Image deformation calibration method irrespective with shooting apparatus

A photographic equipment and distortion calibration technology, applied in image enhancement, image data processing, instruments, etc., can solve problems such as inability to calibrate image distortion, complicated calibration process, and inability to understand photographic equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

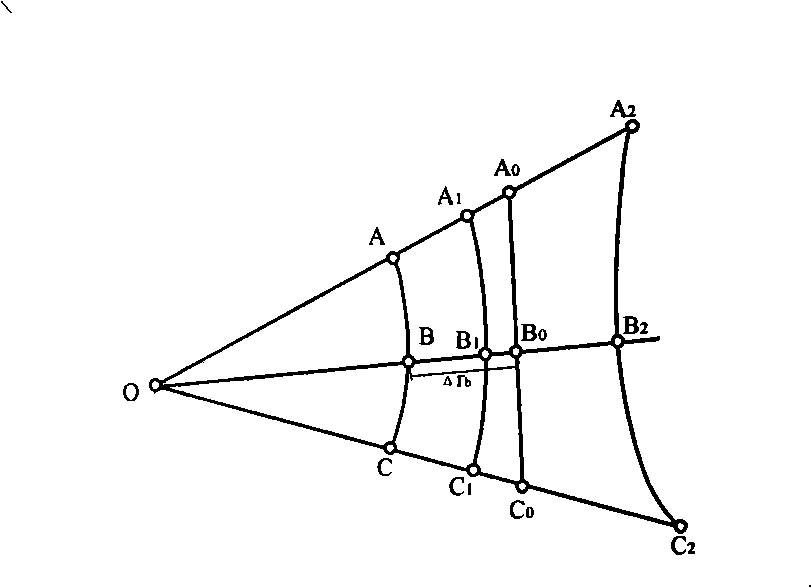

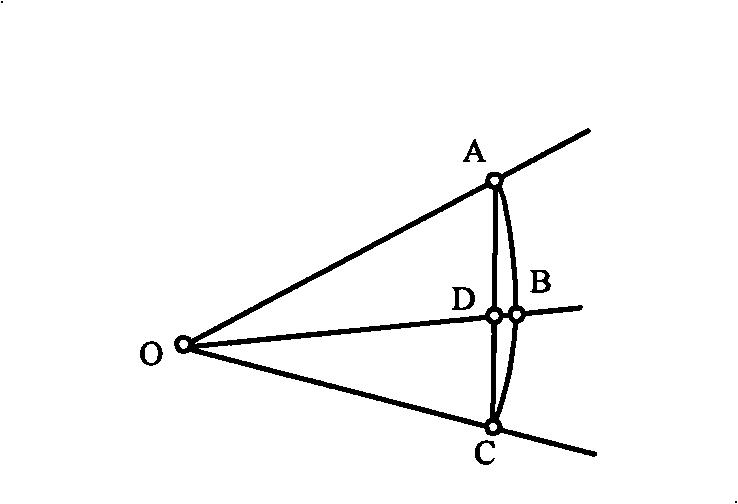

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1, on two walls that are strictly vertical in the room, two high-precision polyester film drawings (such as Figure 5 ), to accurately measure the relationship between two drawings. The decimeter grid of the polyester film drawing is accurate to 0.2mm, which can be used as a precision indoor test site. The spatial three-dimensional coordinates of the 72 grid points on the two drawings become the three-dimensional points of the indoor test site.

[0063] First use the 3D control point pair Figure 5 The image is rigorously solved, and the obtained image distortion coefficient is 2.21×10 -8 . Then use this method to solve the distortion parameters of the image: select Figure 5 The calculation results of the 12 straight-line targets are shown in Table 1.

[0064] Table 1

[0065]

[0066]

[0067] Note: Set the difference between the distortion radials of two adjacent calculations to be less than 0.5 pixels, and the iterative approach calculation end...

Embodiment 2

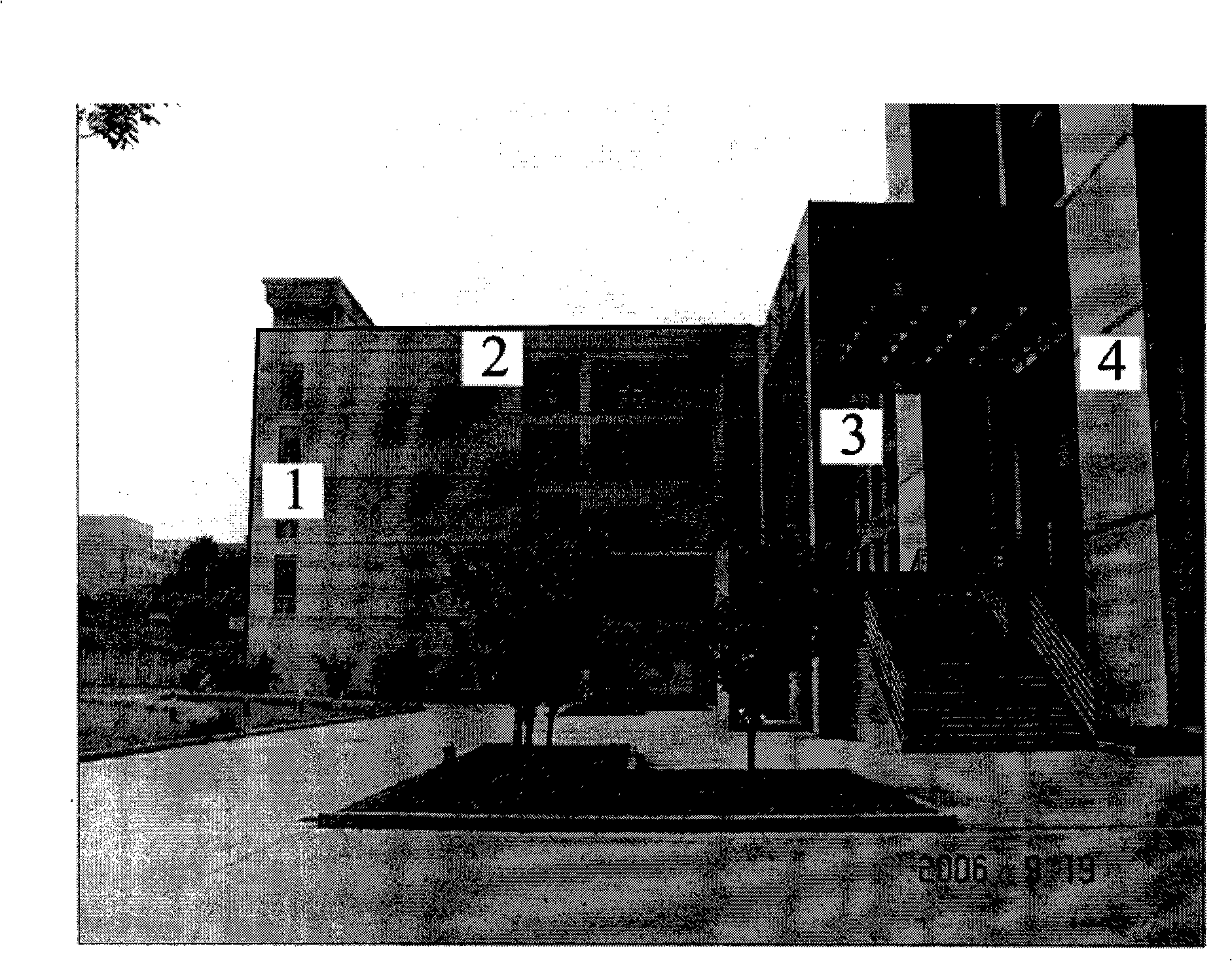

[0069] Embodiment 2, in Image 6 In, solve its distortion coefficient to close-range image, extract four obvious building edges from image, calculate image distortion respectively with the method of the present invention, calculation result is shown in Table 2, calculates the average value as the distortion coefficient 2.23×10 of this image -8 . The result of the digital camera's identification through the three-dimensional identification field is 1.98×10 -8 , both of which are also very close.

[0070]

[0071] Note: Set the difference between the distortion radials of two adjacent calculations to be less than 0.5 pixels, and the iterative approach calculation ends. It is required in advance that the difference between the distortion coefficients of each image obtained is less than 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com