car body structure

A technology for the body and the front of the car body, which is applied in the directions of the substructure, the upper structure, and the subassembly of the upper structure, can solve the problems such as the inability to fully exert the energy absorption performance, the inability to fully utilize the energy absorption performance of the front side frame, etc. The effect of smooth load transfer, improved strength, and improved absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

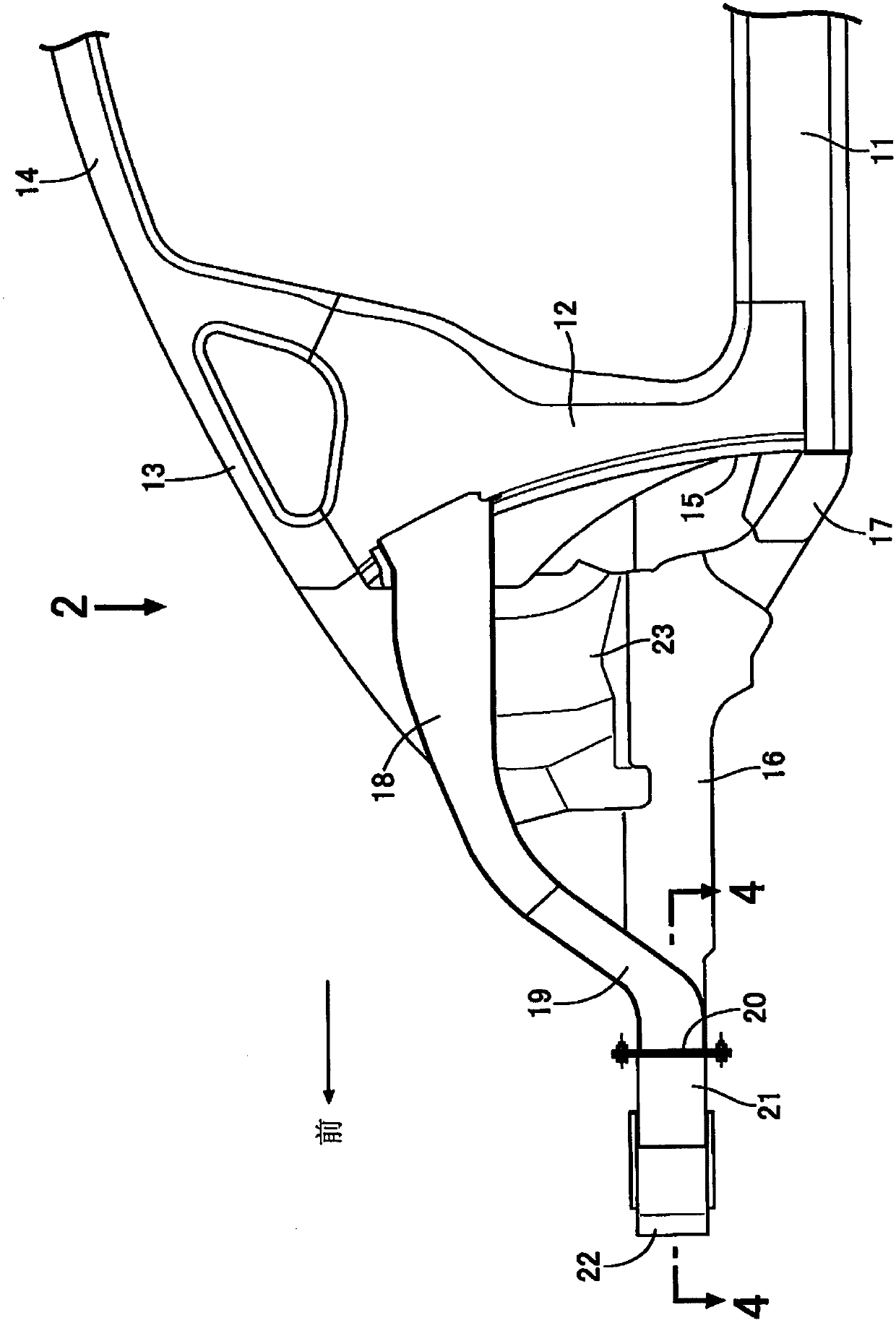

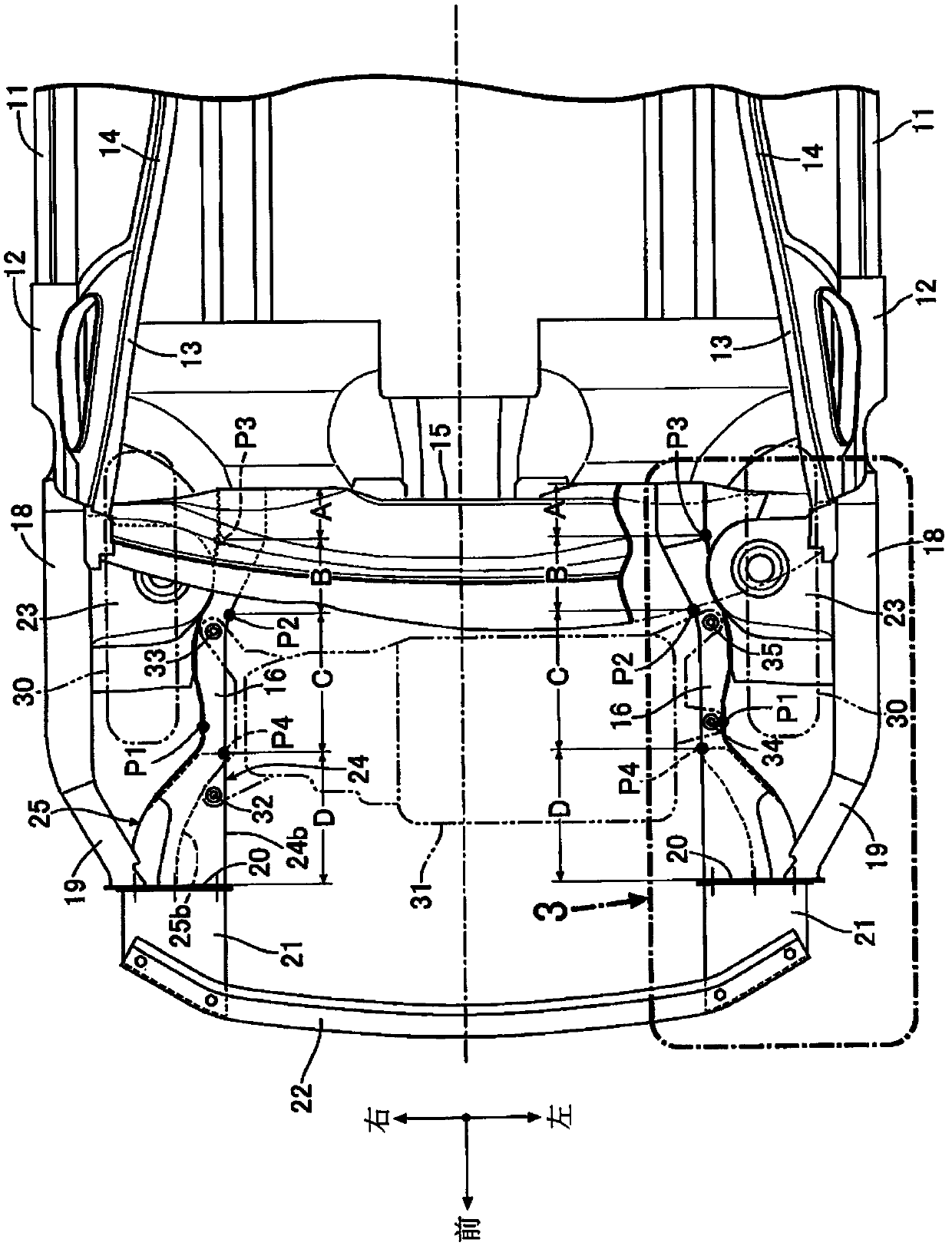

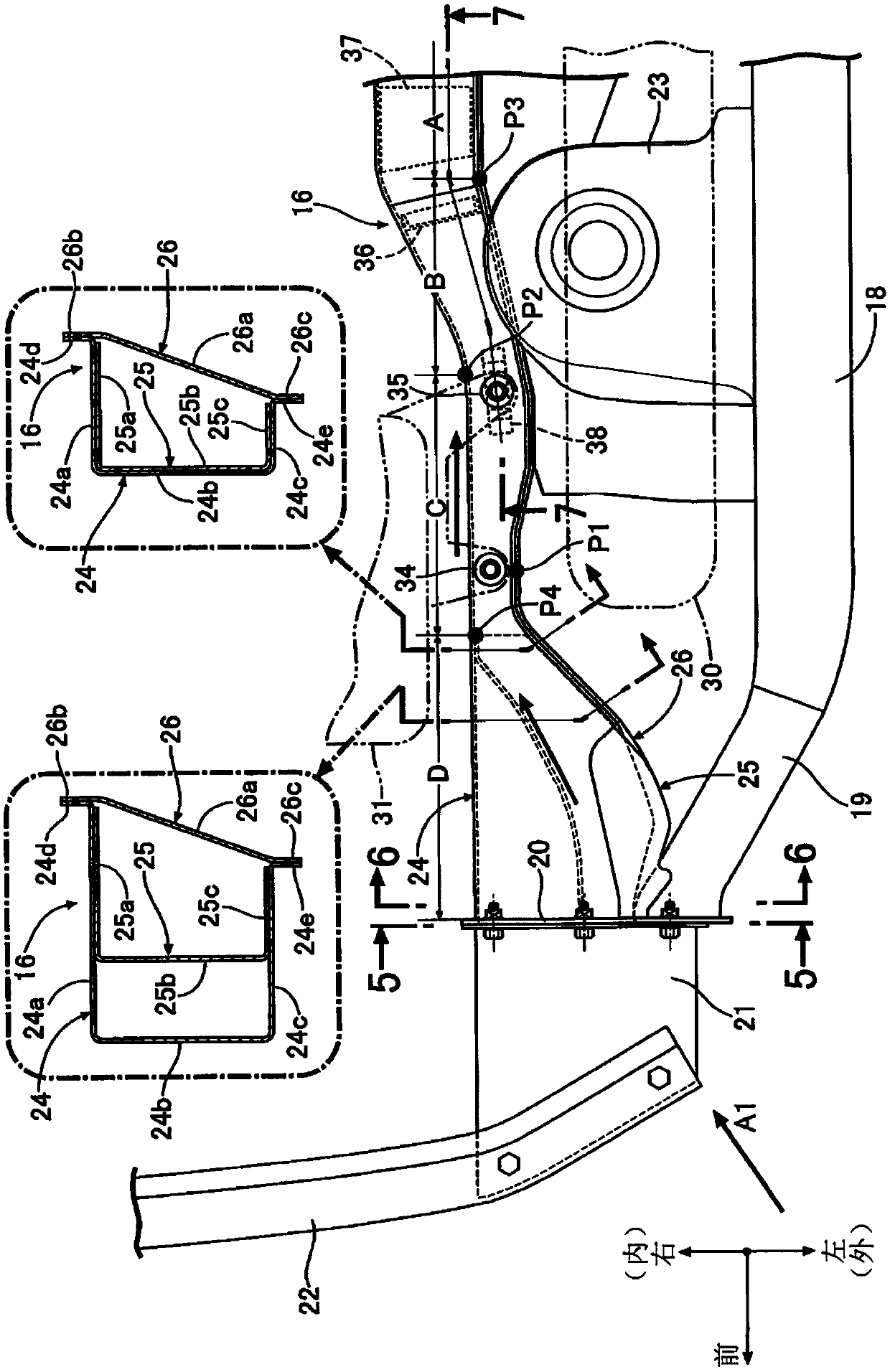

[0038] Below, based on Figure 1 to Figure 7 , the embodiment of the present invention will be described. In addition, the front-rear direction, the left-right direction (vehicle width direction), and the up-down direction in this specification are defined based on the occupant sitting on the driver's seat.

[0039] Such as figure 1 with figure 2 As shown, a pair of left and right side beams 11, 11 extend forward and rearward along the both sides of the floor of the compartment in the vehicle width direction, and a pair of left and right front pillars stand upright from the front ends of the pair of left and right side beams 11, 11. Bottom 12,12, from the upper end of a left and right pair of front pillar bottoms 12,12, extend back upwards with a left and right pair of front pillar tops 13,13, the upper ends of this left and right pair of front pillar tops 13,13 are aligned with the left and right sides. The front ends of the pair of roof side rails 14, 14 are connected. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com