Floor-placed indoor unit

An indoor unit and floor-standing technology, which is applied in the field of floor-standing indoor units, can solve the problems such as the inability to provide sufficient air for the back heat exchanger, the reduction of heat exchange efficiency of the heat exchanger, etc. The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

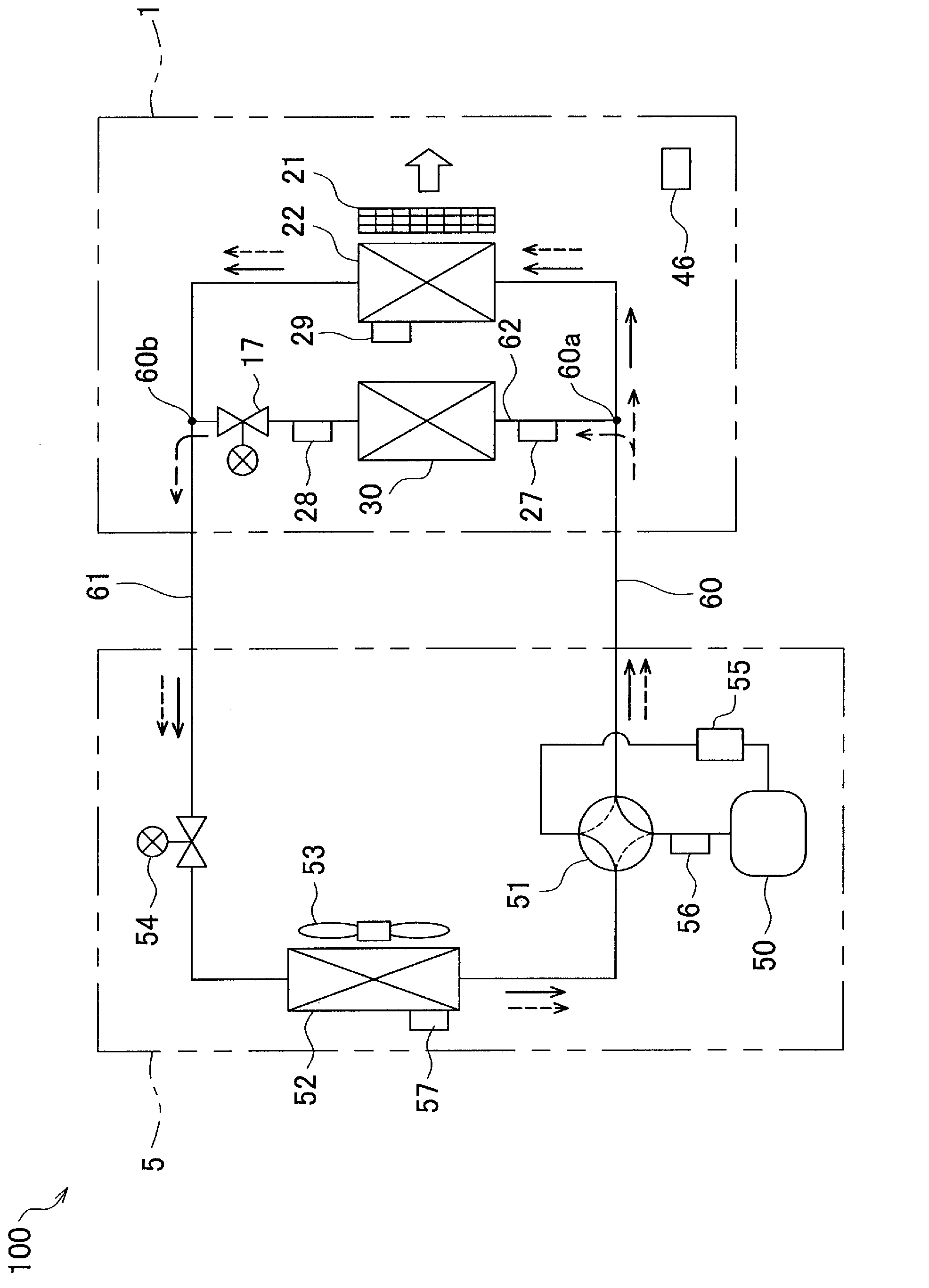

[0044] Next, the air conditioner 100 provided with the floor-standing indoor unit 1 of the embodiment of the present invention will be described.

[0045]

[0046] Such as figure 1 As shown, the air conditioner 100 of the present embodiment includes a floor-standing indoor unit 1 (hereinafter, simply referred to as “indoor unit”) installed indoors, and an outdoor unit 5 installed outdoors. The indoor unit 1 includes an indoor heat exchanger 22, a cross-flow fan 21 arranged near the indoor heat exchanger 22, a radiation panel 30, an indoor electric valve 17, and an indoor temperature sensor 46 for detecting indoor air temperature. In addition, the outdoor unit 5 includes a compressor 50, a four-way switching valve 51, an outdoor heat exchanger 52, an outdoor fan 53 arranged near the outdoor heat exchanger 52, and an outdoor electric valve 54.

[0047] The refrigerant circuit 60 has an annular main flow path 61 that connects the indoor heat exchanger 22, the compressor 50, the four-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com