Manufacturing method of laminated film

一种薄膜、环氧树脂的技术,应用在化学仪器和方法、层压、分层产品等方向,能够解决运转费用上升、加热烤箱长、偏振镜薄膜或保护薄膜光学补偿薄膜变形等问题,达到有效制造、简便制造的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example A~F

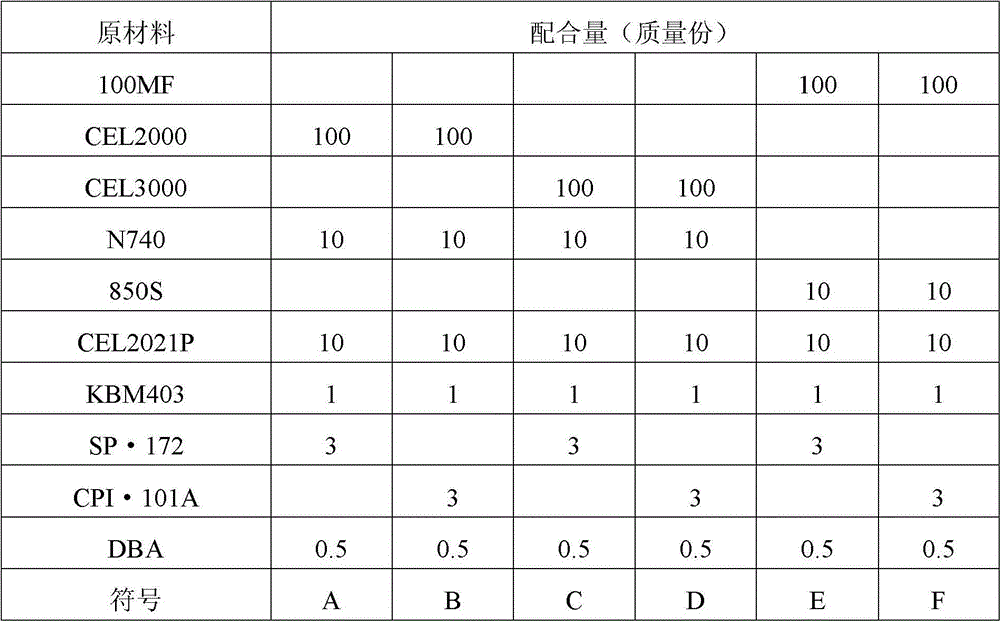

[0069] Production Examples A-F Preparation of Photocurable Epoxy Resin Adhesives

[0070] The following raw materials were measured and added to a container made of polyethylene, and mixed and stirred with a mixer to obtain a uniform photocurable epoxy resin adhesive (viscosity: 150 mPa / s (25° C.)).

[0071] [Table 1]

[0072]

[0073] 100MF: Trimethylolpropane triglycidyl ether, Kyoyoung Chemical Co., Ltd.

[0074] Epichrome EXA-850S: 4,4'-diglycidyloxy-2,2'-diphenylpropane, Dainippon Ink Chemical Co., Ltd.

[0075] Epichrome N740: Phenol Novolak Type Epoxy Oligomer, Dainippon Ink Chemicals Co., Ltd.

[0076] CEL2000: 1,2-epoxy-4-vinylcyclohexane, Daicel Chemical Industry Co., Ltd.

[0077] CEL3000: 1, 2: 8, 9 Diepoxylimonene, Daicel Chemical Co., Ltd.

[0078] CEL2021P: 3,4-epoxycyclohexenylmethyl-3',4'-epoxycyclohexene carboxylate, Daicel Chemical Co., Ltd.

[0079]CPI-101A: Photopolymerization Catalyst Sunapro Co., Ltd.

[0080] SP-172: Photopolymerization catalys...

Embodiment 1~6 and comparative example 1~3

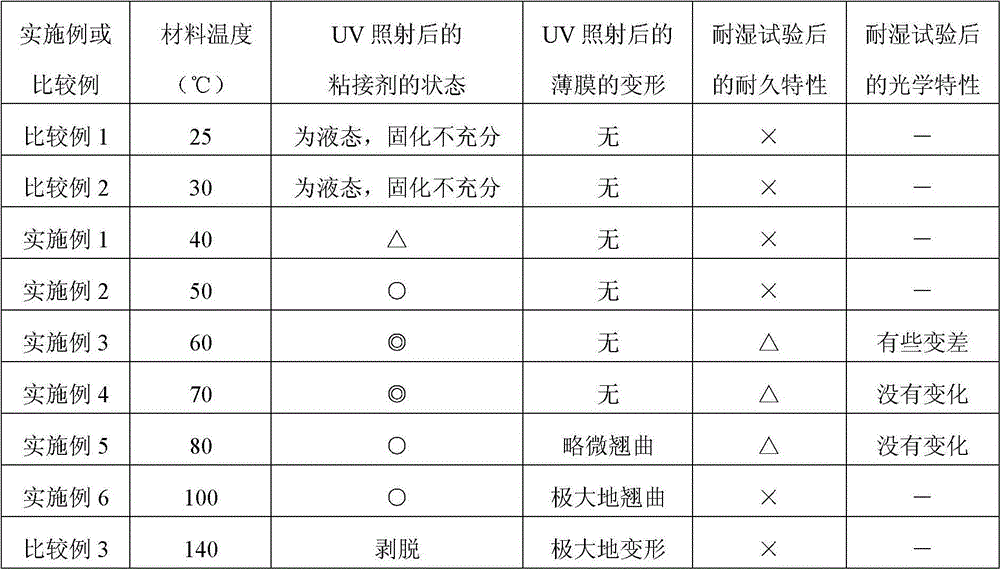

[0083] Production of Laminated Films (Polarizers) of Examples 1-6 and Comparative Examples 1-3

[0084] By means of the photocurable epoxy resin adhesive (symbol: A) prepared in the production example, a triacetyl cellulose film was bonded to one side of a polyvinyl alcohol polarizer film that was uniaxially stretched and dyed with iodine, An amorphous polyolefin-based resin film (Zionoa Film manufactured by Nippon Zeon Co., Ltd.) was bonded to the other surface to obtain a film having a three-layer structure. Using an infrared lamp, heat the obtained three-layer structure film to room temperature (25°C), 30°C, 40°C, 50°C, 60°C, 70°C, 80°C, 100°C, 120°C, and 140°C, and use it immediately Metal halide lamp (manufactured by Aigrafix Co., Ltd.), with an irradiation intensity of 200 mW / cm 2 (405nm), cumulative light intensity 1000mJ / cm 2 (405 nm), light irradiation was performed to obtain a laminated film. The adhesive layer between the laminated films has a uniform thickness o...

Embodiment 7~13

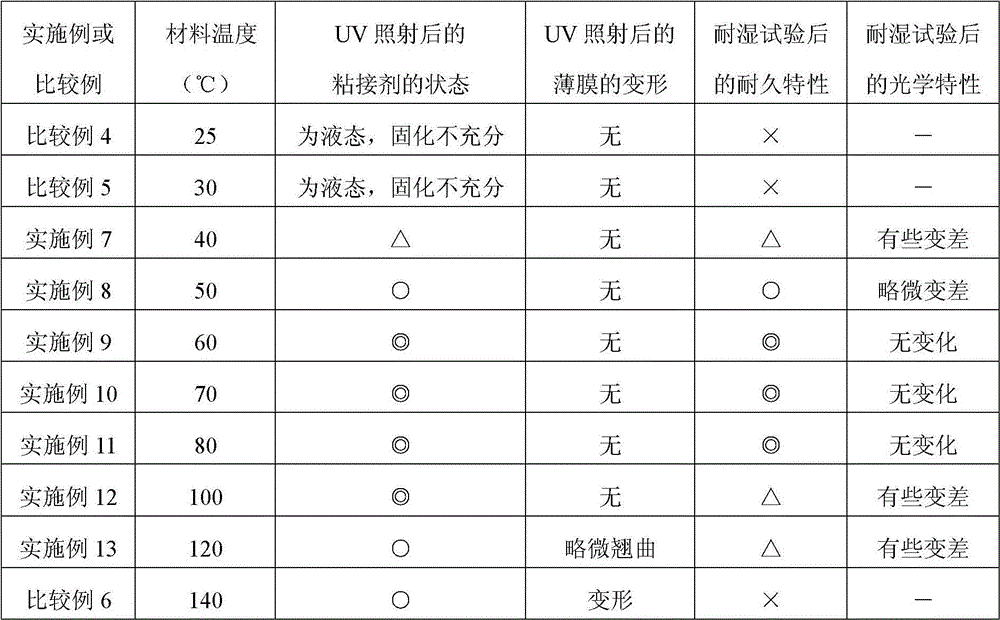

[0109] Manufacture of Laminated Films of Examples 7-13 and Comparative Examples 4-6

[0110] In the manufacture of the laminated films of Examples 1 to 6 and Comparative Examples 1 to 3, between the metal halide lamp and the adherend film, an optical filter (Aigraficus Corp. system), and irradiate light. In the same manner as in Examples 1 to 6 and Comparative Examples 1 to 3, laminated films of Examples 7 to 13 and Comparative Examples 4 to 6 were obtained, respectively.

[0111] [table 3]

[0112]

[0113] As can be seen from Table 3, if an optical filter with a cutoff wavelength below 390nm is arranged between the metal halide lamp and the adherend, then compared with the case where no arrangement is made, the polarizer and the film will have less denaturation, and an optical filter with Laminated film with good adhesion and durability characteristics. Even if instead of a filter with a cutoff wavelength of 390nm or less, a filter with a cutoff wavelength of less than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com