Expanding cavity adjustable exhaust silencer

A technology for exhaust mufflers and expansion chambers, which is applied in the direction of exhaust devices, noise reduction devices, machines/engines, etc. It can solve the problems that the muffler cannot achieve low-frequency noise reduction, achieve internal structure stability, reduce the generation of regenerative noise, and The effect of the low frequency noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

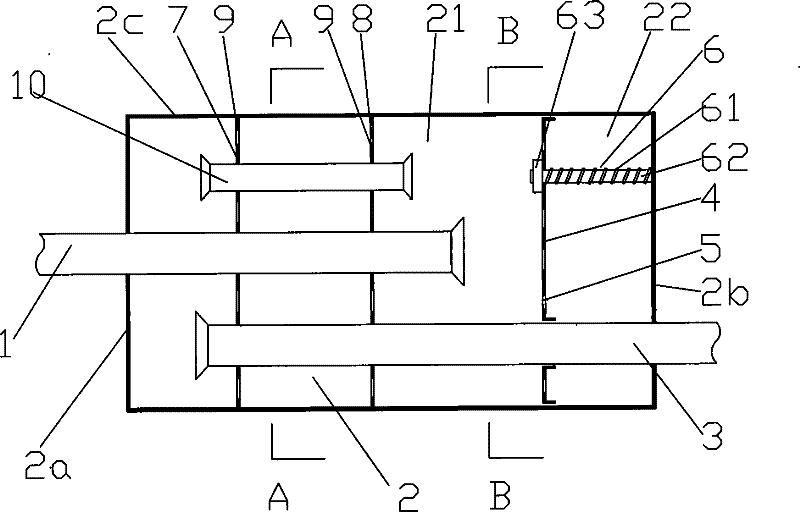

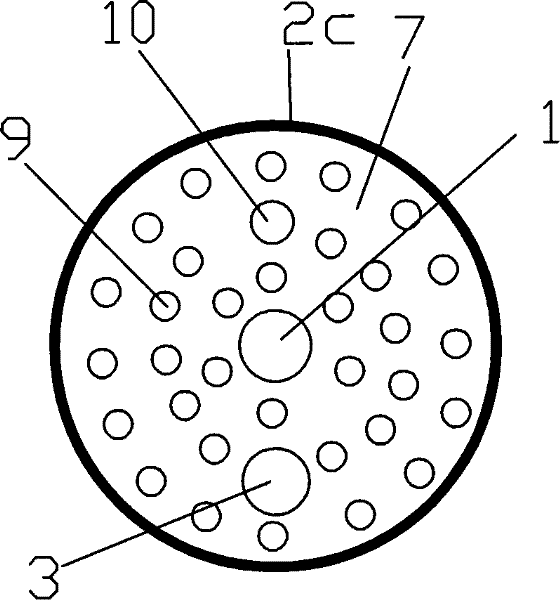

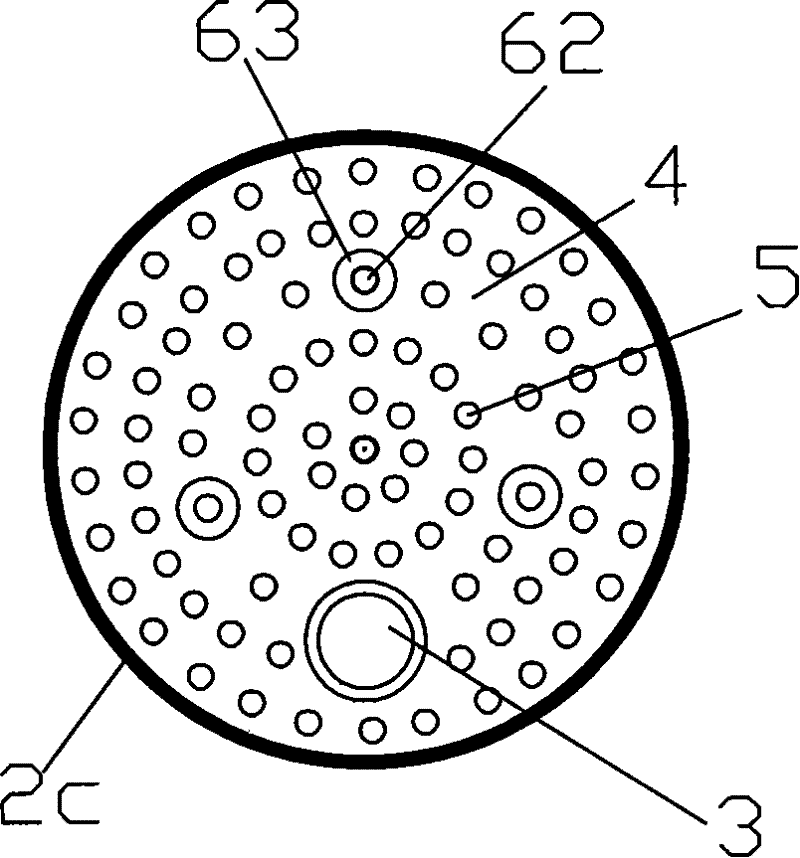

[0024] figure 1 It is a structural schematic diagram of Embodiment 1 of the present invention, figure 2 for figure 1 Sectional view along A-A direction; image 3 for figure 1 Section view along B-B direction; as shown in the figure, the exhaust muffler with adjustable expansion chamber of the present invention includes an intake pipe 1, an expansion chamber 2 and an exhaust pipe 3, and the expansion chamber 2 includes a chamber wall 2c, a front end cover 2a and a rear The end cap 2b, the expansion cavity 2 is provided with a movable partition 4 transversely perpendicular to the cavity wall 2c, the movable partition 4 divides the expansion cavity 2 into a cavity I 21 and a cavity II 22, and the passage between the cavity I 21 and the cavity II 22 A plurality of resonance holes 5 are connected, and the resonance holes 5 of the present embodiment are arranged on the movable partition 4; the air outlet of the air intake pipe 1 and the air inlet of the exhaust pipe 3 are arrang...

Embodiment 2

[0028] Figure 4 It is a schematic structural diagram of Embodiment 2 of the present invention, Figure 5 for Figure 4 As shown in the sectional view along the direction C-C, the difference between this embodiment and the first embodiment is that the resonance hole 5 is arranged on the pipe section where the exhaust pipe 3 passes through the chamber II 22 .

[0029] Certainly, locking device 63 is not limited to nut, can also be the locking mechanisms such as elastic clasp or pin; Elastic preload device 6 is not limited to three, also can be one or more; Can realize invention Purpose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com