Tepid environment universal sheet shaping test machine

A sheet metal forming and testing machine technology, applied in the direction of using mechanical devices, analyzing materials, strength characteristics, etc., can solve the problems that the sheet metal simulation forming performance test cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

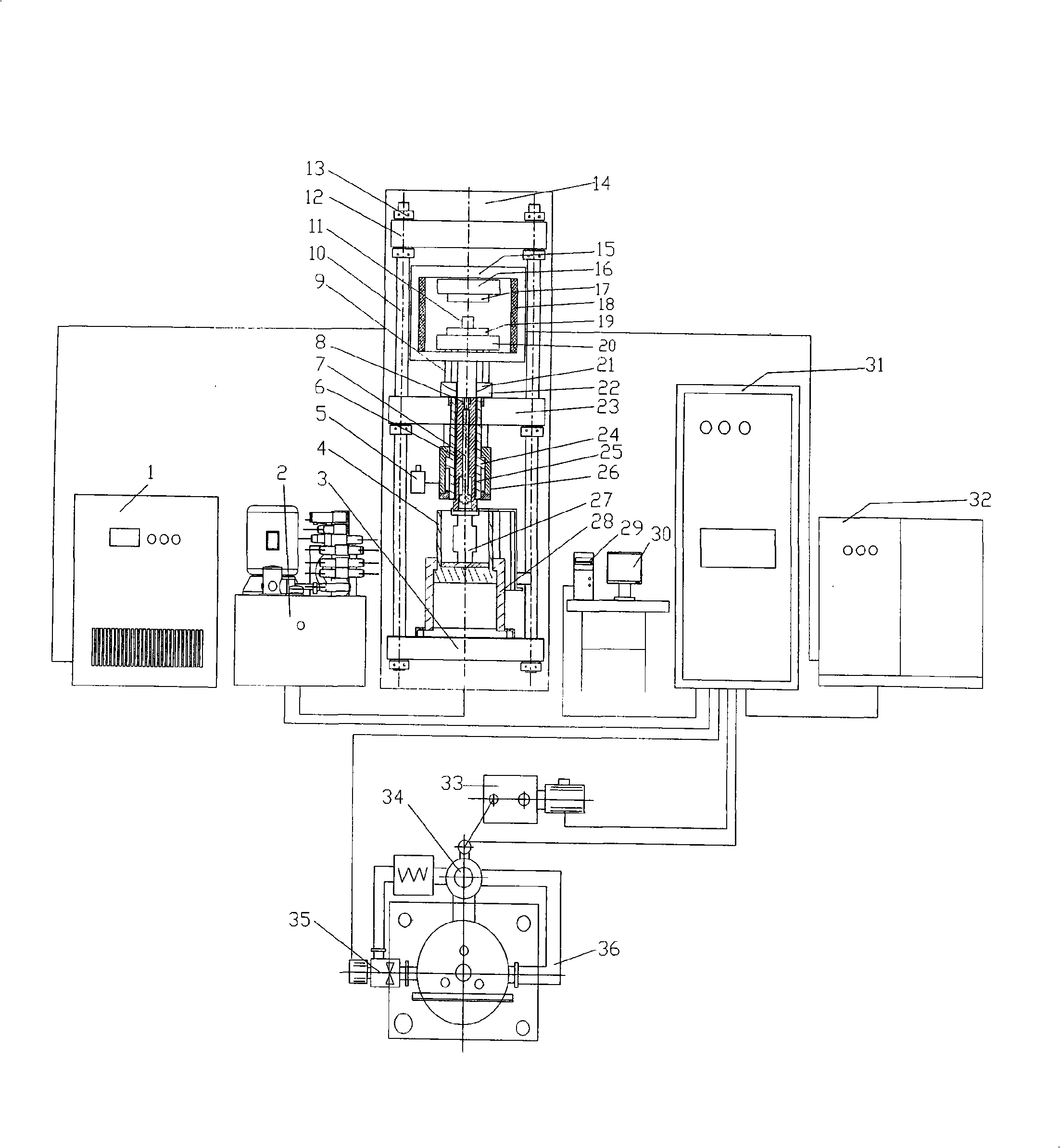

[0029] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] As shown in Fig. 1, a kind of warm environment universal plate formability testing machine of the present invention, it specifically comprises:

[0031] The main engine 14 is composed of a lower beam 3, a middle beam 23, an upper beam 12, four columns 10 and several nuts 13. The main cylinder 28 is installed on the lower beam 3, and together with the main cylinder piston 4, it forms a main piston that can realize reciprocating motion. Cylinder, main oil cylinder piston 4 is installed with force sensor 27, main oil cylinder piston rod 6, punch 11 sequentially from bottom to top; edge holder cylinder 26 is installed under the middle crossbeam 23, forms together with edge holder cylinder piston 24 and can realize reciprocating Moving blankholder piston cylinder, blankholder cylinder piston 24 is installed with blankholder spherical support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com