Heat exchanger

A technology of heat exchangers and connectors, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve problems such as undesired mixing, and achieve better operation, avoid damage, and operate safely and efficiently. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

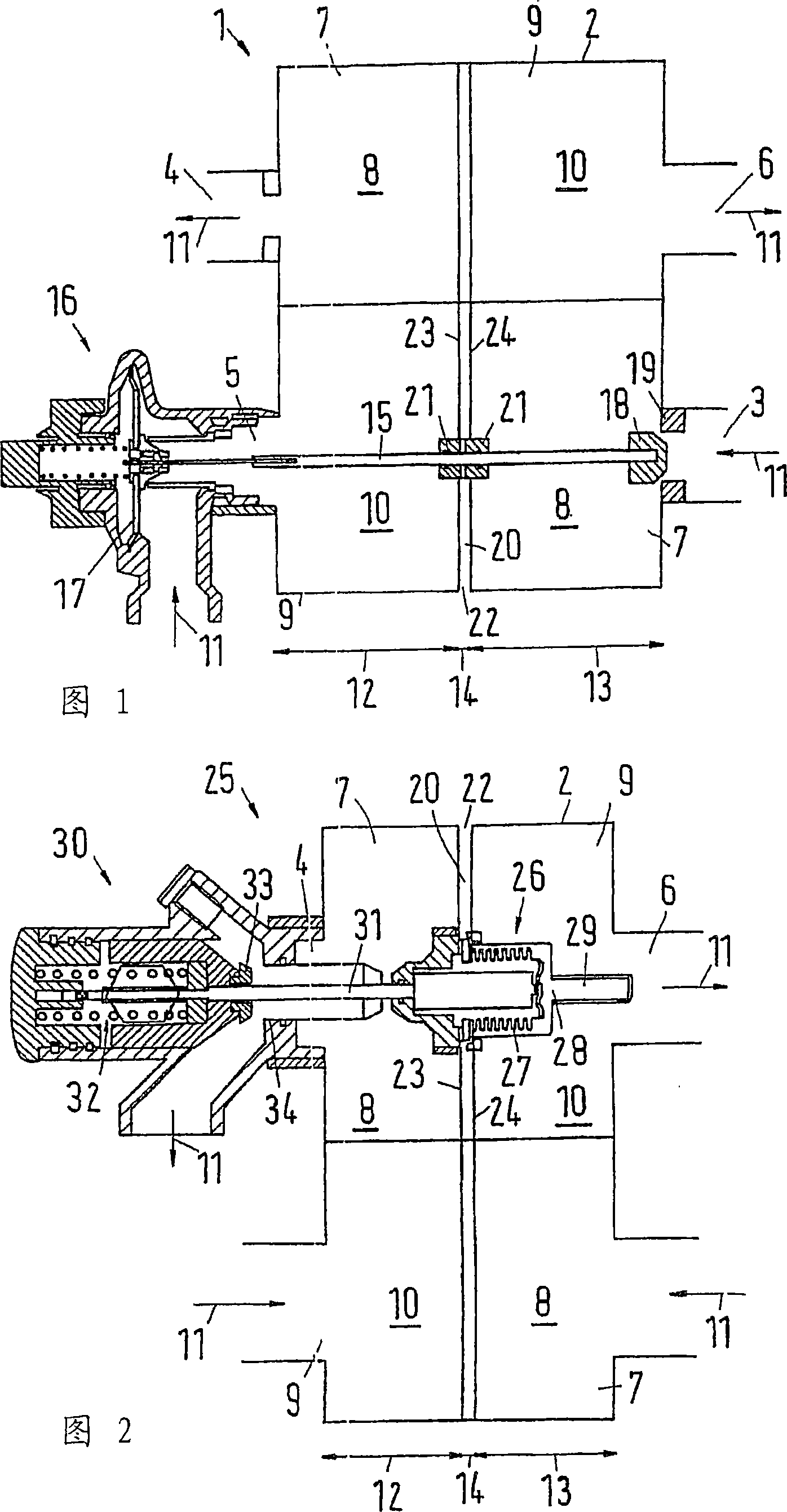

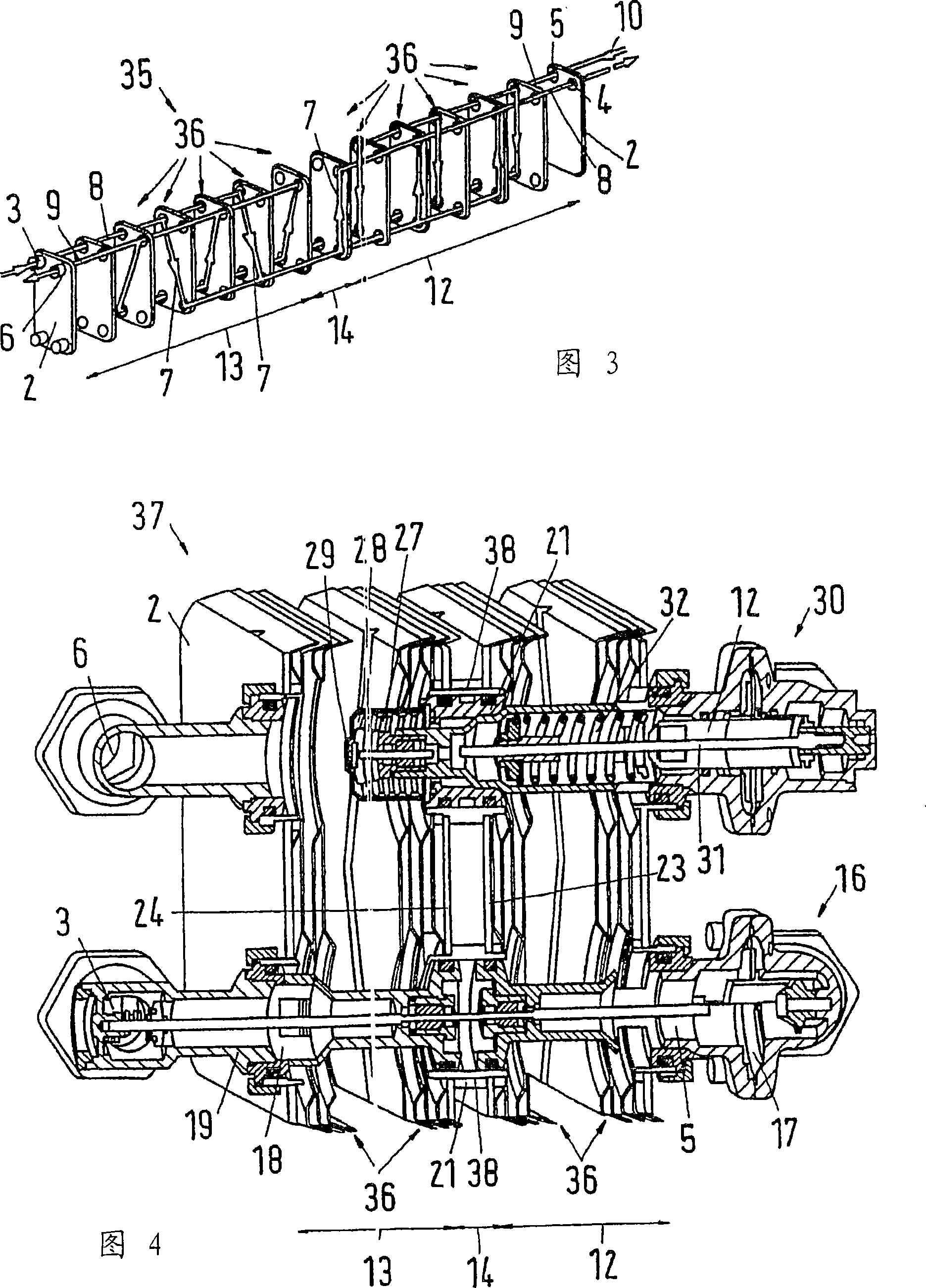

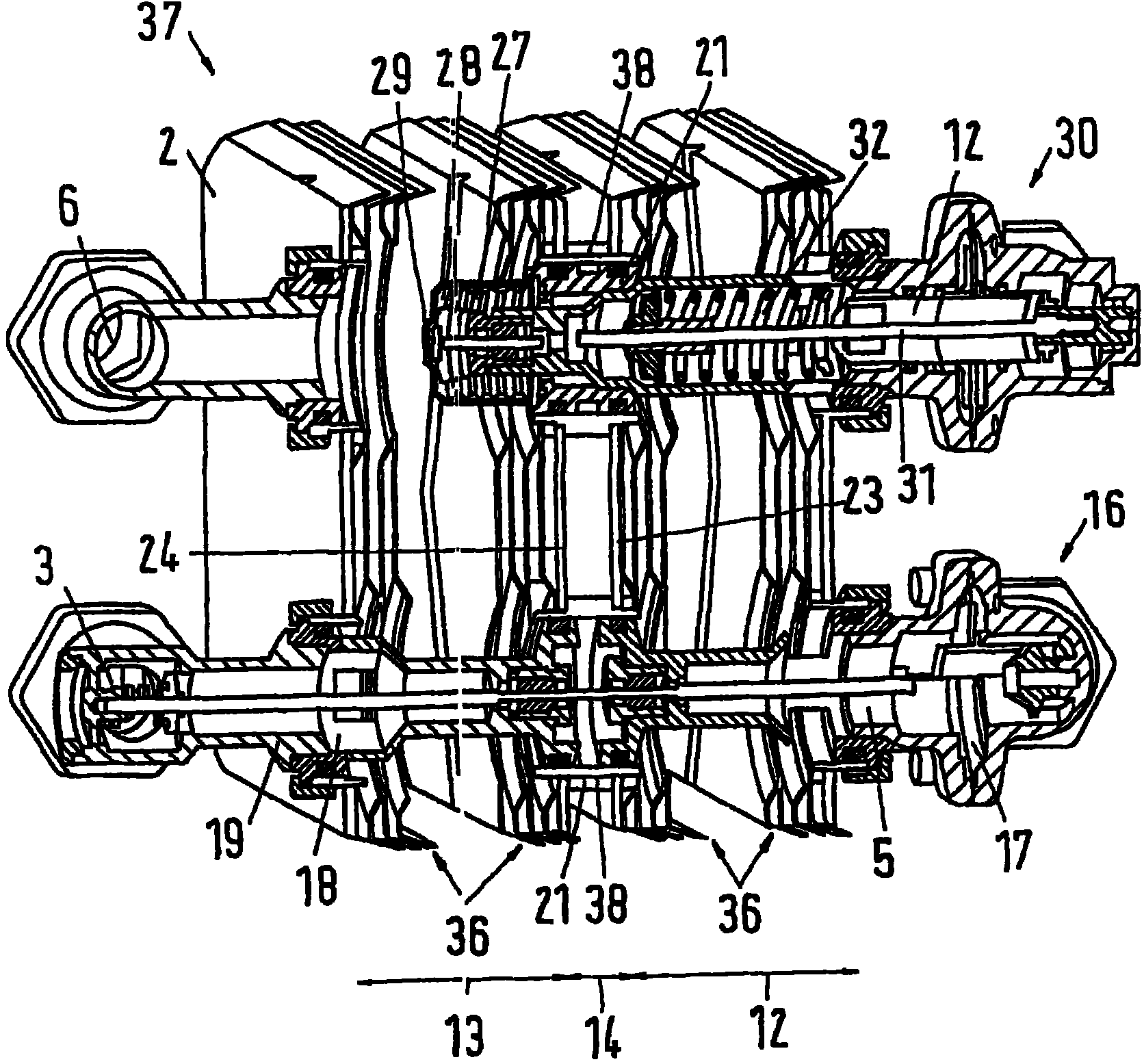

[0027] figure 1 A cross-sectional view of a heat exchanger 1 with a housing 2 with a primary inlet connector 3 , a primary outlet connector 4 , a secondary inlet connector 5 and a secondary outlet connector 6 is schematically shown. Between the primary inlet connector 3 and the primary outlet connector 4 the primary flow path 7 of the primary case 8 is arranged, and between the secondary inlet connector 5 and the secondary outlet connector 6 the secondary side 10 is arranged. Stage flow path9. exist figure 1In the sectional view of , the flow paths 7, 9 are only partially visible. The direction of flow is indicated by arrow 11 . Fluid from the primary side 8 enters at the primary inlet connector 3 and exits at the primary outlet connector 4 . Fluid from the secondary side 10 enters at the secondary inlet connector 5 and exits at the secondary outlet connector 6 . In the heat exchanger 1 , the fluid on the primary side 8 gives heat to the fluid on the secondary side 10 , s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com