Valve stem balance mechanism of gas pressure regulator

A gas pressure regulator and balance mechanism technology, applied in mechanical equipment, gas/liquid distribution and storage, pipeline systems, etc., can solve problems such as air pressure fluctuations, gap size fluctuations, and affecting the safe use of gas, achieving good sealing, Improve the accuracy and reliability of pressure regulation, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

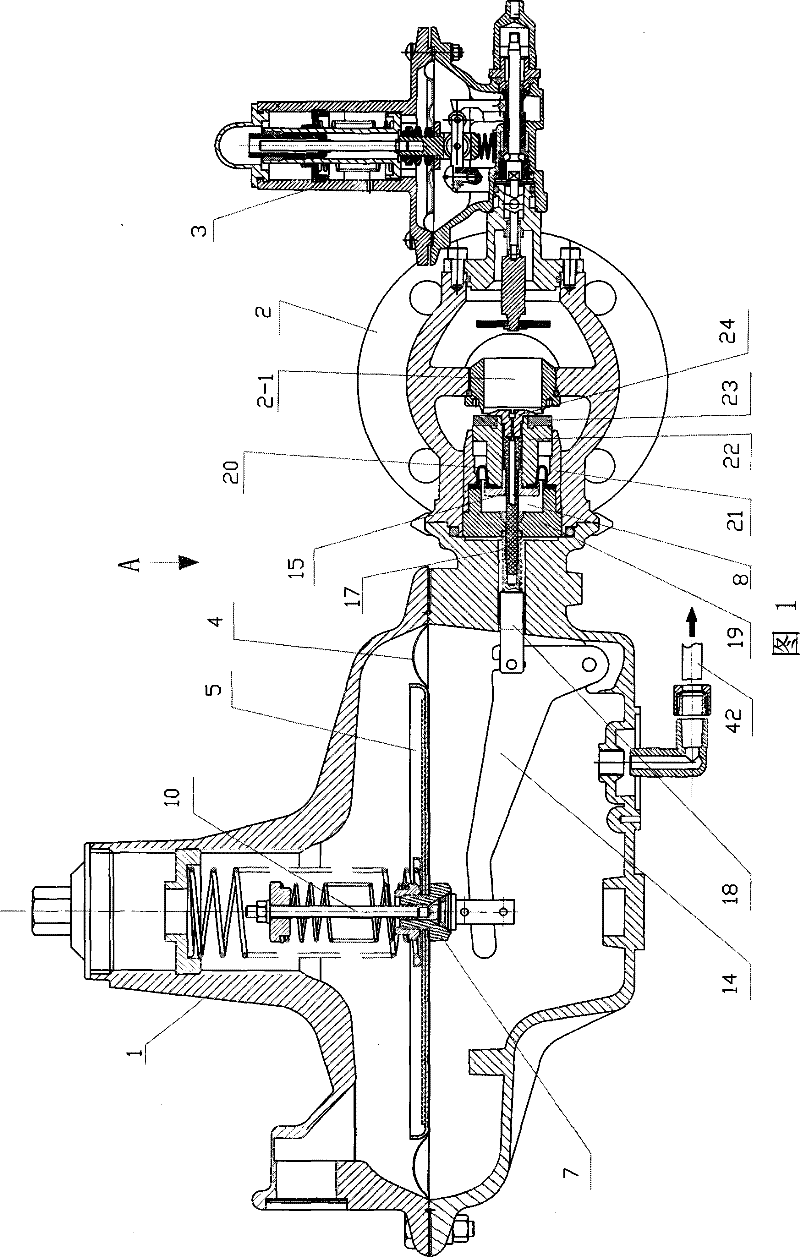

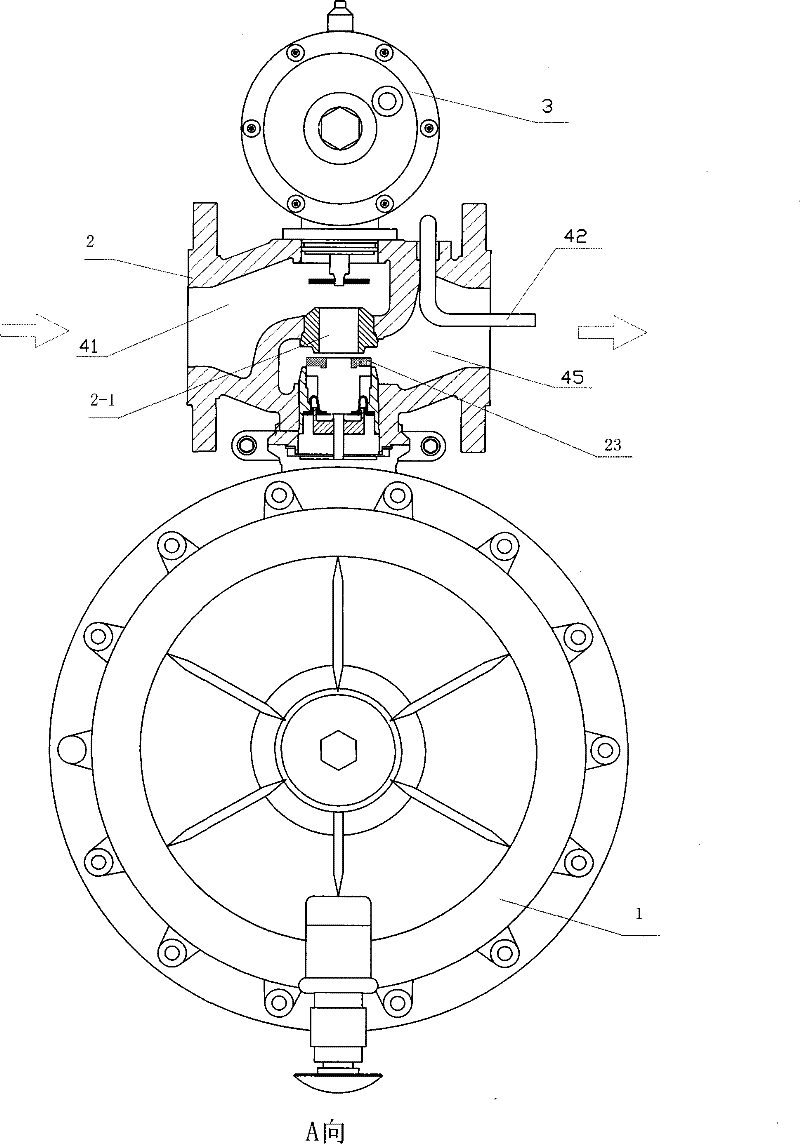

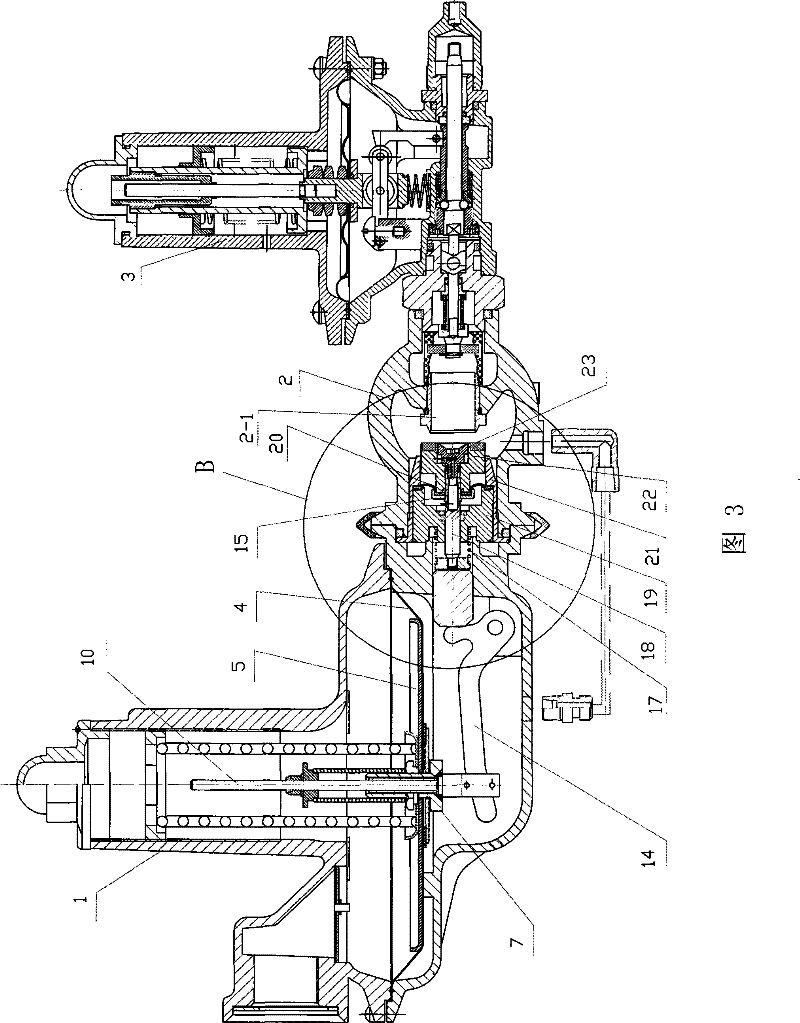

[0018] See Figure 2-4 , the gas pressure regulator of this embodiment includes: a valve body 2, a main pressure regulating valve 1 disposed on one side of the valve port 2-1 of the valve body 2, and a safety shut-off valve 3 disposed on the other side of the valve port 2-1 .

[0019] The main pressure regulating valve 1 comprises: an upper casing and a lower casing, a main membrane 4 is arranged between the upper casing and the lower casing; a tray 5 is arranged on the main membrane 4, and a pressure applying mechanism and a Built-in relief valve 7. The lower end of the screw rod 10 vertically connected with the tray 5 is provided with a lever 14, and the connection between the main pressure regulating valve 1 of the gas pressure regulator and the valve body 2 has a valve stem channel, and a valve stem 18 is arranged in the valve stem channel; the lever 14 transitions The block 16 is connected with the valve rod 18 in transmission to adjust the size of the gap between the v...

Embodiment 2

[0033] On the basis of Embodiment 1, the valve stem balance mechanism of the gas pressure regulator of this embodiment has the following differences, see figure 1 , the front end of the valve rod 18 in this embodiment is directly connected to the screw rod 10 vertically arranged on the tray 5 and the main membrane 4 through the lever 14 in the main pressure regulating valve 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com