Self-dumping box of closed wagon

A closed-type freight car technology, applied in the field of railway freight cars, can solve problems such as potential safety hazards, flooding of gravel roadbeds, and impact on railway speed-up needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

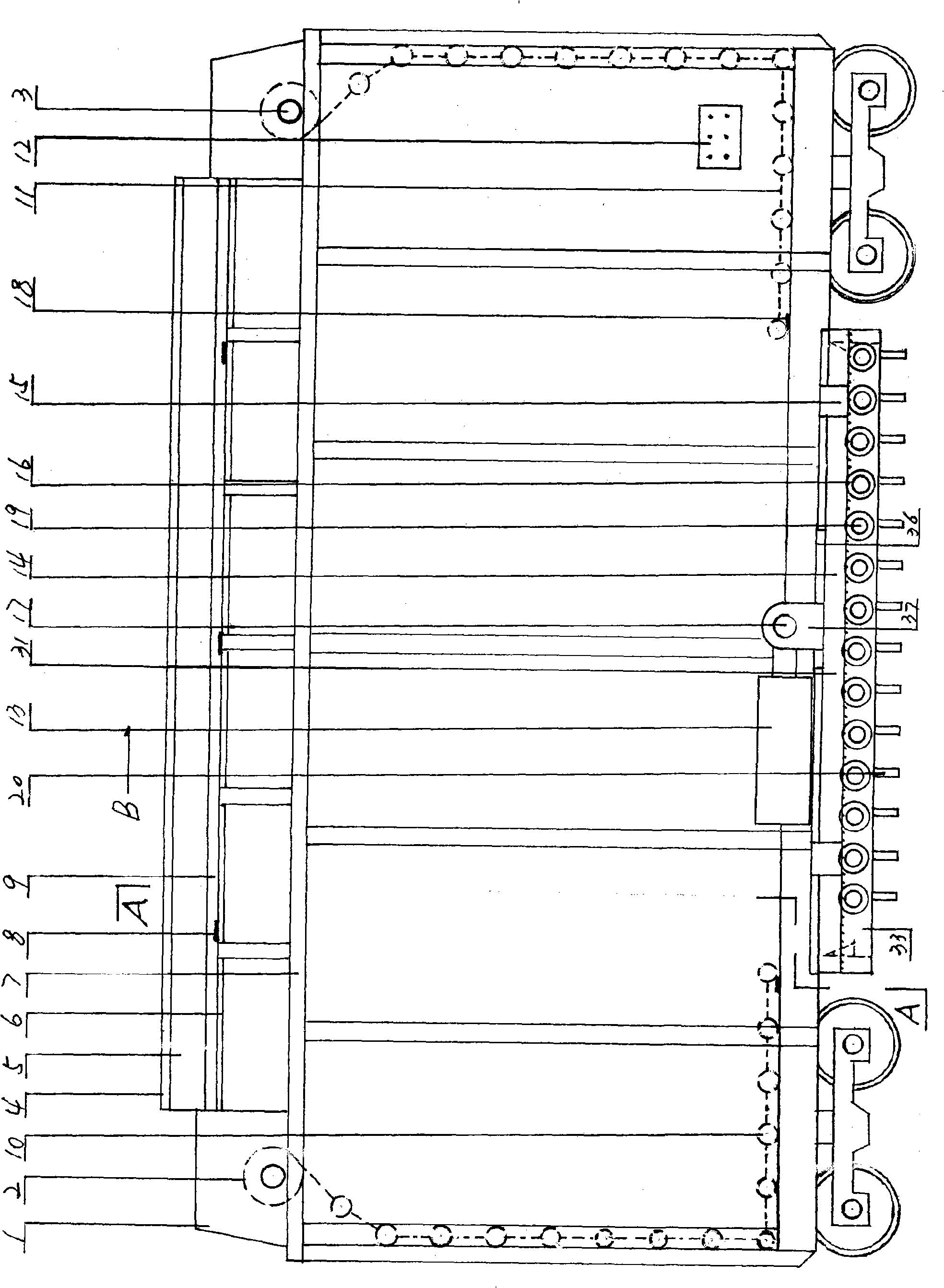

[0014] figure 1 , the front view of the carriage

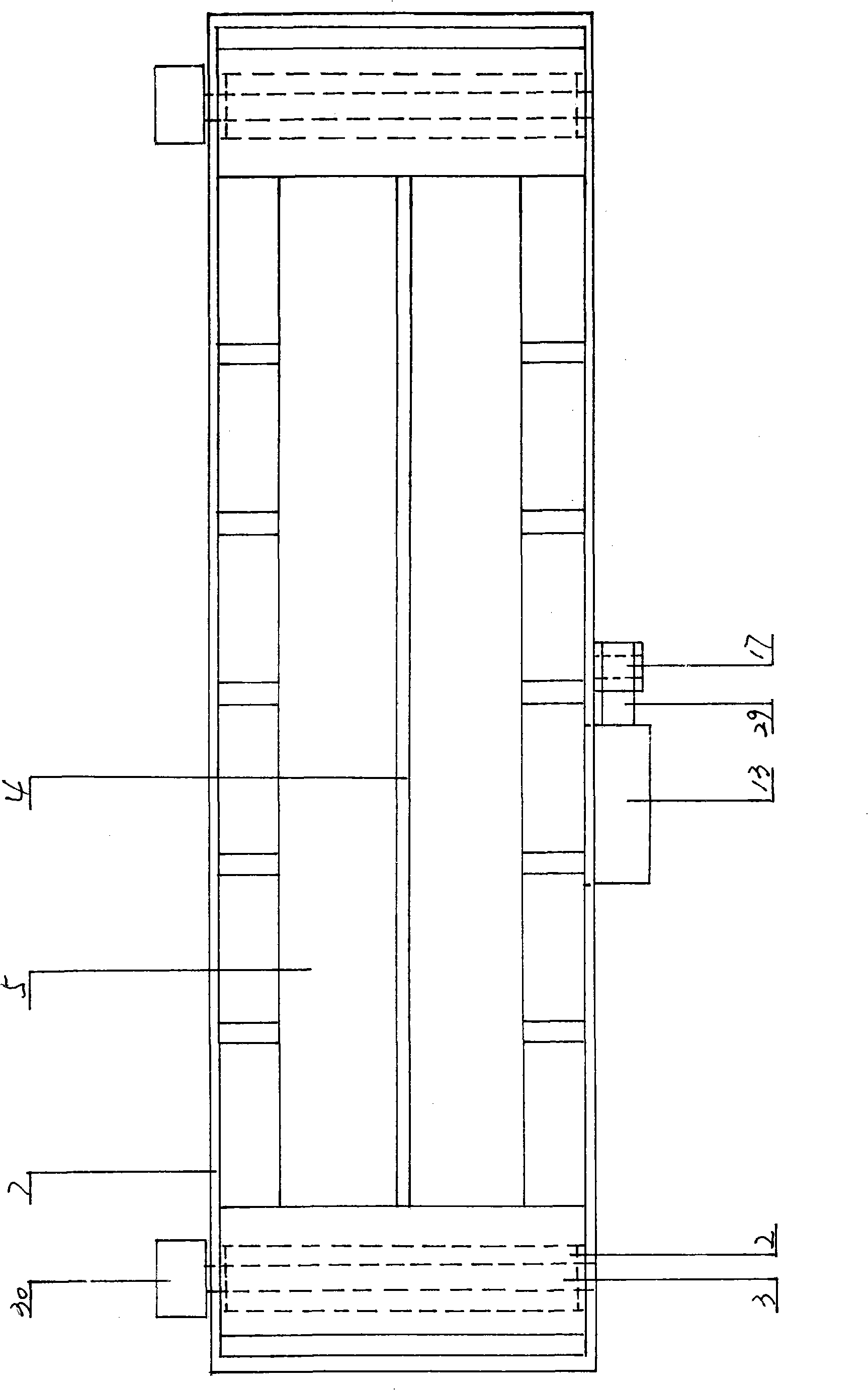

[0015] figure 2 , top view of the compartment

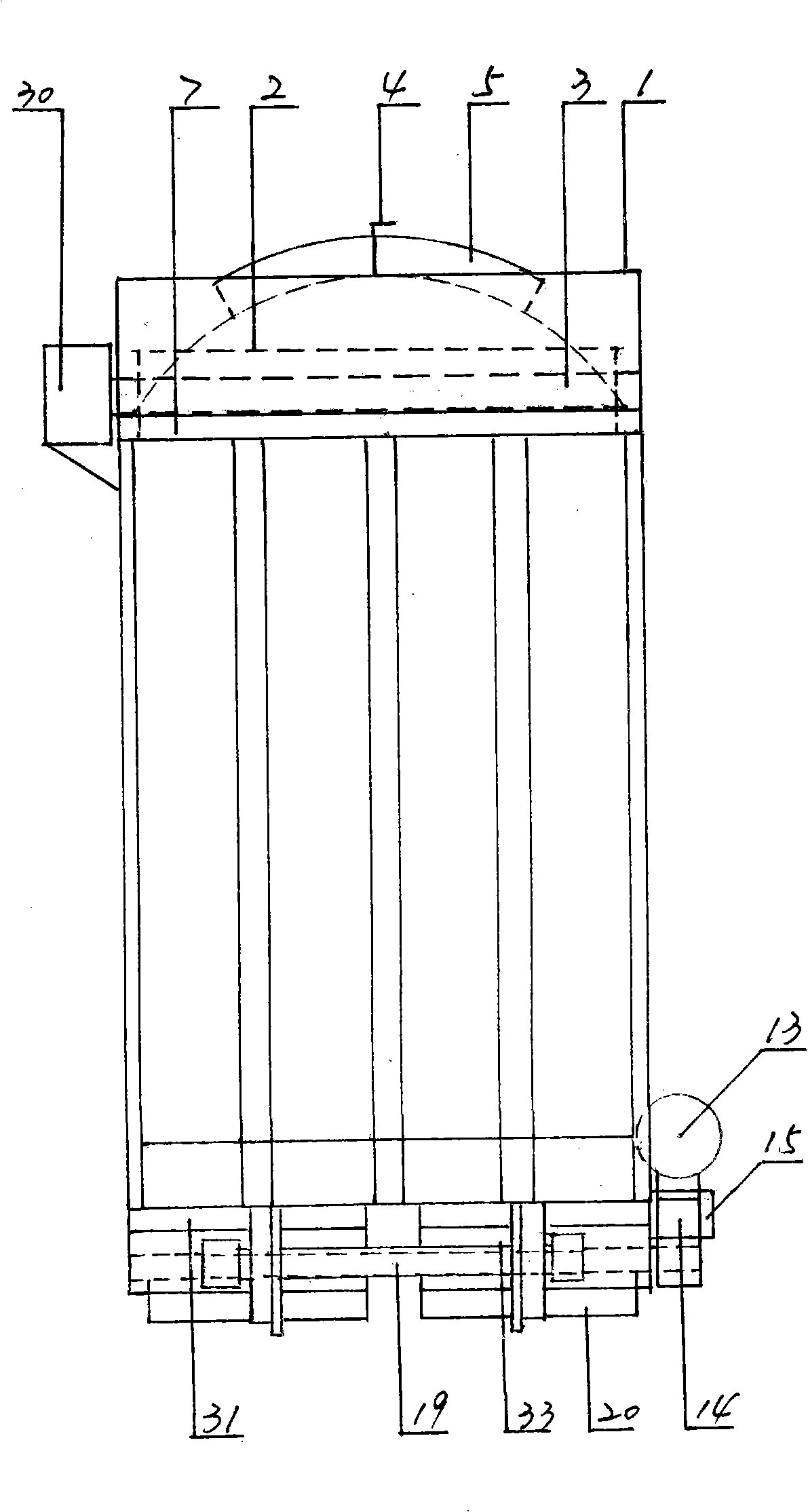

[0016] image 3 , B side view of the compartment

[0017] Figure 4 , Front view of the inner side of the door leaf

[0018] Figure 5. Side view of the door leaf

[0019] Figure 6 , A-A sectional view of the compartment

[0020] Figure 7 , door switch side view

[0021] Figure 8. Folding side view

[0022] Figure 9. Folding page main view

[0023] Figure 10, the front view of the bucket and lower mouth frame

[0024] Figure 11. Top view of combination of bucket and hinge

[0025] 1. Rolling shutter door cover, 2. Rolling shutter roller, 3. Rolling shutter shaft, 4. Access control, 5. Door leaf, 6. Door frame, 7. Ring beam, 8. Hinge, 9. Door leaf frame, 10, Hinge shaft, 11 , rolling door panel, 12, control panel, 13, hydraulic cylinder, 14, rack, 15, rack baffle, 16, gear, 17, rack shaft pin, 18, half door sheet, 19, hinge shaft, 20 , hinge plate, 21, door leaf p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com