Self-discharge tray type three-dimensional fermentation system

A fermentation system and tray-type technology, which is applied in the field of self-unloading tray-type three-dimensional fermentation system, can solve the problems of undiscovered fermentation equipment, etc., and achieve the effect of solving environmental protection treatment and resource utilization, low integration, and miniaturization of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the following describes the specific implementation, structure, Features and their effects are described in detail below.

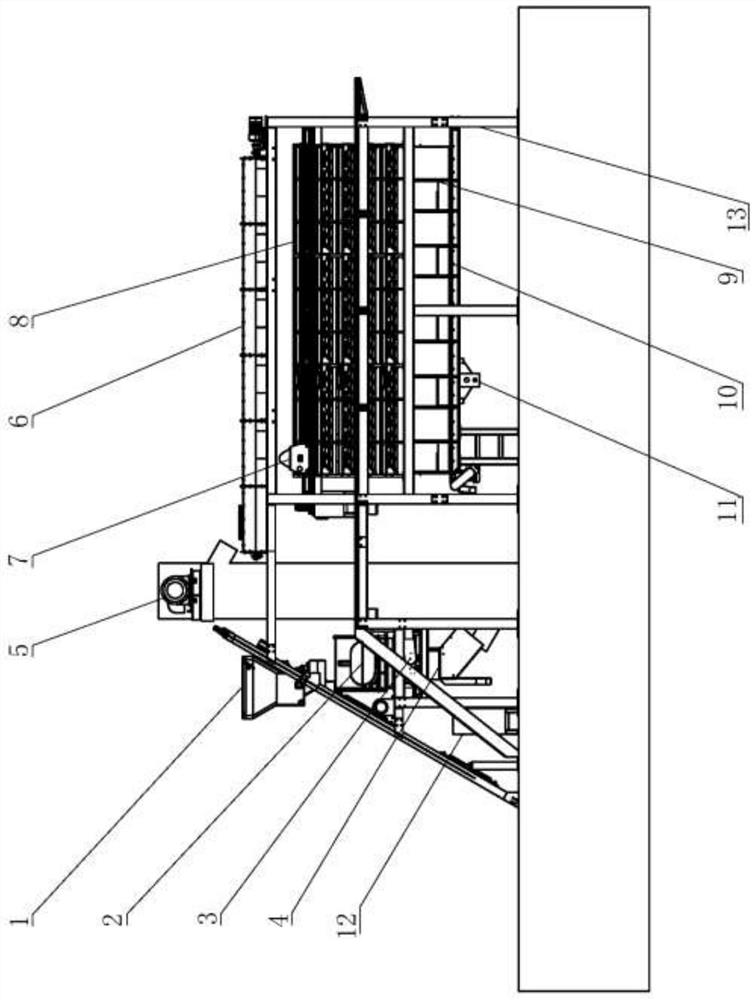

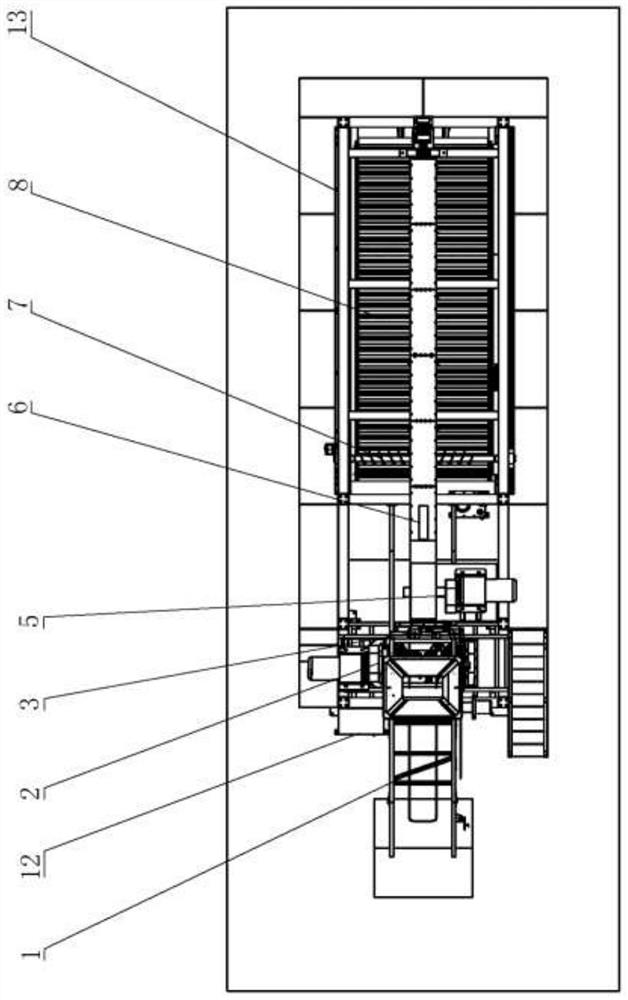

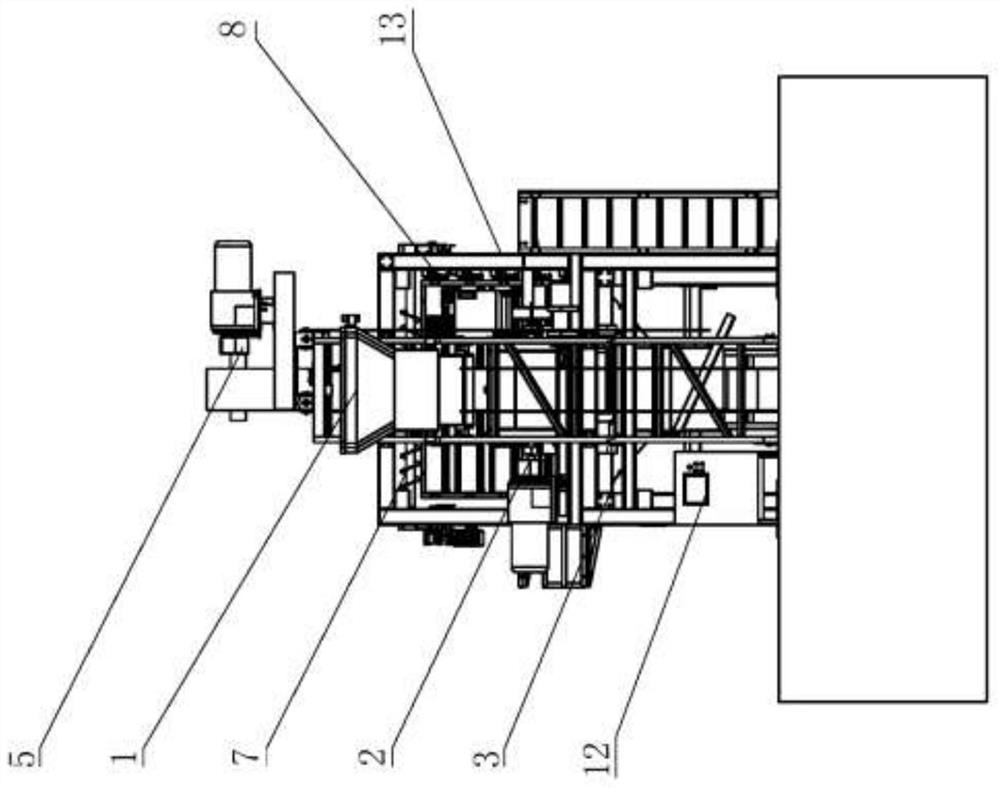

[0047] see Figure 1 to Figure 3 As shown, the self-discharging tray-type three-dimensional fermentation system of the present invention is mainly composed of a material lifting device 1 and a fermentation tray 8 . The fermentation tray 8 is three-dimensionally stacked and installed, and the material lifting device 1 is installed on one side of the fermentation tray 8 . The fermentation tray 8 is provided with a tray side frame 81 , a rotatable bottom plate 82 , a bottom plate linkage mechanism 83 and a bottom plate driving mechanism 84 . The rotatable bottom plate 82 is connected with the bottom plate driving mechanism 84 through the bottom plate linkage mechanism 83 in a driving manner. The rota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com