Fatigue-testing machine

A fatigue testing machine and frame technology, which is applied in the direction of applying repetitive force/pulse force to test the strength of materials, etc., can solve the problems of inconsistent experience components and standards, and can not meet the needs of the rapid development of the textile industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

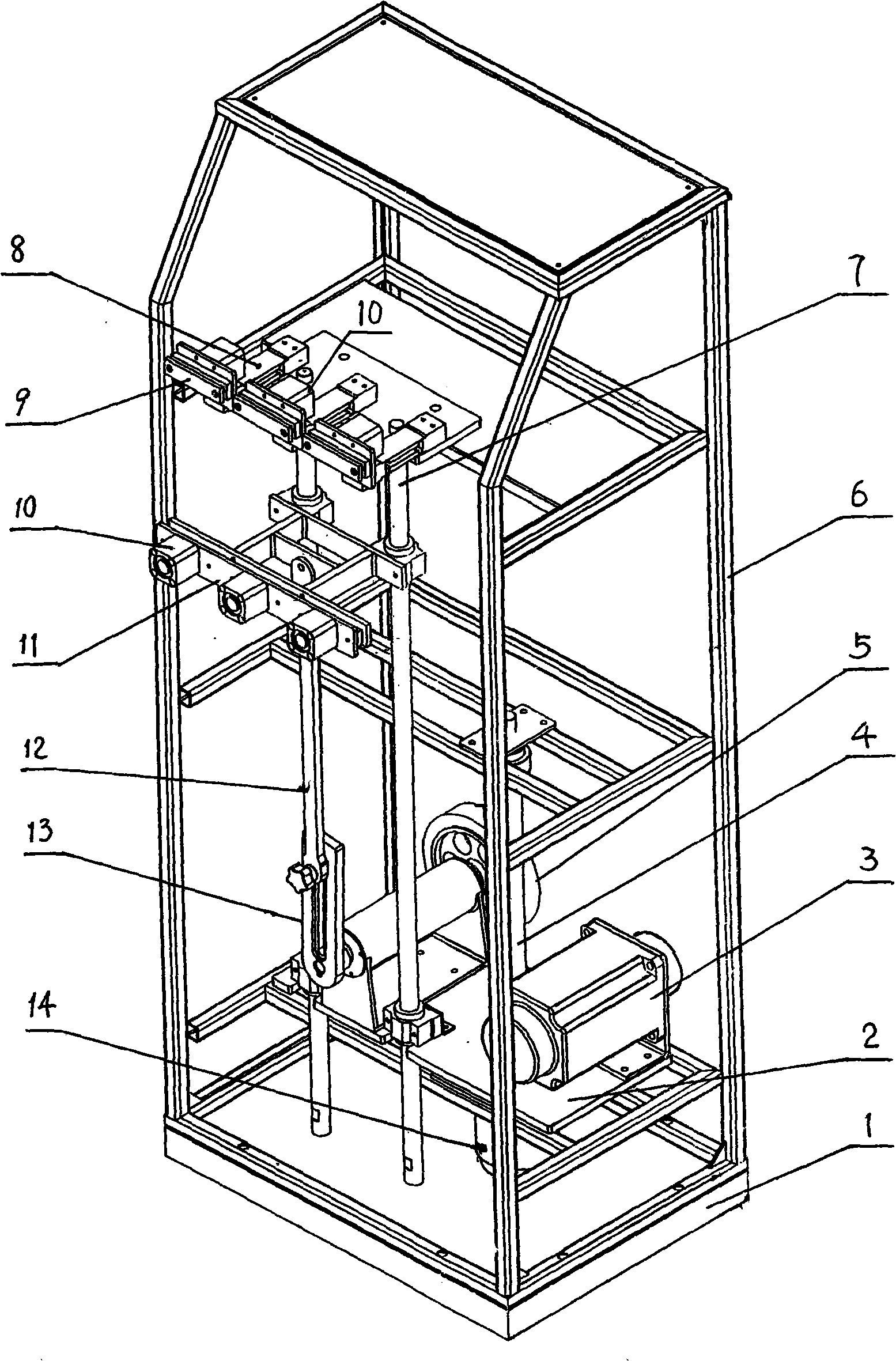

[0014] like figure 1 As shown, the fatigue testing machine includes a frame 6 installed on the machine base 1 . The lower ends of the two parallel guide rails 7 are all fixed on the base 1, and the upper ends are fixedly connected with the frame 6. The upper holder 9 can be directly fixed with the frame 6 , and can also be fixedly connected with the frame 6 through the sensor 8 , and the lower holder 11 is slidably installed on the guide rail 7 . An air cylinder 10 is also installed on the upper holder 9 and the lower holder 11, and its function is to provide power for clamping the sample.

[0015] The skateboard 2 is also slidingly connected with the guide rail 7, and the main motor 3 and the transmission wheel 5 are fixedly installed on the skateboard 2. The axle of the transmission wheel 5 is connected to the crank 13, and the upper end of the connecting rod 12 matched with the crank 13 is connected to the lower holder 11. .

[0016] When the main motor 3 is working, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com