Apparatus for adjusting timing of needle and looptaker of sewing machine

A technology for sewing machines and machine needles, which is applied in the direction of sewing machine needle seats, sewing machine collar mechanisms, sewing machine components, etc., and can solve problems such as inability to ensure stable operation of sewing machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

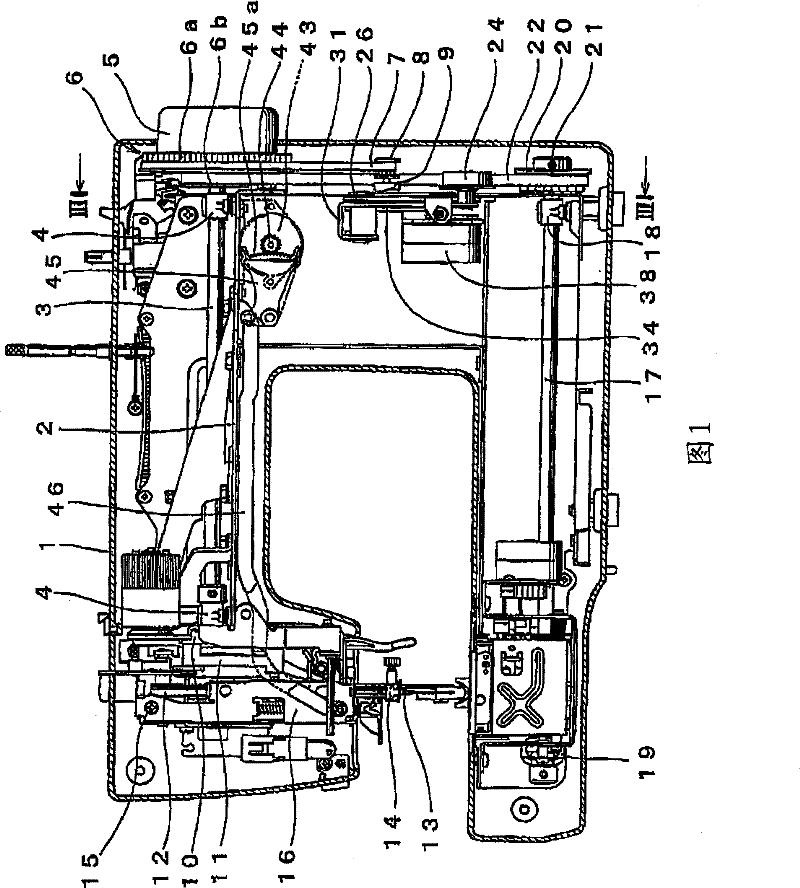

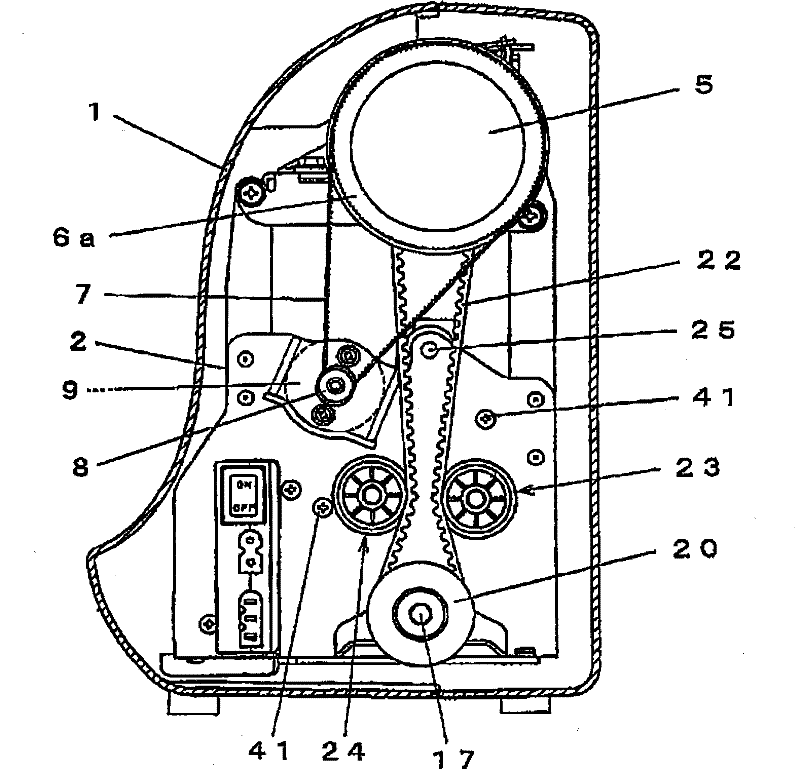

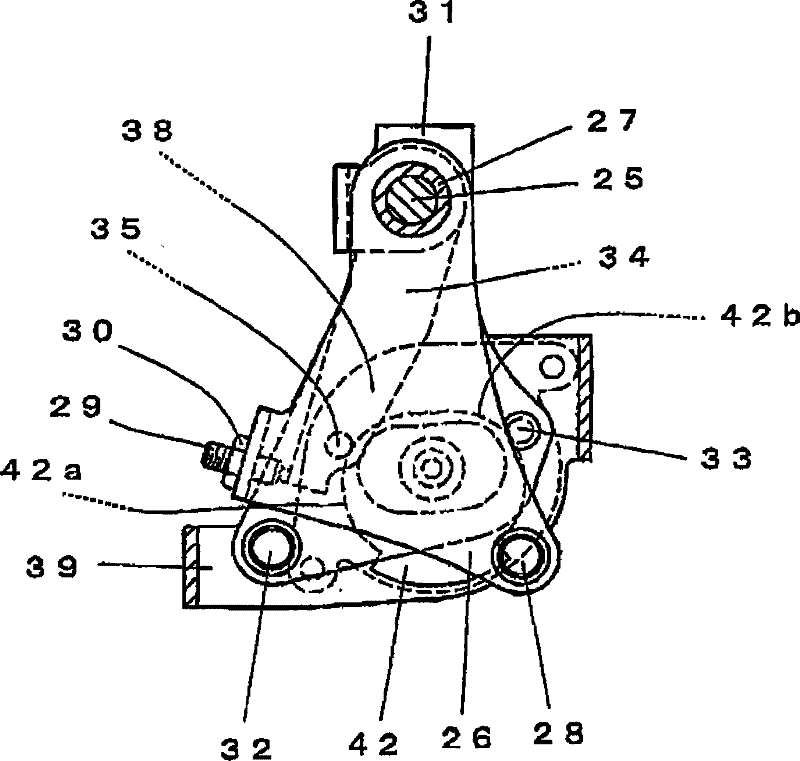

[0036] The first embodiment of the present invention will be described below with reference to the drawings. Such as figure 1 with figure 2 As shown, the sewing machine according to this embodiment includes a housing 1 and a frame 2. The upper shaft 3 is rotatably supported by a pair of bearings 4 and 4 fixed to the frame 2. The hand wheel 5 and the pulley 6 are fixedly installed at one end of the upper shaft 3. The pulley 6 includes a driven pulley 6a with a larger diameter and a timing pulley 6b with a smaller diameter (ie, a first timing pulley). The drive motor 9 is mounted to the frame 2, and the motor pulley 8 is fixedly mounted on the output shaft of the drive motor 9 to rotate. A closed endless transmission belt 7 without a joint is fitted to the motor pulley 8 and the driven pulley 6a, thereby lowering the rotation of the shaft of the driving motor 9 and transmitting it to the upper shaft 3. Conventionally, the needle bar crank 10 is fixed to the other end of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com