Retardation compensation element and manufacturing method of the same

一种补偿元件、制造方法的技术,应用在光学元件、偏振元件、光学等方向,能够解决降低对比度、不能避免显示图像质量降低等问题,达到相位差补偿作用改善的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

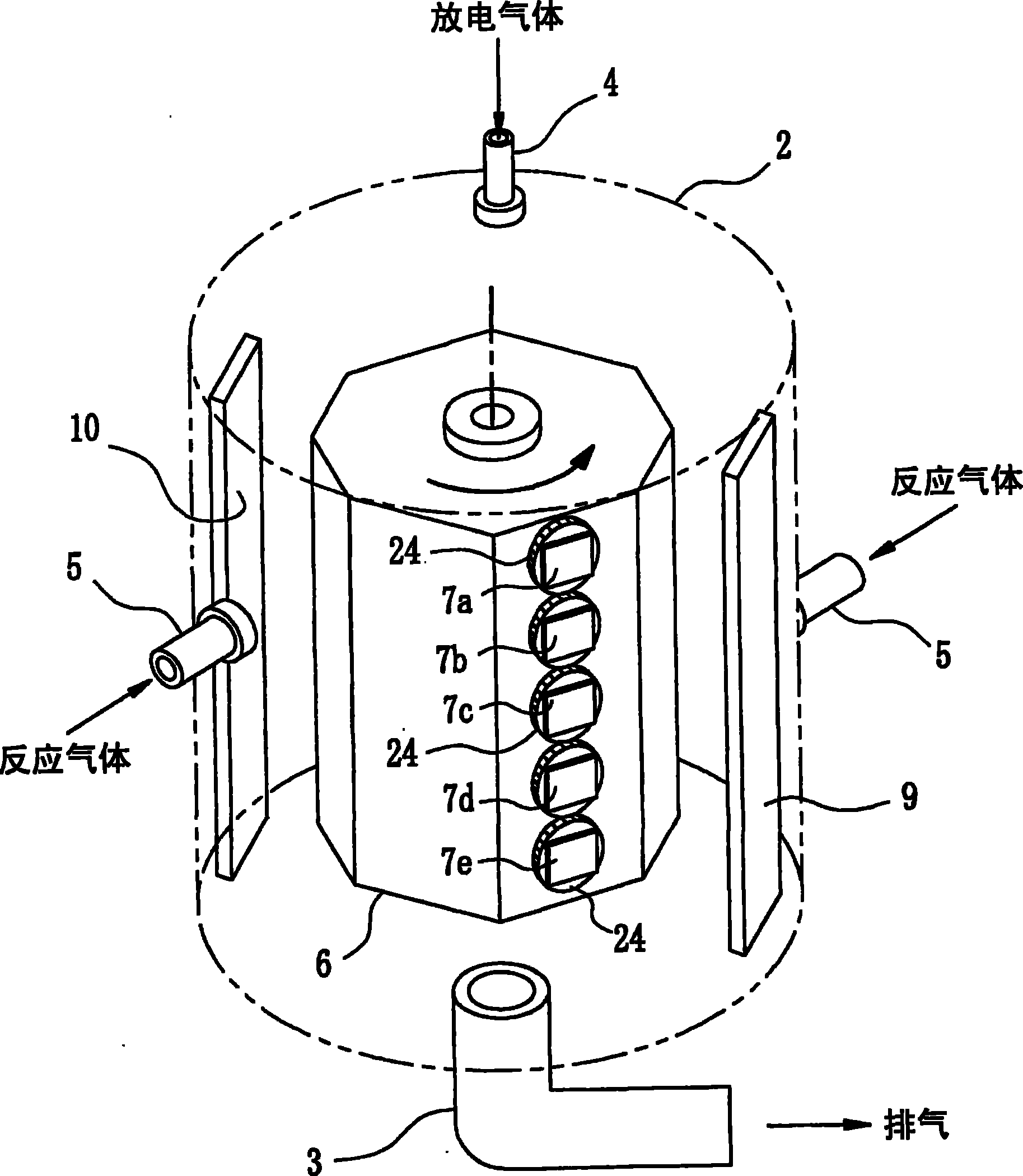

[0032] The phase difference compensation element of the present invention is composed of, for example, figure 1 The sputtering device shown is manufactured. The sputtering device, although its structure is basically Figure 7 The conventional device shown is the same, but the drum body 6 supporting the substrate 7 is provided with a mechanism for rotating the substrate 7 around its normal line. In addition, a freely rotatable substrate holder 24 is provided on the outer peripheral surface of the drum body 6, and the substrate holder 24 holds five substrates 7a-7e, and these substrates 7a-7e can surround it as the substrate holder 24 rotates 90° The normal is rotated by 90°. In addition, the 90° rotation direction may be either clockwise or counterclockwise.

[0033] The other components of the sputtering device and Figure 7 The conventional device shown is the same, and the target material 9 uses Nb with high refractive index. 2 O 5 The film-forming material Nb, the target mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com