Novel continuous jet cooling quenching machine for steel tubes

A continuous, quenching machine technology, applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of high degree of specialization and large investment, and achieve the effect of good environmental conditions, low investment cost, and rapid loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

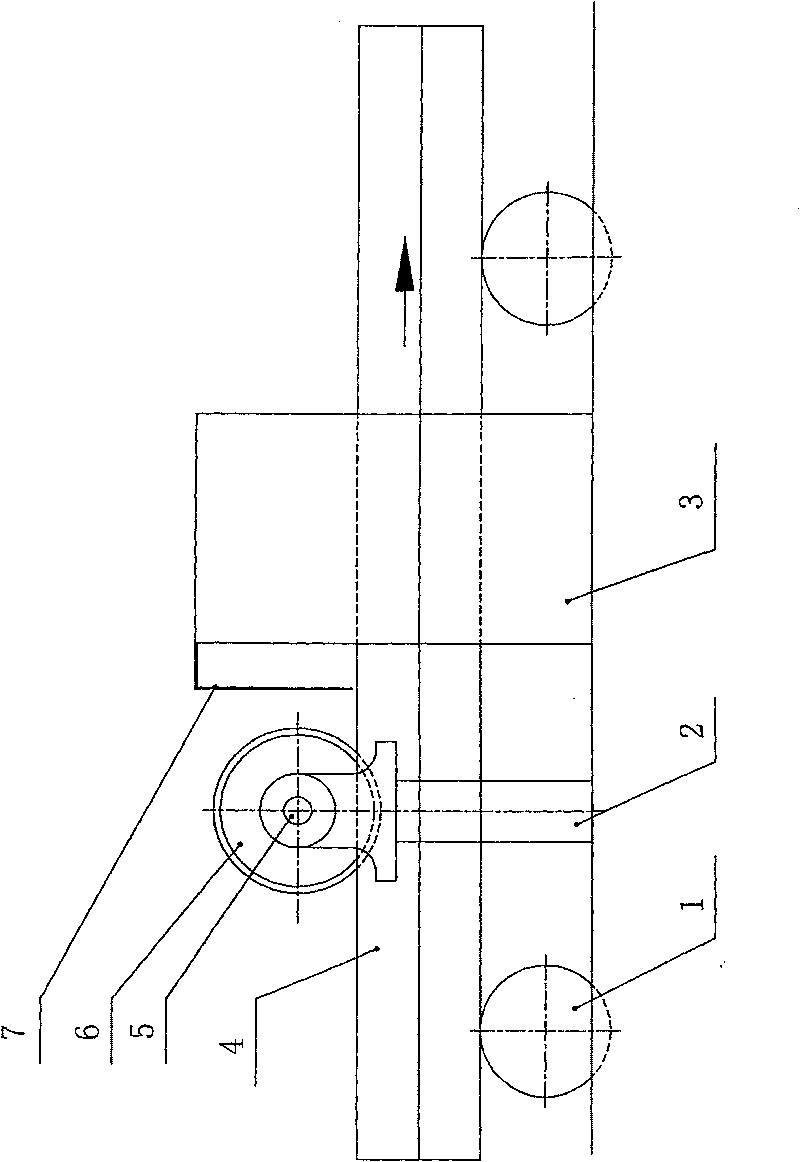

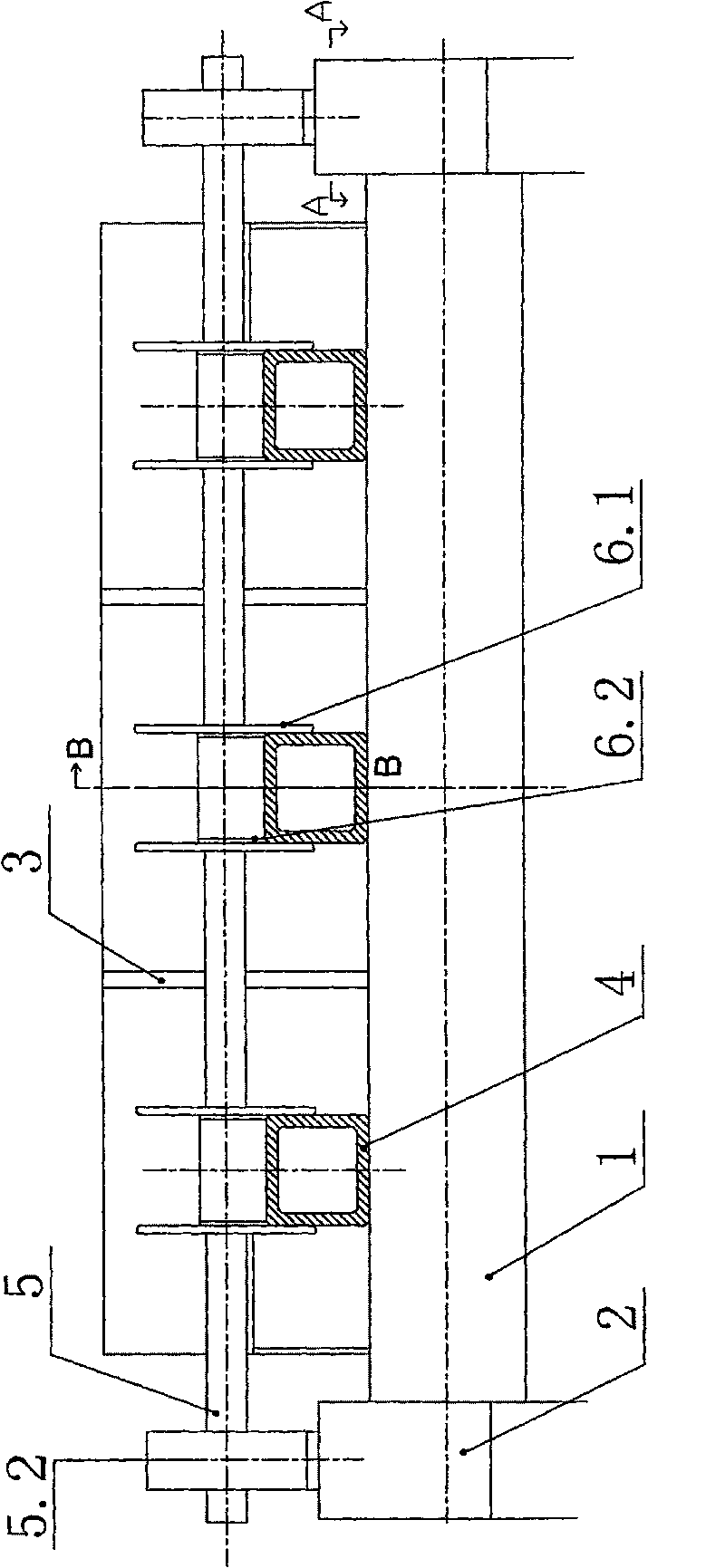

[0023] see Figure 1~2 , The new continuous steel pipe spray cooling quenching machine involved in the present invention is mainly composed of a conveying roller table 1, a support seat 2, a guide roller 5, a guide water retaining assembly 6 and a spray cooler 3.

[0024] Described supporting seat 2 has two parts, is placed in the left and right sides of conveying roller table 1.

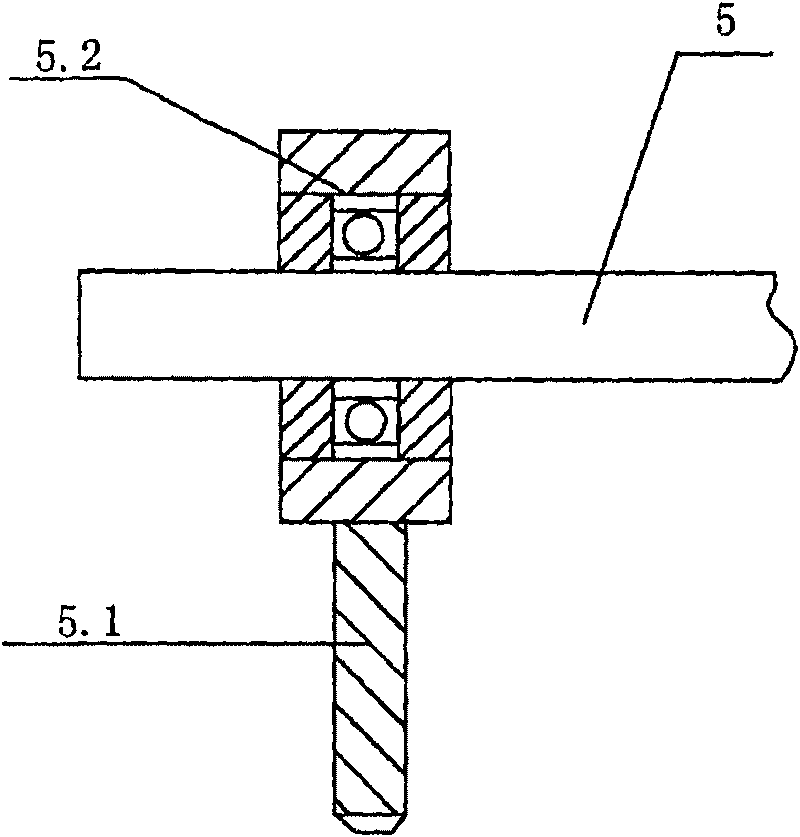

[0025] The guide roller 5 is erected between the left and right support bases 2, bearings 5.2 are installed at both ends of the guide roller 5, and the lower part of the bearing 5.2 shell is fixed downward with a square steel insert rod 5.1, a square steel insert rod 5.1, and a bearing 5.2 Form a whole together with guide roller 5, as image 3 .

[0026] Corresponding to the square steel insert rods 5.1 at both ends of the guide roller 5, the center of the supporting base 2 matched with it is provided with a square slot 2.1, and the square steel insert rods 5.1 at both ends of the guide roller 5 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com