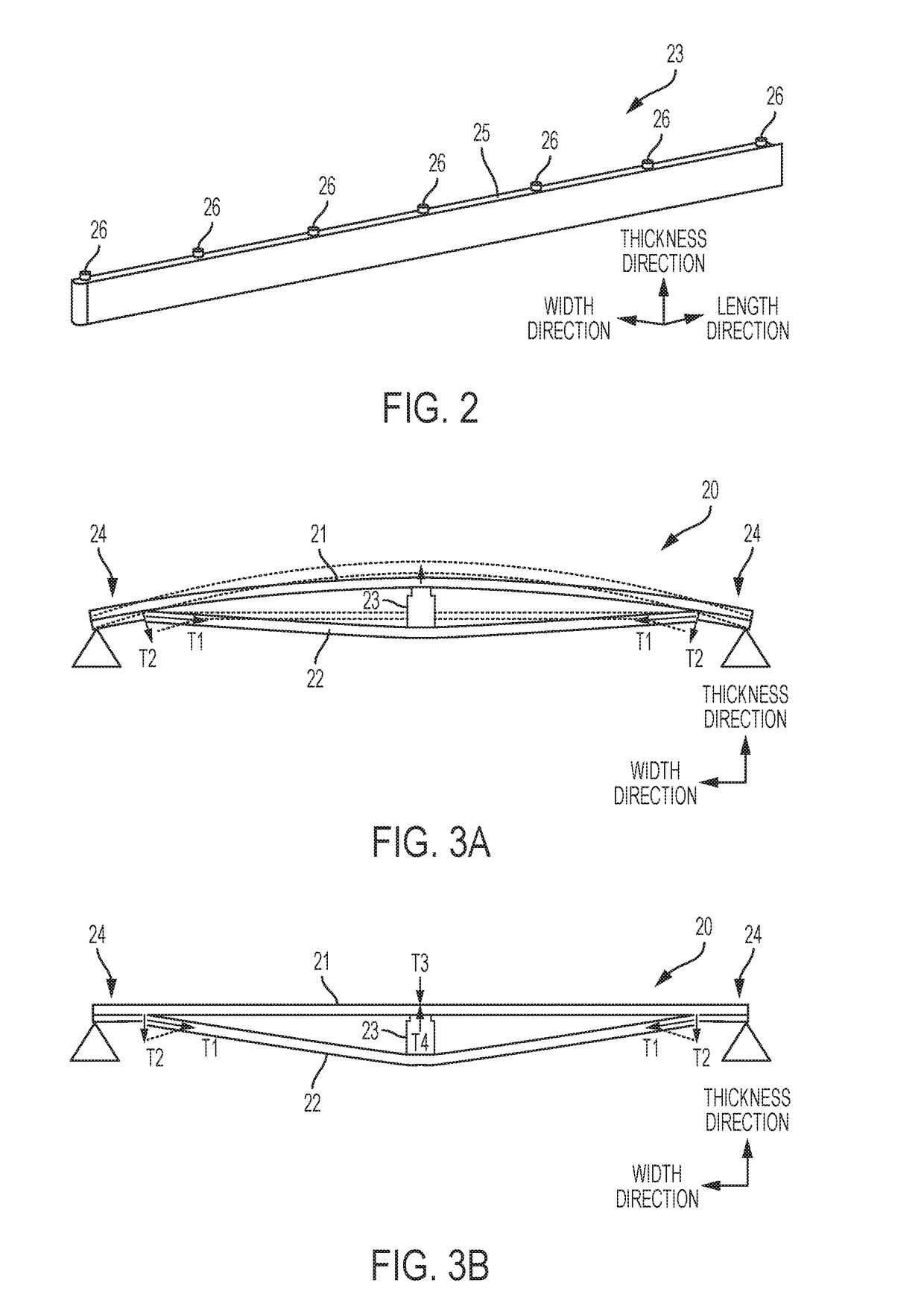

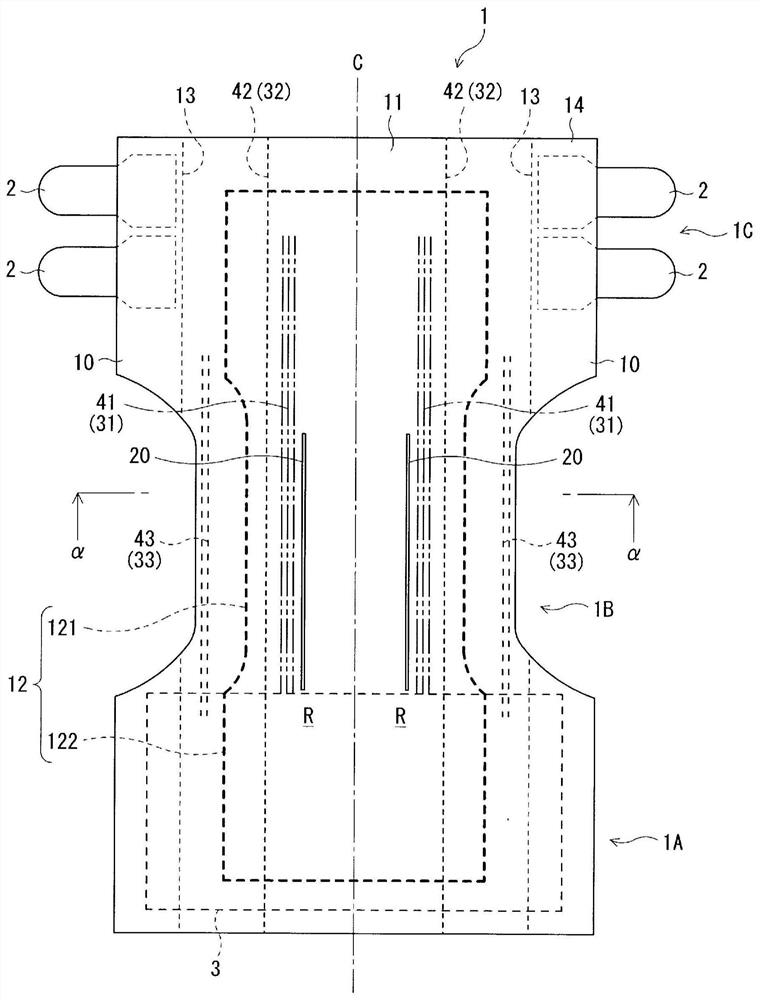

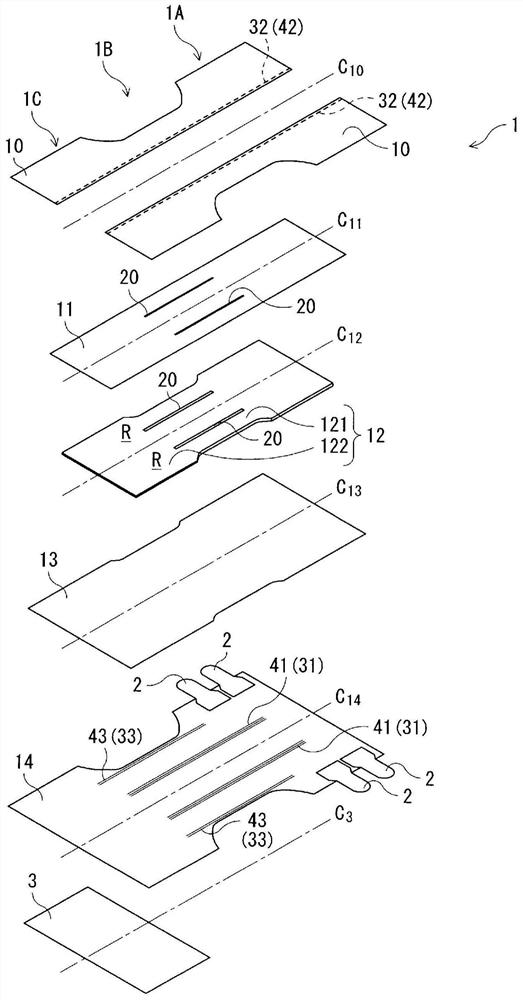

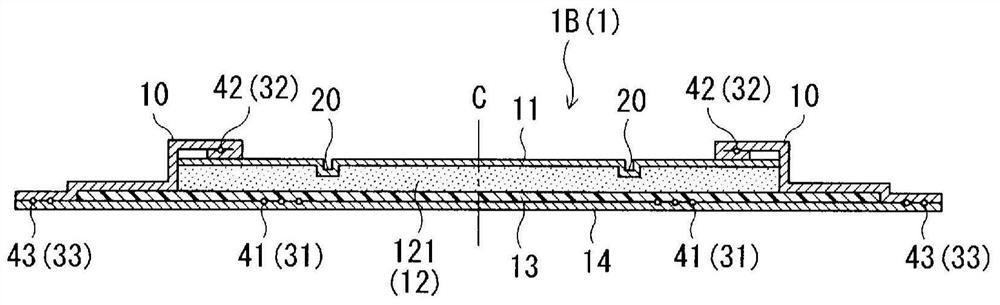

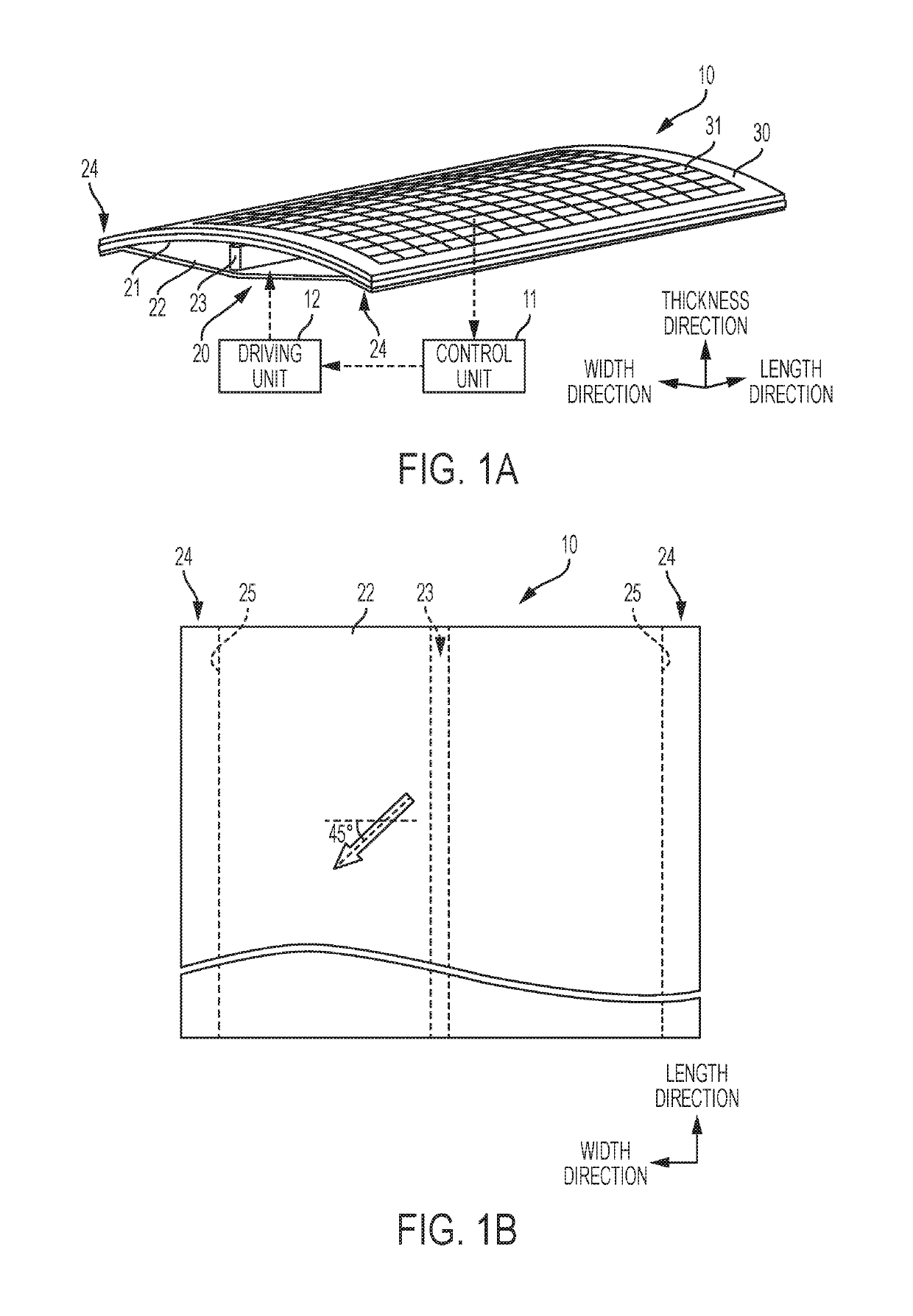

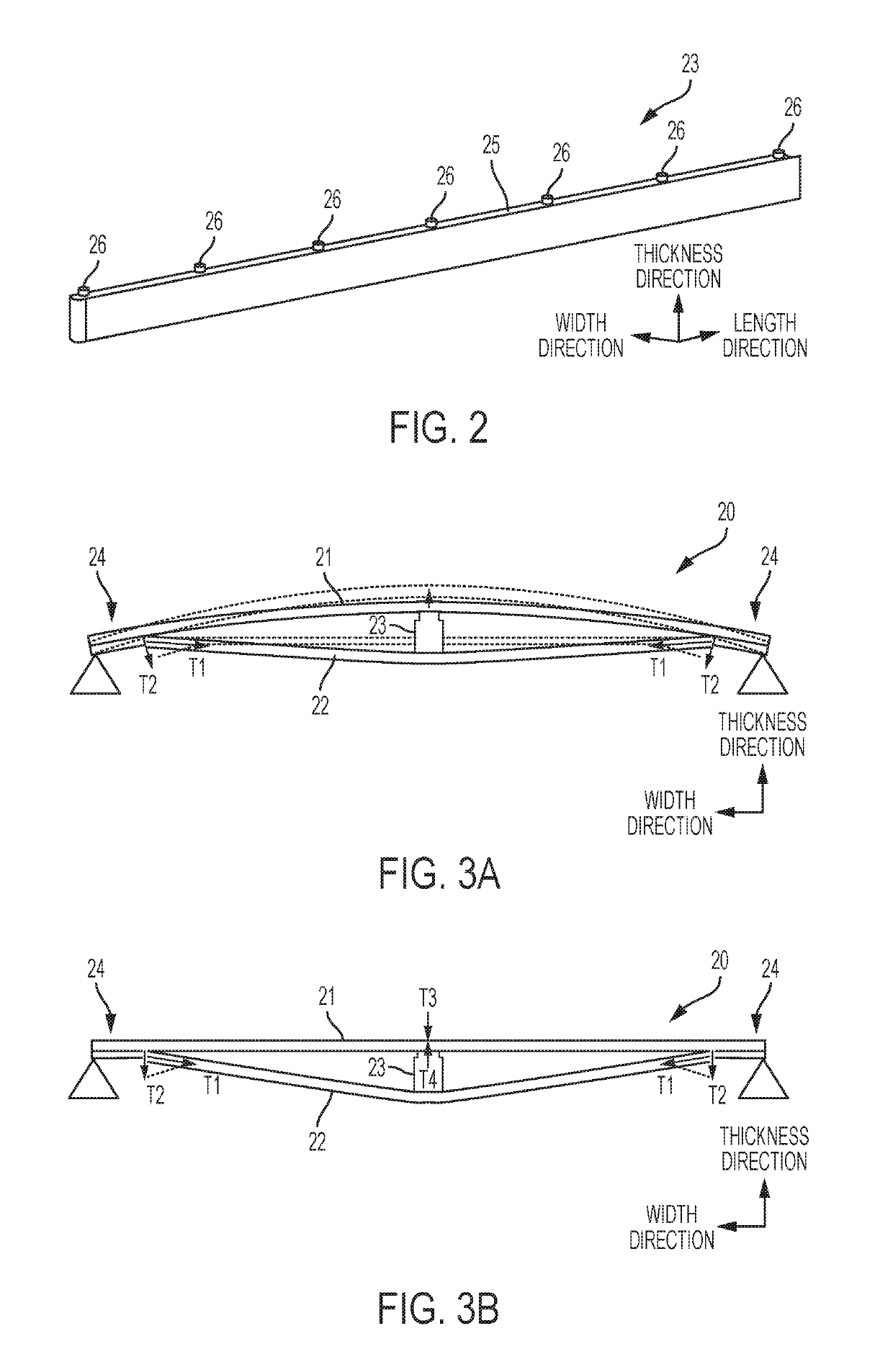

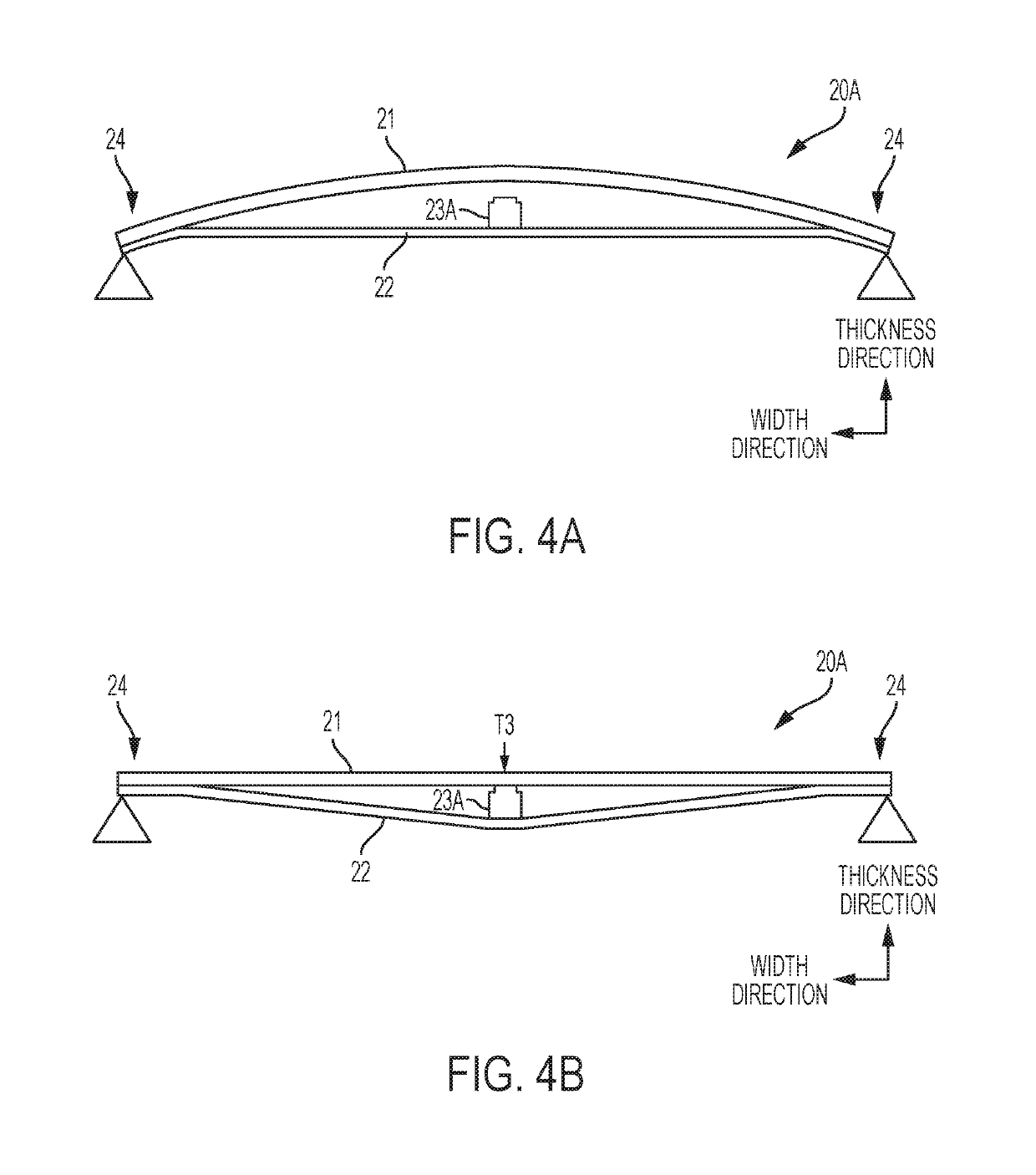

Vibrating device and tactile sense presenting device

ActiveUS20170083099A1Reliable bendingIncrease deflectionInput/output for user-computer interactionMechanical vibrations separationEngineeringElectric energy

A tactile feedback device includes a vibrating device and a touch sensor. The vibrating device comprises a flexible diaphragm and a film which deforms in response to the application of electrical energy thereto, the film being attached to the flexible diaphragm at two spaced locations with a major surface of the film facing a major surface of the flexible diaphragm. The vibrating device further includes a spacer located between the two spaced locations and ensuring that the major surface of the flexible diaphragm is spaced from the major surface of the film. The touch sensor is coupled to the diaphragm and generates an output signal in response to a touch operation. Means are provided to apply electrical energy to the film in response to the output signal.

Owner:MURATA MFG CO LTD

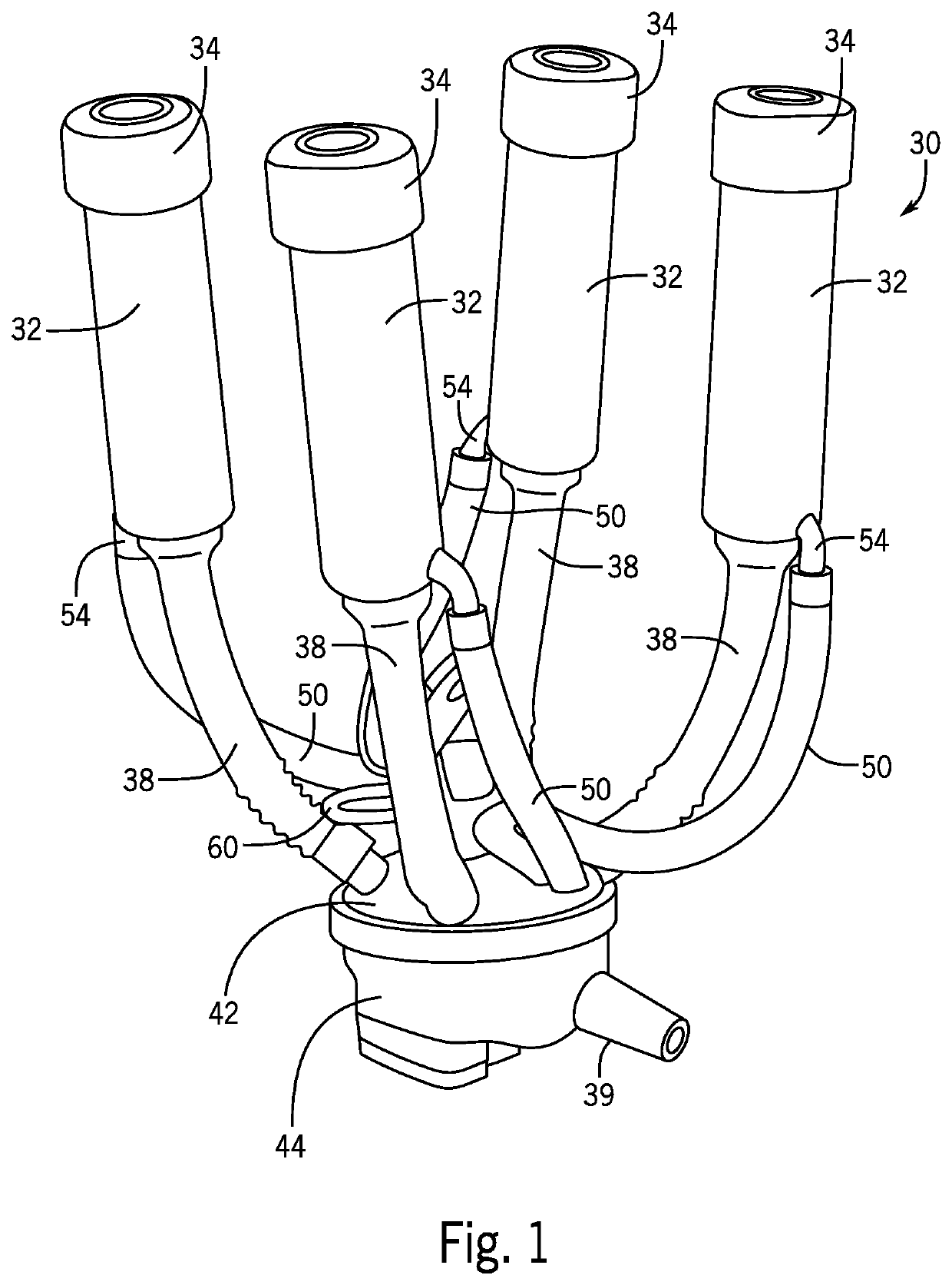

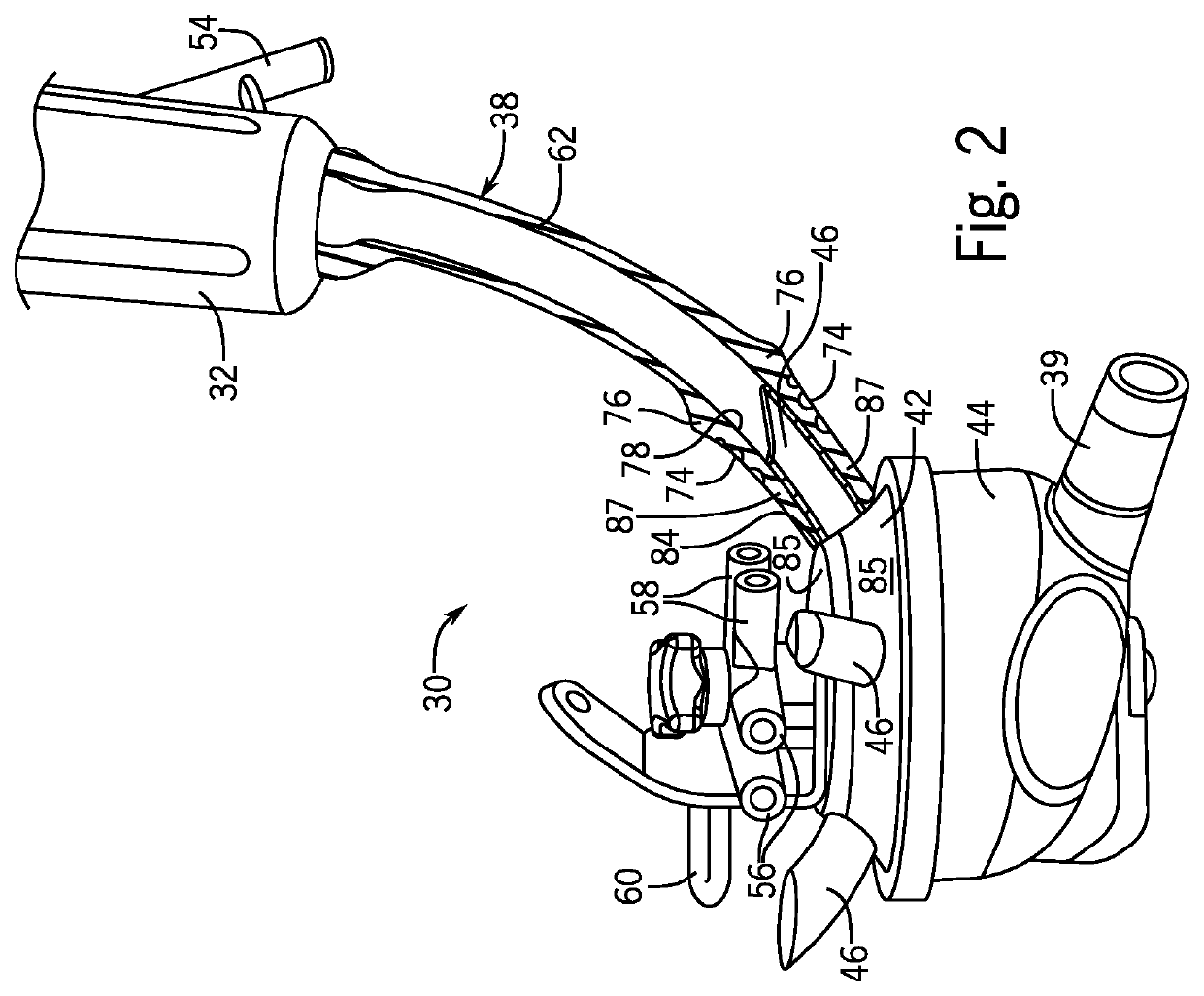

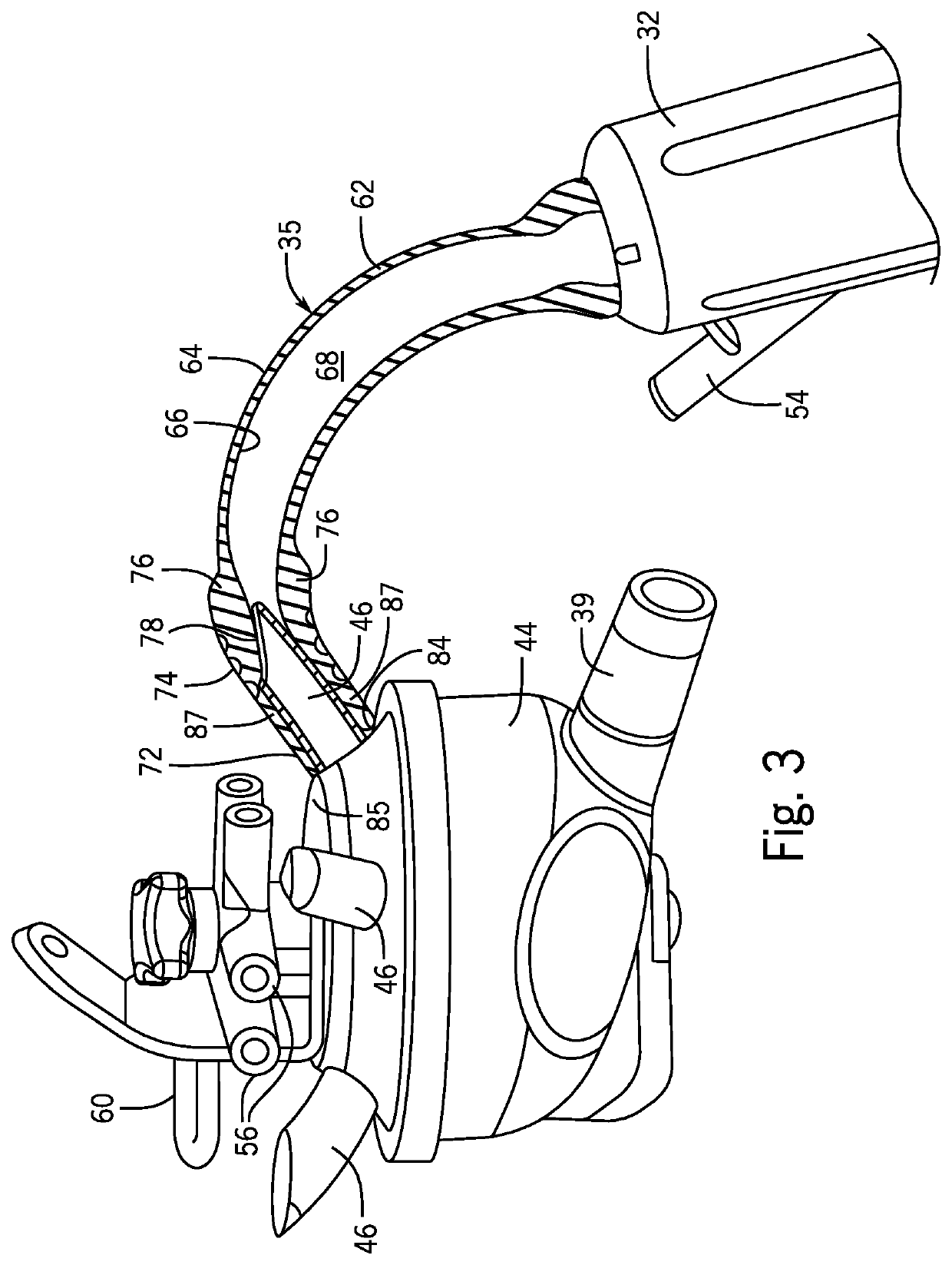

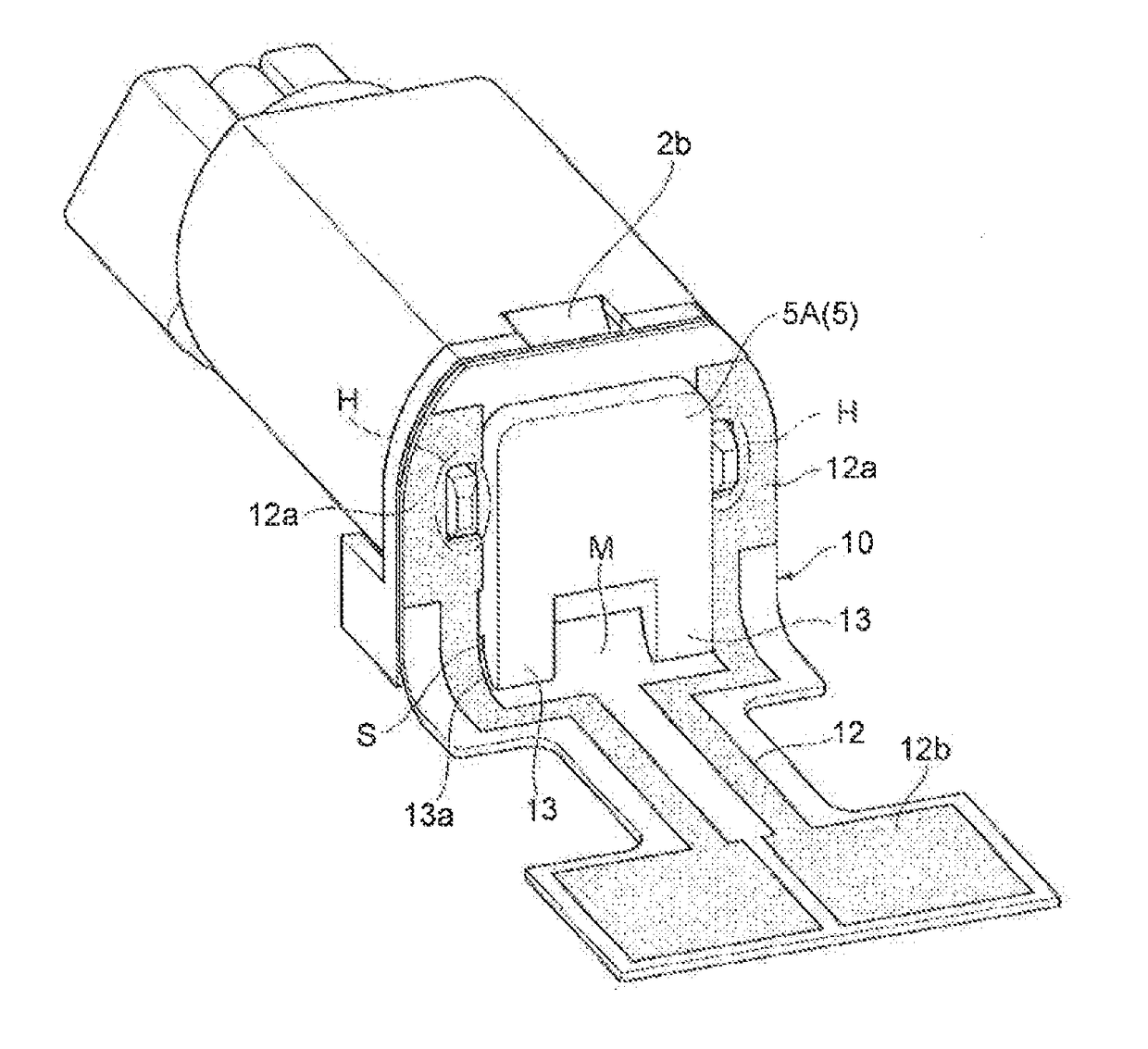

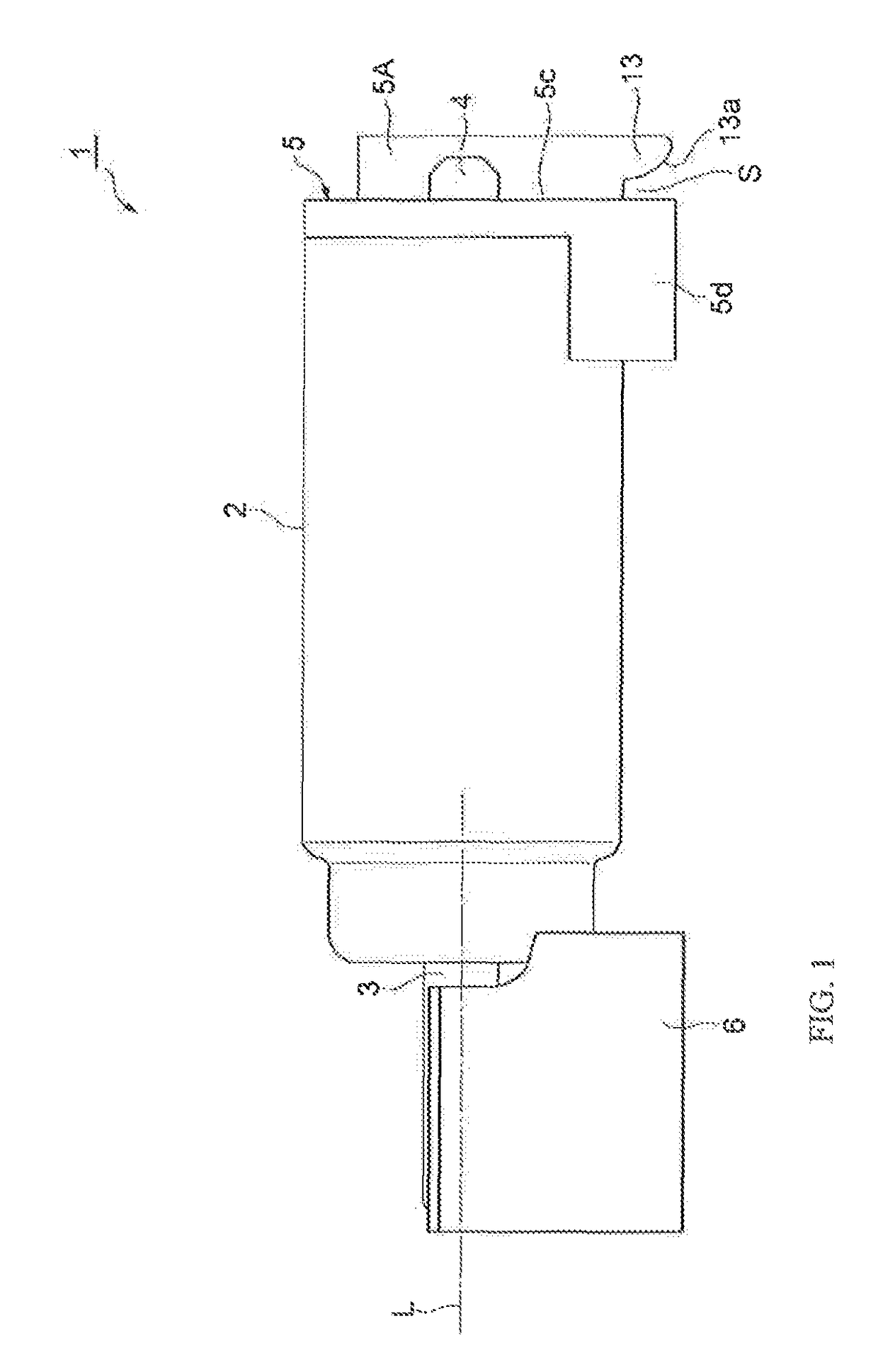

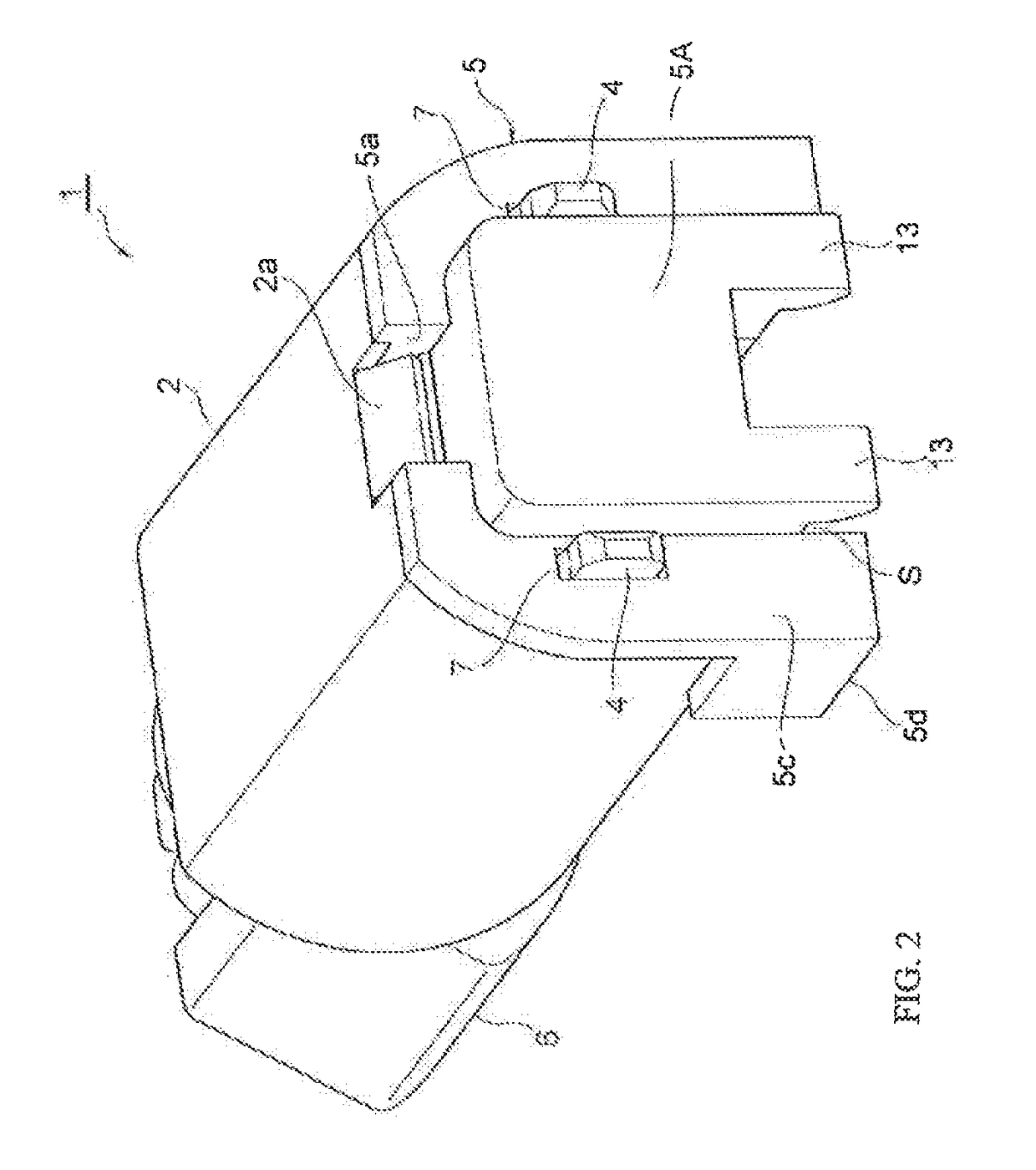

Milker unit short milk tube with milk claw end connector

A milker unit short milk tube having a downstream milk claw connection end having a position and release device joined to and extending away from the downstream milk claw connection end; a controlled flexible portion disposed in an upstream direction from the position and release device; a reinforced portion disposed in upstream direction from the controlled flexible portion; and an interior milking claw inlet sealing surface.

Owner:GEA FARM TECH

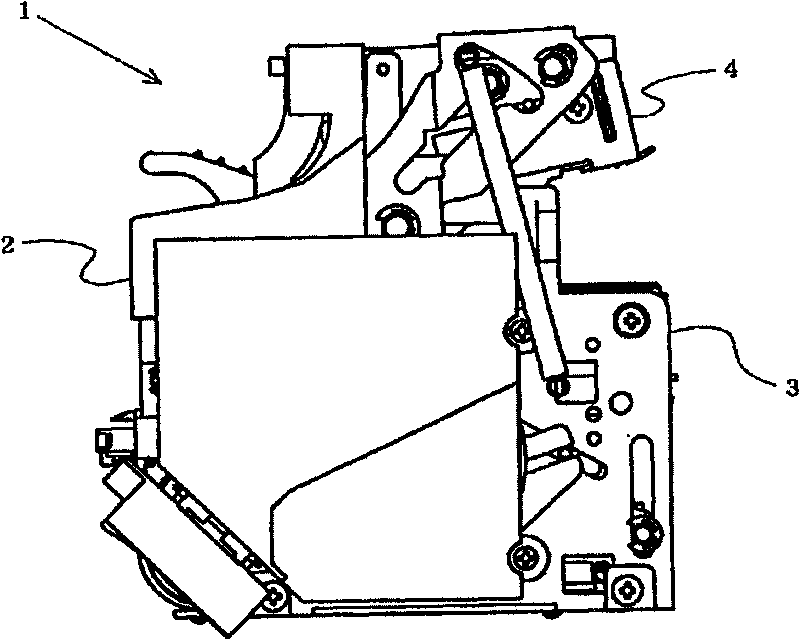

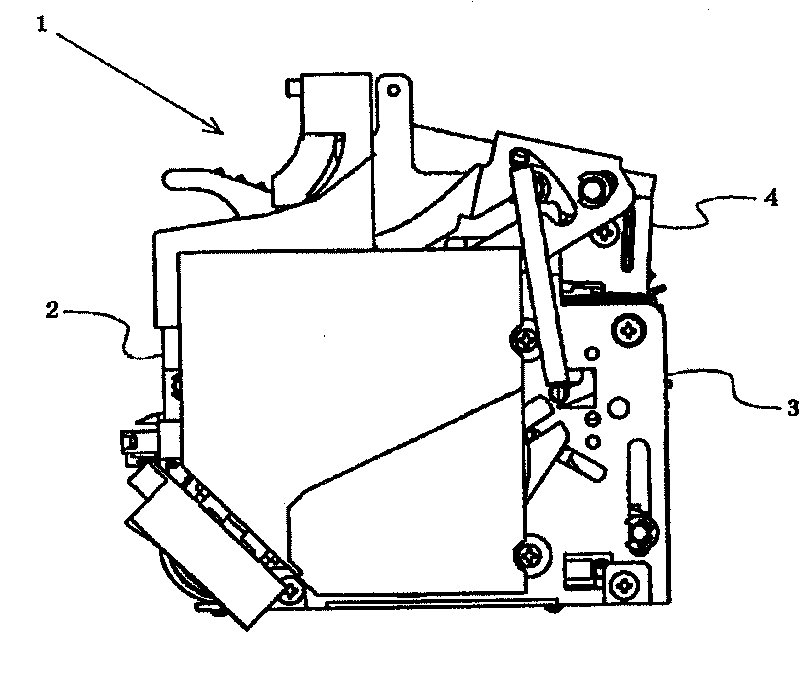

Vibrating compact motor with attached flexible circuit board for a mobile device

InactiveUS9742240B2Prevent peelingReliable bendingAssociation with control/drive circuitsMechanical energy handlingElectric machineFlexible circuits

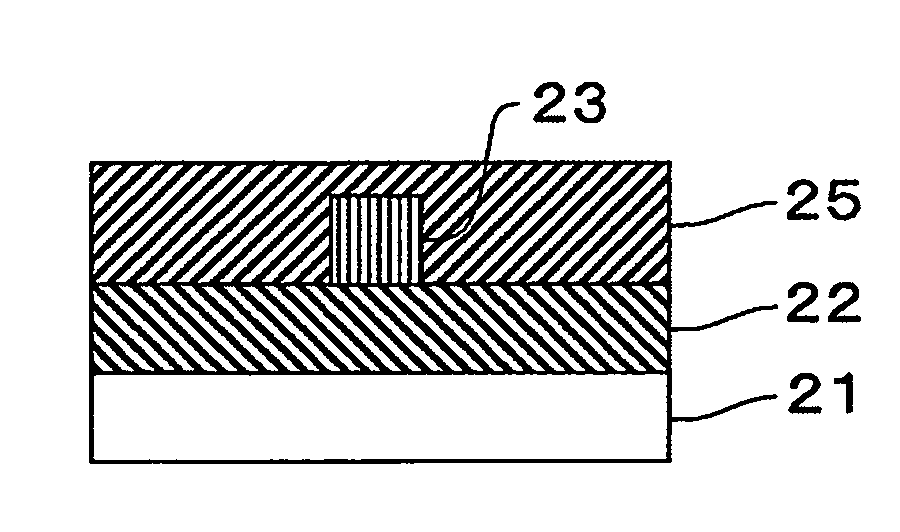

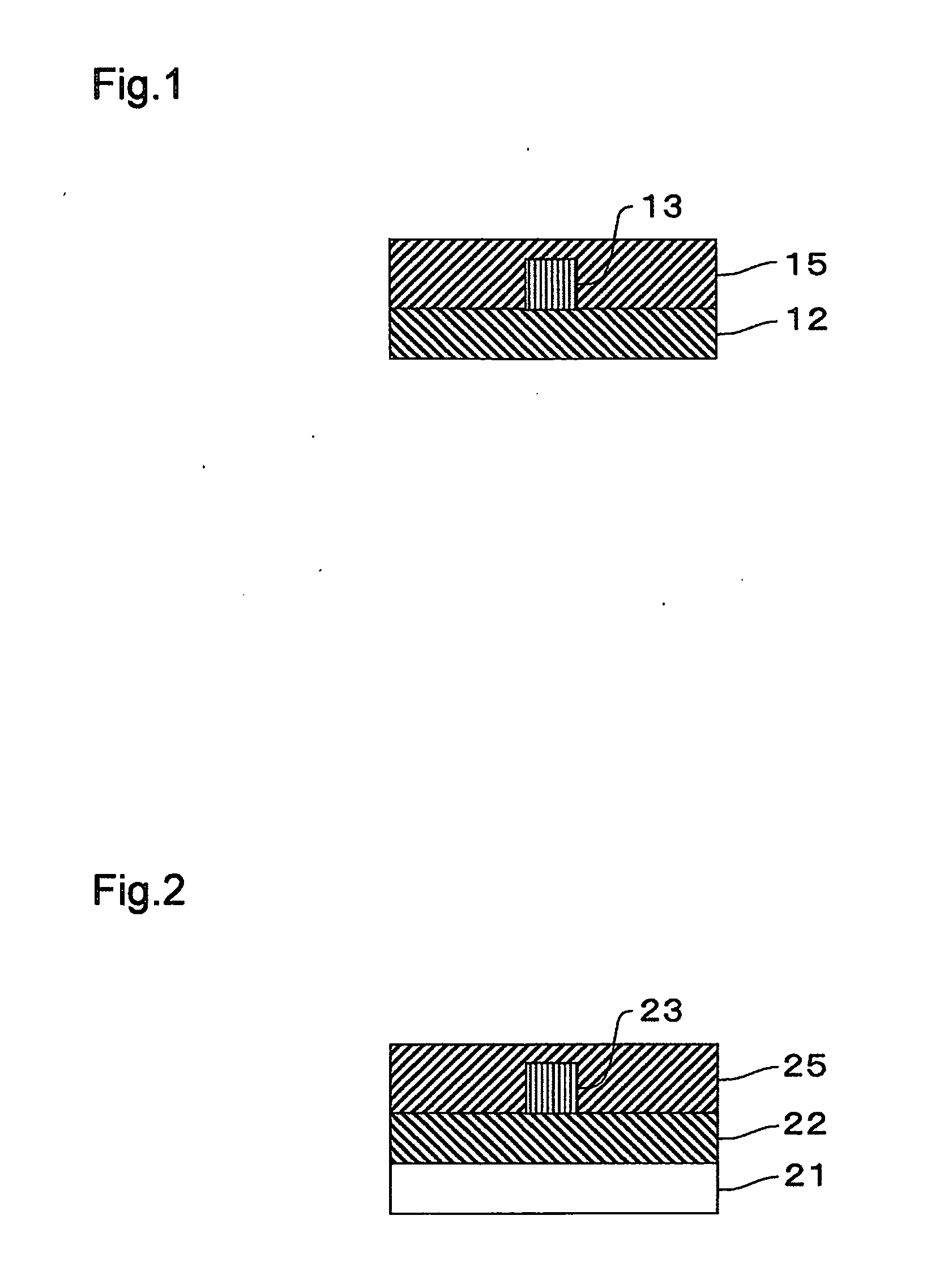

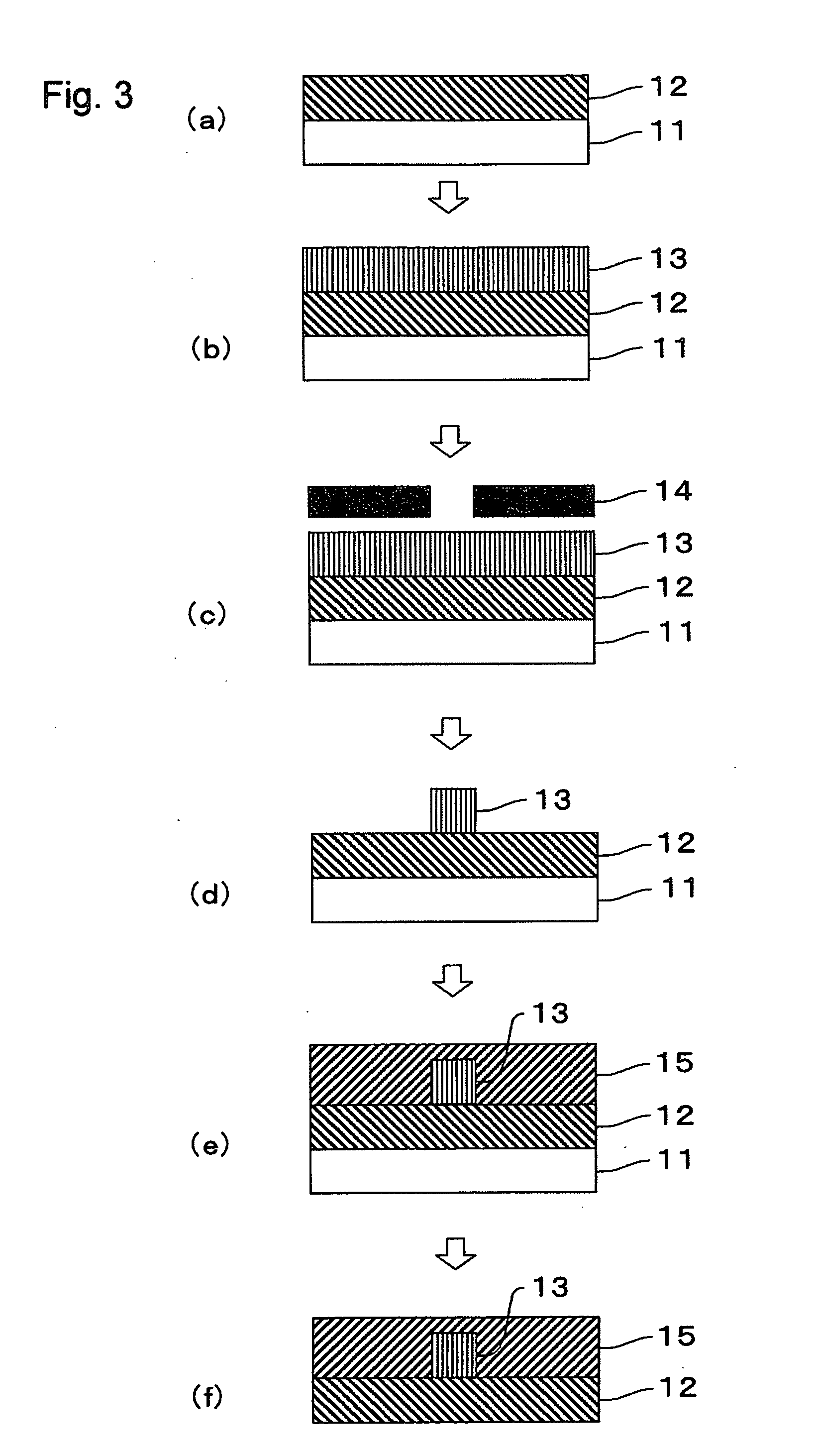

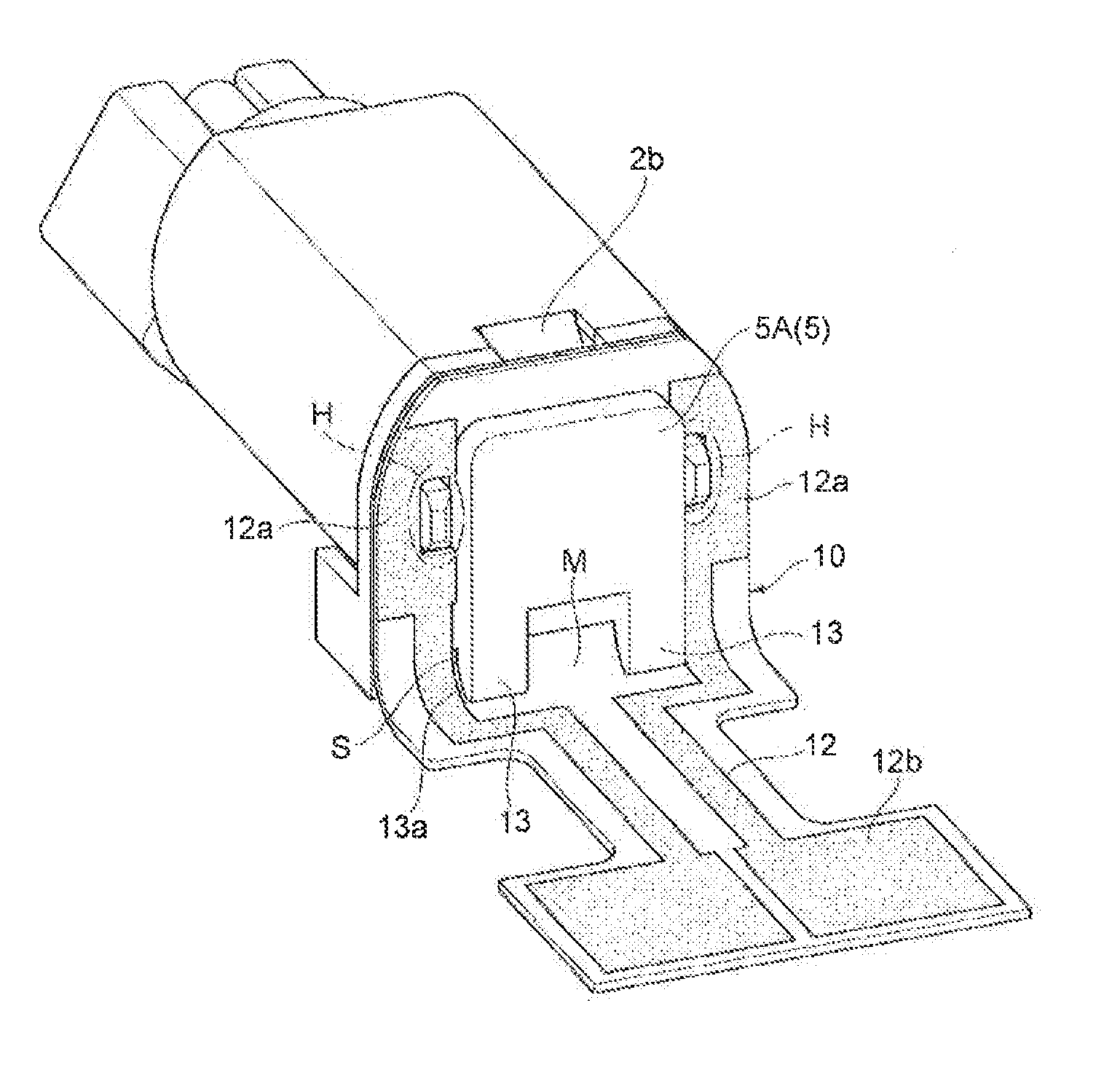

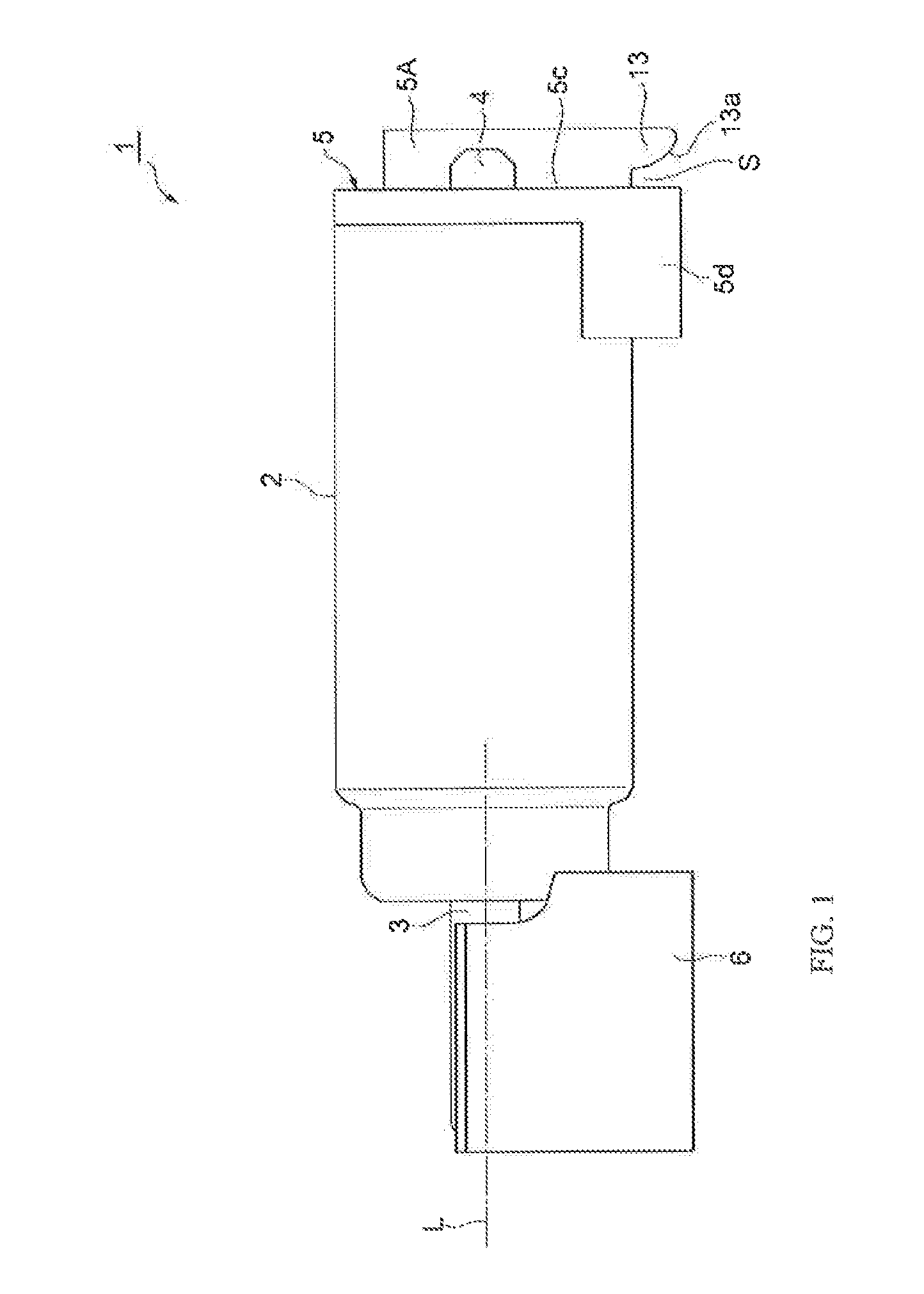

A compact motor which avoids peeling and cracking of the circuit board wiring pattern upon bending the printed circuit board. A projecting part (13), projecting toward the bottom side of the bracket (5), is provided on the back surface (5c) of the bracket (5) of a compact motor. A board insertion groove (S) is formed between the projecting part (13) and the back surface (5c). The flexible printed circuit board (10), inserted inside the board insertion groove (S), abuts the projecting part (13) and is bent facing the back. When the printed circuit board (10) is inserted into the board insertion groove (S) and bent, the printed circuit board (10) is in a state abutting the curved part (13a) of the projecting part (13), so the curved part (13a) of the projecting part (13) regulates bending and, by doing this, stabilizes bending of the flexible printed circuit board (10).

Owner:COPAL CO LTD

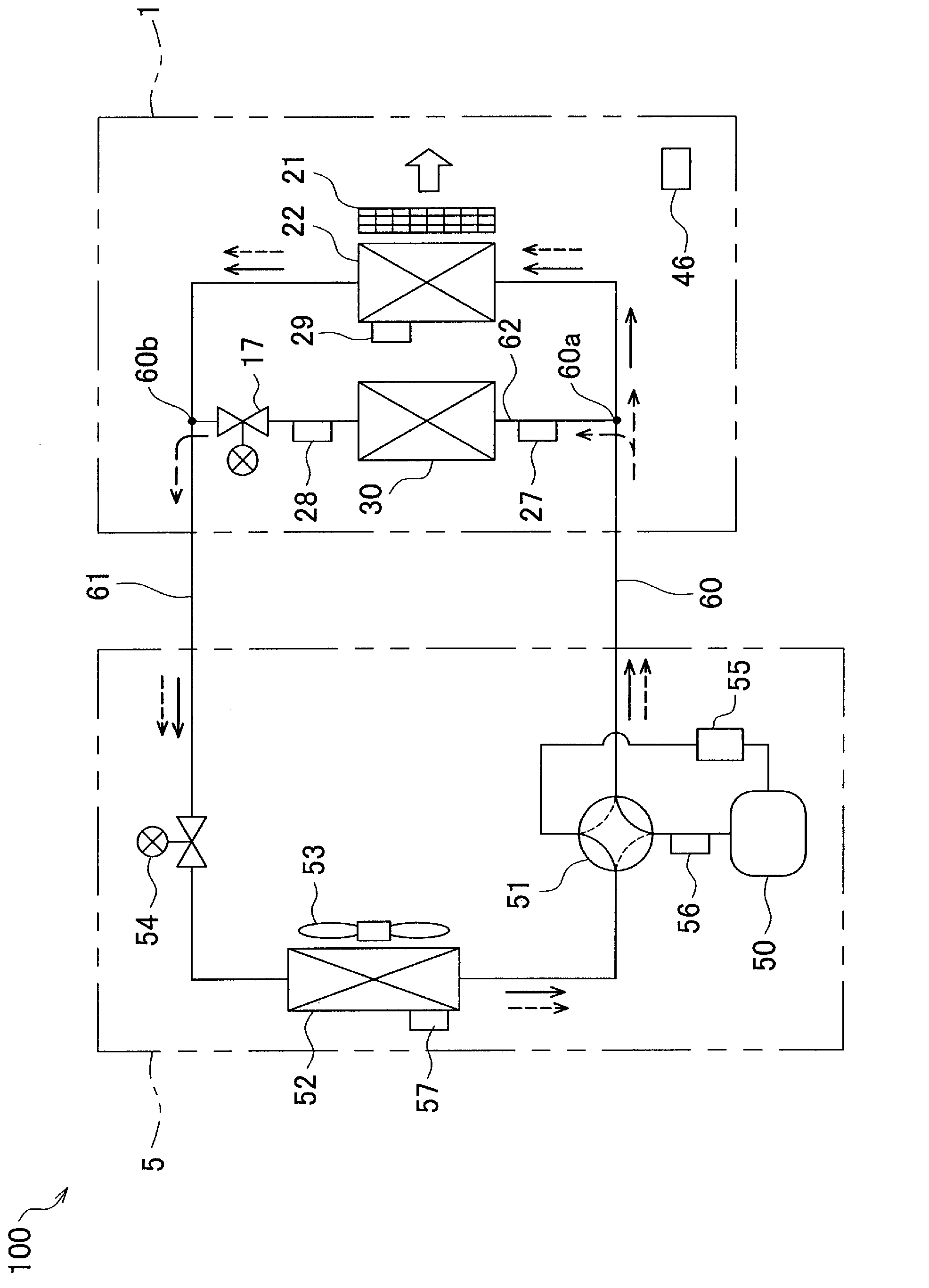

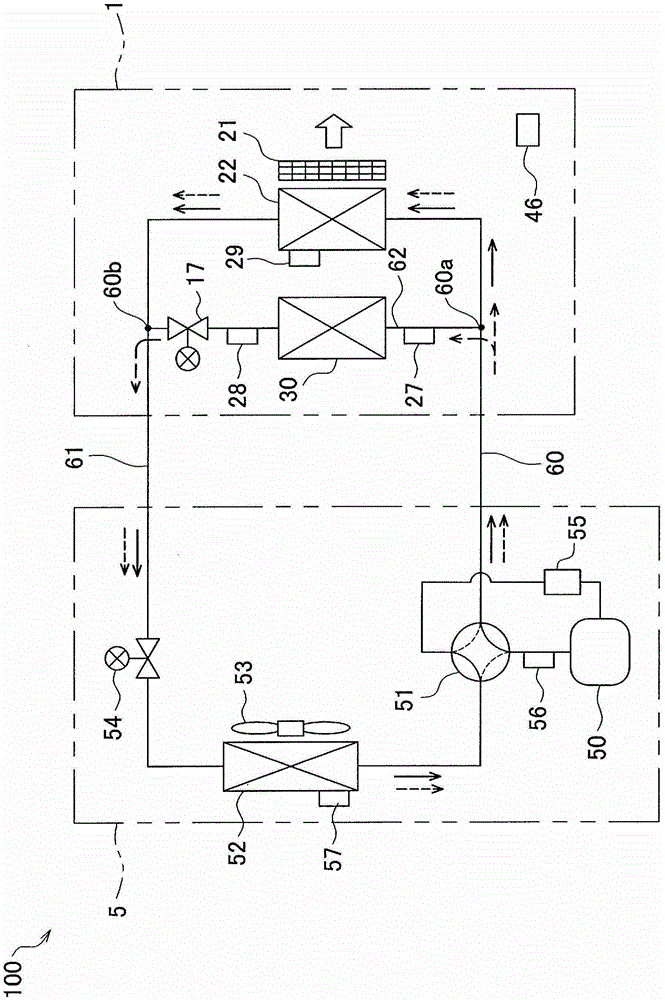

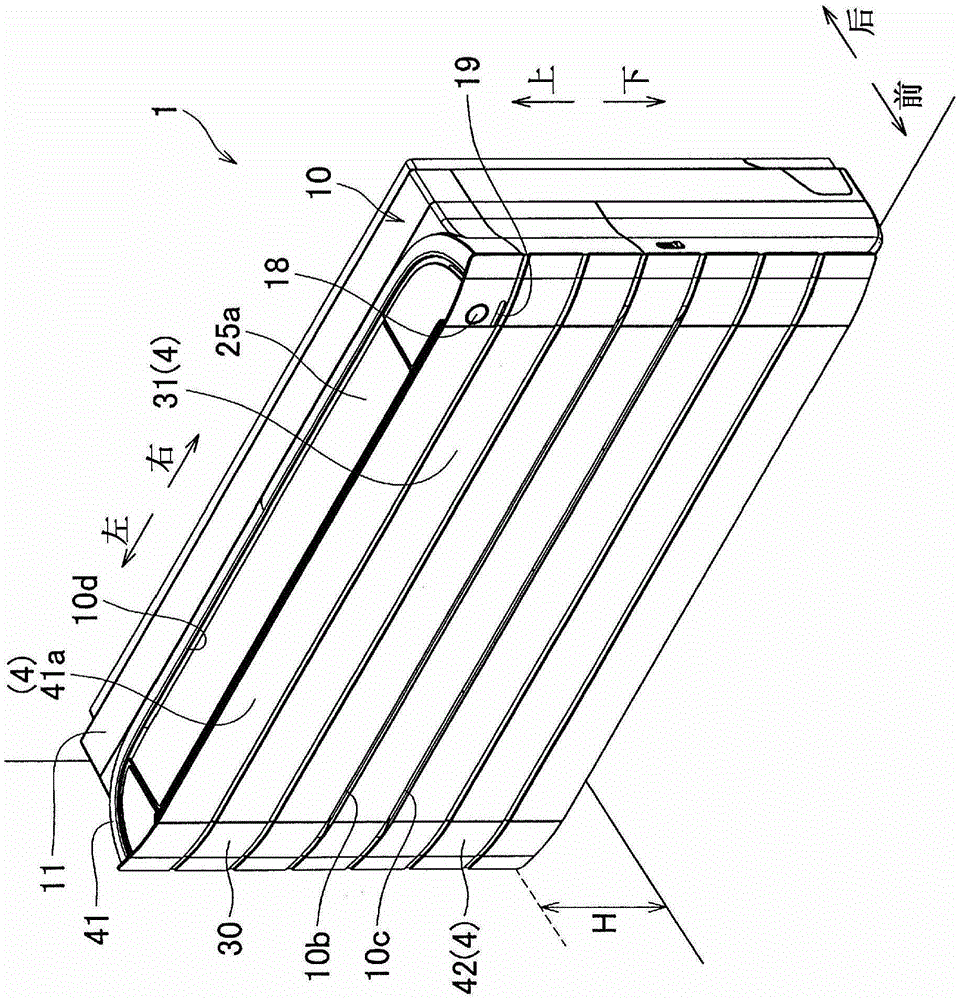

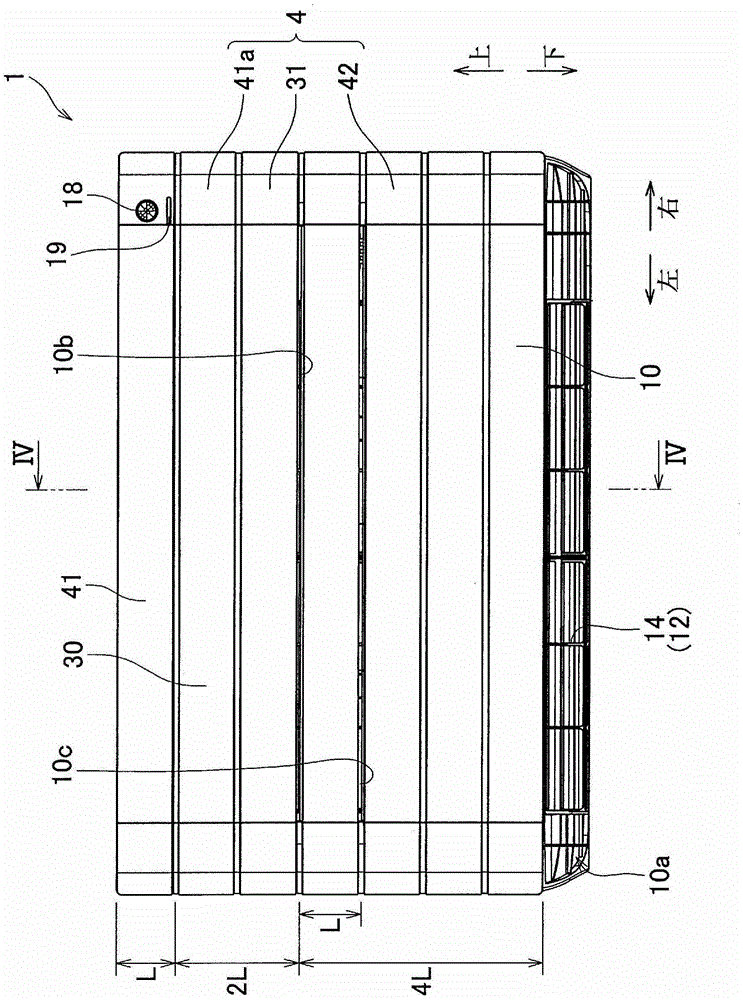

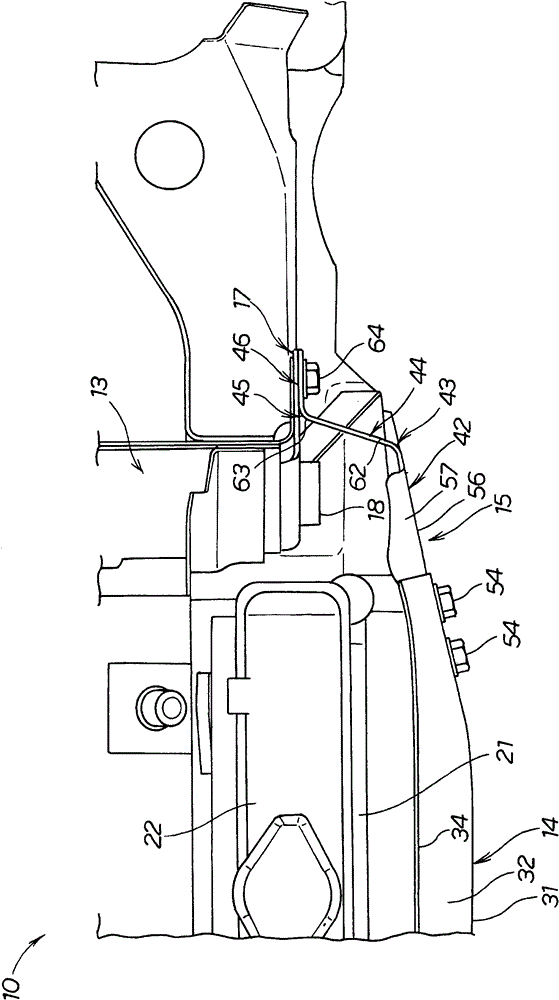

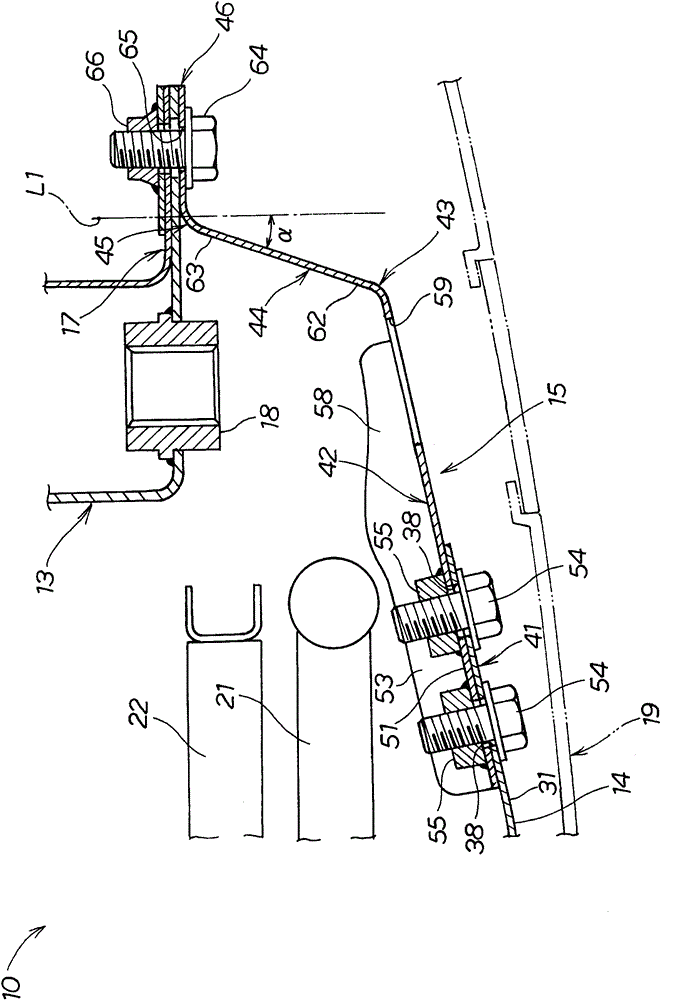

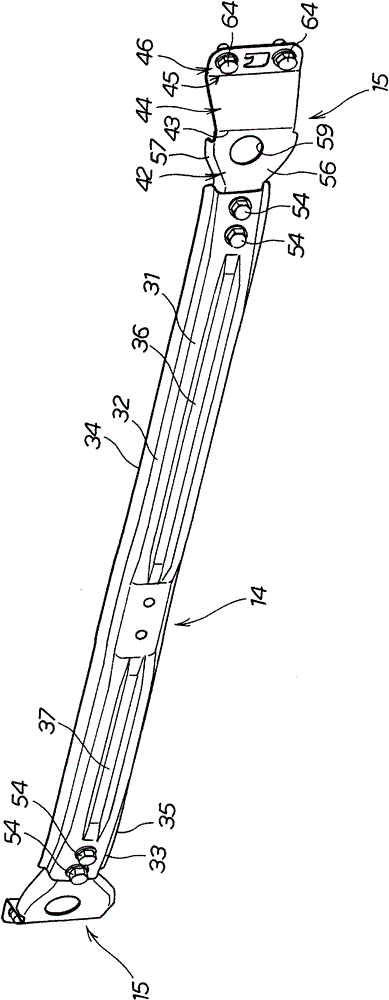

Floor-placed indoor unit

InactiveCN103189688AReduce heat exchange efficiencyCurb supply shortageLighting and heating apparatusSpace heating and ventilation detailsEngineeringSurface heat

The present invention prevents a decrease in heat exchange efficiency. An indoor heat exchanger (22) housed in a casing (10) has: a front-surface heat exchanger (22a) disposed in a manner so as to face the back surface of a front-surface panel (4); and a back-surface heat exchanger (22b) that tilts upward with proximity to the back surface from the vicinity of the bottom end of the front-surface heat exchanger (22a). An upper filter (16a) and a lower filter (16b) are provided to a duct reaching the front-surface heat exchanger (22a) from a main intake port (10a) provided to the front of the bottom end of the casing (10). Also, at least a portion of the section of the bottom filter (16b) further downwards than is the front-surface heat exchanger (22a) is bowed forwards as a bulge.

Owner:DAIKIN IND LTD

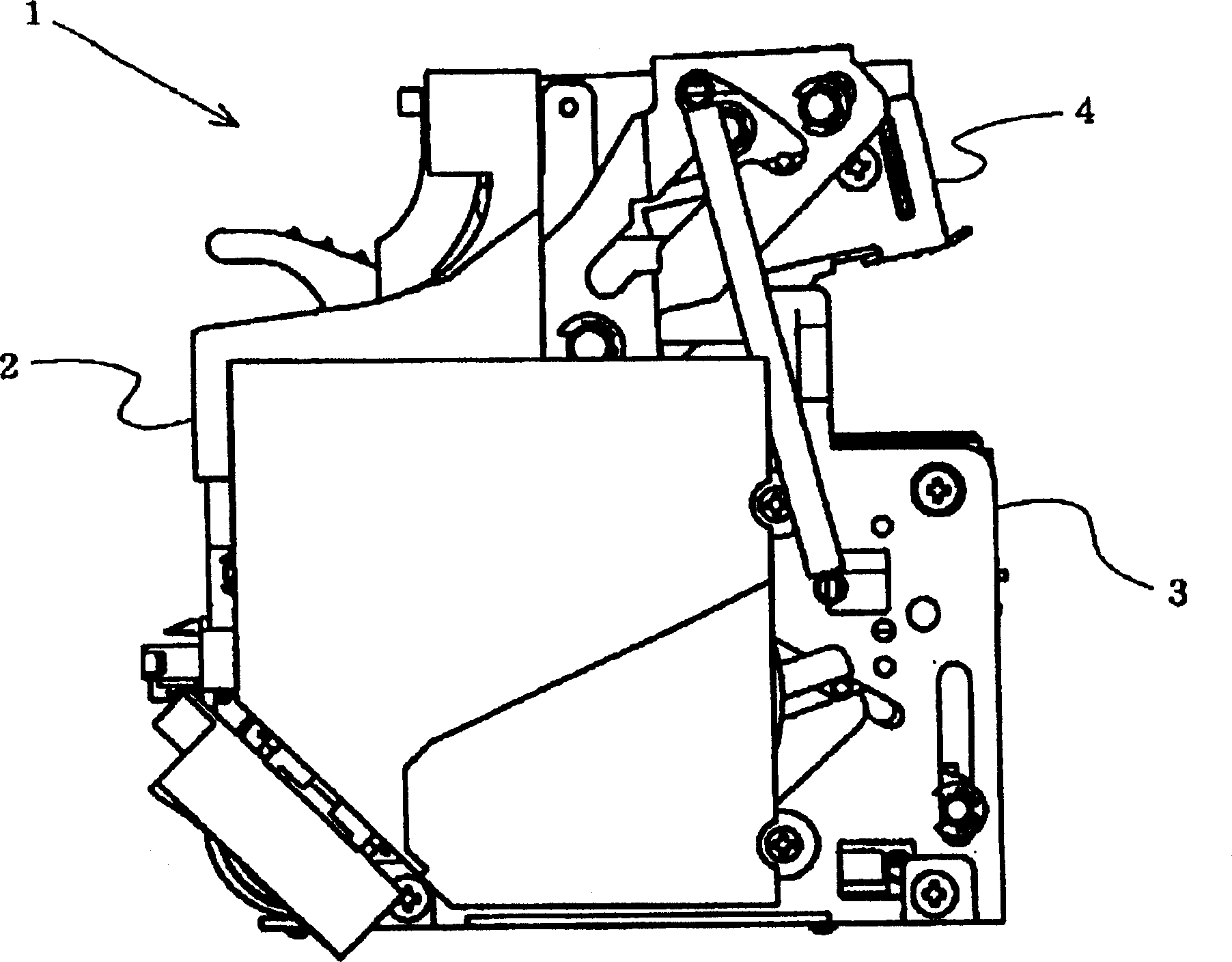

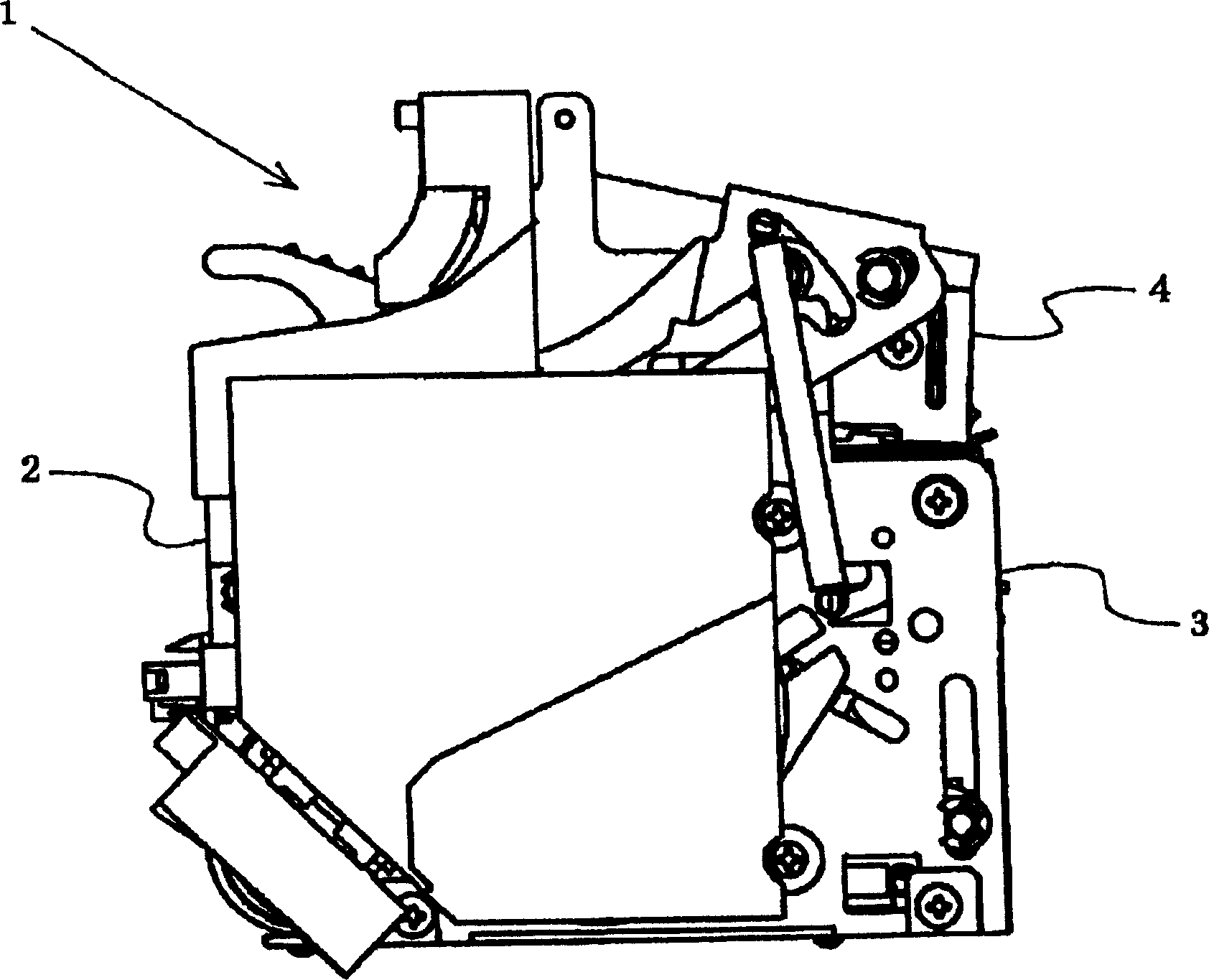

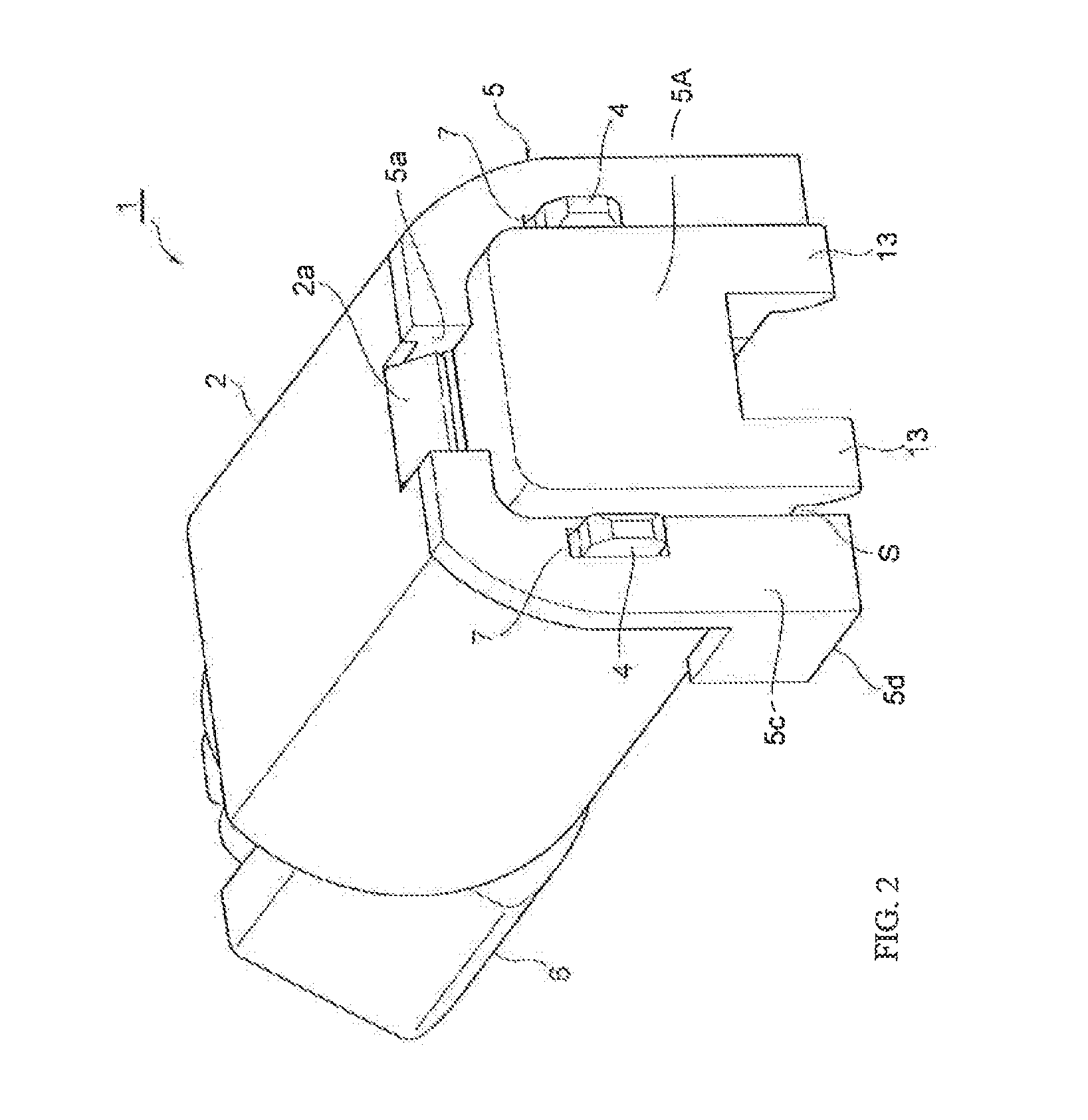

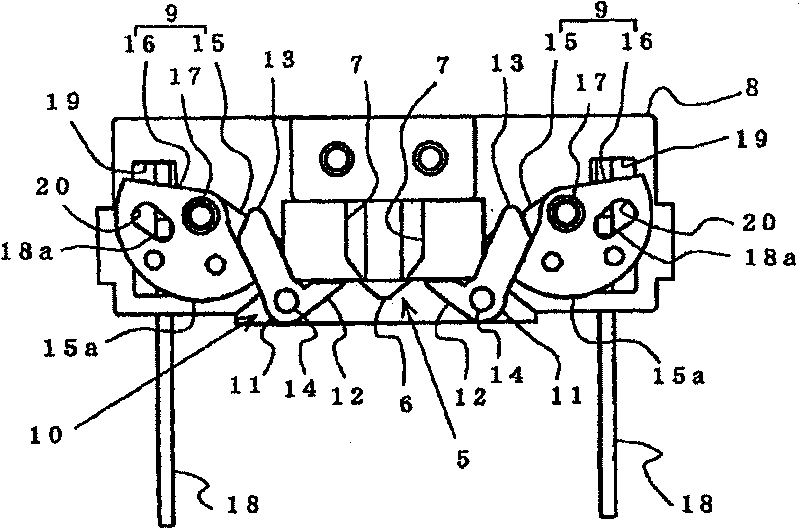

Stapler

InactiveCN1910016AMiniaturizationReduce manufacturing costStapling toolsNailing toolsMechanical engineering

A staple leg cutting mechanism 5 is composed of a fixed cutter 6 interposed between staple legs S1 penetrated through binding sheets and a pair of movable cutters 7 disposed movable from the outside of the staple legs S1 to the inside thereof, and a clincher mechanism 10 is composed of a pair of movable clinchers 11 respectively disposed on the lower surface side of their associated movable cutters 7, whereby the staple legs S1 penetrated through the binding sheets are formed in an inwardly curved manner by the movable clinchers 11 and are then guided into and between the movable cutters 7 and fixed cutter 6, the movable cutters 7 are moved from the outside of the staple legs S1 to the inside thereof to thereby cut the leading end portions of the staple legs S1, and the staple legs S1 are bent along the binding sheets by the movable clinchers 11.

Owner:MAX CO LTD

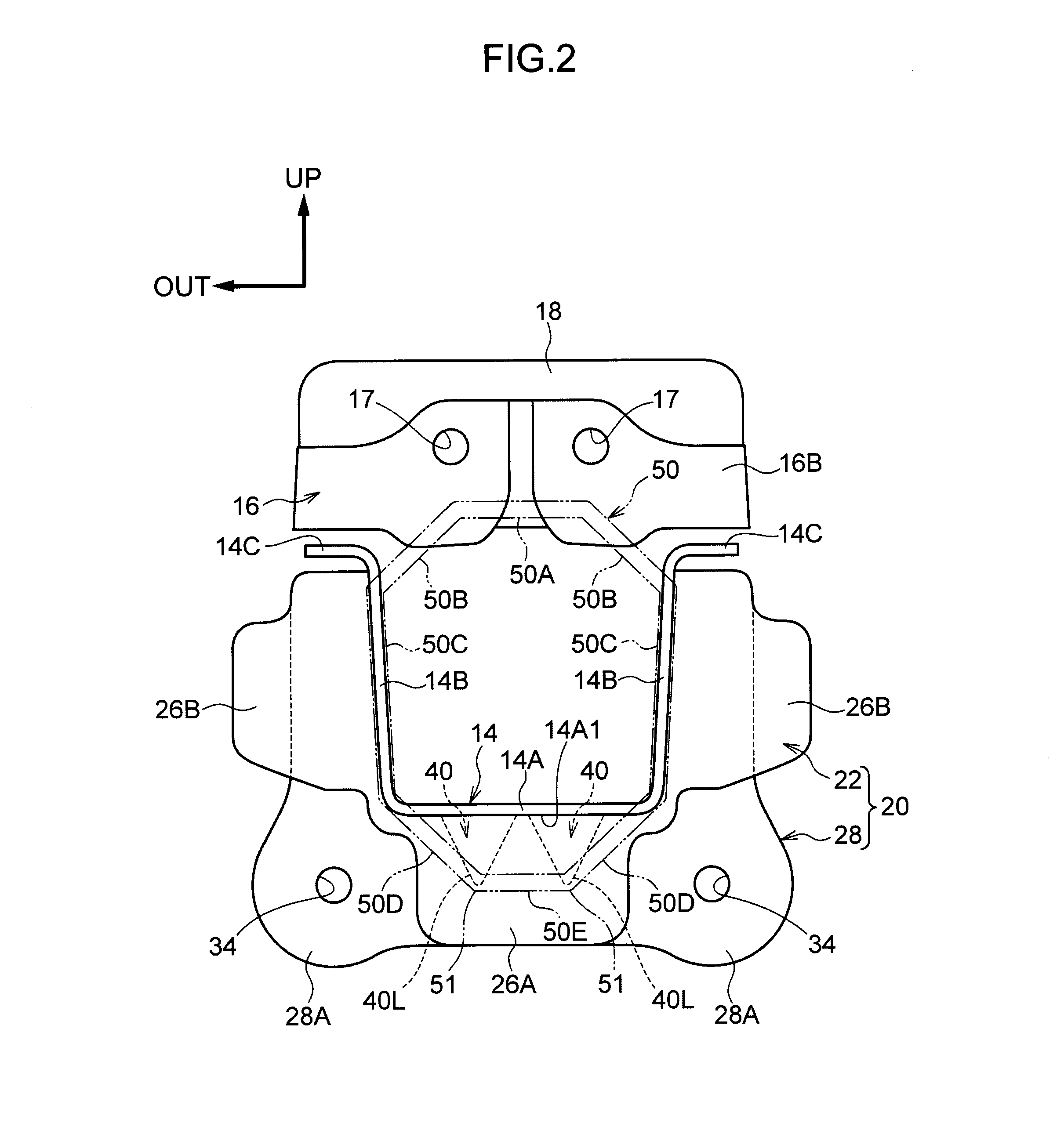

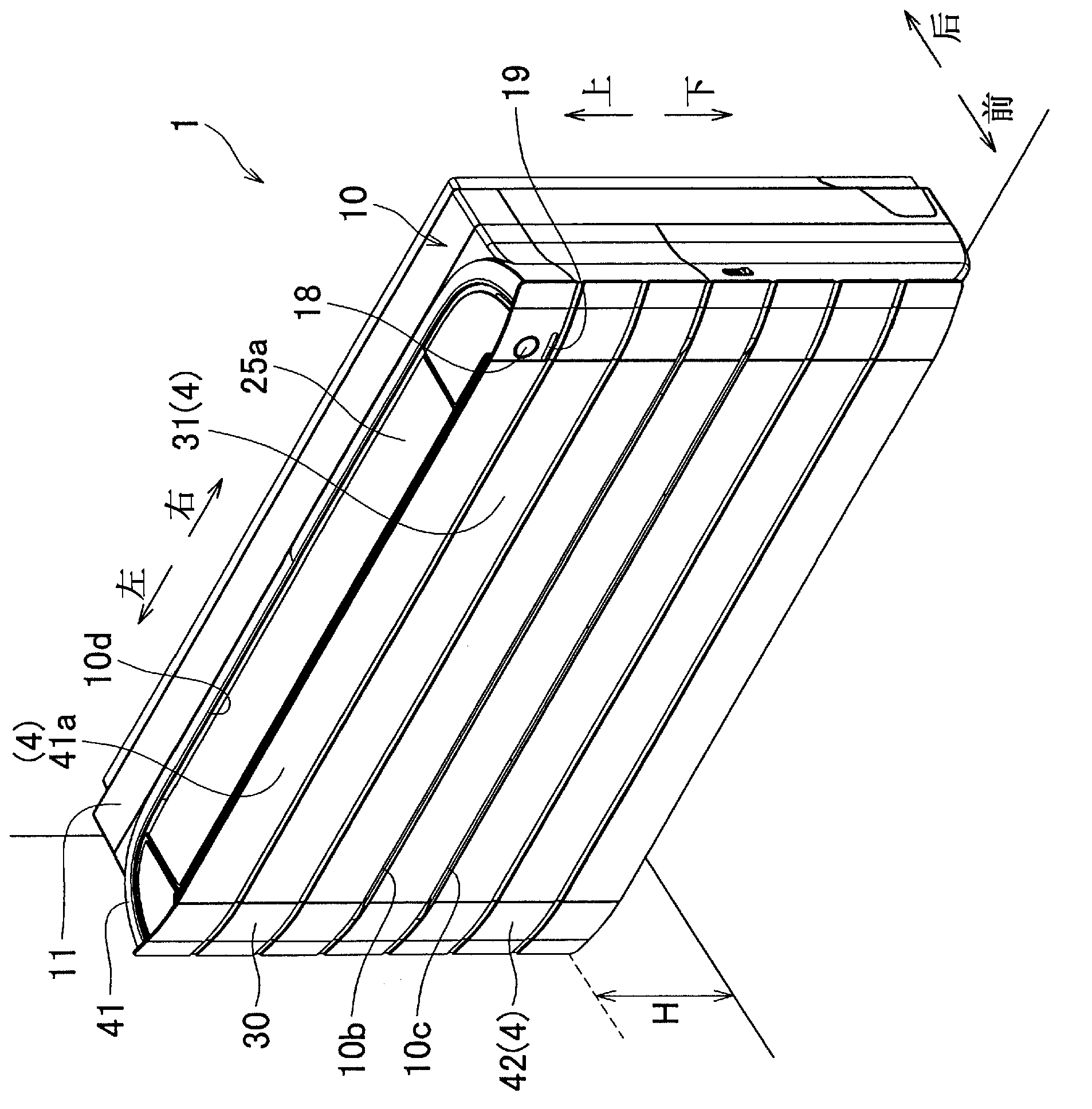

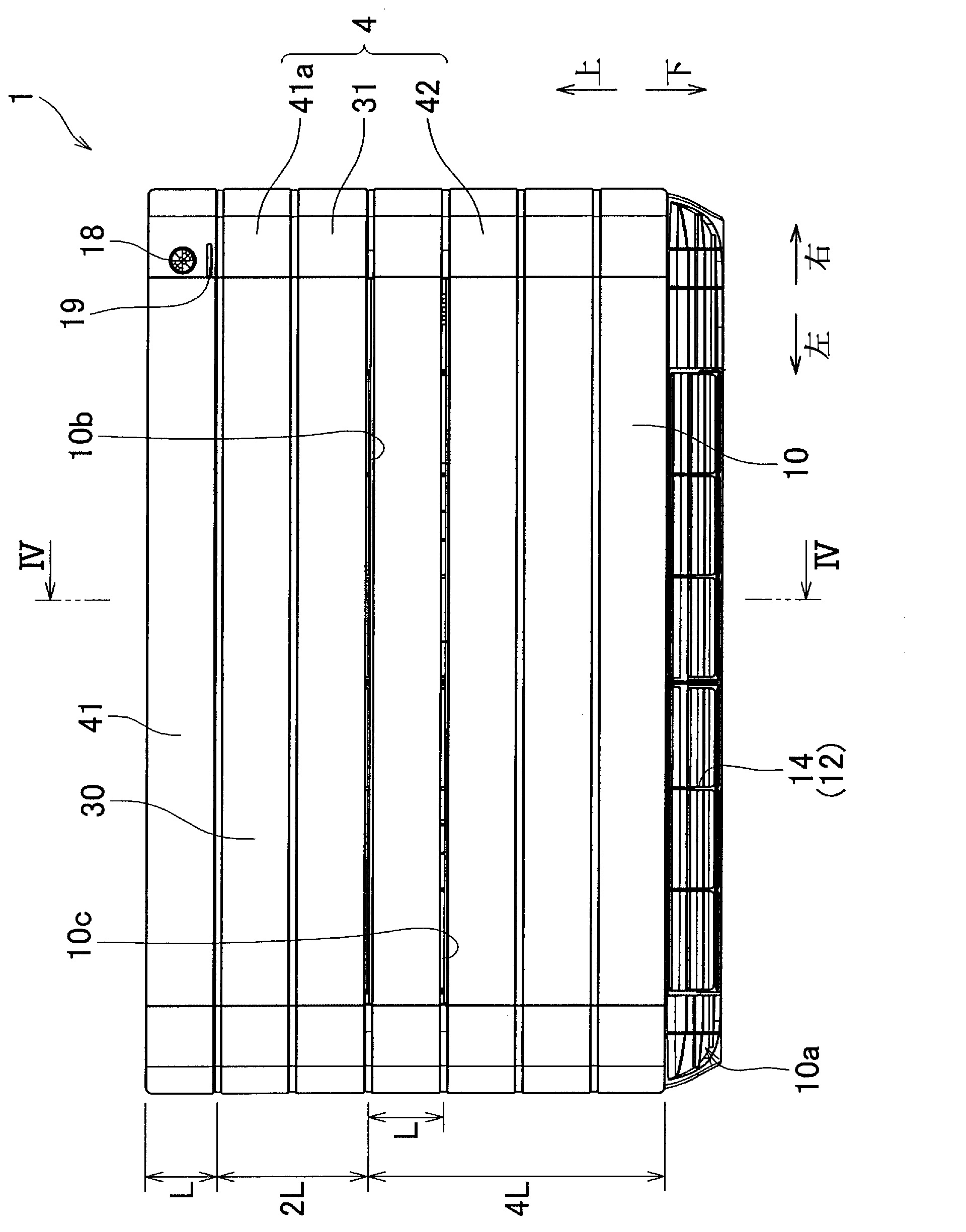

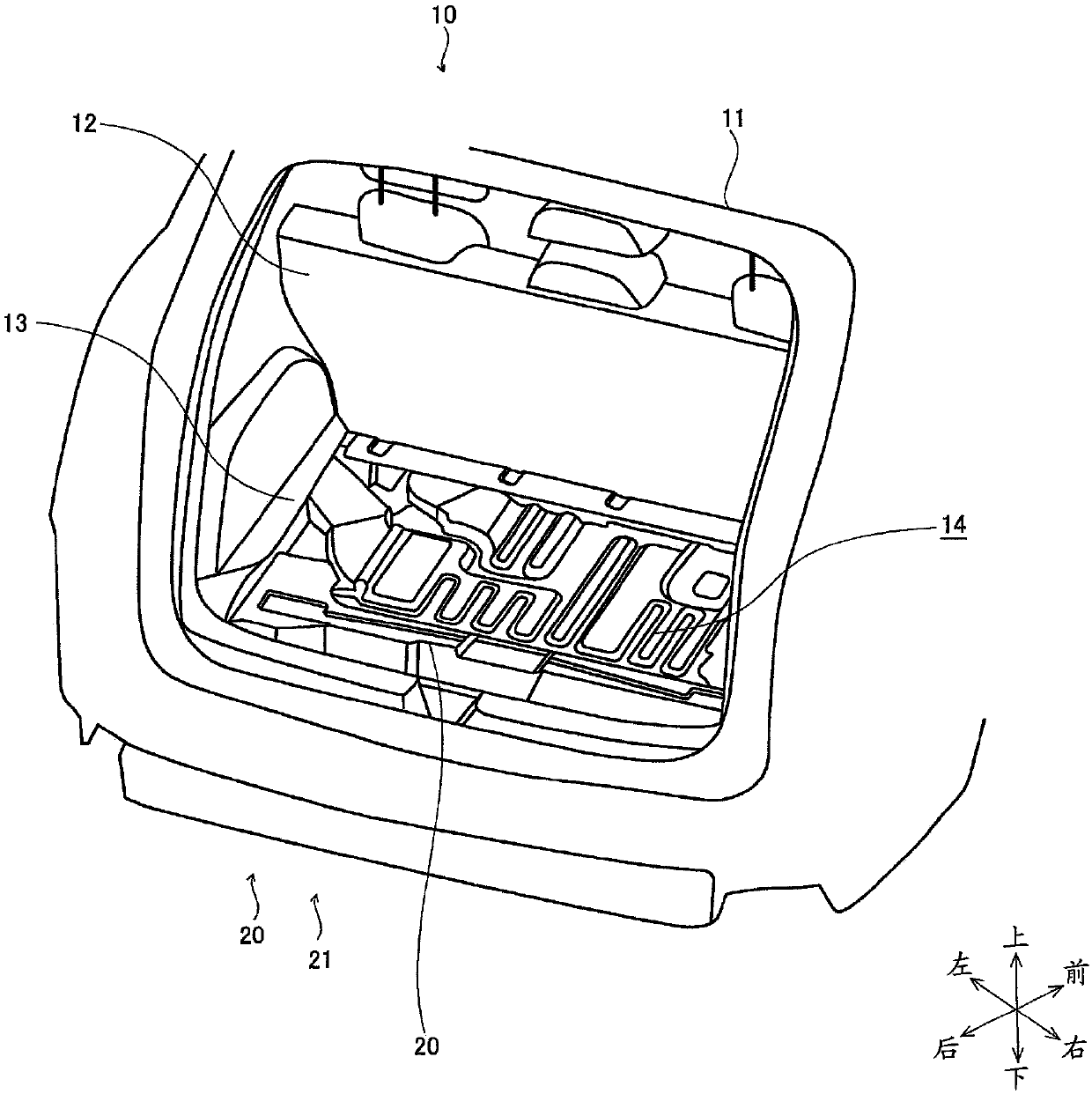

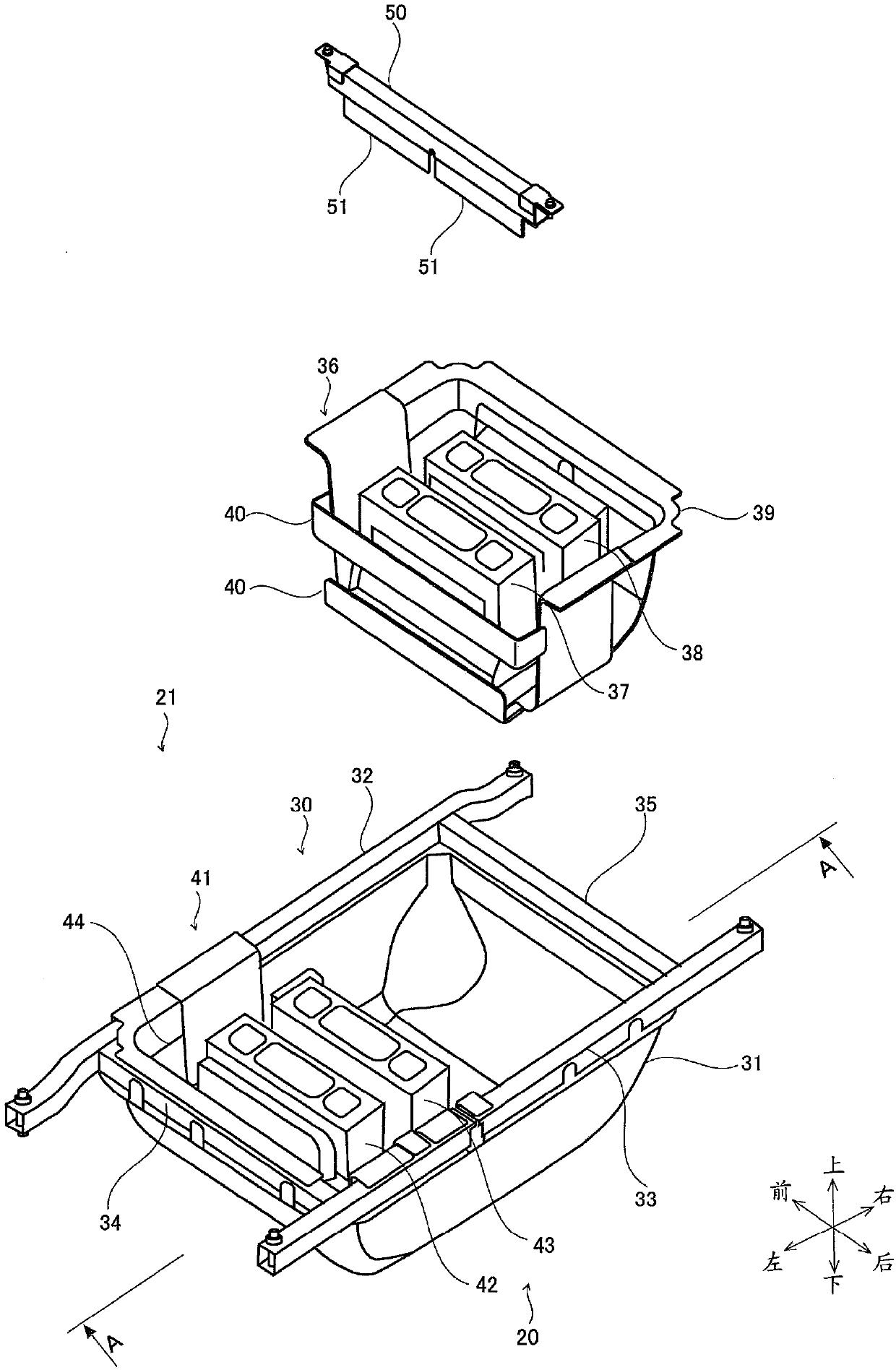

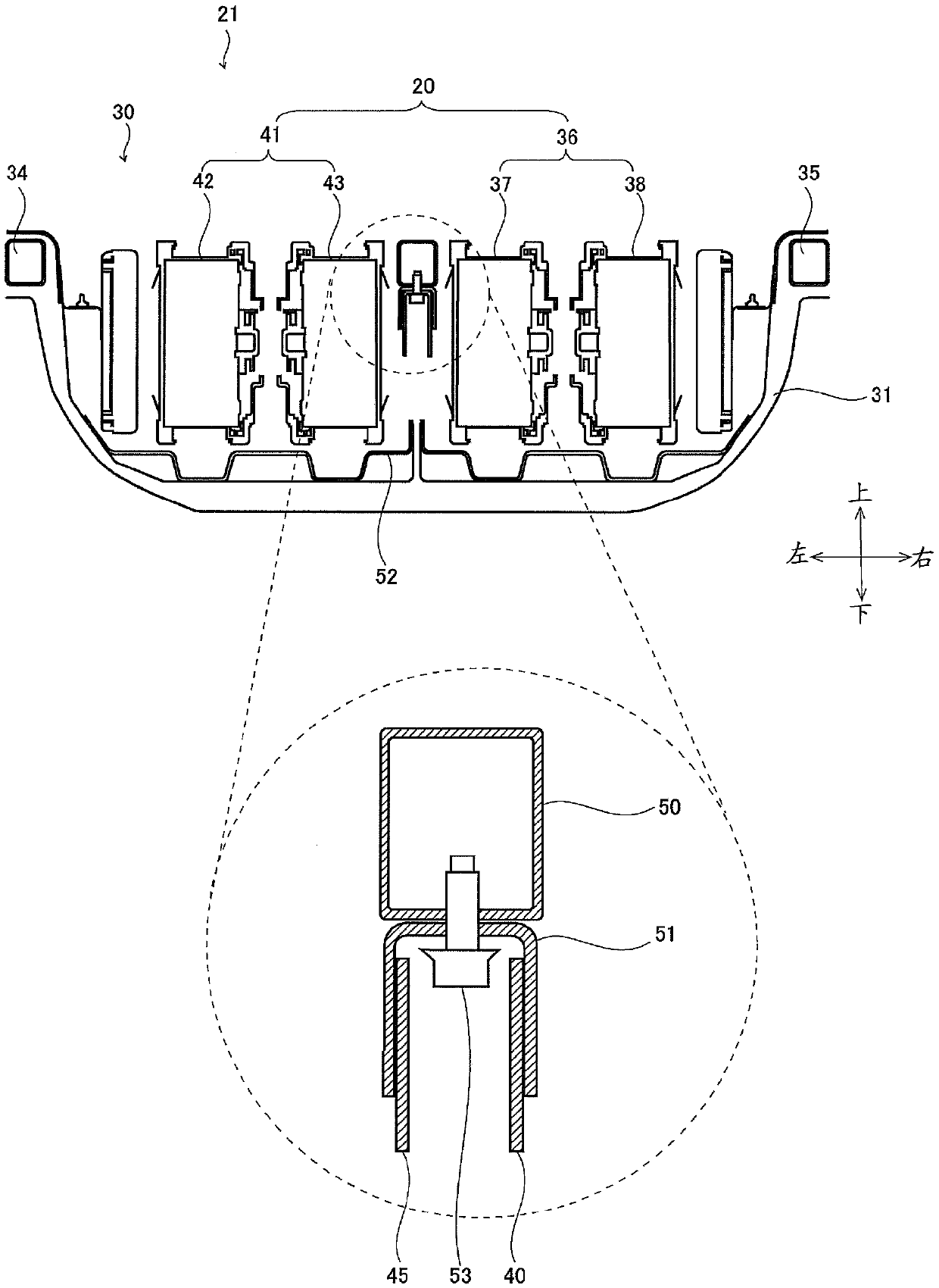

Vehicle battery pack protective structure and vehicle having the vehicle battery pack protective structure

ActiveCN109941083AAvoid breakingPrevent protrudingElectric devicesElectric propulsion mountingElectrical batteryBattery pack

The invention relates to a vehicle battery pack protective structure and a vehicle having the vehicle battery pack protective structure. There is provided a vehicle battery pack protective structure which protects a vehicle battery pack including battery stacks disposed in a width direction of a vehicle. The structure includes: a battery pack storage container (30) that stores the vehicle batterypack (20); and a first upper reinforcing member (50) that extends in a front-rear direction of the vehicle (10) between the battery stacks (37), and is connected to the battery pack storage container(30) at a front end and a rear end. A first fragile part (54) is formed below an intermediate position of the first the upper reinforcing member (50).

Owner:SUBARU CORP

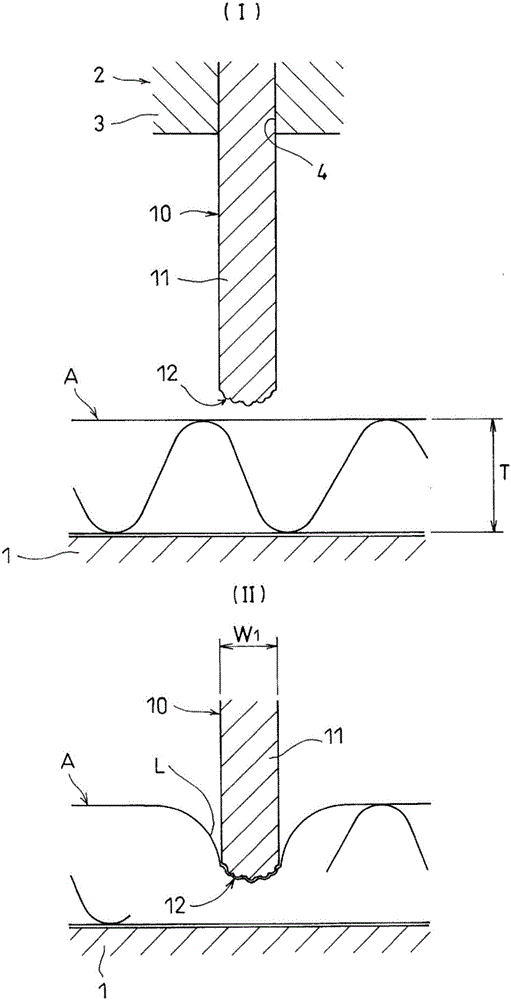

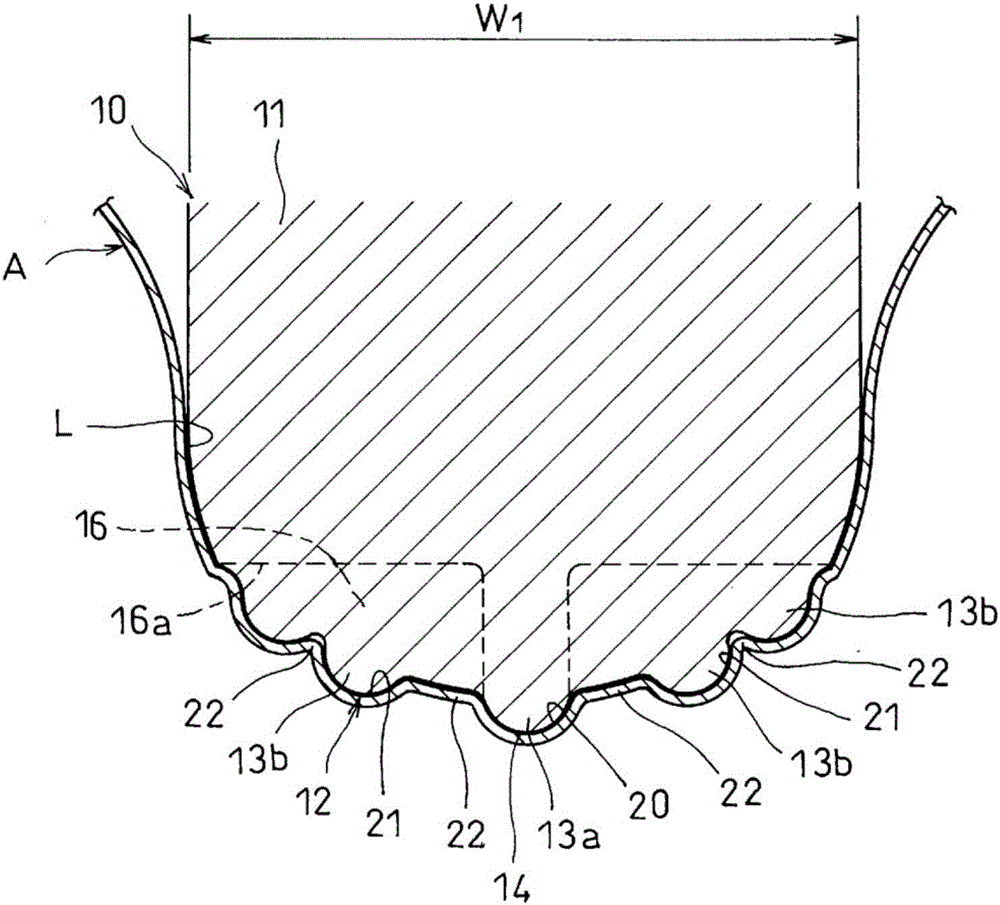

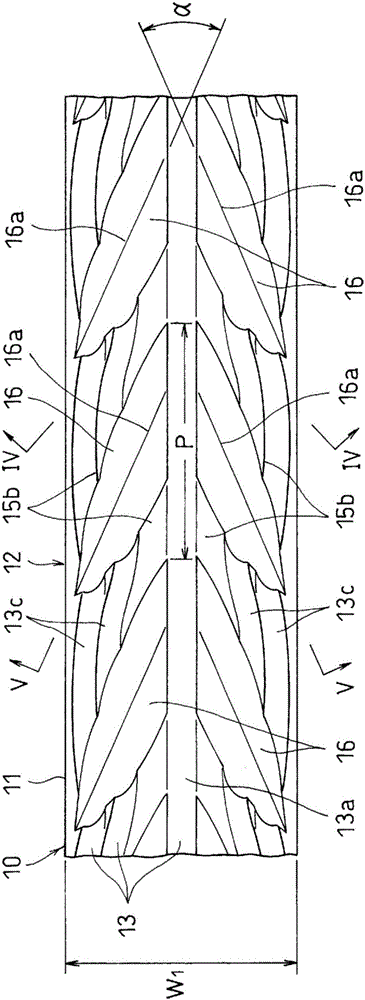

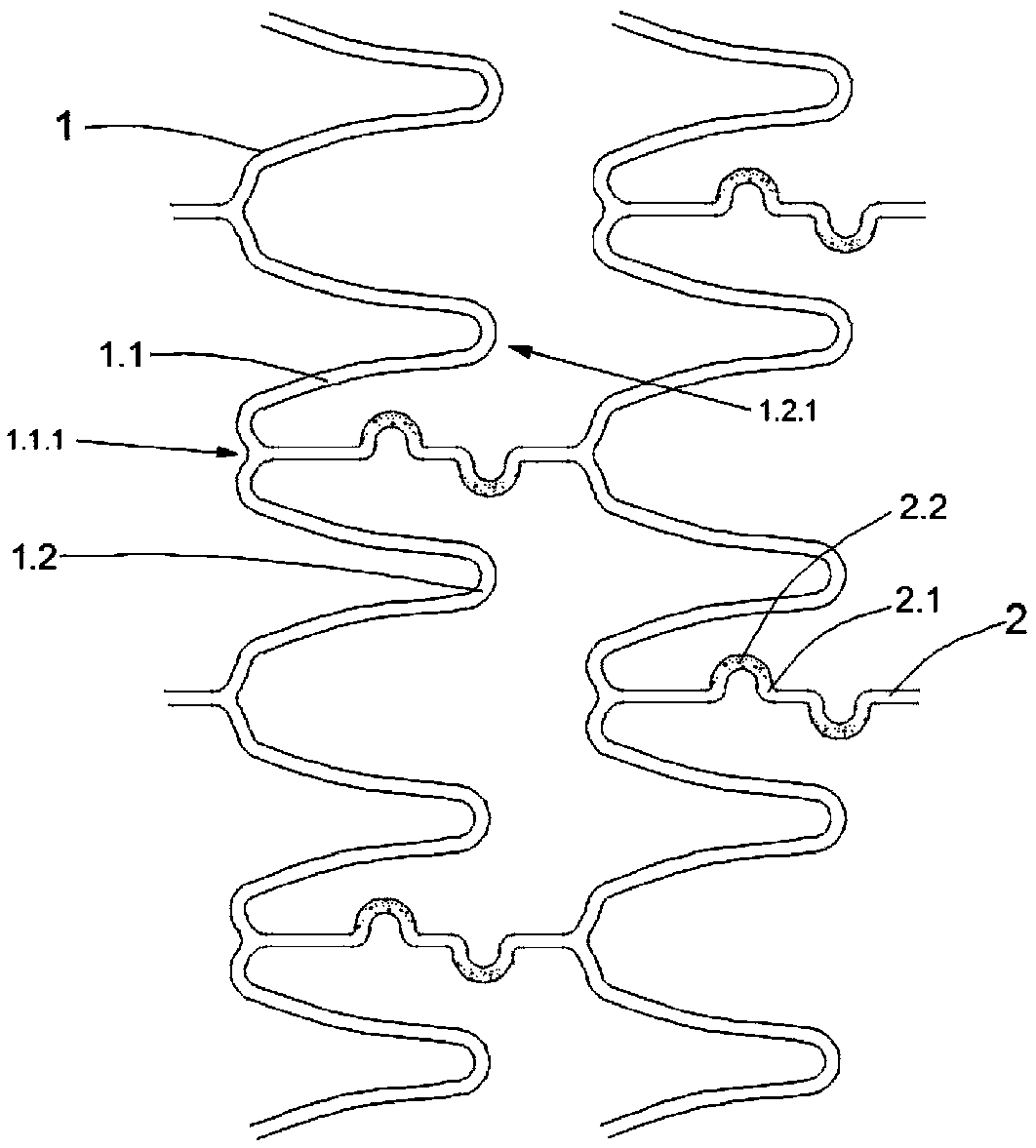

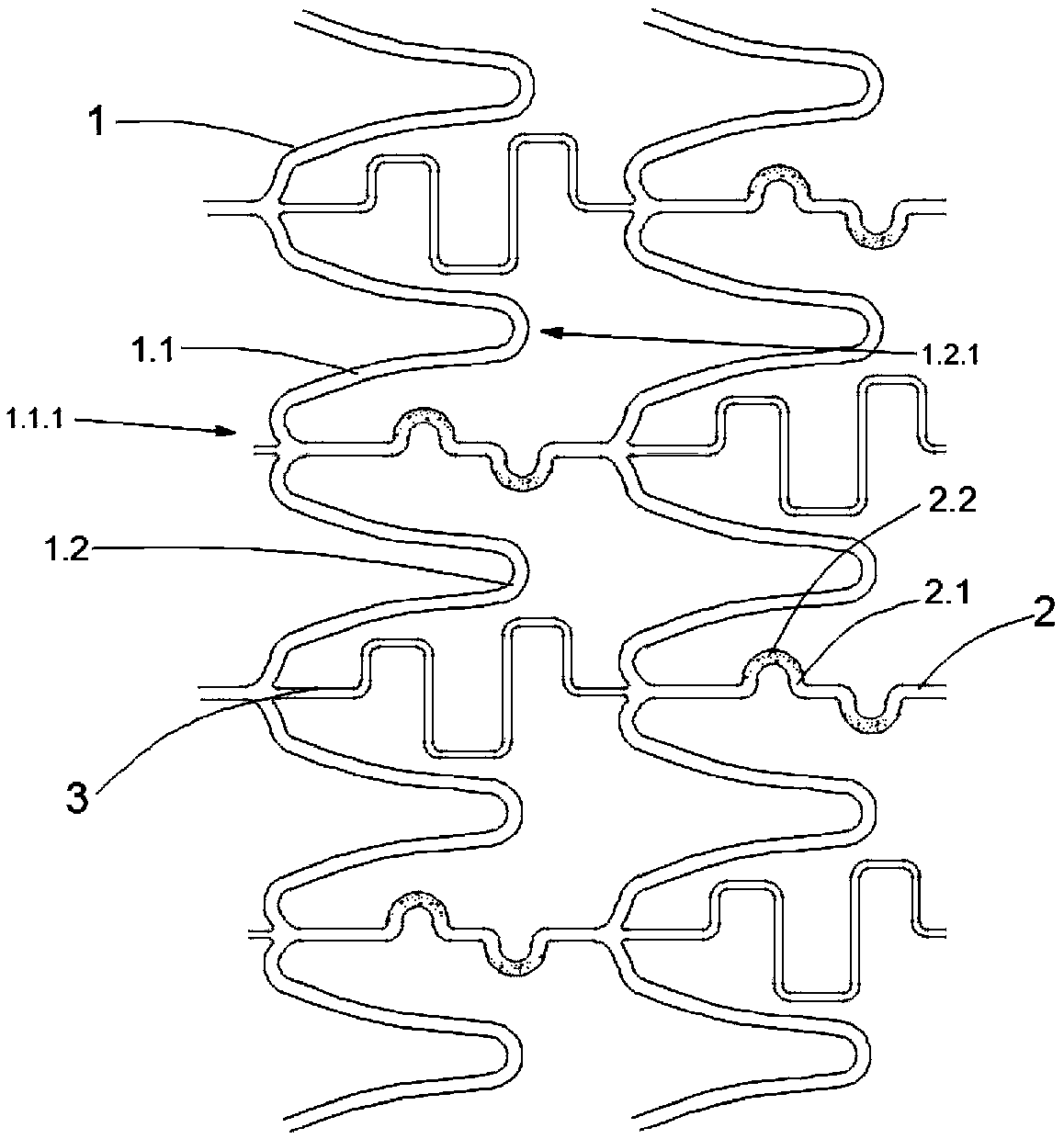

Creasing member, creasing template, and creasing device

InactiveCN106457728AHigh precisionImprove bending strengthMechanical working/deformationBox making operationsCardboardEngineering

According to the invention, crease lines for precisely folding a cardboard sheet are formed. One end of a belt-shaped metal member (11) is used as a creasing part (12), and the creasing part (12) is provided with an odd number of ridges (13a, 13b) extending in the length direction of the belt-shaped member (11) such that one ridge (13a) is provided at the center of the creasing part (12) in the width direction. Intersecting grooves (16) that are inclined with respect to the center ridge (13a) are formed on both sides of the center ridge (13a), which is provided at the center of the creasing part (12) in the width direction, at intervals in the length direction of the creasing part (12). The ridges (13b) provided on both sides of the center ridge (13a) are each segmented in the length direction to form segmented ridges (13c), forming a straight groove (20), discontinuous grooves (21), segmented ribs (22), and intersecting ribs (23) in the groove bottom of a crease line (L) that is formed by pressing the creasing part (12) into a cardboard sheet (A).

Owner:DIEPEX CO LTD

A renal artery radiofrequency ablation catheter with cold saline for sympathetic nerve removal with a sealing valve

InactiveCN104257426BSimple internal structureReduce lumenSurgical instruments for heatingSaline injectionGuide wires

The invention relates to a renal artery sympathetic cold saline radiofrequency ablation catheter with a sealing valve, which comprises: a spiral ablation tube, and a through hole for guide wire penetration and saline injection is arranged in the ablation tube along the spiral direction; connected to the through hole Remote sealing valve. The injection of cold saline in the ablation tube of the present invention and the penetration of the guide wire share a through hole, and a sealing valve is provided at the far end of the through hole. It can inject cold saline through the through hole during ablation to prevent coking of the inner wall of the blood vessel and vascular spasm, which greatly simplifies the internal structure of the inner tube, reduces the outer diameter of the catheter, and reduces the difficulty and cost of manufacturing. When it is spiral, it provides a reliable curvature, so that it is close to the inner wall of the renal artery and improves the ablation effect. The present invention can be applied to renal artery denervation.

Owner:远见企业有限公司

Compact motor

InactiveUS20140175955A1Avoid crackingPrevent peelingAssociation with control/drive circuitsMechanical energy handlingEngineeringFlexible electronics

A compact motor which avoids peeling and cracking of the circuit board wiring pattern upon bending the printed circuit board. A projecting part (13), projecting toward the bottom side of the bracket (5), is provided on the back surface (5c) of the bracket (5) of a compact motor. A board insertion groove (S) is formed between the projecting part (13) and the back surface (5c). The flexible printed circuit board (10), inserted inside the board insertion groove (S), abuts the projecting part (13) and is bent facing the back. When the printed circuit board (10) is inserted into the board insertion groove (S) and bent, the printed circuit board (10) is in a state abutting the curved part (13a) of the projecting part (13), so the curved part (13a) of the projecting part (13) regulates bending and, by doing this, stabilizes bending of the flexible printed circuit board (10).

Owner:COPAL CO LTD

Upsetting method and upsetting device

InactiveCN101257984BLongitudinal bending stopReliable bendingMetal-working apparatusEngine componentsBiomedical engineeringEngineering

Provided is an upsetting method capable of producing an upset-forged product in which a bulging portion has a curved shape with as low a load as possible. The rod-shaped blank (1) is installed on the receiving mold (11) in a state of preventing movement in the axial direction, and the bulging part (2) of the blank (1) is arranged in the insertion hole (21). Holes are provided on the guide body (20) to insert and hold the bulged portion (2) of the blank (1) in a state where longitudinal bending is prevented. Next, press the bulging part (2) of the blank (1) in the axial direction with the punch (30), and move the guide body (20) to the direction opposite to the moving direction of the punch (30). The part (2) to bulge of the blank (1) exposed between the front end portion of the guide body (20) and the receiving mold (11) bulges outward in the radial direction. In this upsetting method, the part to be bulged (2) of the blank (1) is bent while the part to be bulged (2) is bulged.

Owner:RESONAC HOLDINGS CORPORATION

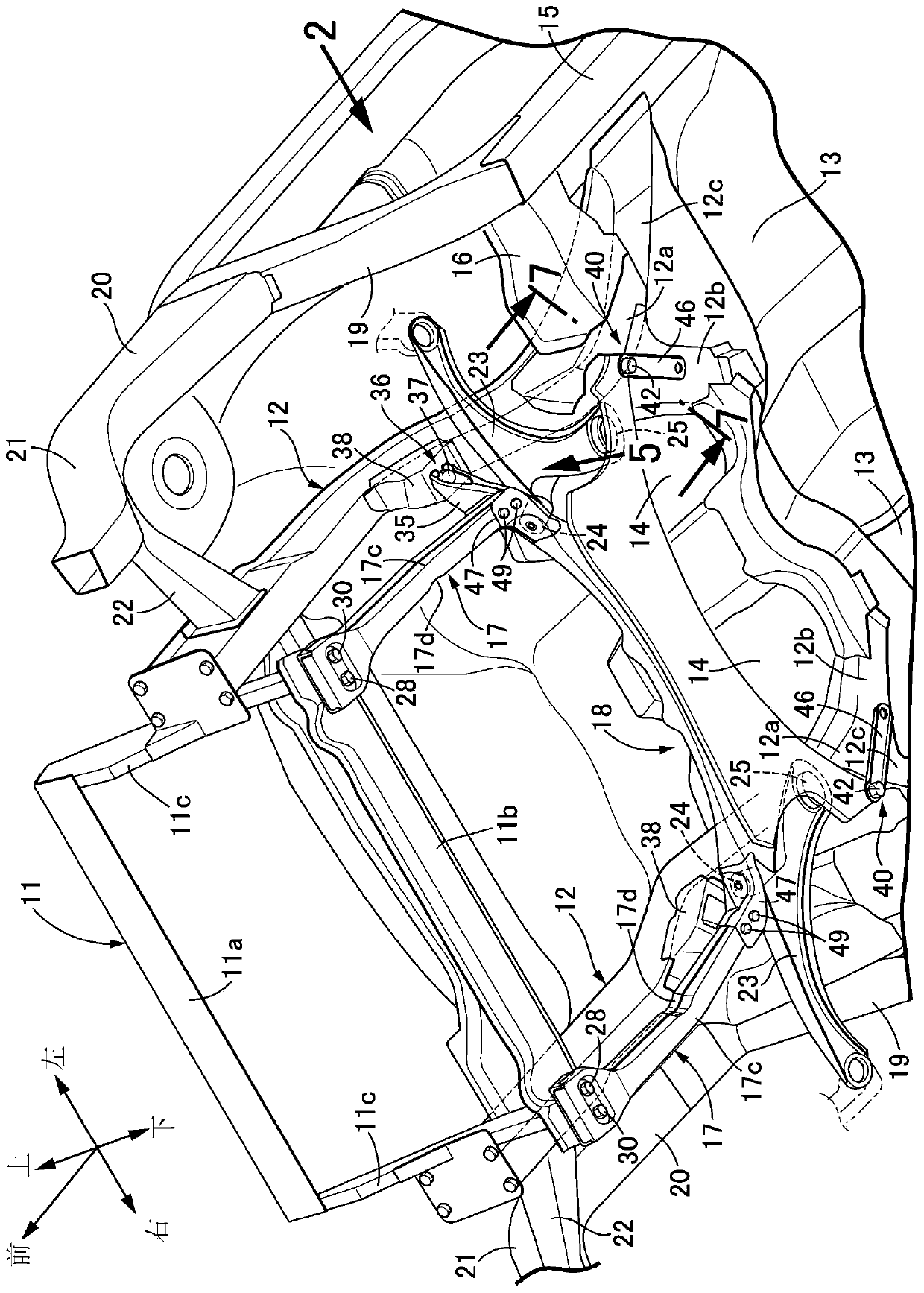

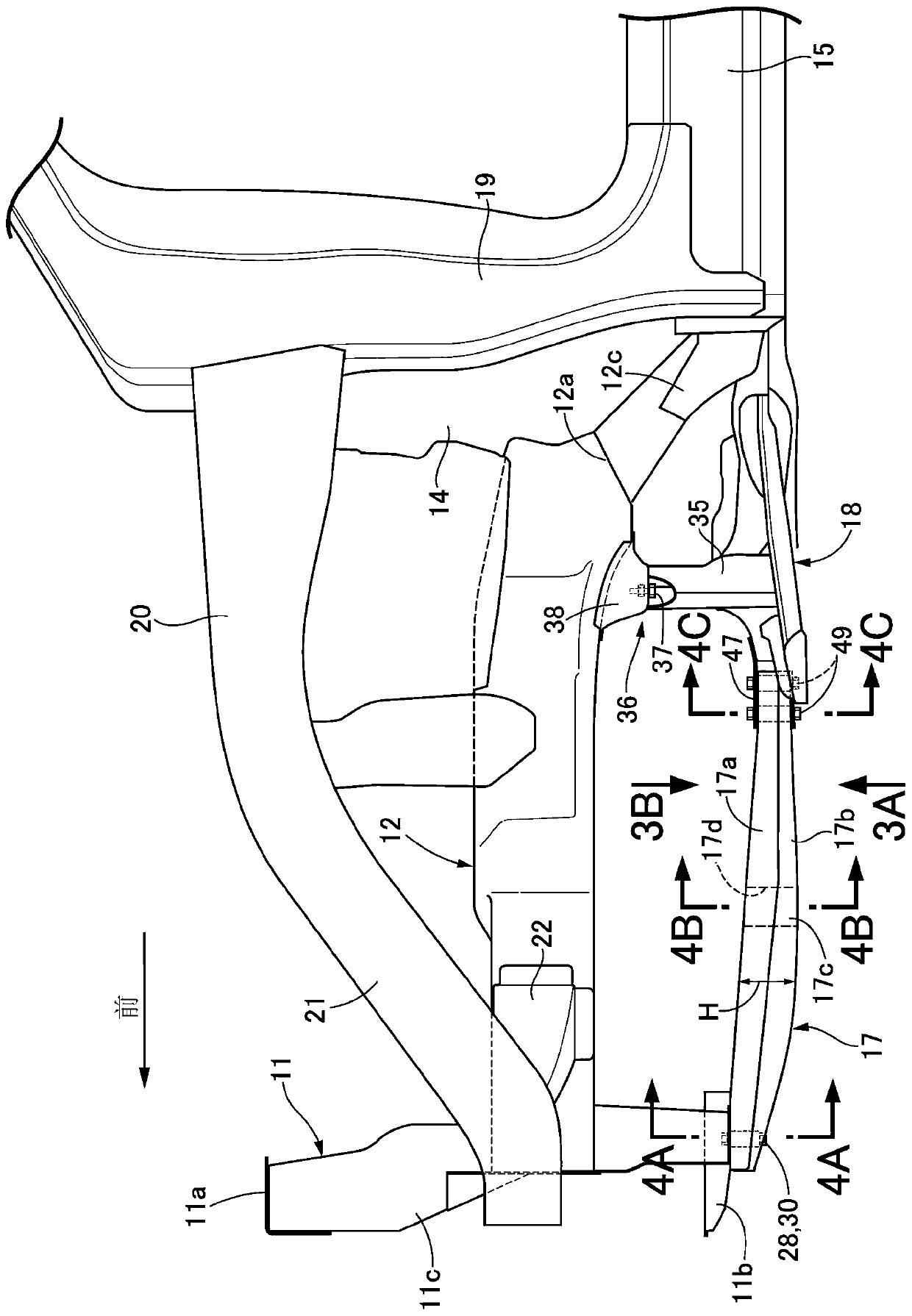

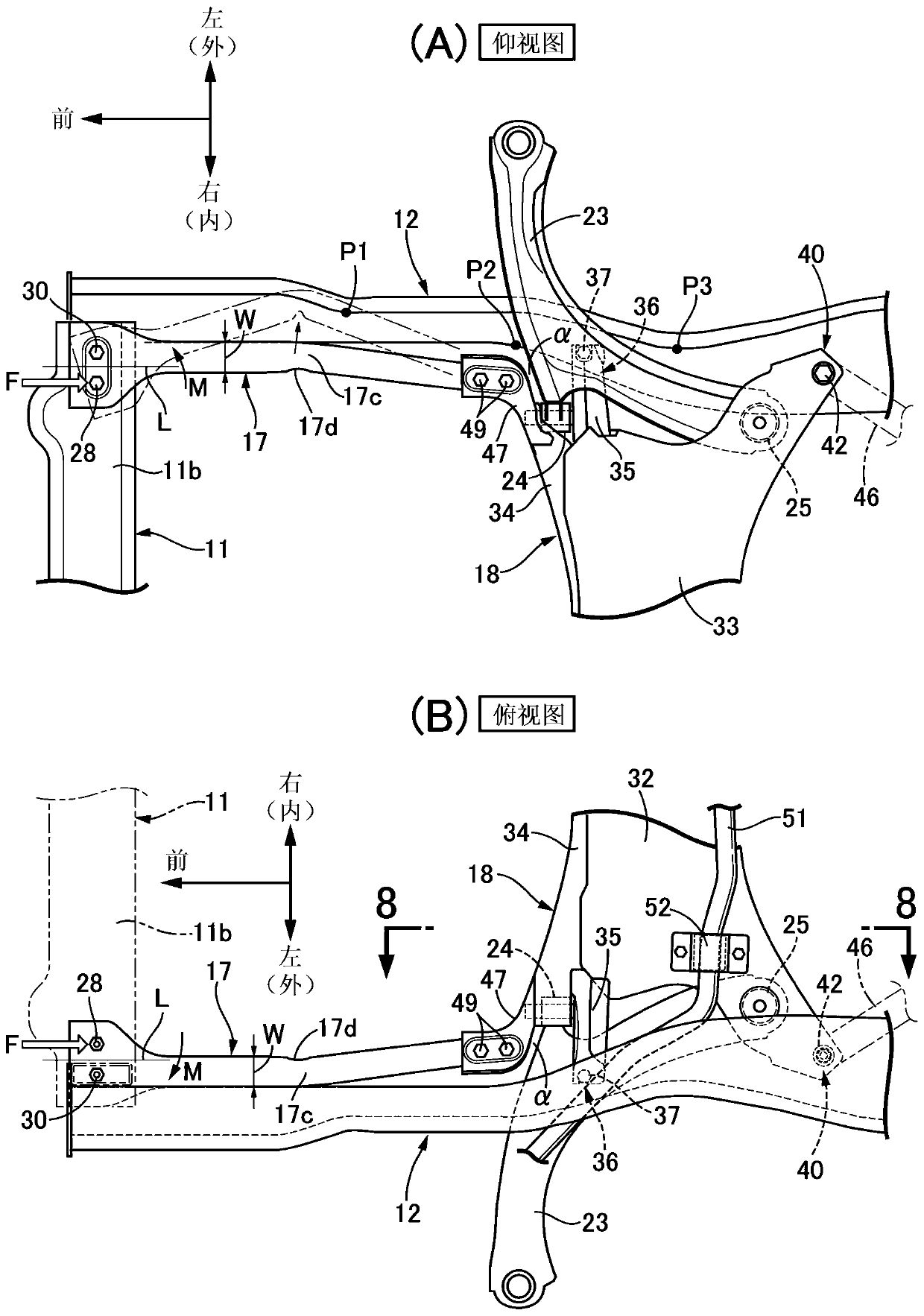

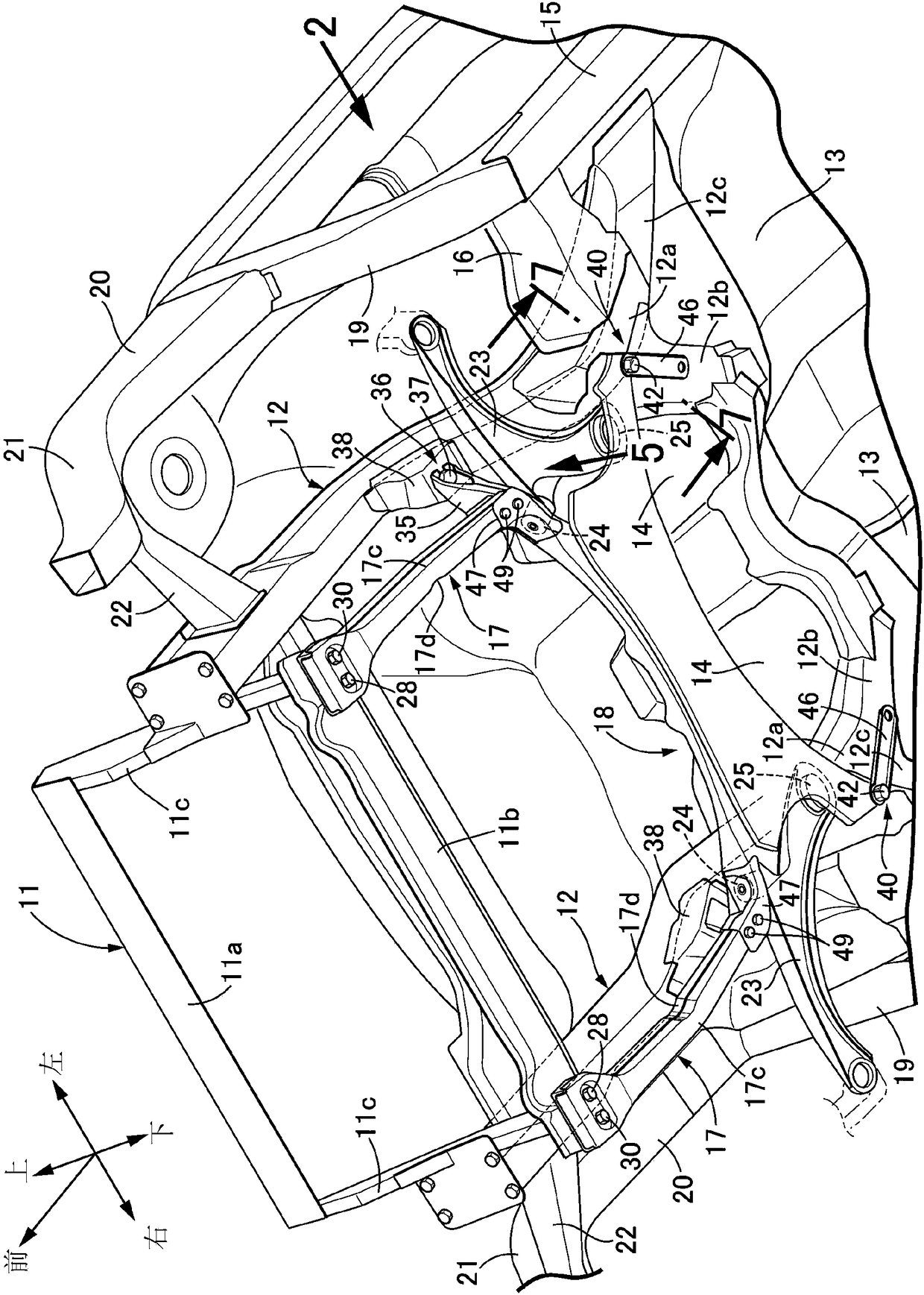

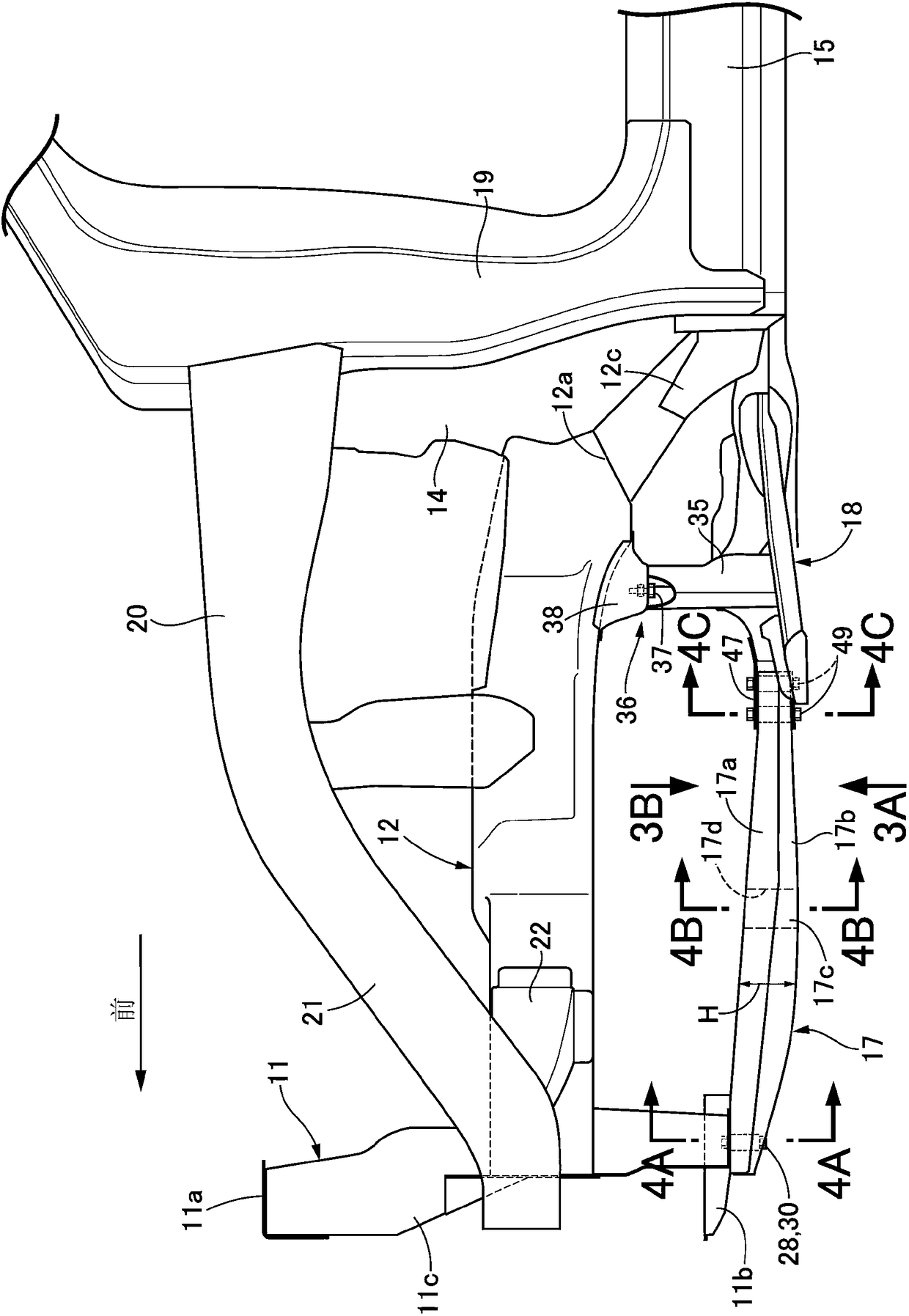

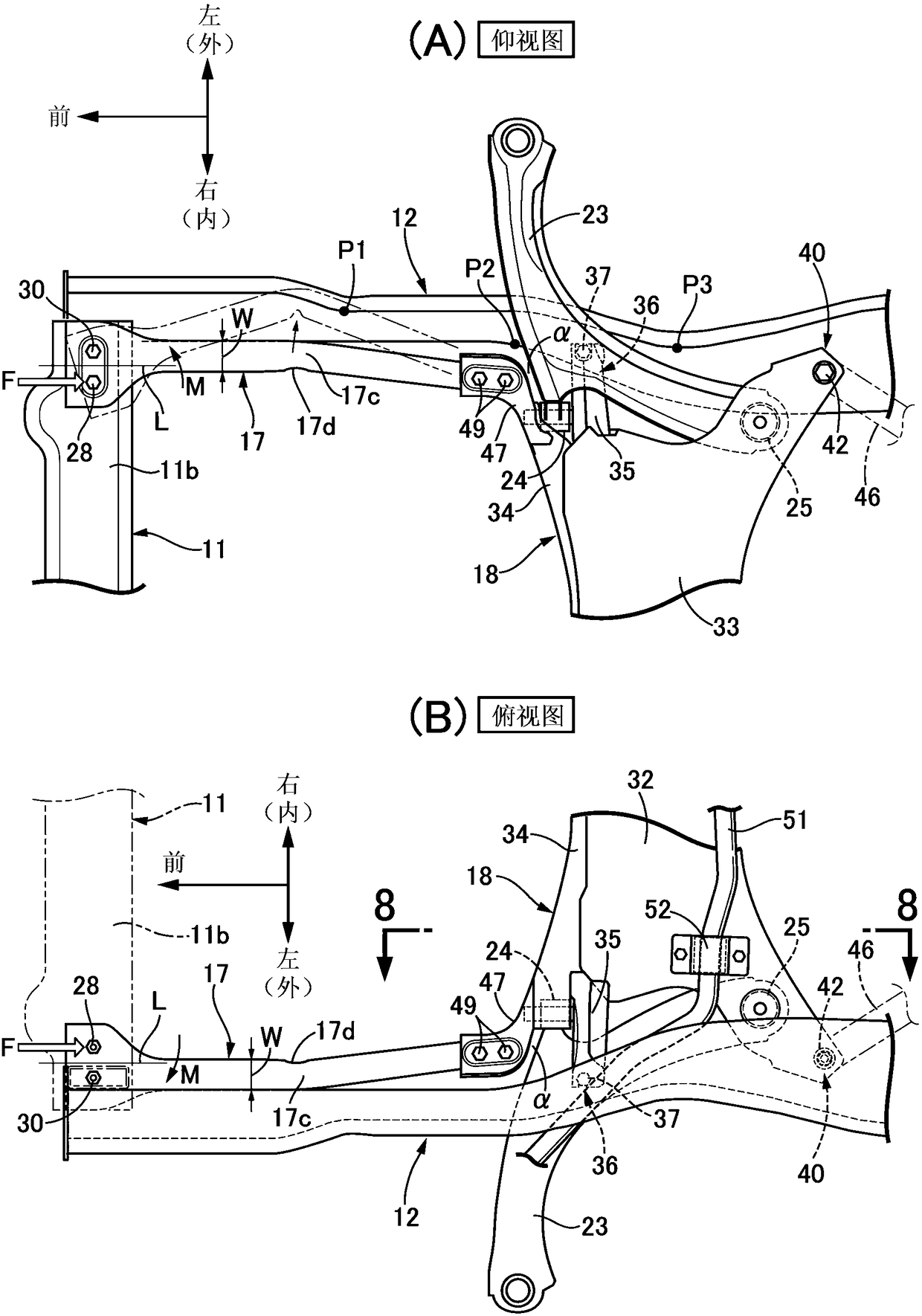

car body structure

ActiveCN108688728BEnsure crush travelPromote absorptionUnderstructuresSuperstructure subunitsHead-on collisionVehicle frame

The invention provides an automobile body structure. Lower load transmission components (17) have a roughly-certain automobile width direction width (W) in the overlooking observation process, bent parts (17c) formed on the middle portions in the front-back direction are bent in the mode of protruding outwards in the automobile width direction, groove parts (17d) extending in the up-down directionare formed in the inner walls of the bent parts (17c) in the automobile width direction, when the lower load transmission components (17) are observed from the side faces, the upper walls are even, the lower walls are bent in the mode of protruding downwards, and the positions near the bent parts (17c) hereby have the largest up-down direction height (H). Therefore, when a head-on collision happens to an automobile, the lower load transmission components (17) are bent to the outer sides in the automobile width direction, the situation that the lower load transmission components (17) make contact with the road surface and a front auxiliary automobile frame (18) is pushed up is avoided, and the crushing travel of retraction of an engine and a transmission hereby can be guaranteed.

Owner:HONDA MOTOR CHINA INVESTMENT CO LTD

Stapler

InactiveCN1910016BMiniaturizationReduce manufacturing costStapling toolsNailing toolsEngineeringMechanical engineering

Owner:MAX CO LTD

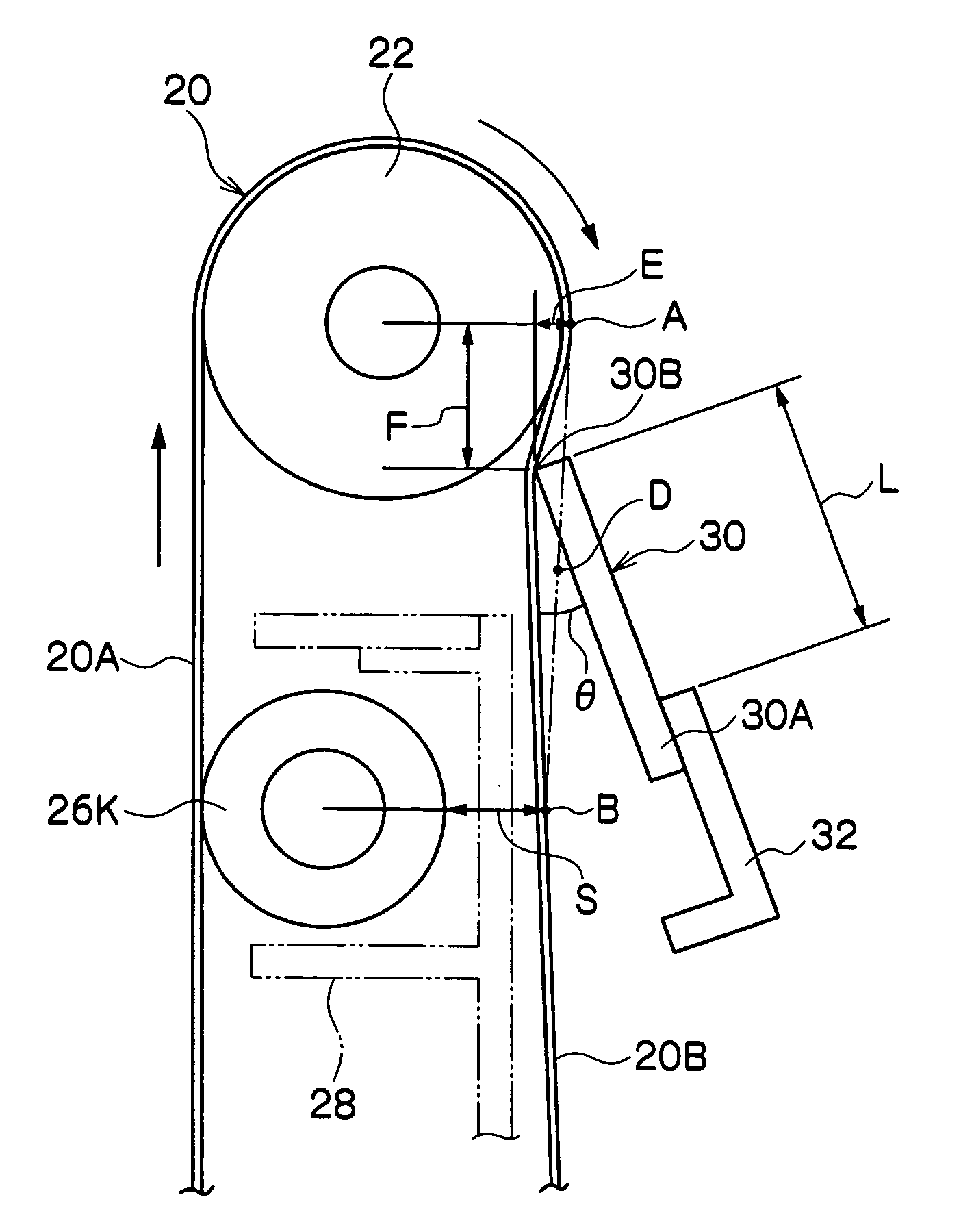

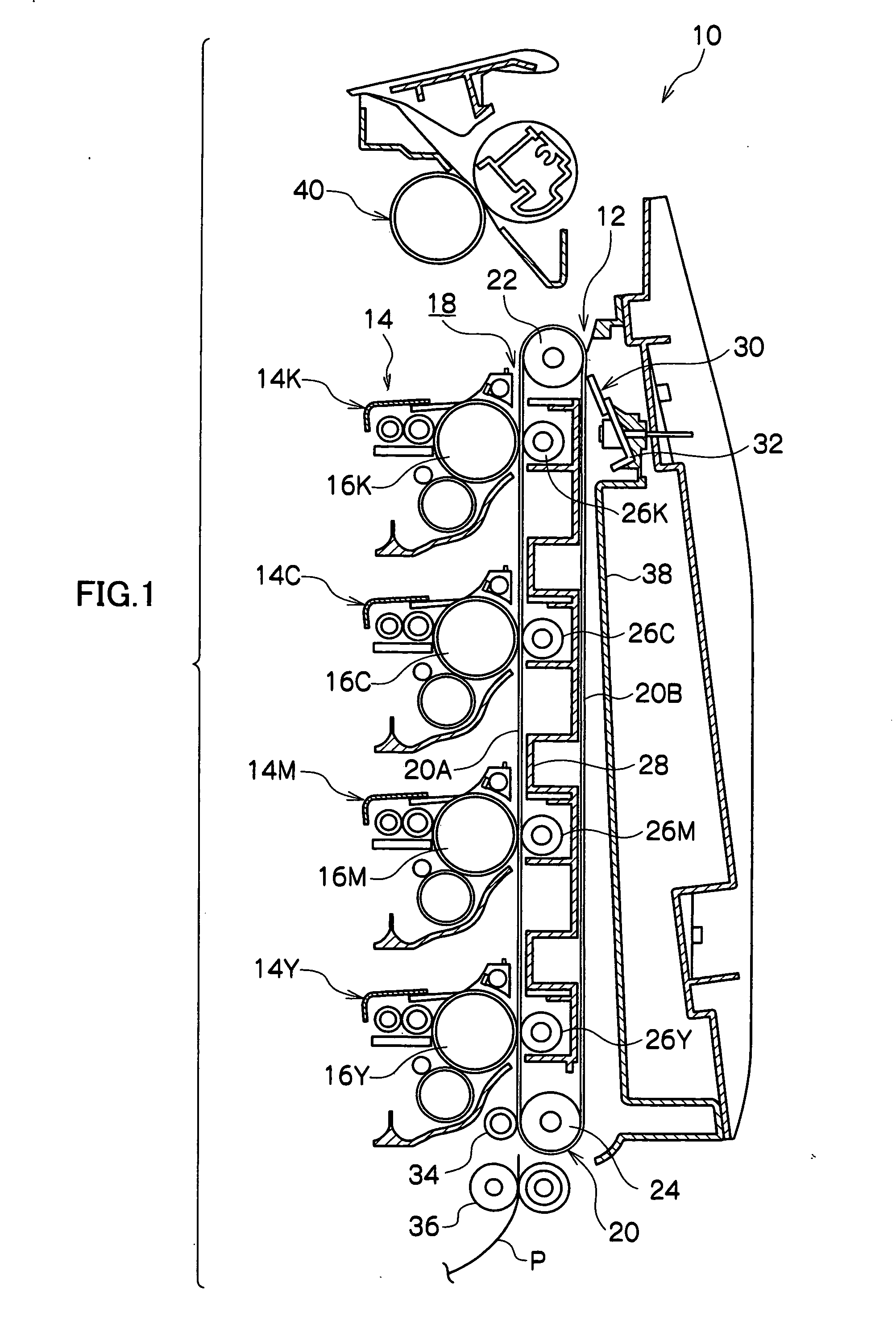

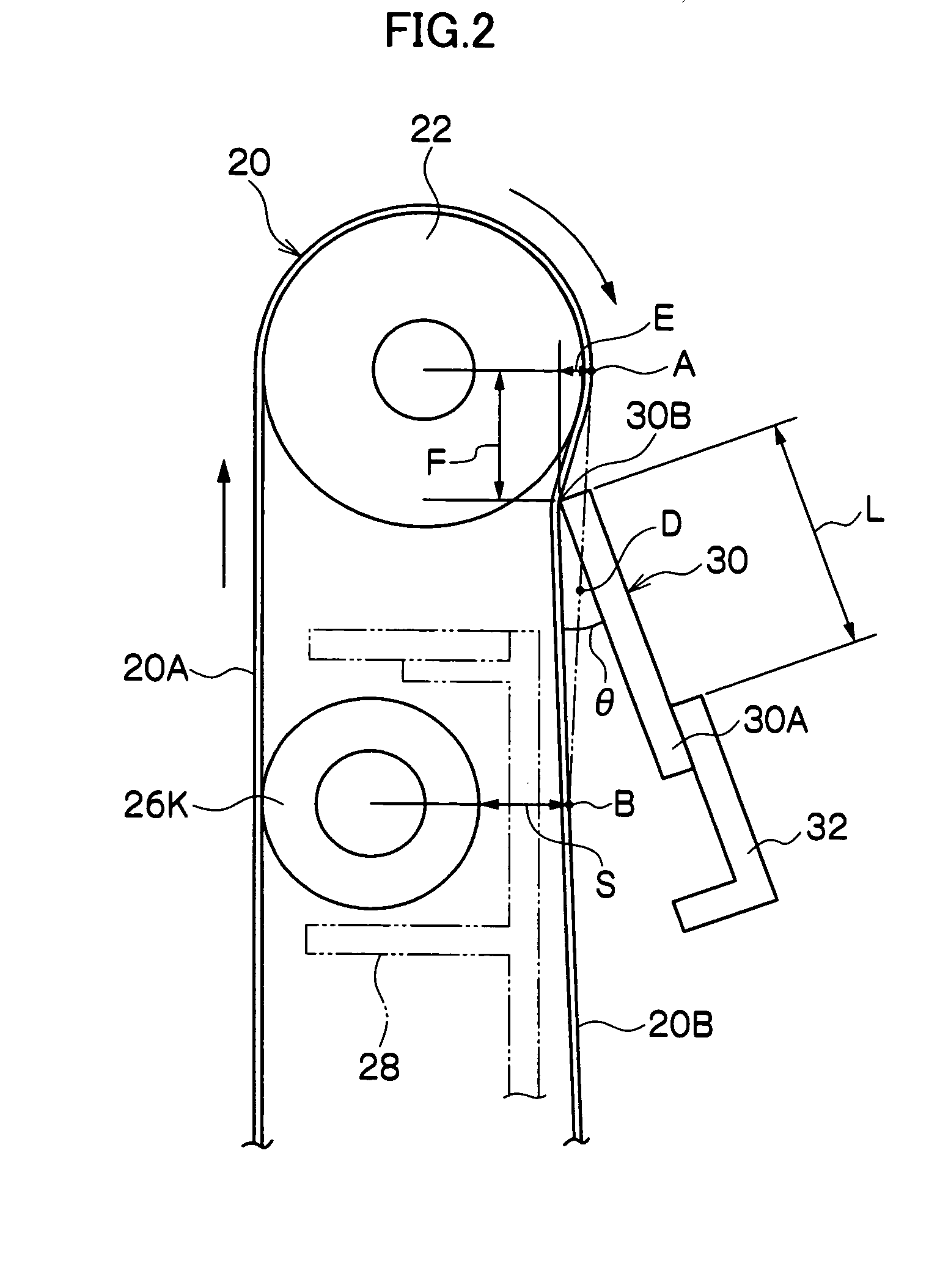

Image forming apparatus

ActiveUS20070261937A1Reliable bendingCleaningElectrographic process apparatusEngineeringTransmission belt

Owner:FUJIFILM BUSINESS INNOVATION CORP

car body structure

ActiveCN107042843BEffective crushPromote absorptionUnderstructuresSuperstructure subunitsEngineeringMechanical engineering

A front side frame has a closed section through coupling between a frame main body having a U-shaped section that opens to the outboard side and a back plate that closes the opening of the frame main body. A reinforcing frame having a U-shaped section that opens to the outboard side in a frame widened section of the front side frame is fitted to the inside of the frame main body. A vehicle-width-direction inboard wall of the reinforcing frame is coupled to a vehicle-width-direction inboard wall of the frame main body at a branch point. A portion of the vehicle-width-direction inboard wall in front of the branch point separates from the vehicle-width-direction inboard wall of the frame main body to the outboard side. The opening of the reinforcing frame is closed by the back plate in the front section of the frame widened section.

Owner:HONDA MOTOR CO LTD

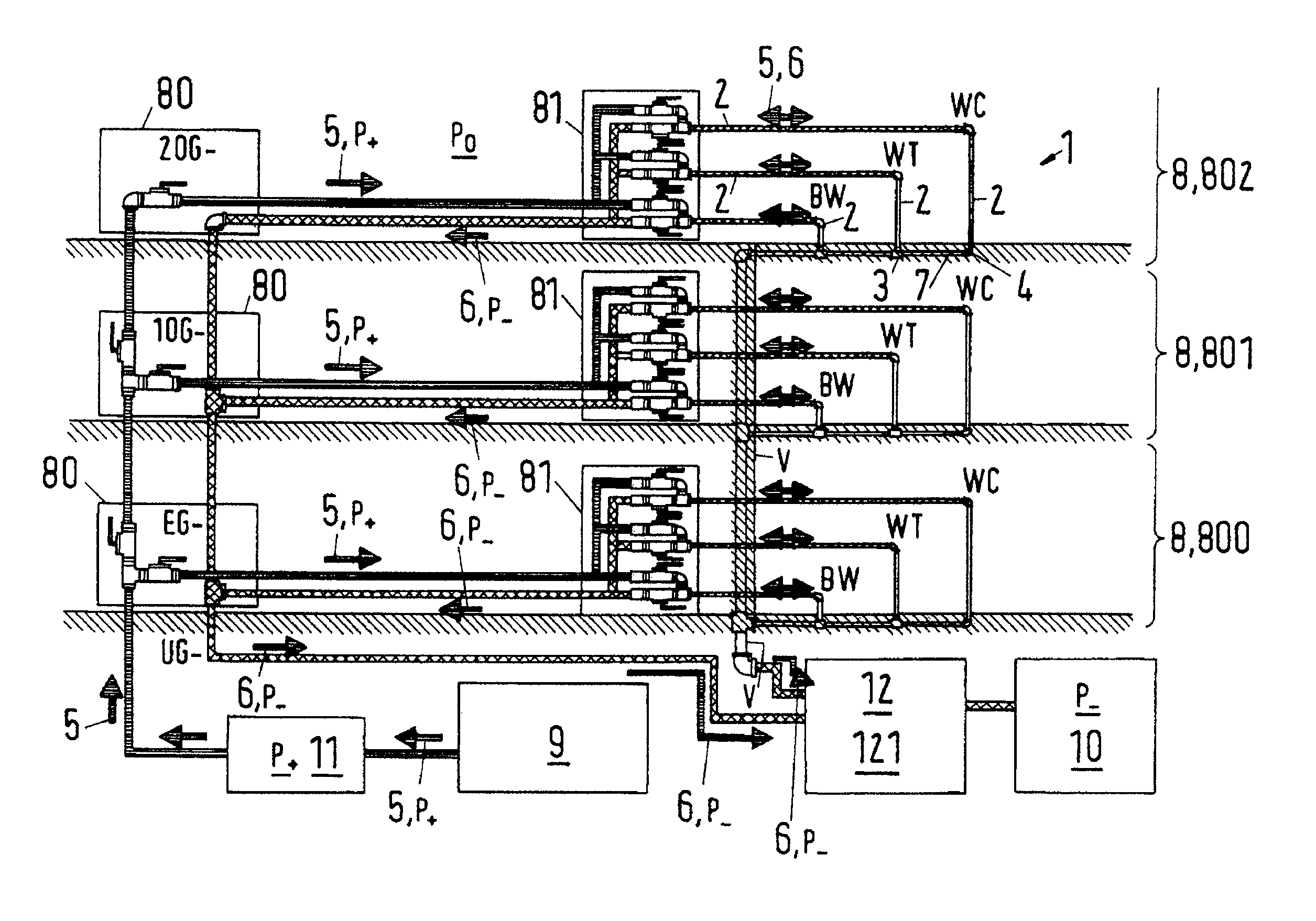

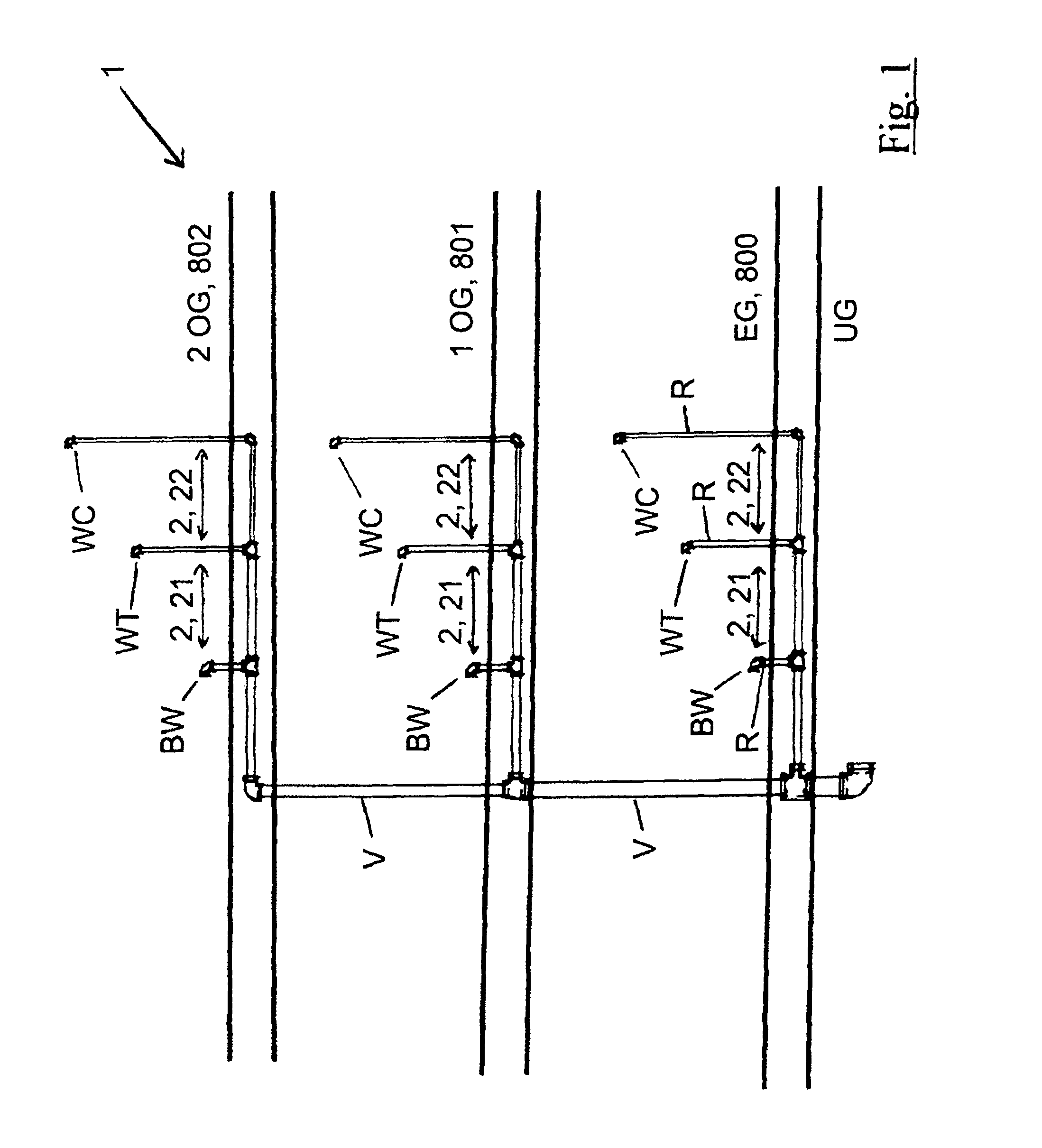

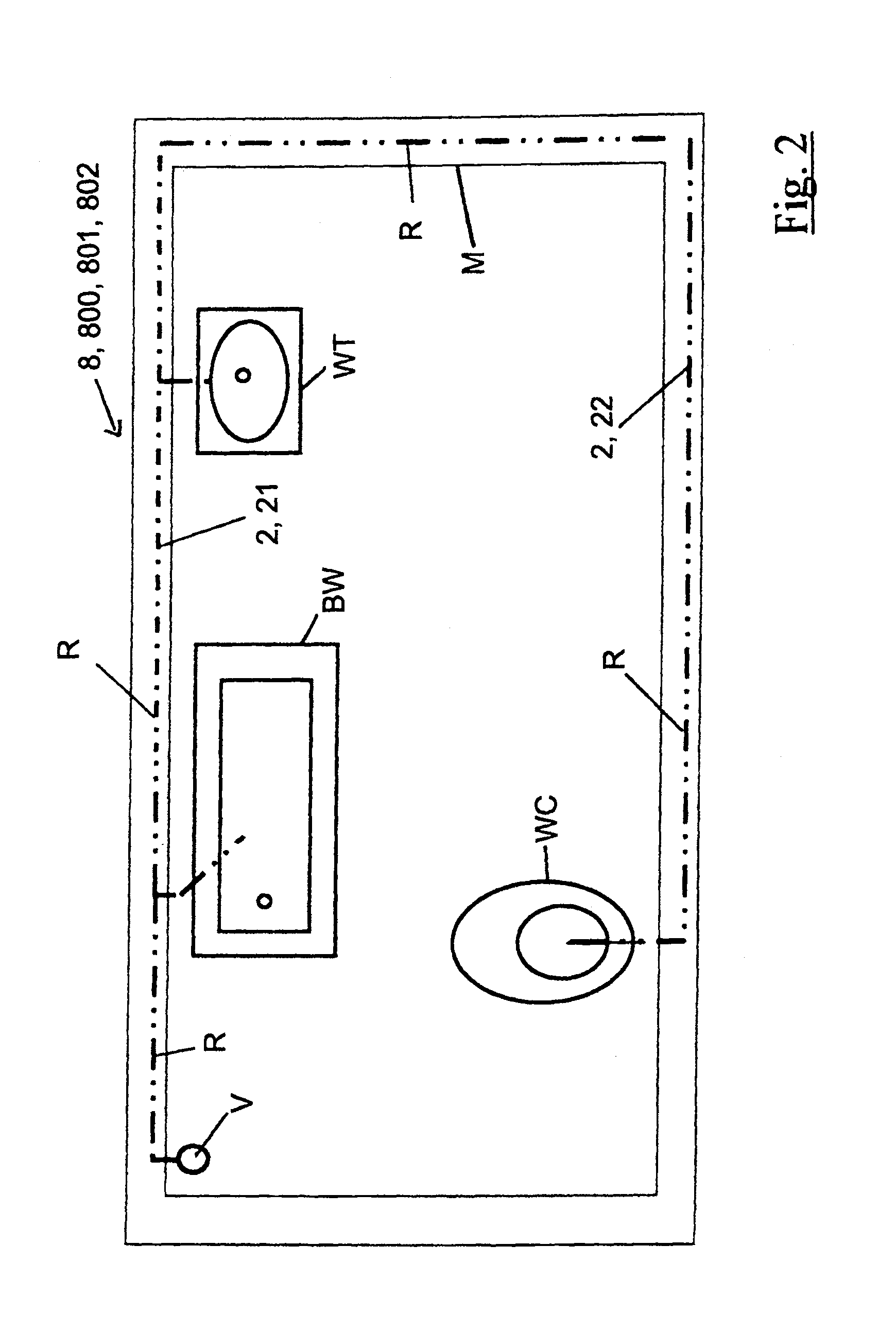

Coating process for the coating of an interior of a pipework system as well as a sub-distributor and a working equipment for the treatment of a pipework system

InactiveUS8580339B2Reliable and cost-effective and simpleReliable bendingLiquid surface applicatorsMultiple way valvesPartial systemEngineering

A coating process for the interior of a pipework system, which includes a subsystem having a first part-system and a second part-system coupled to the first part-system, wherein the part-system can be pressurized by a pressure difference via a first connection of the first part-system and via a second connection of the second part-system, and wherein the first connection of the second part-system is identical to the second connection of the first part-system. In a second process step the first part-system is pressurized in such a way that a fluid-flow of the coating material is established through the first part-system and then the first connection of the second part-system is pressurized after the coating material leaves the second connection of the first part-system so that the first part-system and the second part-system is consecutively fed with the coating material.

Owner:CEC SYST

Coaxial stripping device

ActiveCN103474863BSimple structureReduce manufacturing costLine/current collector detailsApparatus for removing/armouring cablesEngineeringCam

The invention discloses a coaxial-wire peeling device which comprises a rack. A locating tool for enabling coaxial wires to be fixedly arranged and a drawing mechanism for drawing cladding layers of the coaxial wires are arranged on the rack. The drawing mechanism comprises a mounting base which is arranged on the rack in a sliding mode and is driven by a driving device. The mounting base is provided with a mounting cavity. At least two mounting shafts arranged in parallel are fixedly arranged in the mounting cavity. Two clamping jaw single bodies arranged in pairs are arranged on the mounting shafts in a sliding mode. A first cam mechanism is arranged between the two clamping jaw single bodies and is driven by a first power unit and used for enabling the clamping jaw single bodies to open or close. Clamping vice jaws are formed when the two clamping jaw single bodies are closed. The coaxial-wire peeling device solves the technical problems that a traditional coaxial-wire peeling device is large in size and low in peeling efficiency.

Owner:GOERTEK INC

absorbent article

ActiveCN109414358BReliable bendingImprove comfortAbsorbent padsBandagesEngineeringMechanical engineering

Owner:OJI HLDG CORP

Novel heart stent of improved structure

The invention discloses a novel heart stent of an improved structure, and relates to the technical field of condenser devices. The technical problem that an existing heart stent is not ideal in supporting performance, ductility and flexibility is mainly solved. The novel heart stent comprises multiple layers of metal supports and connectors for connecting the adjacent metal supports. Each metal support is formed by cyclically and alternately connecting a plurality of first structures without elasticity and a plurality of second structures with elasticity, the first structures and the second structures are each in a strip shape and form crests and troughs respectively after being connected, and the crest circular arc radius of the first structures is larger than the trough circular arc radius of the second structures. The first structures and the second structures of the adjacent metal supports are oppositely and neatly arrayed and have the same direction. The connectors are each in a strip shape. The connectors between the adjacent metal supports are arranged at intervals and staggered with the connectors of the same metal supports. The middle of each connector is formed by connecting two staggered third structures, and the third structures are each in a semicircular shape. The novel heart stent has the advantages of being high in ductility and flexibility, stable, reliable andlong in service life.

Owner:刘永华

floor-standing indoor unit

InactiveCN103189688BReduce heat exchange efficiencyCurb supply shortageLighting and heating apparatusSpace heating and ventilation detailsEngineeringMicro heat exchanger

Prevent heat exchange efficiency from decreasing. The indoor heat exchanger (22) housed in the casing (10) includes: a front heat exchanger (22a) arranged to face the back of the front panel (4); and a back heat exchanger (22b) along with It is inclined upward as it approaches from the vicinity of the lower end of the front heat exchanger (22a) to the back. An upper filter (16a) and a lower filter (16b) are provided in the flow path from the main suction port (10a) provided in front of the lower end of the casing (10) to the front heat exchanger (22a). And at least a part of the part below the front heat exchanger (22a) of the lower filter (16b) is curved so that it may protrude forward.

Owner:DAIKIN IND LTD

Automobile front body structure

InactiveCN101920685BRigid enoughReliable bendingUnderstructuresSuperstructure subunitsStructural engineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

Automobile body structure

ActiveCN108688728AIncreased crush strokeImprove energy absorption performanceUnderstructuresSuperstructure subunitsVehicle frameLow load

The invention provides an automobile body structure. Lower load transmission components (17) have a roughly-certain automobile width direction width (W) in the overlooking observation process, bent parts (17c) formed on the middle portions in the front-back direction are bent in the mode of protruding outwards in the automobile width direction, groove parts (17d) extending in the up-down directionare formed in the inner walls of the bent parts (17c) in the automobile width direction, when the lower load transmission components (17) are observed from the side faces, the upper walls are even, the lower walls are bent in the mode of protruding downwards, and the positions near the bent parts (17c) hereby have the largest up-down direction height (H). Therefore, when a head-on collision happens to an automobile, the lower load transmission components (17) are bent to the outer sides in the automobile width direction, the situation that the lower load transmission components (17) make contact with the road surface and a front auxiliary automobile frame (18) is pushed up is avoided, and the crushing travel of retraction of an engine and a transmission hereby can be guaranteed.

Owner:HONDA MOTOR CHINA INVESTMENT CO LTD

Vibrating device and tactile sense presenting device

ActiveUS10365718B2Increase deflectionMake the diaphragm thin and less rigidInput/output for user-computer interactionMechanical vibrations separationEngineeringElectric energy

A tactile feedback device includes a vibrating device and a touch sensor. The vibrating device comprises a flexible diaphragm and a film which deforms in response to the application of electrical energy thereto, the film being attached to the flexible diaphragm at two spaced locations with a major surface of the film facing a major surface of the flexible diaphragm. The vibrating device further includes a spacer located between the two spaced locations and ensuring that the major surface of the flexible diaphragm is spaced from the major surface of the film. The touch sensor is coupled to the diaphragm and generates an output signal in response to a touch operation. Means are provided to apply electrical energy to the film in response to the output signal.

Owner:MURATA MFG CO LTD

Vehicle rear portion structure

ActiveUS9656695B2Improve transmission efficiencyReliable bendingUnderstructuresSuperstructure subunitsEngineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com