Preparation of potassium platinochloride

A technology of potassium chloroplatinite and potassium chloroplatinate is applied in chemical instruments and methods, sodium/potassium compounds, ruthenium/rhodium/palladium/osmium/iridium/platinum compounds, etc., to achieve low production cost and good operating environment , the effect of short preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

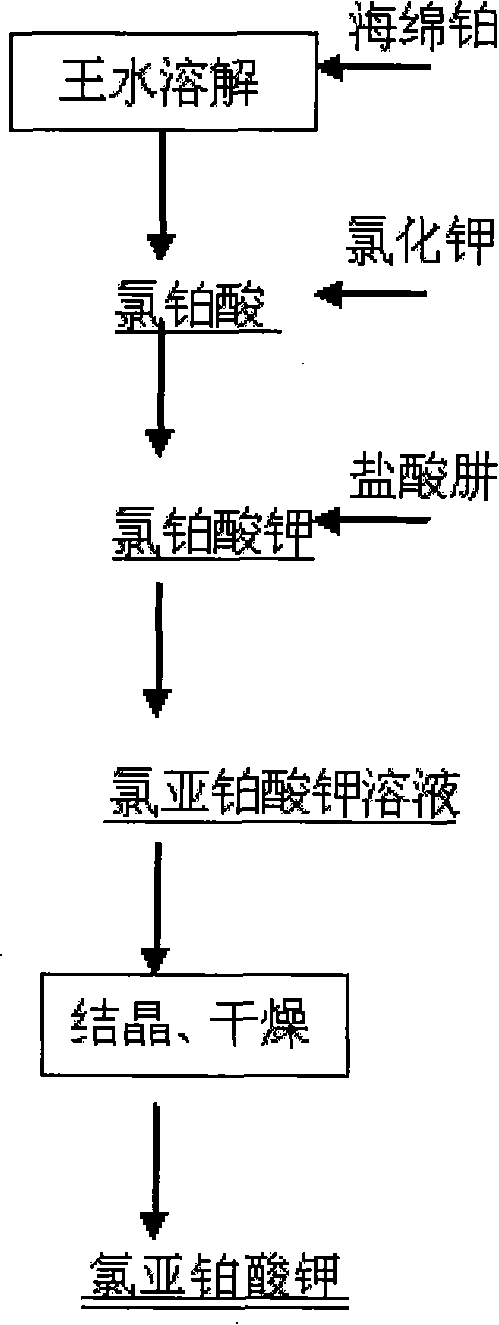

[0013] A kind of preparation method of potassium chloroplatinite, its preparation process is to adopt sponge platinum as raw material to prepare chloroplatinic acid solution and potassium chloride solution to prepare potassium chloroplatinate, then use hydrazine hydrochloride as reducing agent to reduce chloroplatinic acid Potassium preparation of pharmaceutical intermediate potassium chloroplatinite. Include the following steps:

[0014] a) Preparation of potassium chloroplatinate: Weigh a certain amount of platinum sponge, put it into a beaker after washing, add appropriate amount of aqua regia in batches, heat appropriately, and the reaction process is based on the principle of uniform bubbling. After the reaction stops, add concentrated hydrochloric acid dropwise under heating and boiling to catch the nitrate until the system no longer emits brown nitrogen oxides, and then add an appropriate amount of water to catch the acid. Filter, heat and concentrate the filtrate to t...

Embodiment 1

[0021] Weigh 100g of platinum sponge, put it into a beaker after washing, add an appropriate amount of aqua regia, and heat it appropriately. The principle of the reaction process is uniform bubbling. After the reaction stopped, the obtained solution was concentrated until crystals were precipitated, and concentrated hydrochloric acid was added dropwise to remove the nitrate until the system no longer emits brown nitrogen oxides, then concentrated until crystals were precipitated, and an appropriate amount of deionized water was added to remove the acid. Filter, and the filtrate is formulated into a 50g / L solution for subsequent use.

[0022] Weigh 80.0g of potassium chloride, make a 20% solution, filter, and use the filtrate for later use. Take the above chloroplatinic acid solution and add it dropwise to the potassium chloride solution under stirring, a yellow precipitate appears in the solution, after the dropwise addition, continue to stir for 1-2 hours to complete the rea...

Embodiment 2

[0026] The specific implementation rules are the same as example 1, and the difference is that the sponge platinum input amount is 500g, and chloroplatinic acid is mixed with a solution of 100 g / L, and potassium chloride consumption is 401g, which is made into a 20% solution, and potassium chloroplatinate is 1200g , 8000ml of distilled water was added, and the amount of reducing agent hydrazine hydrochloride was 136g. The obtained product was sampled for full elemental analysis and XRD detection, platinum content: 46.2%, potassium content: 17.6%, no compounds other than potassium chloroplatinite were detected. The product yield is 95.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com