Heat treatment method for tool

A heat treatment method and heat treatment device technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of not being able to open the heating furnace immediately, not being able to accurately grasp the heating and cooling time, and being inconvenient for operators to operate, so as to avoid The effect of scalding the operator, accurate heating time and quick cooling time, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below by means of specific embodiments:

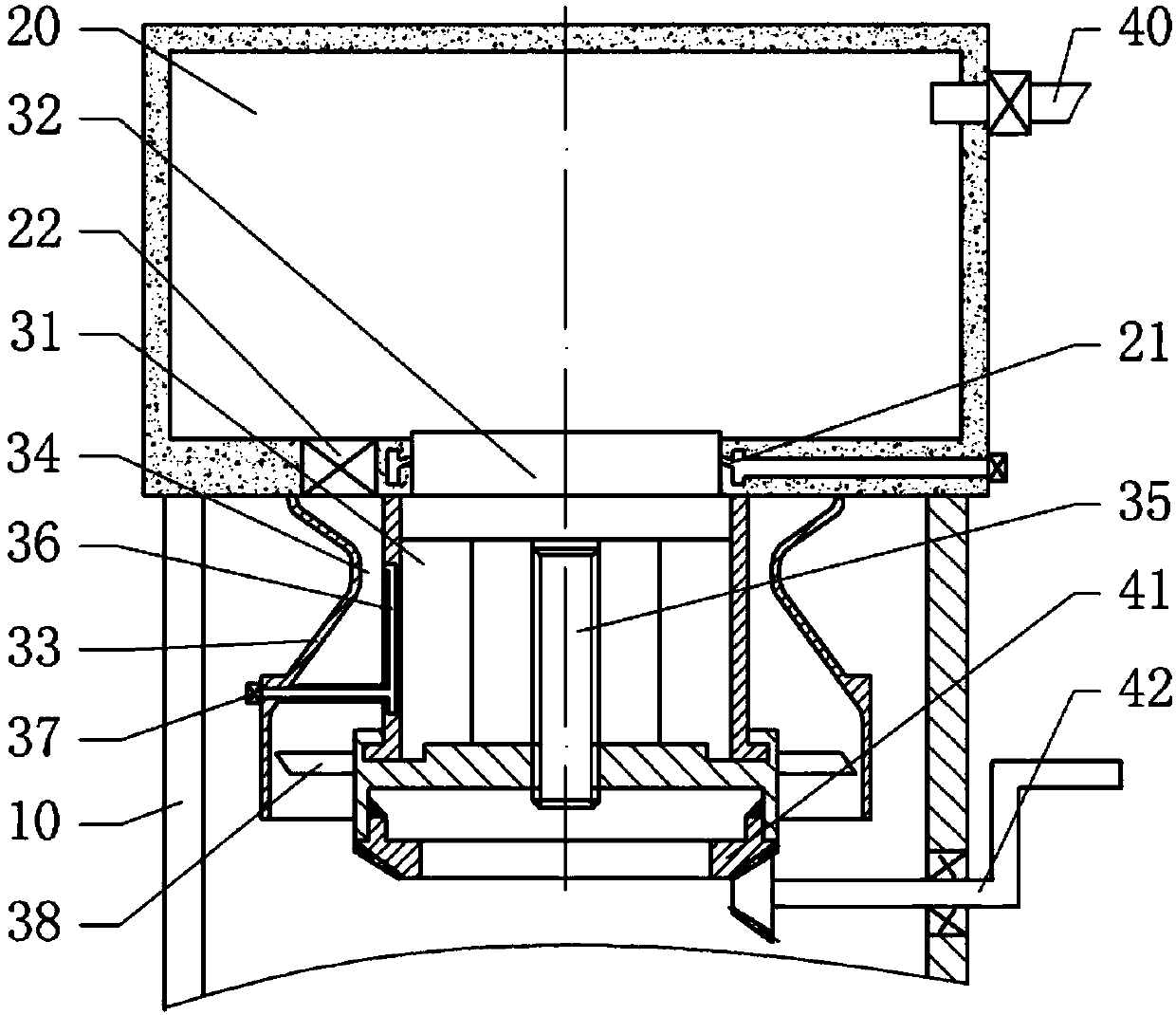

[0029] The reference signs in the drawings of the description include: frame 10, heating box 20, air duct 21, valve 22, quick cooling box 31, tool table 32, Venturi tube 33, throat 34, pull rod 35, liquid nitrogen channel 36 , liquid nitrogen source 37, paddle 38, vacuum machine 40, first bevel gear 41, rotating handle 42, guide rib.

[0030] The tool heat treatment method of the present embodiment comprises the following steps:

[0031] Step (1), immerse the tool in engine oil for three hours, heat it to 500-600°C, and then cool it naturally;

[0032] Step (2), quenching and low-temperature tempering are carried out to the tool.

[0033] Step (2) is carried out using a tool heat treatment device, such as figure 1As shown, the tool heat treatment device includes a frame 10 , a heating box 20 , a quick cooling mechanism, and a vacuum machine 40 connected to the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com