Compliance regulation means of suspension clearance and control current of electromagnetic type maglev train

A technology for controlling current and maglev trains, applied in electric vehicles, electric traction, vehicle components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

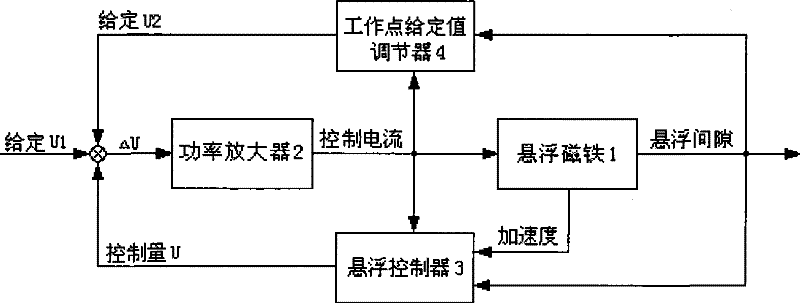

[0017] see figure 1 , The levitation control unit of the present invention is composed of a levitation magnet 1, a power amplifier 2, a levitation controller 3 and an operating point given value regulator 4. The specific connection relationship is that the levitation controller 3 receives the levitation gap signal, acceleration signal and control current signal, and outputs the control value U signal; the working point given value regulator 4 receives the control current signal and the levitation gap signal, After the curve function is calculated, the given U2 signal is output; the suspension magnet 1 receives the control current signal, and outputs the suspension gap signal and the acceleration signal; the power amplifier 2 receives the ΔU signal, which is composed of the given U1 signal, the given U2 signal and the control value U signal Superimposed, the output control current signal. Wherein, the given U1 signal is an external input signal, and the suspension gap signal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com