Method for rebuilding guide current hole to jet flow internal energy dissipating drilled shaft flood discharge hole

A technology of diversion tunnels and flood discharge tunnels, which is applied in buildings, traditional hydroelectric energy, hydropower stations, etc., can solve the problems of not meeting the requirements of flood discharge at the same time, occupying a large area, and small flood discharge flow, so as to reduce cavitation damage Risk, small footprint, large flood discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

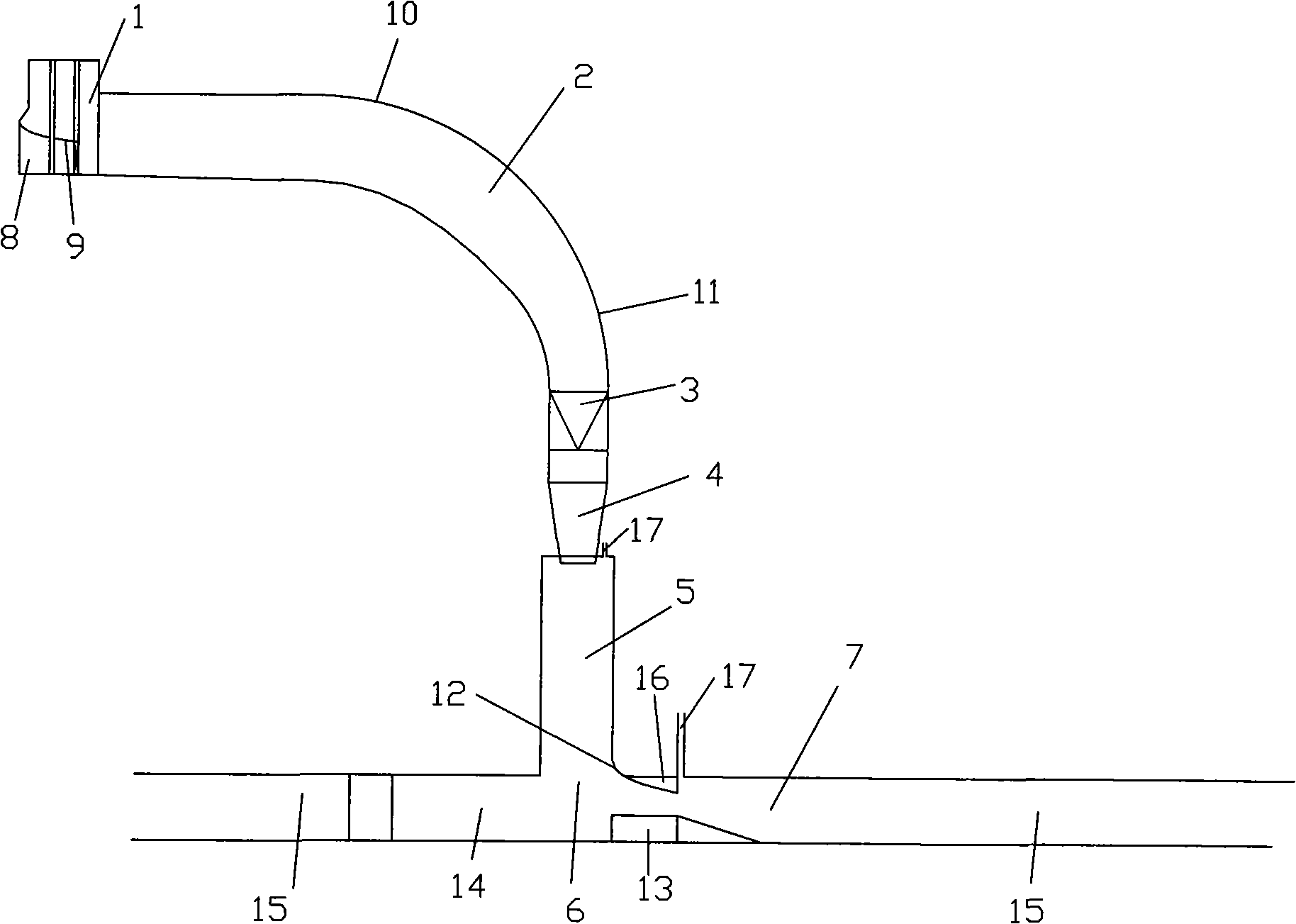

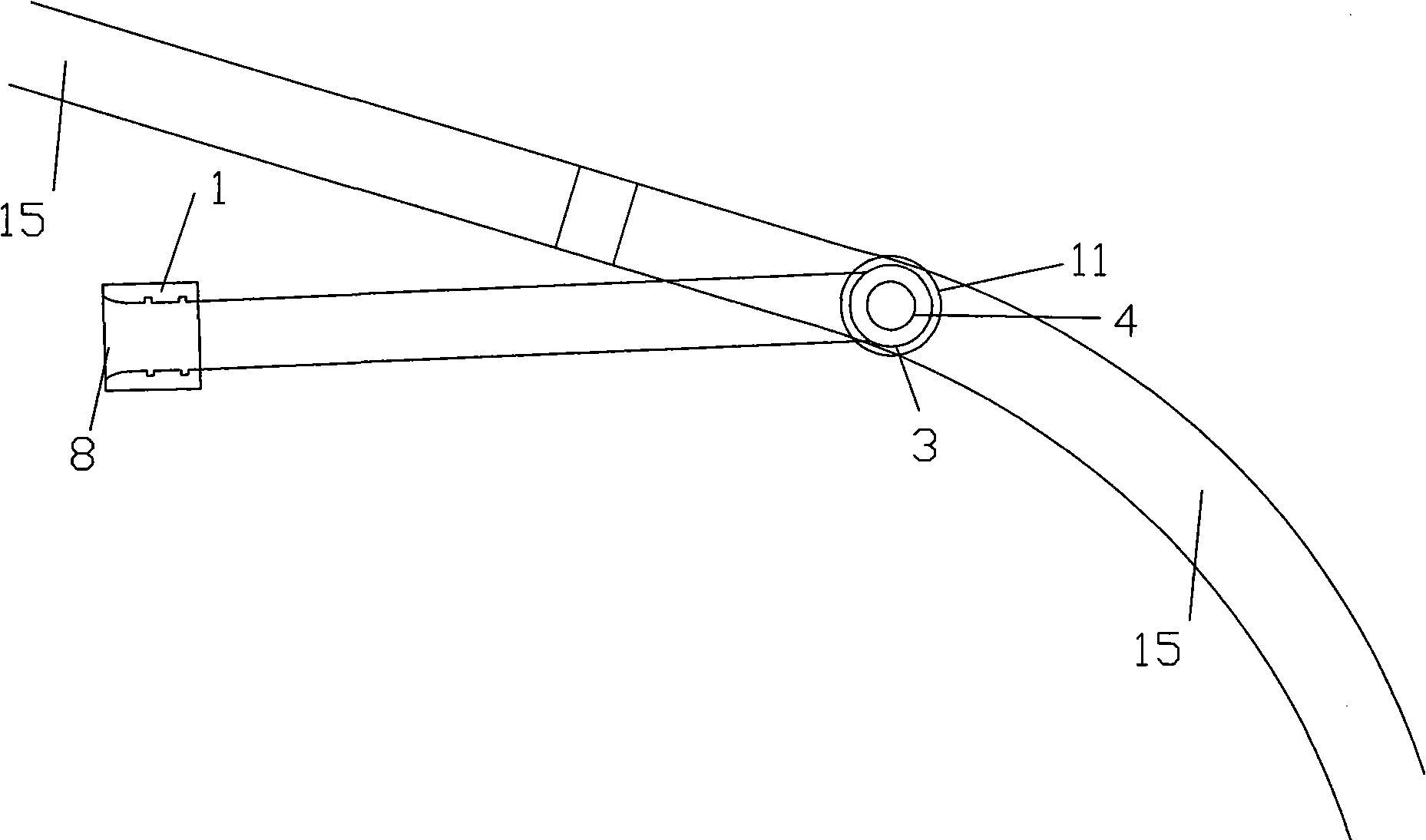

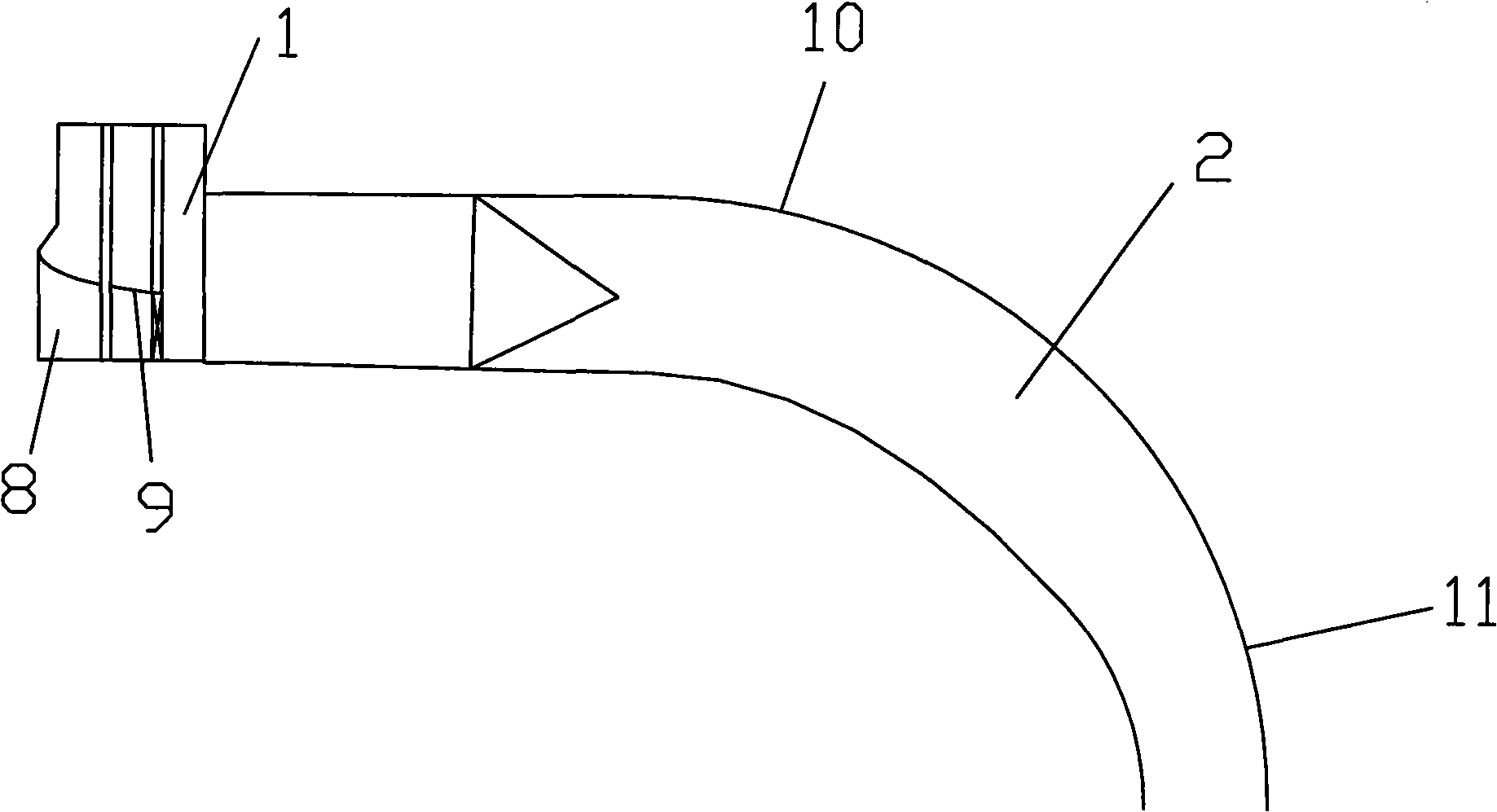

[0044] Such as figure 1 , 2 , 3, the embodiment of the present invention is to build a vertical shaft downstream of the water inlet end of the diversion tunnel. For the jet outlet, a plug is set in the first half of the diversion hole at the junction of the vertical shaft and the diversion hole to form a blind chamber.

[0045] The pressurized tunnel includes: a short pressure water inlet 1, a water diversion section 2, a water flow adjustment section 3, and a contraction section 4;

[0046] The shaft includes a shaft section 5, a shaft tunnel connection section 6, and a diversion tunnel section 7;

[0047] The short pressure water inlet 1 described therein comprises a port 8 and a pressure plate 9, the top and side curves of the port 8 are all elliptic curves, the major axis of the elliptic curve at the top is taken as the height of the orifice, and the minor axis is taken as 0.35 times the height of the orifice. The height of the orifice, the slope of the pressing plate 9...

Embodiment 2

[0065] The structure and implementation method of this embodiment are the same as in Embodiment 1, and the calculation method is as follows:

[0066] (1) Calculate the size of the short pressure inlet 1 according to the designed flood discharge flow;

[0067] Design flood flow Q 设 =2553m 3 / s, μ=0.96-0.12h / b+0.01H / h=0.913, the calculated size of short pressure water inlet 1 is h=10m, b=14m;

[0068] (2) Calculate the parabolic segment 10 coefficient according to the average velocity of the water flow;

[0069] Check the flood discharge flow as Q 校 =2741m 3 / s, calculated According to the test, the flow rate correction coefficient obtained is c=1.18, and the parabolic segment 10 coefficient a=g / (2c 2 V 2 ) = 0.0092;

[0070] (3) Calculate the outlet diameter of the shrinkage section 4 according to the flood discharge flow;

[0071] The outlet diameter of the contraction section 4 is D=α(Q 校 2 / g) 1 / 5 =1.2×(2741 2 / 9.8) 1 / 5 =18m;

[0072] (4) Determine the height...

Embodiment 3

[0075] The structure and implementation method of this embodiment are the same as in Embodiment 1, and the calculation method is as follows:

[0076] (1) Calculate the size of the short pressure inlet 1 according to the designed flood discharge flow;

[0077] Design flood flow Q 设 =2553m 3 / s, μ=0.96-0.12h / b+0.01H / h=0.913, the calculated size of short pressure water inlet 1 is h=10m, b=14m;

[0078] (2) Calculate the parabolic segment 10 coefficient according to the average velocity of the water flow;

[0079] Check the flood discharge flow as Q 校 =2741m 3 / s, calculated According to the test, the flow rate correction coefficient obtained is c=1.18, and the parabolic segment 10 coefficient a=g / (2c 2 V 2 ) = 0.0092;

[0080] (3) Calculate the outlet diameter of the shrinkage section 4 according to the flood discharge flow;

[0081] The outlet diameter of the contraction section 4 is D=α(Q 校 2 / g) 1 / 5 =1.5×(2741 2 / 9.8) 1 / 5 =22.5m;

[0082] (4) Determine the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com