Multiple mounting head with collective rotary drive and adjustable lifting device for component holding devices

A technology of electronic components and assembly heads, applied in the direction of electrical components, electrical components, etc., can solve the problems of reduced assembly efficiency and achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

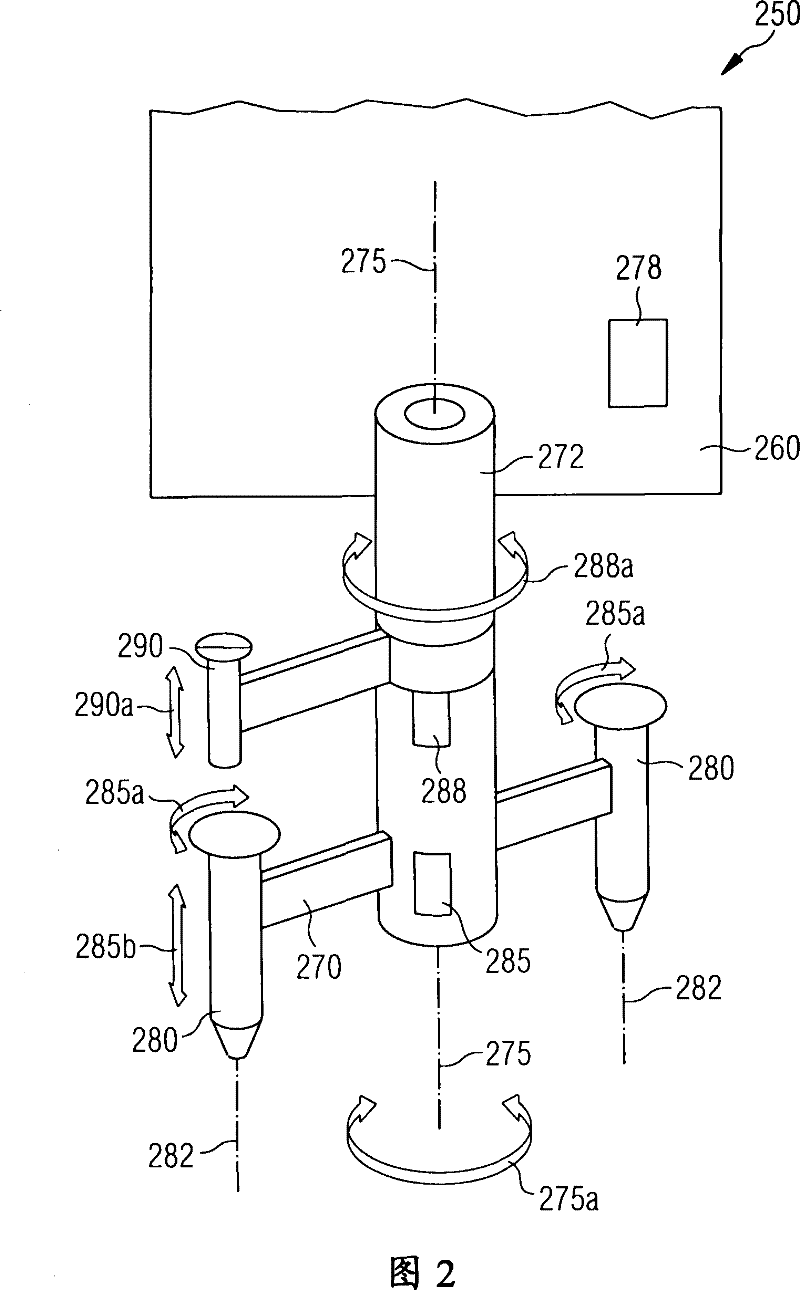

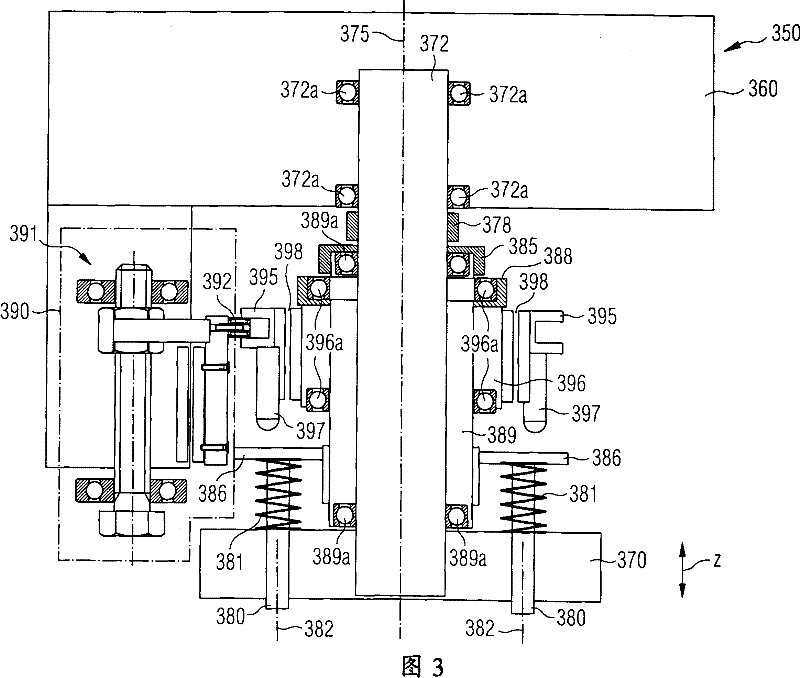

[0037] It should be noted here that the reference designations of identical or mutually corresponding elements in the figures differ only in their first numerals.

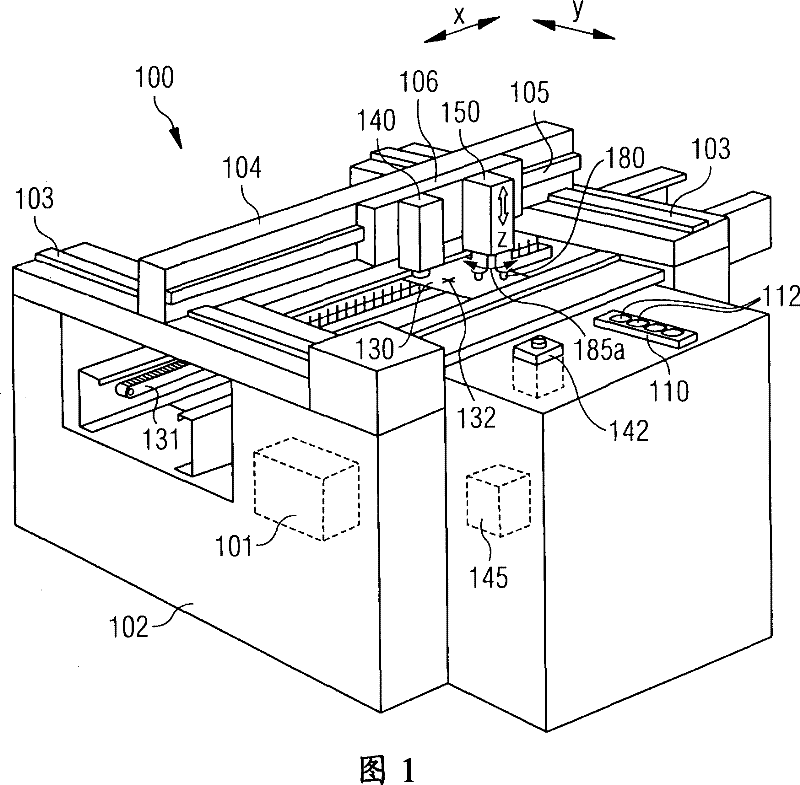

[0038] figure 1 A mounting device 100 is shown which has a frame 102 on which two parallel-pointing guides 103 are arranged. Two guides 103 carry a transverse support arm 104 . The transverse support arm 104 itself has a guide 105 on which a support part 106 is movably arranged. The two guides 103 run in the y-direction and the guides 105 run in the x-direction. Arranged on the carrier part 106 is a mounting head 150 which has two holding devices 180 .

[0039] The two holding devices 180 are fastened to a rotor (not shown) of the multi-head assembly head 150, which is rotatable about the rotor axis of rotation. The axis of rotation of the rotor is positioned parallel to the z-direction, which is perpendicular to the x-direction and the y-direction. The corresponding rotational movement of the holding device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com