Phase change material heat exchanger

A phase change material and heat exchanger technology, applied in indirect heat exchangers, heat exchanger types, heat storage equipment, etc., can solve the problems of uneconomical and low efficiency of cooling/heating large space, and achieve stable energy efficiency in seasons , high efficiency, the effect of reducing the peak load of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

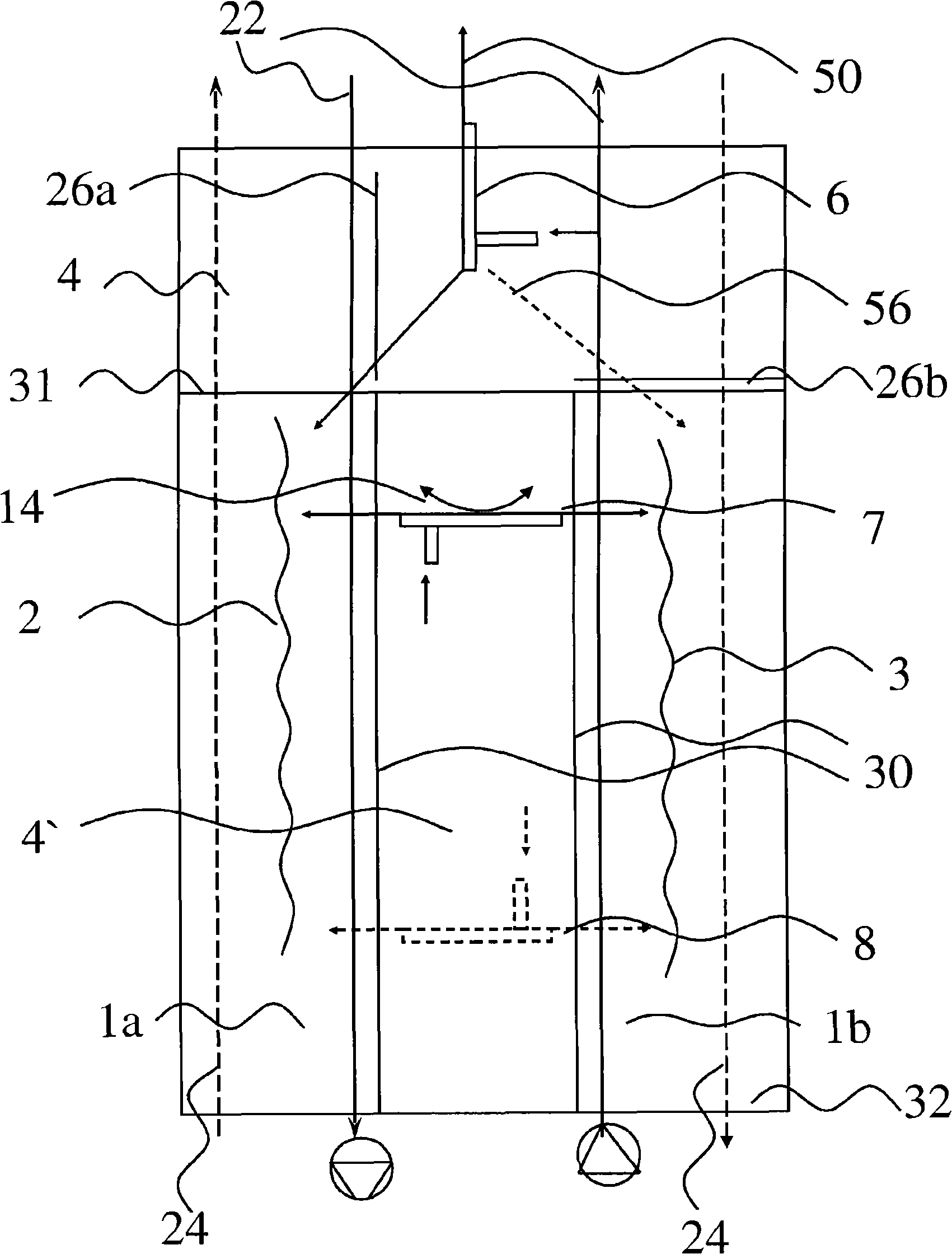

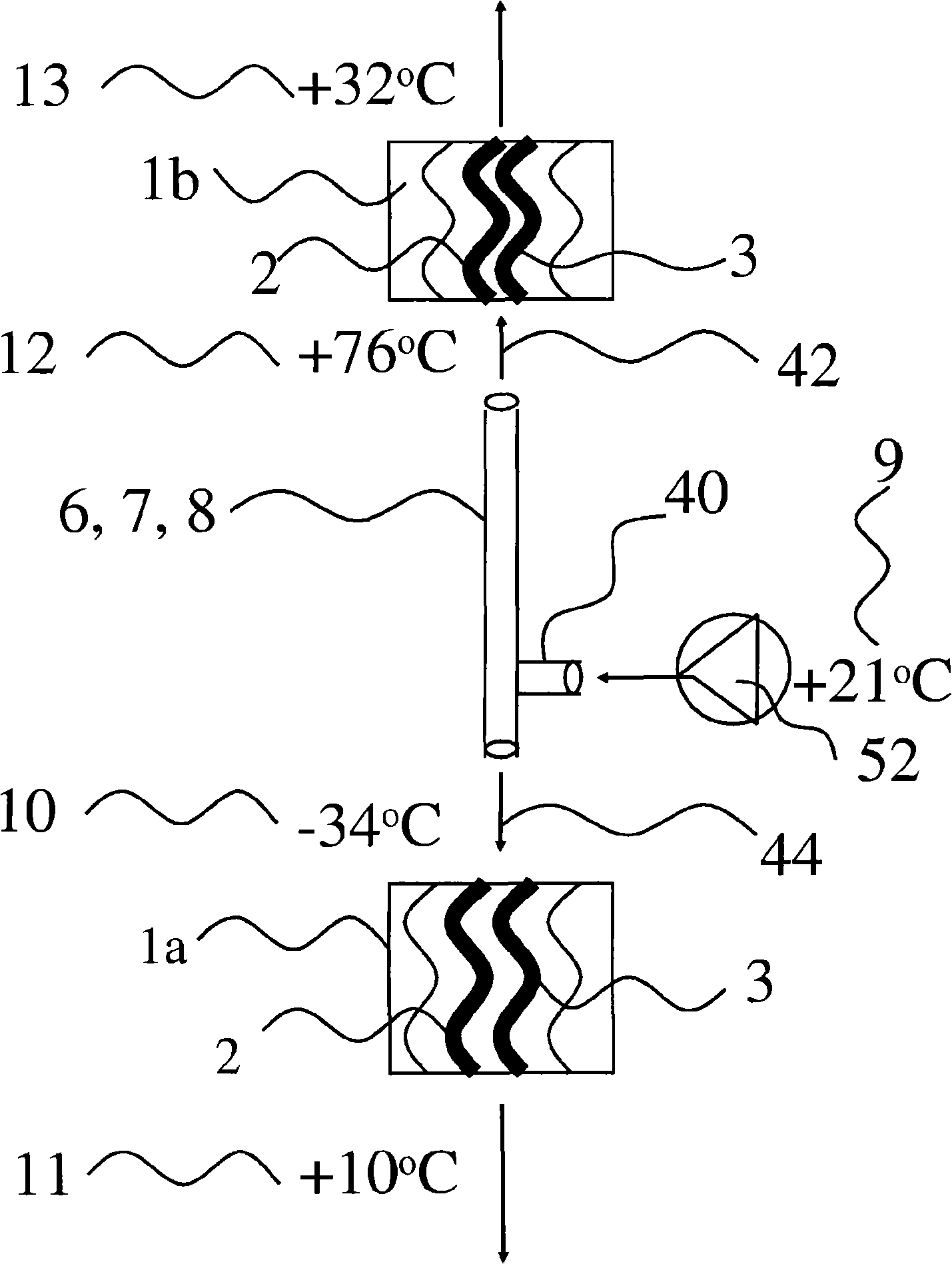

[0028] Such as figure 1 It can be seen that the PCM heat exchanger arrangement according to the invention comprises at least two regenerative heat exchanger units 1a and 1b operating according to the principle of regenerative counter-flow, through which the air, gas or liquid flow follows Alternating and alternately reversed opposite flow directions are directed into and out of the device. Air flow is indicated by arrows 22 and 24 . The solid arrows 22 show the air flow in one cycle and the dashed arrows 24 show the air flow in the second cycle. The change of direction of the air flow in the units 1a and 1b can be achieved by means of known technical devices, such as diverters, fans, reflectors, flaps, or wheel diverters. These known art devices for changing the direction of the air flow in the units 1a and 1b are shown schematically by means of parts 26a and 26b.

[0029] Alternatively, as a variation on the air flow to two units, a single rotary type recuperator could be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com