Device for making tubular containers

A tubular and container technology, applied in the direction of soft tubular containers, containers, flexible containers, etc., can solve the problems of difficult to obtain positioning, increased container manufacturing time, complex equipment structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

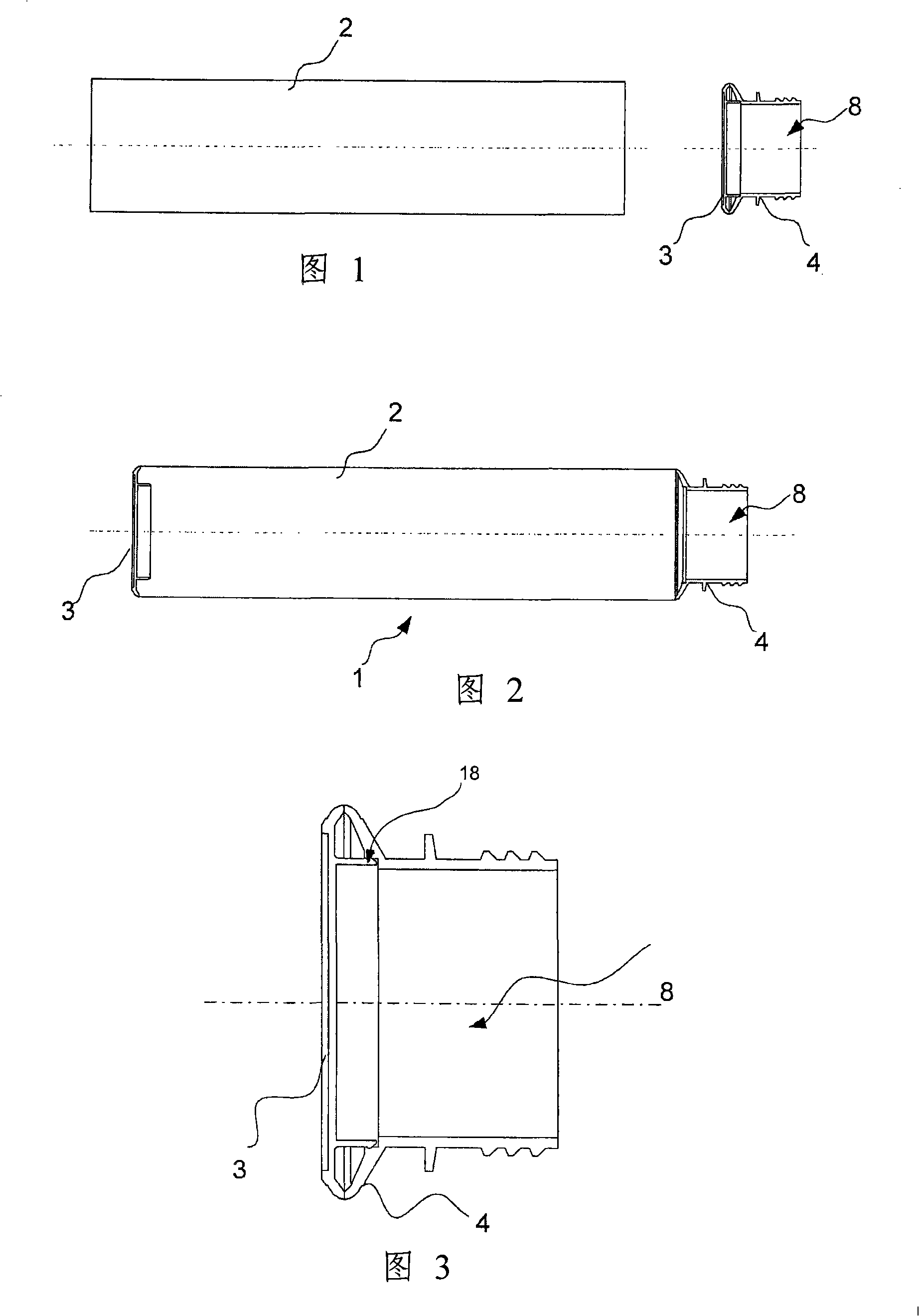

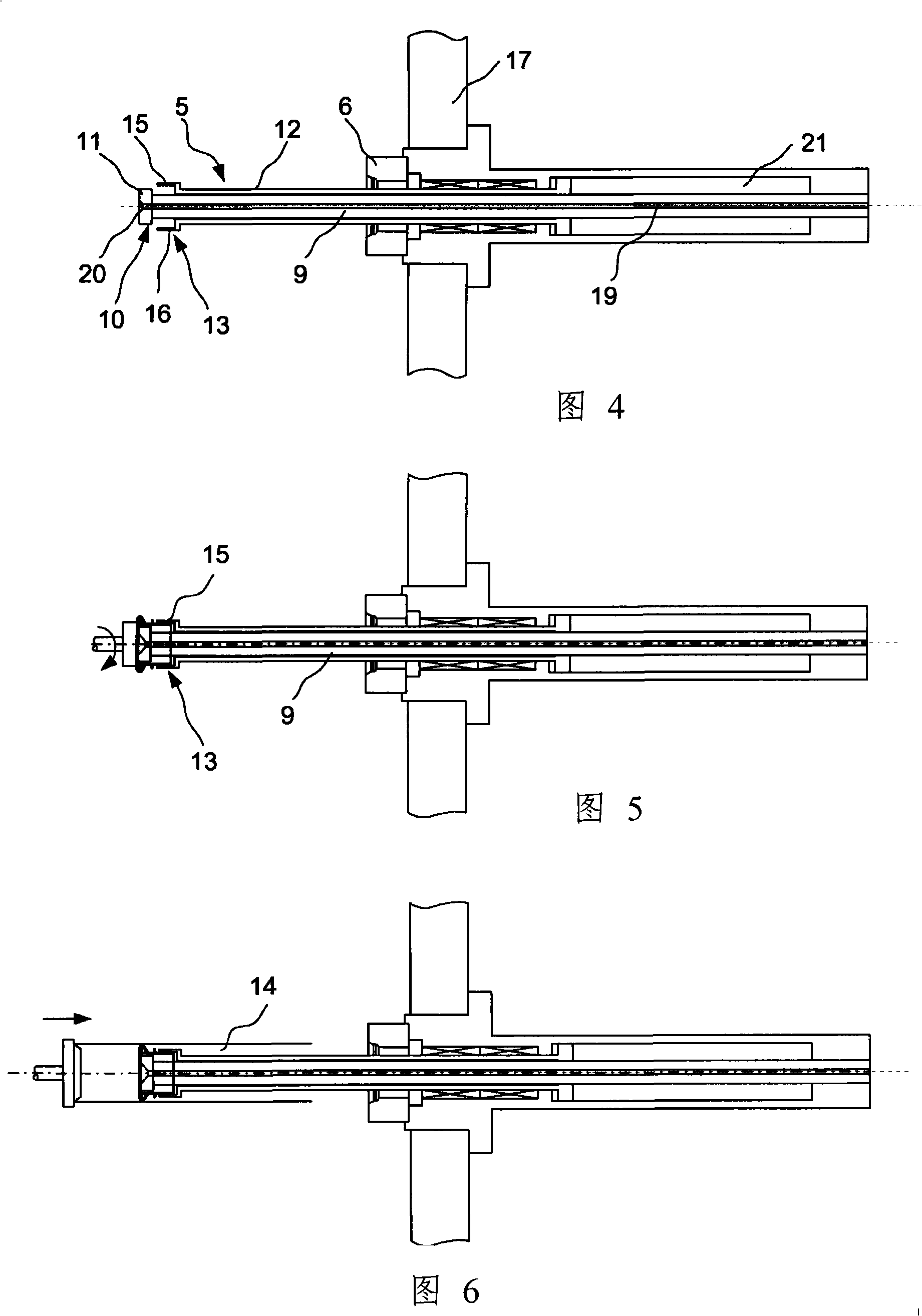

[0052] FIG. 1 shows three parts of a container 1 usable with the device of the invention, namely a flexible tubular body 2 , eg a laminated tube, a rigid base 3 and a top 4 including a neck 8 . In a first step, the base body 3 is fixed to the top 4 by means of a snap-in mechanism 18 (see FIG. 3 ). It will be obvious that any other temporary fixation system may be used. In an inventive variant not shown, the top and the base are first manufactured in one piece by injection, the two elements being subsequently separated during the manufacturing process, for example by breaking of the temporary coupling. The base body 3 is then separated from the top 4 during the manufacturing process, as described below. Figure 2 shows the container 1 in the formed state at the end of the manufacturing process. The base 3 has been welded to the lower end of the tubular body 2 and the top 4 has been welded to the upper end of the tubular body 2 .

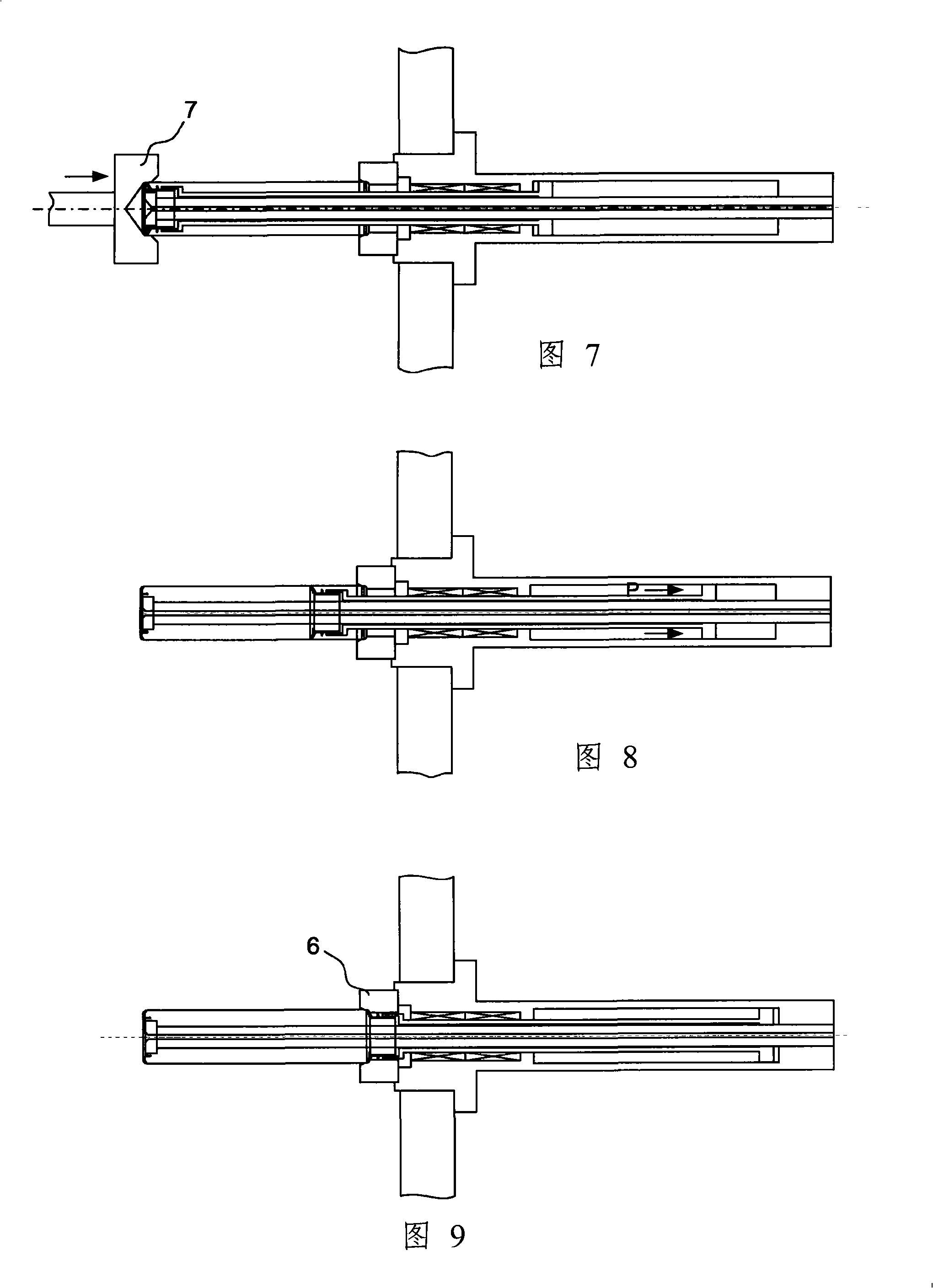

[0053] Figure 4 shows the manufacturing unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com