Fluid operated linear motor

A linear drive, fluid technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of large investment costs for machines and personnel, and achieve the effect of reducing weight, simplifying assembly, and reducing external dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

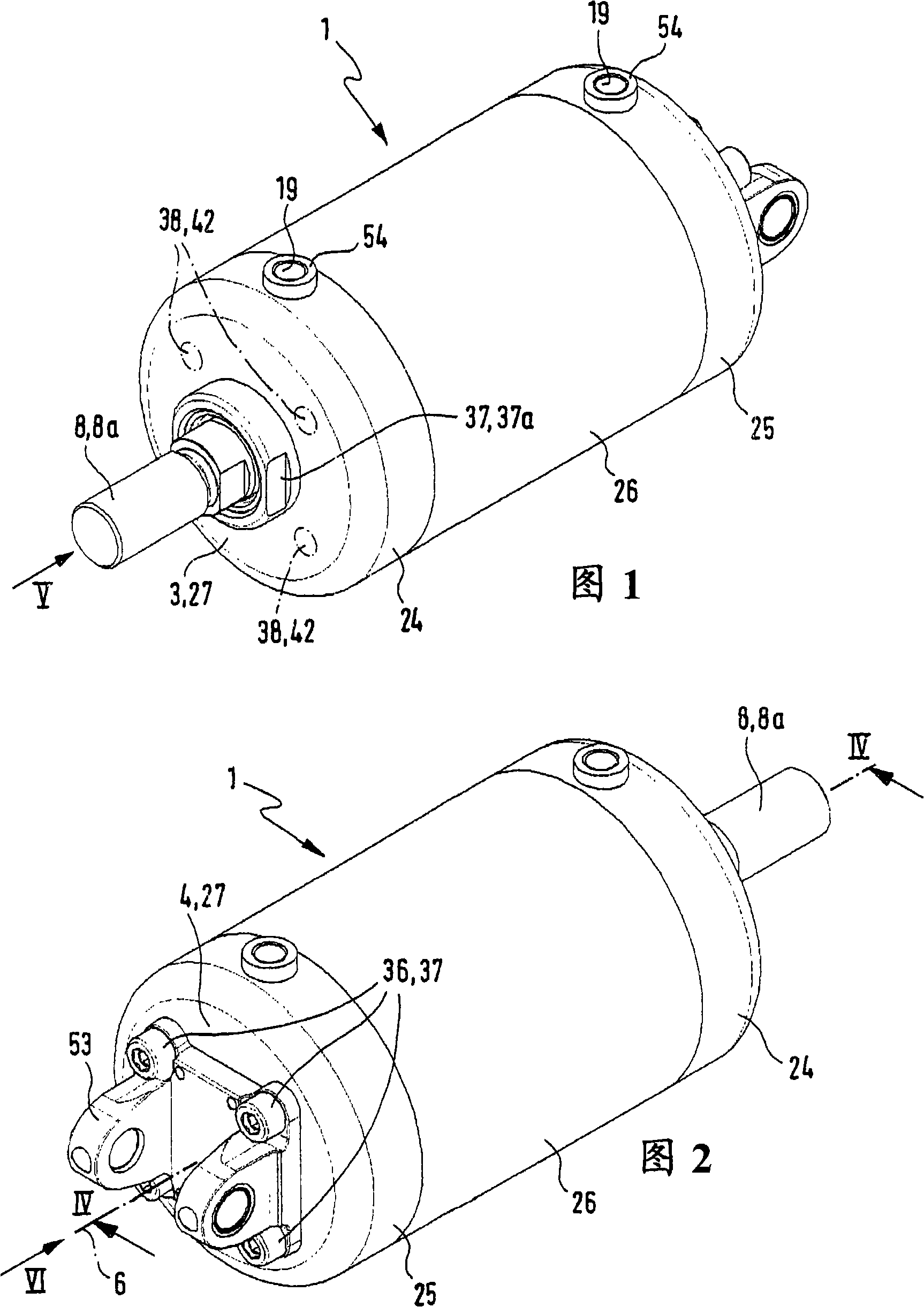

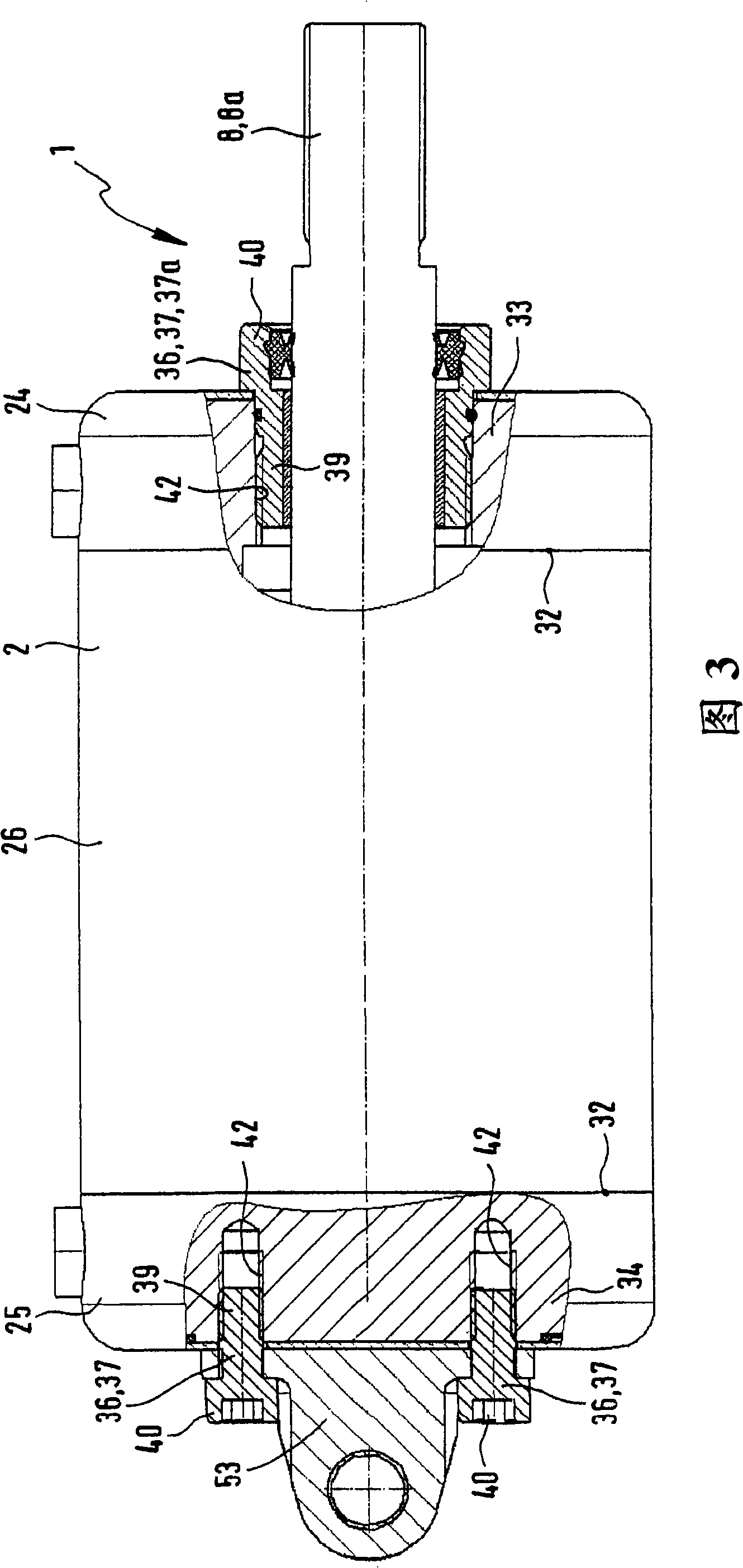

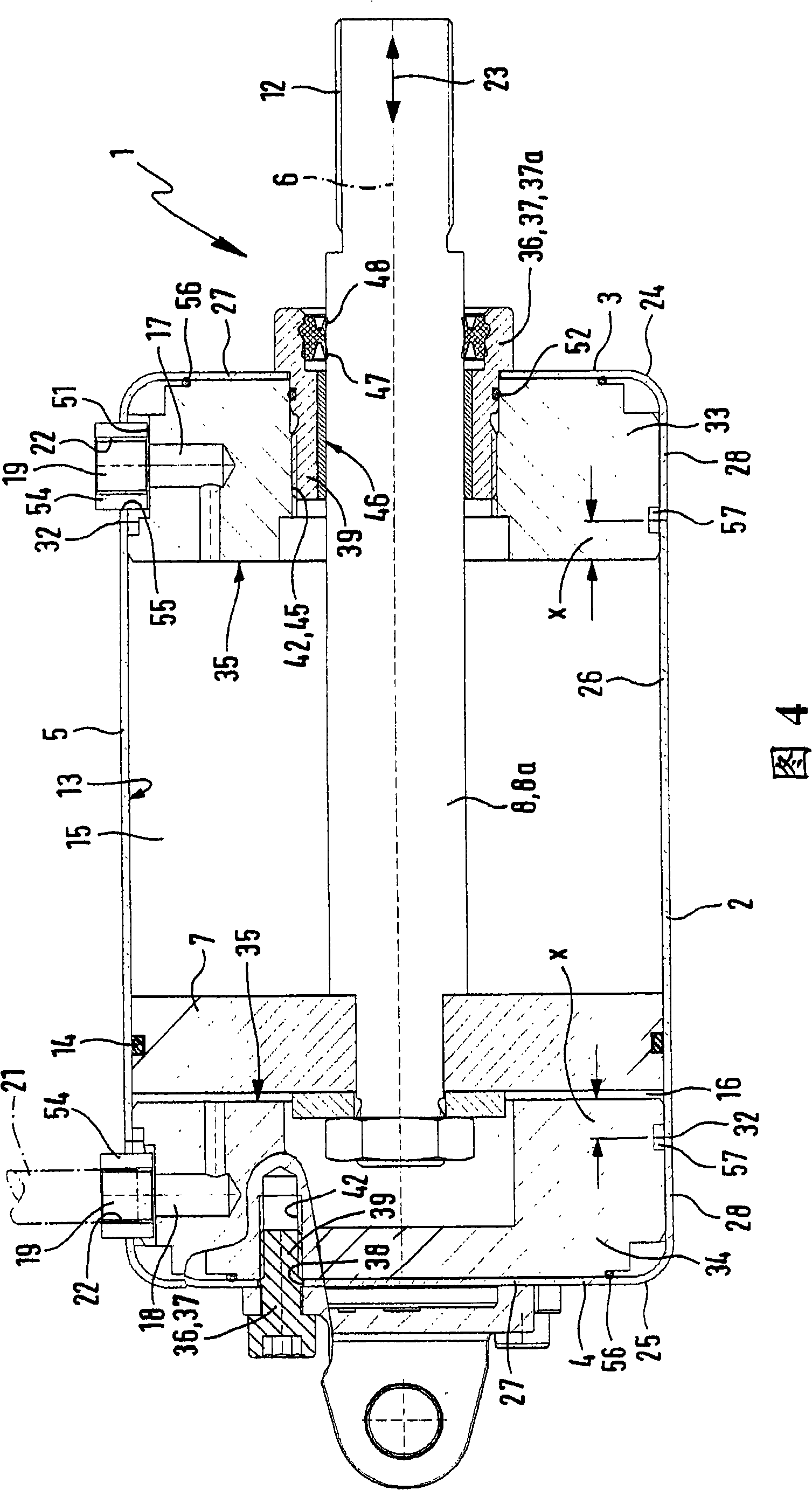

[0028] The linear actuator marked as 1 as a whole is driven by fluid power, and the driving medium may be a liquid medium or a gaseous medium. The medium is preferably compressed air.

[0029] The linear actuator 1 has an elongated housing 2 having a front end connecting wall 3 and a rear end connecting wall 4, and a tubular peripheral wall 5 extending axially between them. Preferably, the housing 2 is cylindrical as a whole and particularly cylindrical.

[0030] A piston 7 is provided inside the housing, and the piston 7 slides linearly in the direction of the longitudinal axis 6 of the housing 2 and is movably coupled with a drive output portion 8 contactable from the outside of the housing 2. The output drive part 8 is preferably a piston rod 8a, which extends in the outward direction through the front end wall 3 and its part located on the outside of the housing 2 is provided with a male thread 12 or some other attachment mechanism on which The member to be displaced or positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com