Biological filtering device for treating toluene gas

A biofiltration and biofilter technology, which is applied in the direction of air quality improvement, dispersion particle separation, chemical instruments and methods, etc., can solve the problems of uneven biofilm distribution, increased pressure drop, and insufficient nutrients, and achieve easy hanging Membrane, reasonable structure, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

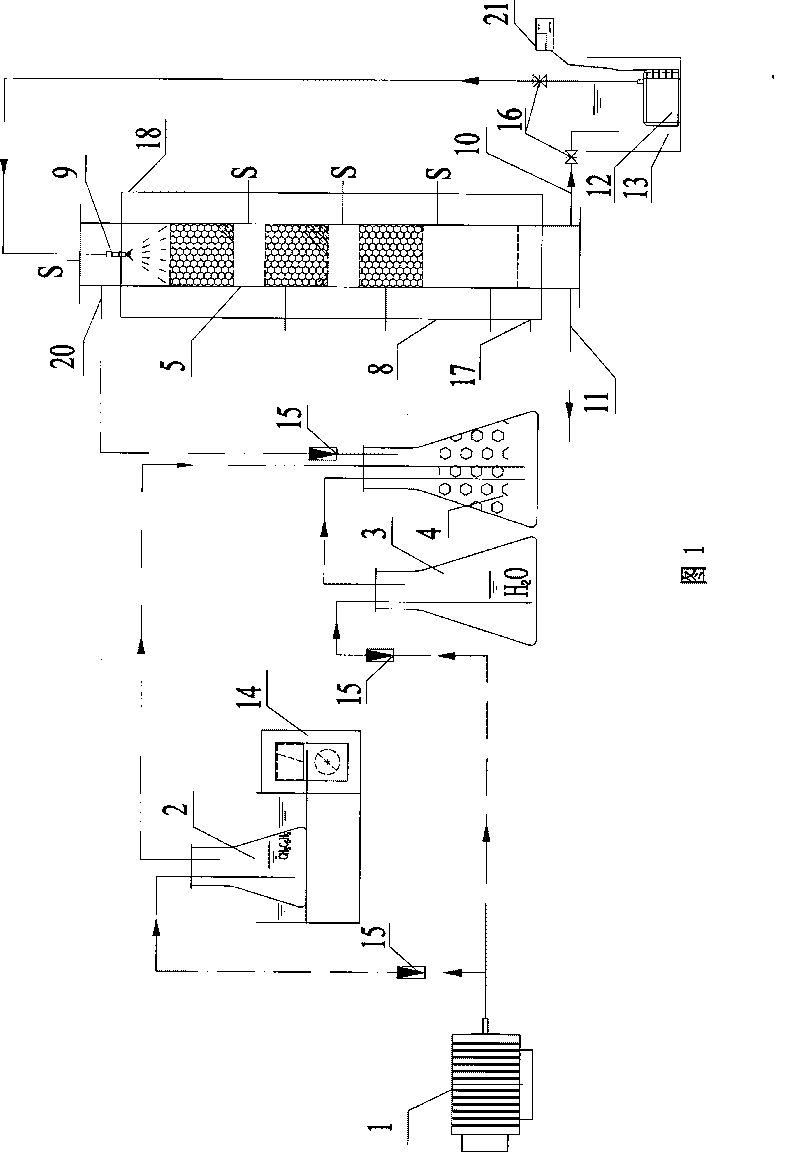

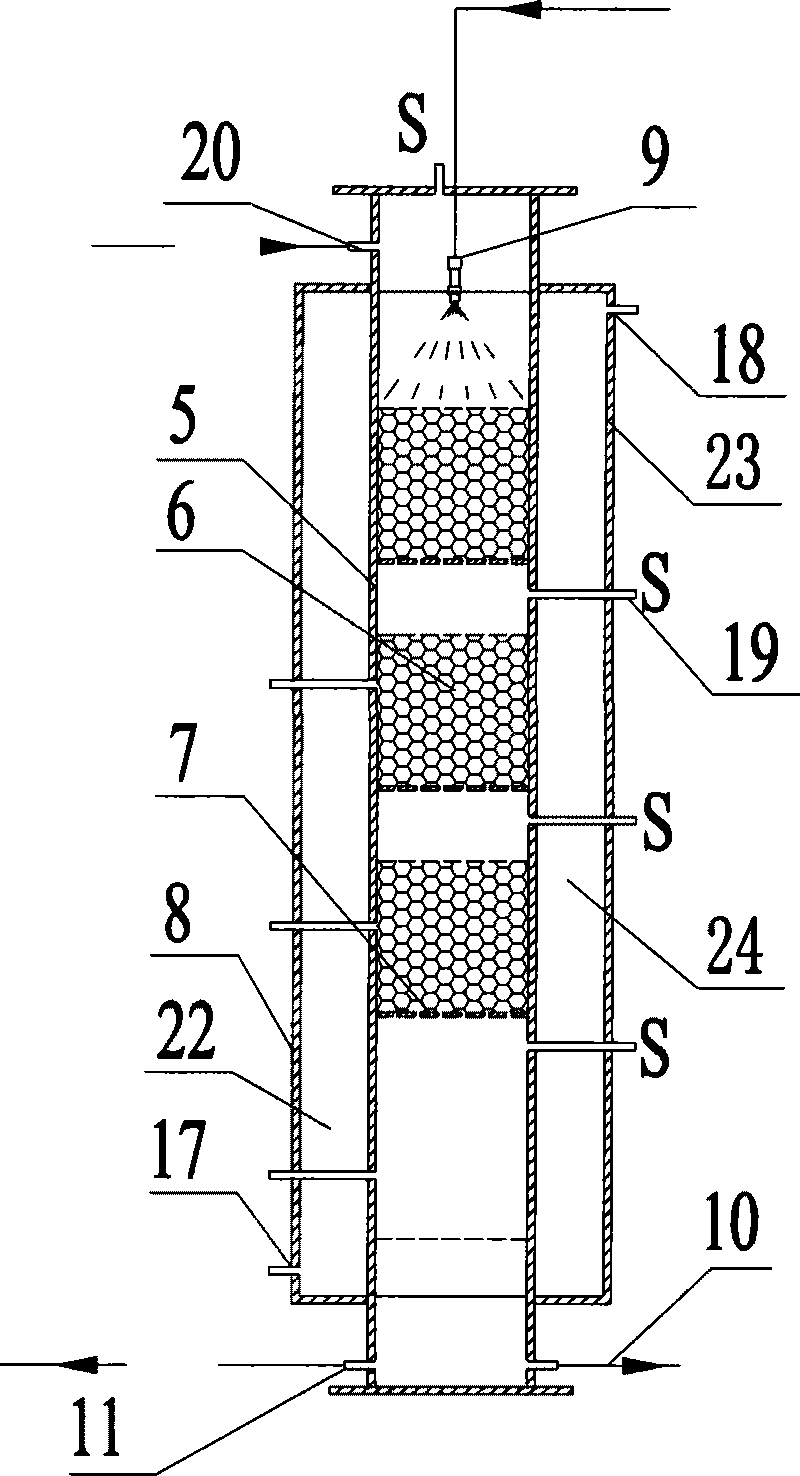

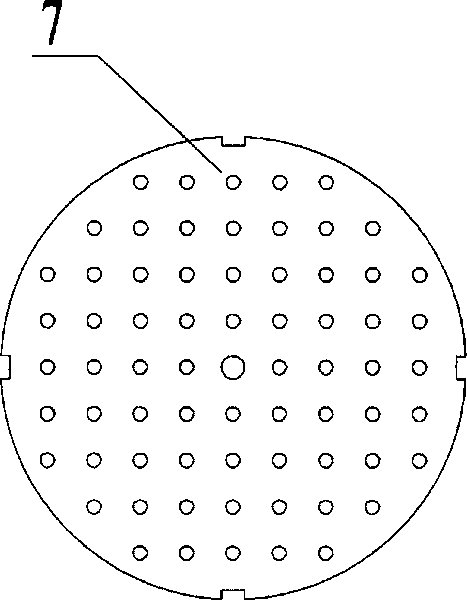

[0039] Figure 1, figure 2 , image 3Shown, the present invention is a kind of biofiltration device for processing toluene gas, and it comprises gas distribution system, biofilter 5, nutrient solution dripping system and water bath constant temperature system, and the nutrient solution nozzle 9 of nutrient solution dripping system is positioned at biological filter At the top of the device 5, the outlet of the gas distribution system is connected to the air inlet 20 on the upper end of the biofilter 5 through a pipeline. The water bath constant temperature system is located outside the biofilter 5. There is one or more integral biological filter material layers 6, and the biological filter material layer 6 is supported by the supporting sieve plates 7 at the bottom of each layer. interval. The biological filter material layer 6 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com