Connecting component of combined frame

A combined frame and component technology, applied in the direction of connecting components, furniture connections, building components, etc., can solve the problems of inconvenient assembly, inconvenient positioning under the partition board, inconvenient use, etc., and achieve the effect of reliable assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

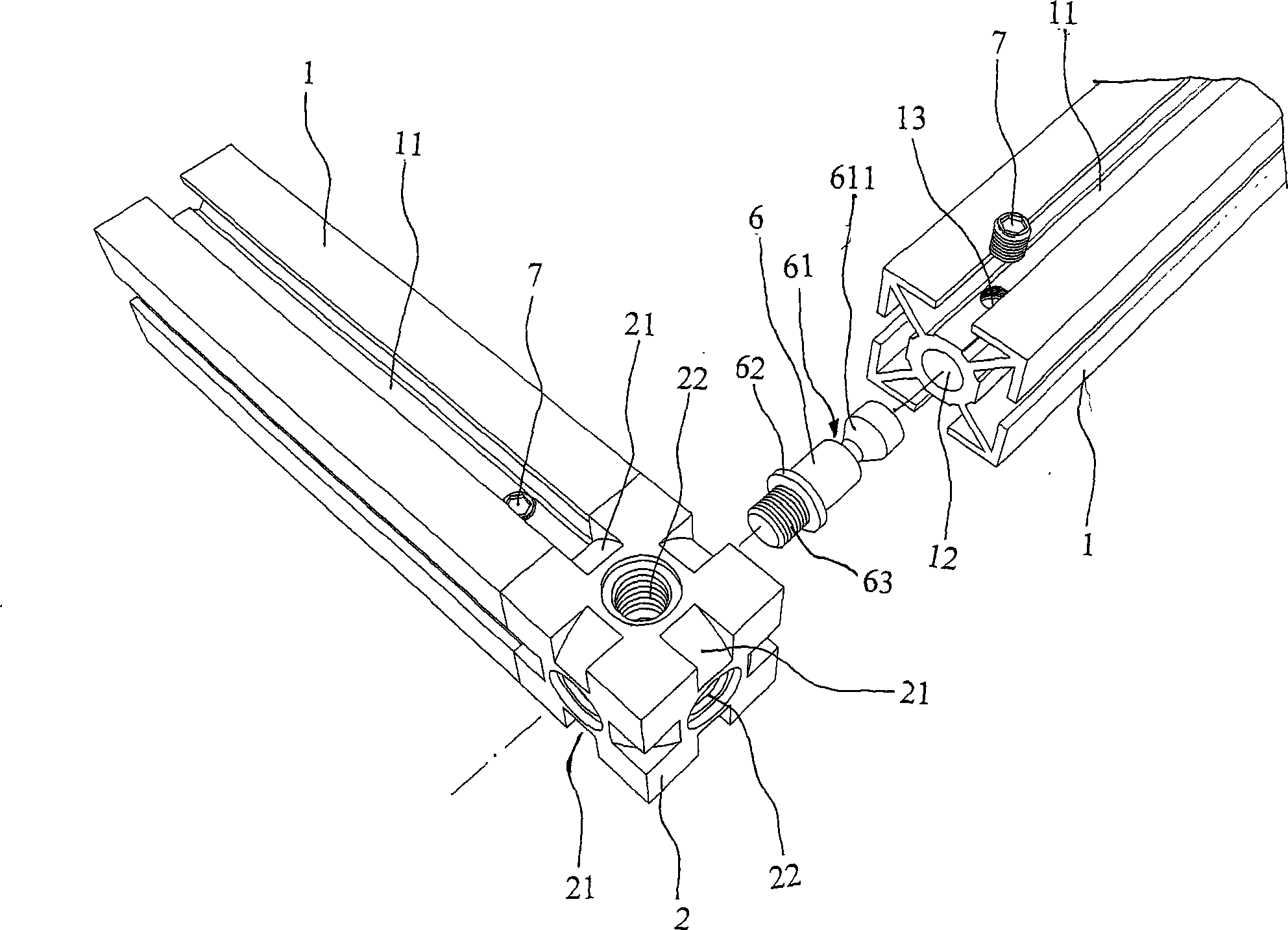

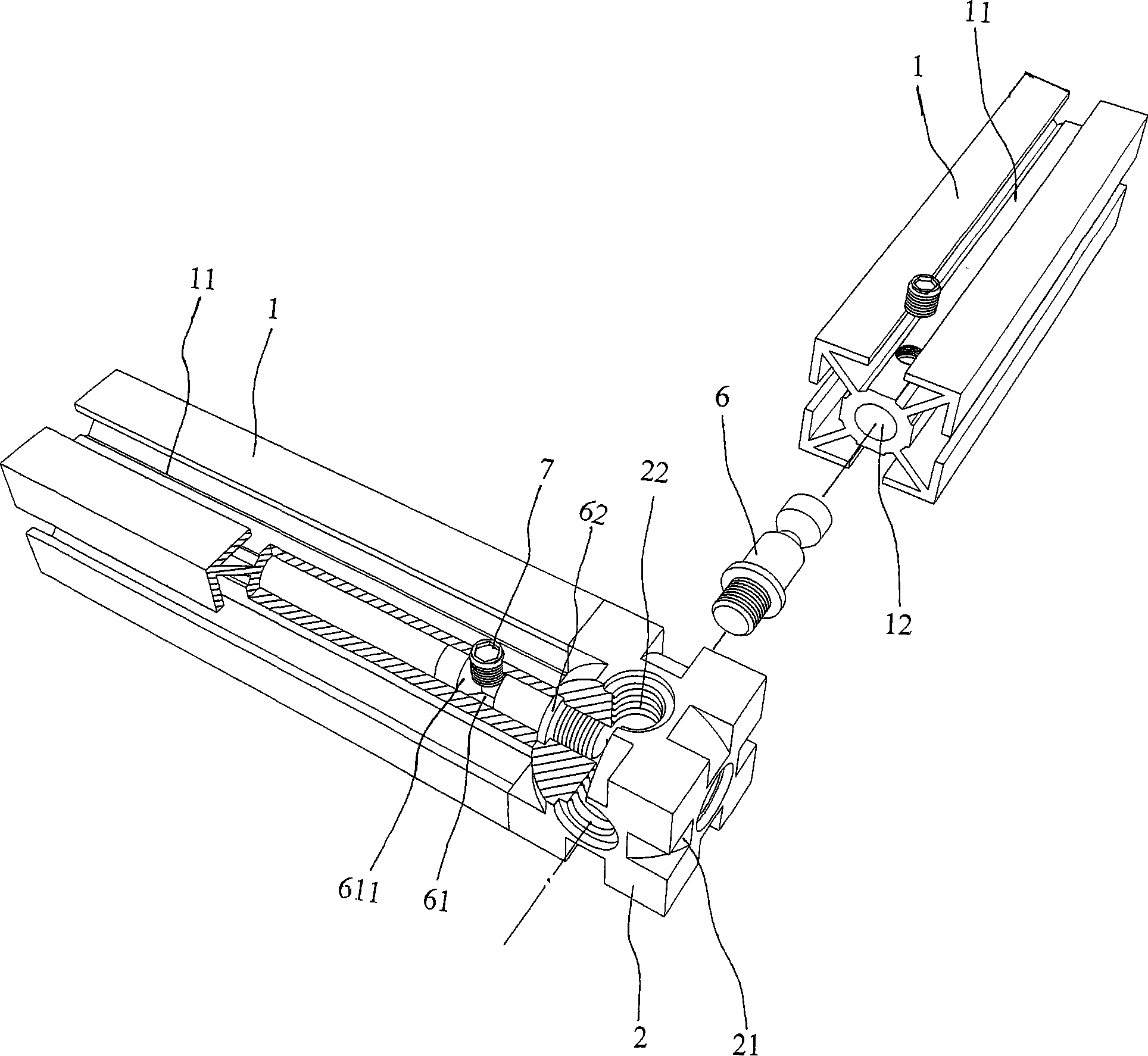

[0038] like Figure 1-13 Shown is the first embodiment of the present invention, a joint assembly of a combined frame, including a combined column 1 and a connecting head 2 for connecting the combined column 1 .

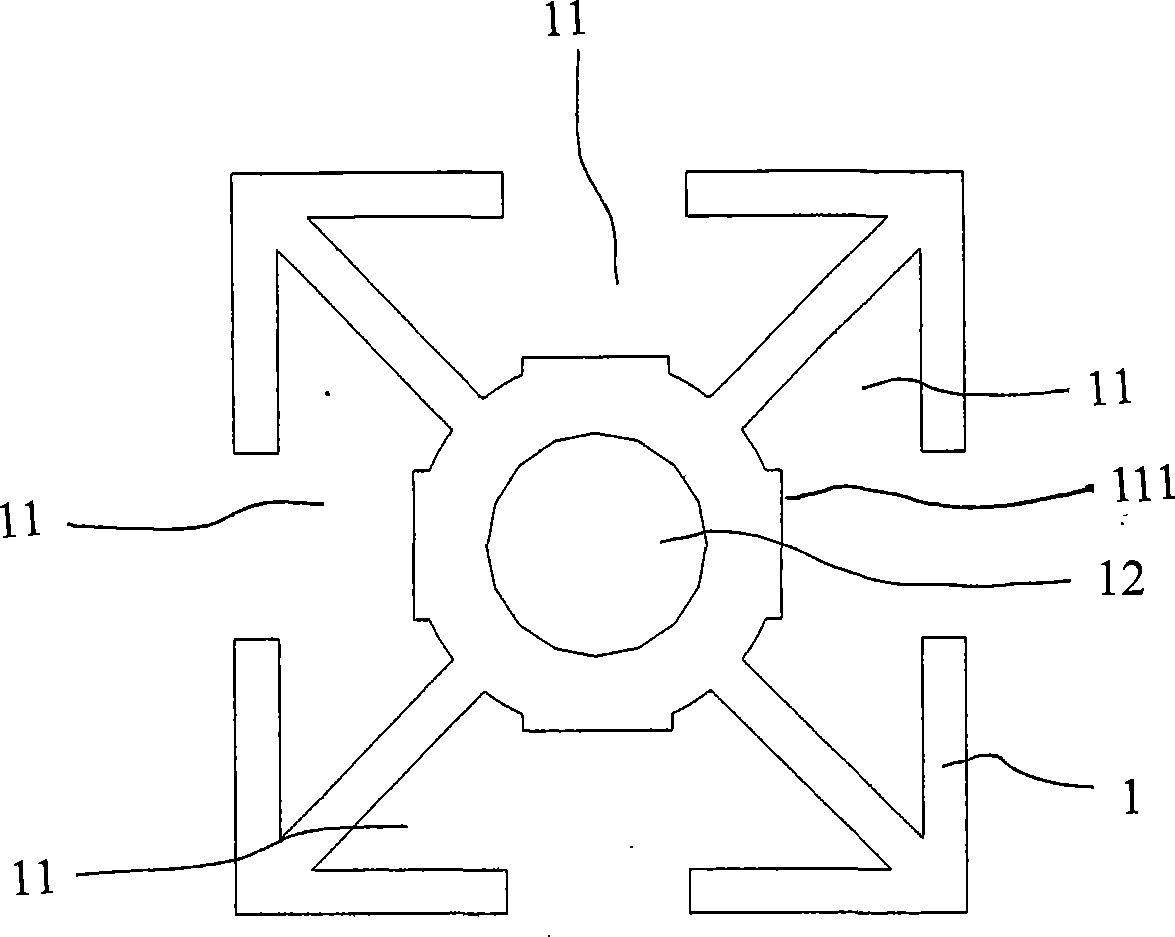

[0039] Wherein, the section of the combined column 1 is square and has four sides, that is, the combined column 1 is generally in the shape of a cuboid, and a through groove 11 with a certain width is formed on each side along the length direction of the combined column. Groove 11 is a dovetail groove, and the bottom of the dovetail groove is a plane.

[0040] The connector 2 has six outer surfaces matching the section of the composite column 1, that is, the connector 2 is generally in the shape of a cube, and the outer surface of the connector 2 is connected to the composite column 1 through a connecting structure.

[0041] The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com