Joint construction, door and window frame, and manufacturing process of the oor and window frame

A technology of structure and joint parts, applied in the field of joint structure, can solve the problems of insufficient surface contact between the frame material and joint parts, difficulty in ensuring friction force, failure to ensure friction force, etc., to improve rigidity, ensure joint strength, and prevent pushing The disappearing effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, various embodiments of the present invention will be described with reference to the drawings.

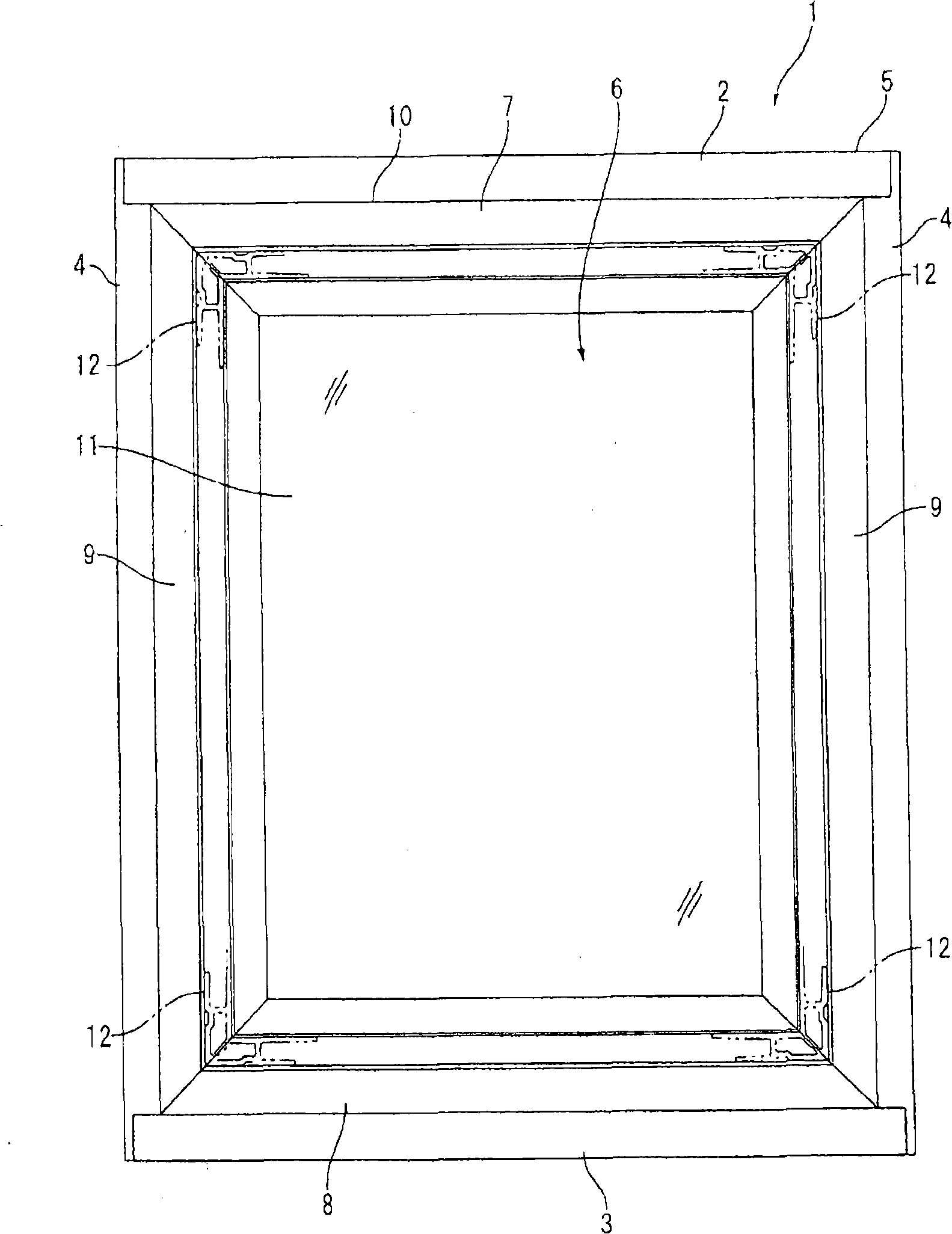

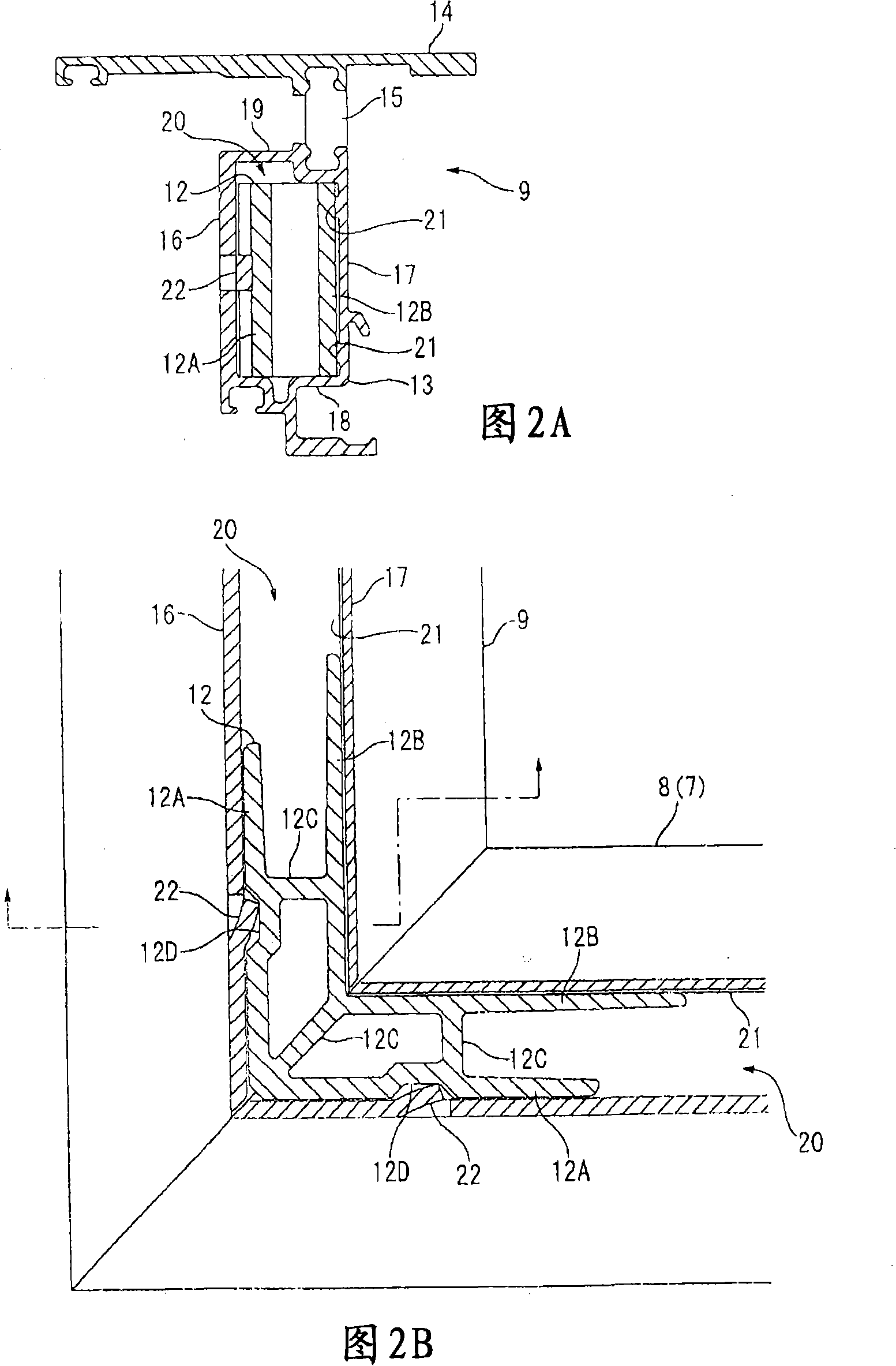

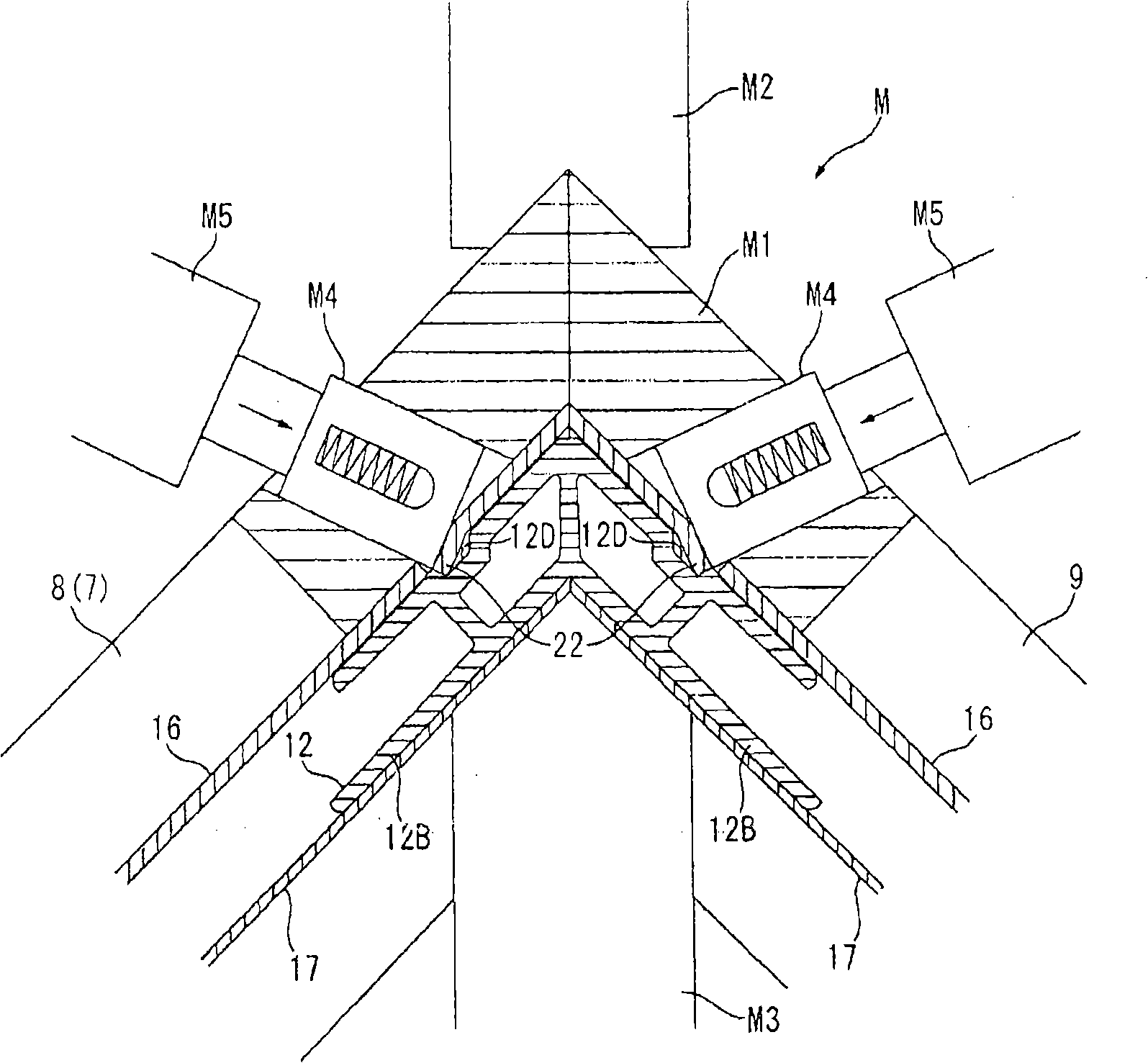

[0041] figure 1 It is a front view which shows the window 1 which is a door and window frame concerning embodiment of this invention. 2A and 2B are enlarged cross-sectional views showing a part of the partition 6 of the window 1 . image 3 It is a sectional view showing the manufacturing method of the partition 6 .

[0042] exist figure 1 2A and 2B, the window 1 has a window frame 5 that frames the upper frame 2, the lower frame 3, and the left and right vertical frames 4, and a partition 6 that is freely opened and closed inside the window frame 5. And constitute. The partition 6 has a partition frame 10 as a frame body including an upper frame 7 , a lower frame 8 , and left and right vertical frames 9 , and a glass plate 11 as a surface material embedded and supported in the partition frame 10 . The window frame 5 is constituted by fixing the upper frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com