Multifunctional and composite type foam-preventing recovery device for biofermentation

A technology of biological fermentation and recovery device, which is applied in biochemical cleaning device, enzymology/microbiology device, bioreactor/fermenter combination, etc. production, increase the resistance of stirring operation, etc., to eliminate living organisms and other sources of pollution, achieve significant energy-saving effects, and increase the output of the tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

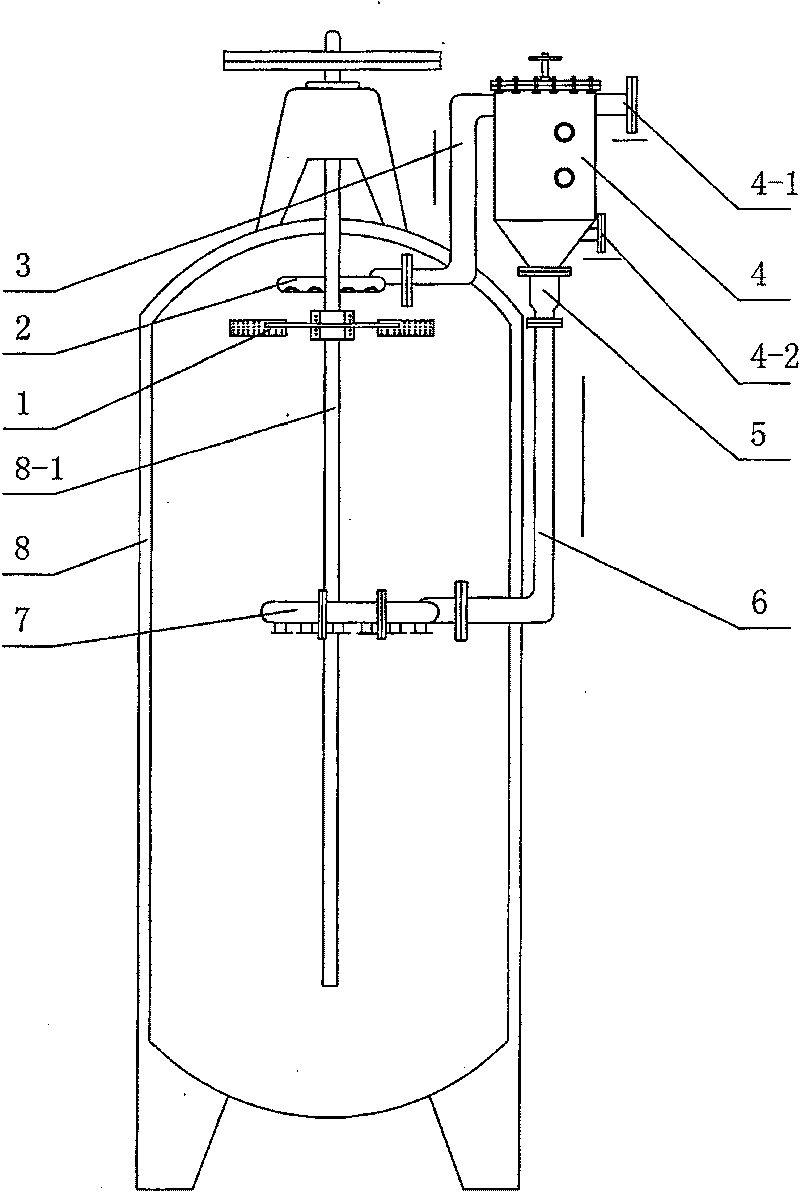

[0030] The anti-foam recovery device for multifunctional composite biological fermentation of the present invention comprises the following equipment:

[0031] a. A new type of foam arrester

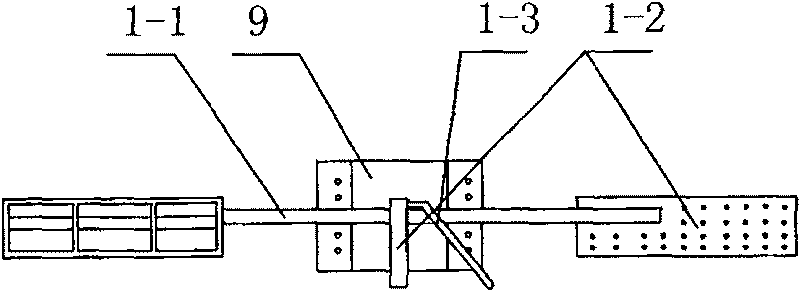

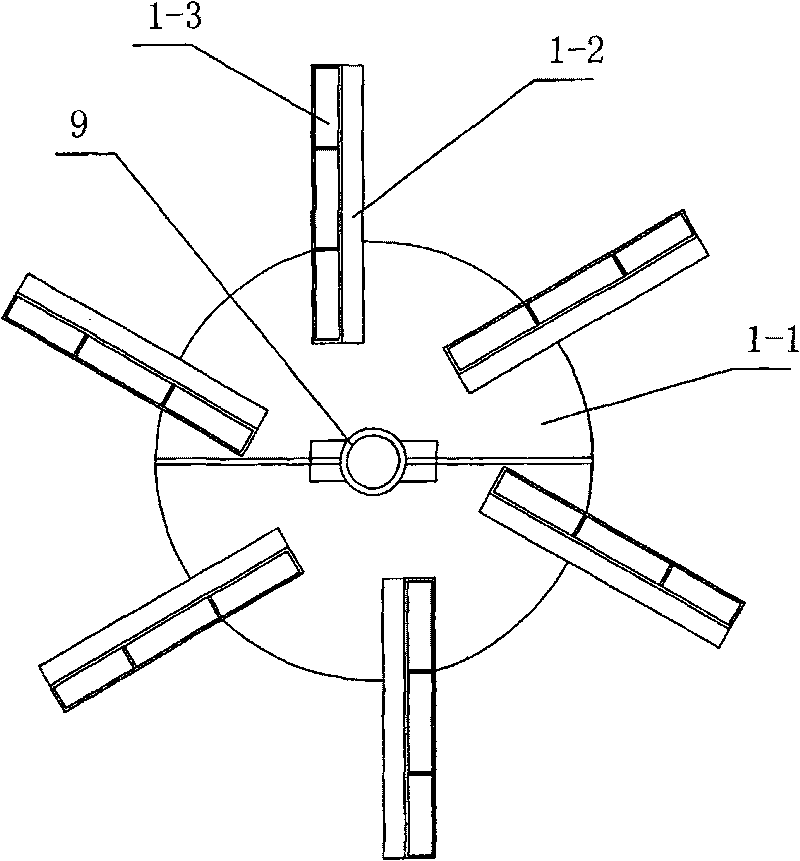

[0032]The novel foam arrester 1 includes a center plate 1-1 and several foam arrestors 1-2. There are six foam arrestors 1-2, which are fastened and evenly installed on the outside of the center plate 1-1 in a sunken type close to the top edge. on the ring. The anti-foam board 1-2 is a cavity structure, and its lower bottom surface adopts the principle of linear acceleration and is densely covered with variable-diameter diversion acceleration holes, and the rear side can also be installed with an empty frame loose-leaf steering baffle 1-3. Described empty frame loose-leaf turning baffle 1-3 is made up of A-type baffle frame 1-31 and the loose-leaf liftable piece 1-32 that is built-in and fixed on it. A shaft sleeve 9 is installed in the center of the center disc 1-1. The novel foam ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com