On-line ammonia detection device in continuous annealing furnace and its application method

A continuous annealing furnace and detection device technology, applied in the direction of electrochemical variables of materials, etc., can solve the problems that manual analysis is difficult to meet the requirements of modern production, unfavorable batch detection, long time consumption, etc., to save time, improve timeliness, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

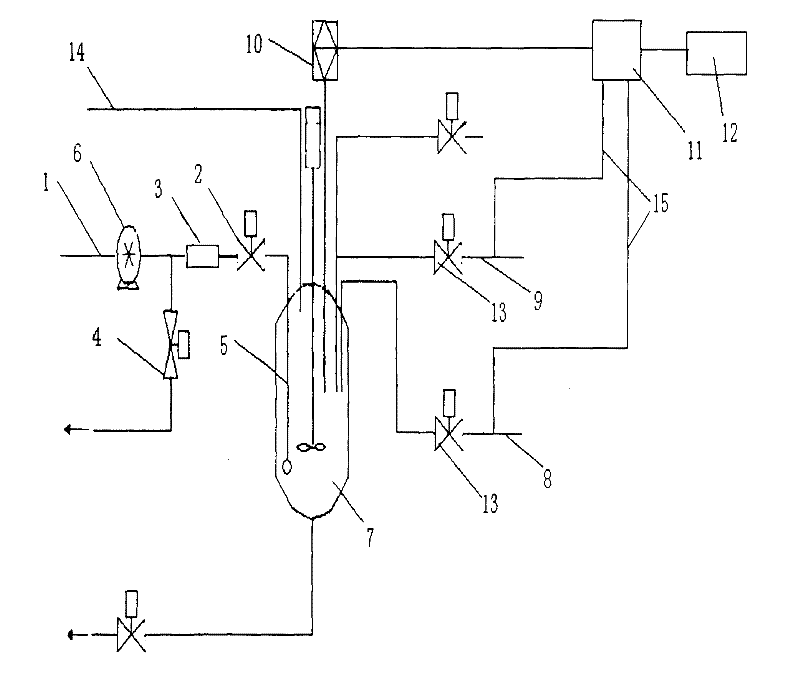

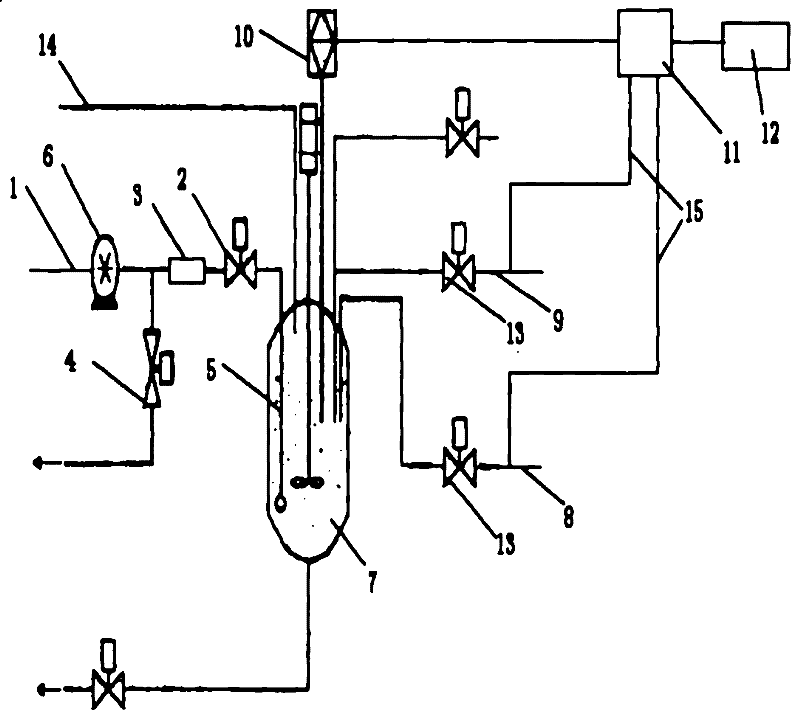

[0035] The ammonia on-line detection device in the continuous annealing furnace is composed of an inlet pipe 1, a flow control valve 2 connected to the inlet pipe 1, a flow meter 3, a return gas valve 4, and a delivery pipe 5. An air pump 6 is installed on the intake pipe 1, a flow control valve 2 and a flow meter 3 are conventionally connected successively on the delivery pipe 5, and an absorption pool 7 is placed at the end of the delivery pipe 5 behind the flow meter 3 and inserted into the absorption pool 7; in the PLC The controller 11 is respectively connected to the sulfuric acid tube 8, the sodium hydroxide tube 9 and the pH electrode 10 through the signal line 15; between the PLC controller 11 and the sulfuric acid tube 8 and between the PLC controller 11 and the sodium hydroxide tube 9 Connect the electromagnetic valve 13 respectively; Set the outlet end of the sulfuric acid pipe 8 and the sodium hydroxide pipe 9 and the exhaust pipe 13 above the liquid level in the a...

Embodiment 2

[0047] The ammonia on-line detection device in the continuous annealing furnace is the same as that in Example 1.

[0048] A method for using an online ammonia detection device in a continuous annealing furnace, the steps of which are:

[0049] 1), the concentration is that the sulfuric acid solution of 0.2mol / L is added into 0.085 liters in the absorption pool 7 through the sulfuric acid pipe 8;

[0050] 2), open the air pump 6 and the flow control valve 2, and input the gas in the continuous annealing furnace into the absorption pool 7 at a rate of 2.0 liters / minute, and the inflow time is 1.5 minutes, and stand for 4 minutes;

[0051] 3), in the absorption pool 7, drip the sodium hydroxide solution with a concentration of 0.5mol / L through the sodium hydroxide tube 9, titrate to the end point, and stir while dripping until uniform;

[0052] 4), use the pH electrode 10 to indicate the titration end point;

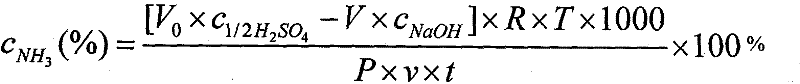

[0053] 5), the calculation formula will be: c ...

Embodiment 3

[0059] The ammonia on-line detection device in the continuous annealing furnace is the same as that in Example 1.

[0060] A method for using an online ammonia detection device in a continuous annealing furnace, the steps of which are:

[0061] 1), the sulfuric acid solution that concentration is 0.3mol / L is added into 0.075 liters in the absorption pool 7 through the sulfuric acid tube 8;

[0062] 2), open the air pump 6 and the flow control valve 2, the gas in the continuous annealing furnace is input in the absorption pool 7 with the speed of 2.5 liters / minute, and its inflow time is 1 minute, and stands still for 4.5 minutes;

[0063] 3), in the absorption pool 7, drip the sodium hydroxide solution with a concentration of 0.5mol / L through the sodium hydroxide tube 9, titrate to the end point, and stir while dripping until uniform;

[0064] 4), use the pH electrode 10 to indicate the titration end point;

[0065]5), the calculation formula will be: c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com