Shock resistance axial seal device for screw shaft of ship

An end-face sealing and impact-resistant technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of inability to automatically compensate, lack of maintainability, unstable wire springs, etc., and achieve stable performance of friction pair water sealing Reliable, good seawater corrosion resistance, and the effect of improving safety and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

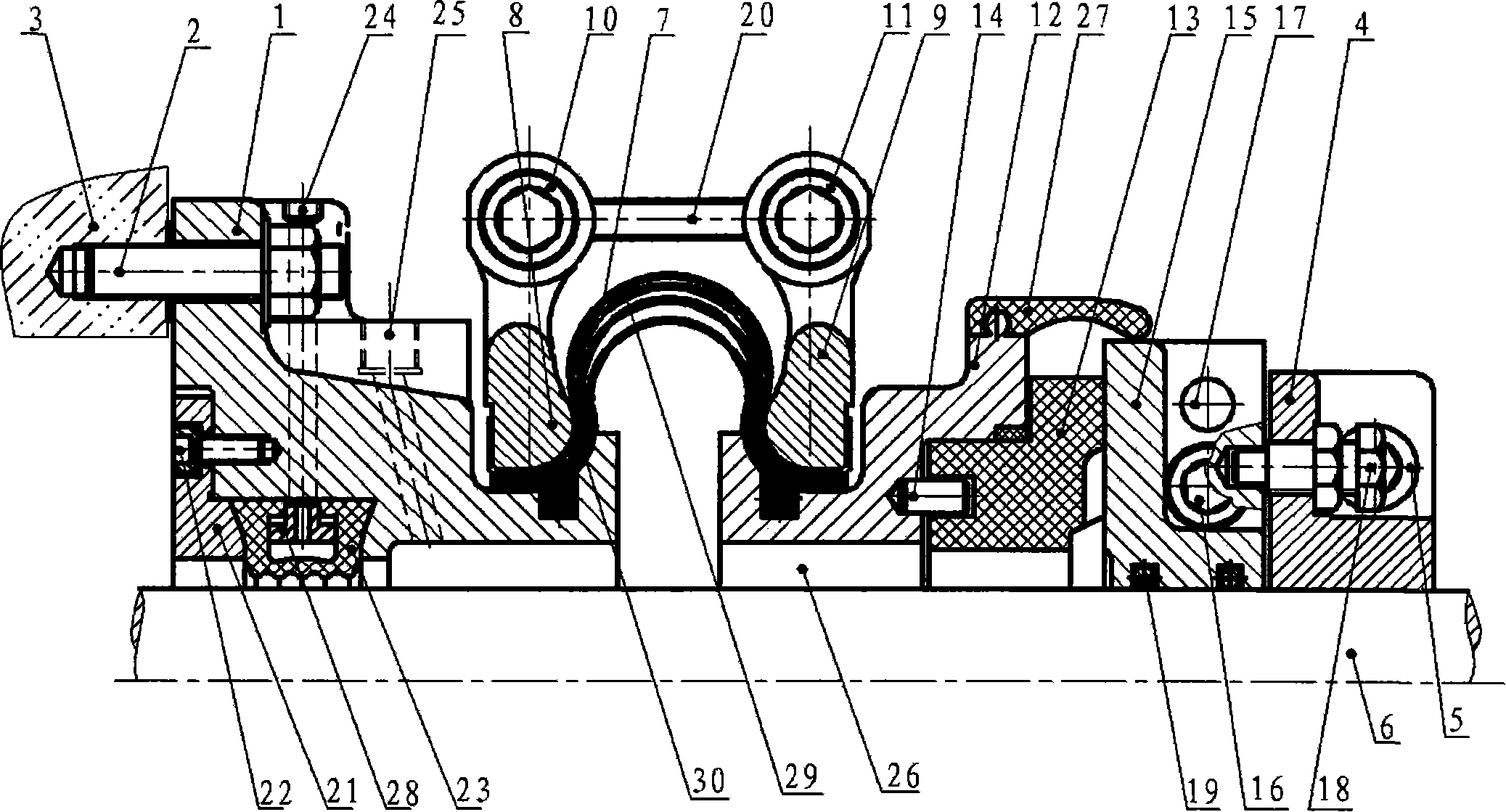

[0025] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

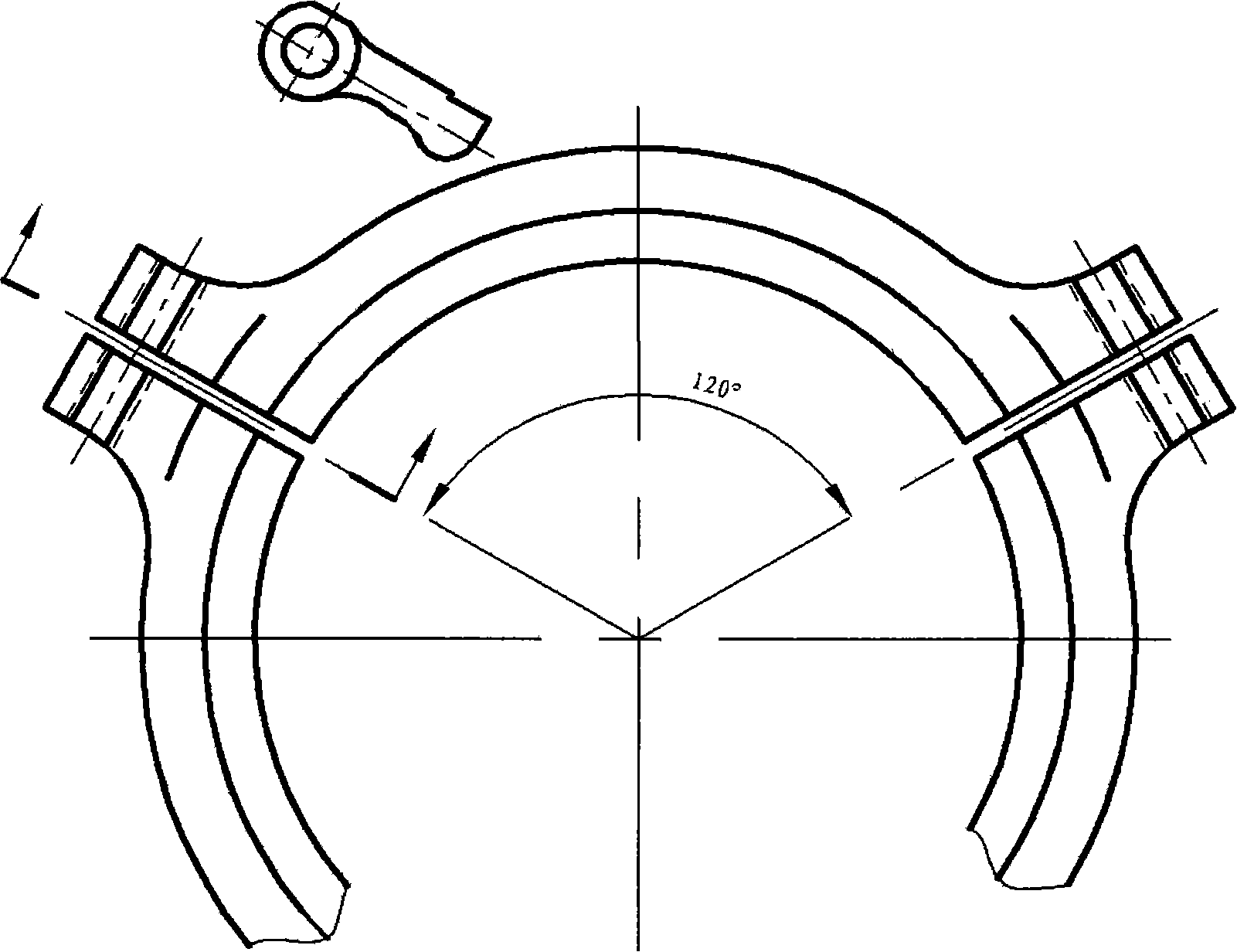

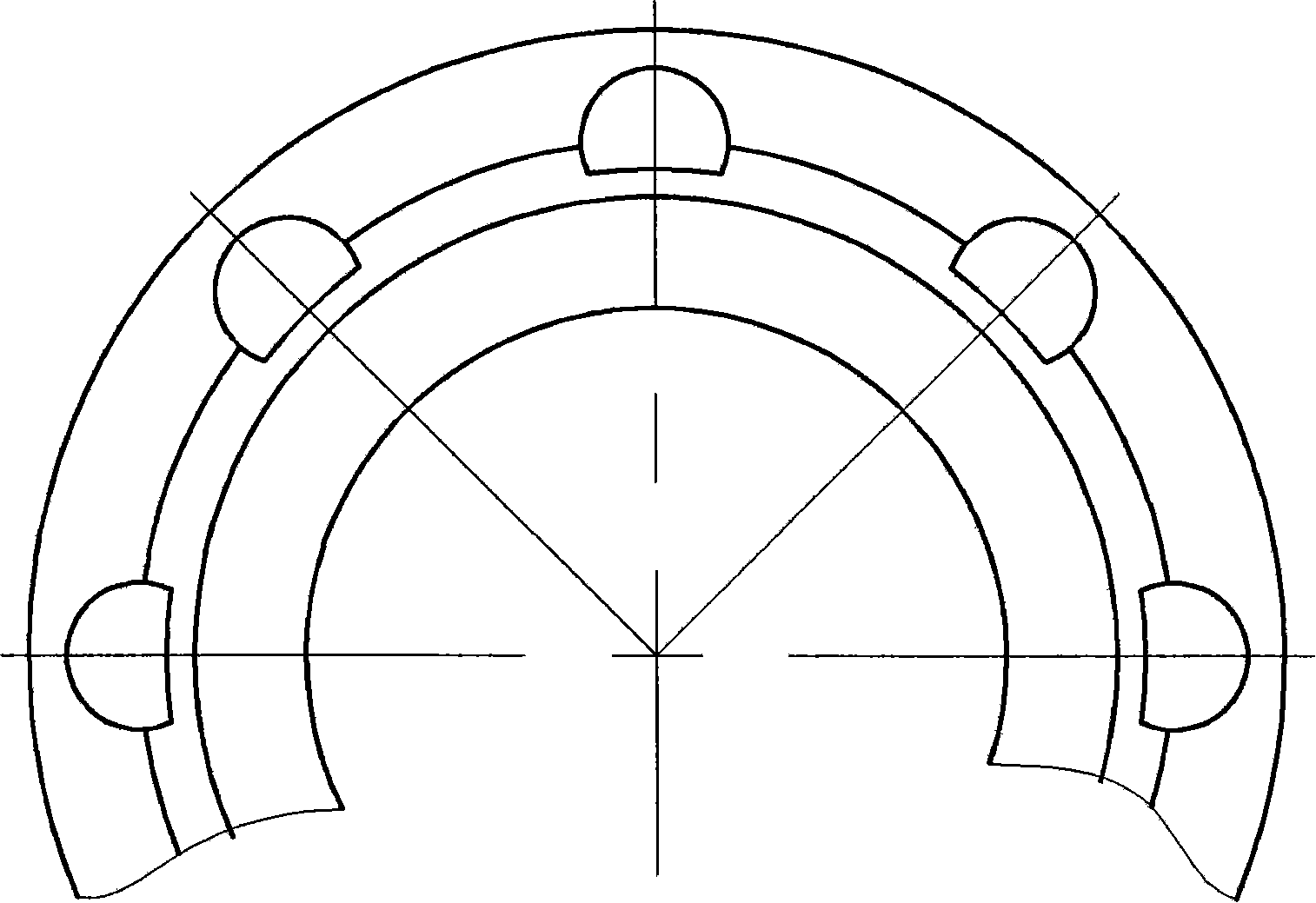

[0026] as attached figure 1 As shown, the present invention consists of a mounting base 1, a transmission snap ring 4, an Ω-shaped elastic compensator 7, main collars 8, 9, lock nuts 10, 11, a seal ring bracket 12, a seal ring 13, a support ring 15, Cone pin 17, bolt 18, o-shaped ring 19, adjusting screw rod 20, pressure ring 21, inflatable seal 23, splash guard 27 and several seals and connectors are assembled. The installation base 1 is fixed on the hull stern tube seat 3 with bolts 2 . The transmission snap ring 4 is formed by two halves of the annular body, and is fastened on the stern shaft 6 by bolts 5 and taper pins. The left and right ends of the Ω-shaped elastic compensator 7 are firmly pressed on the installation base 1 and the sealing ring bracket 12 by the main collars 8 and 9 through the locking bolts 10 and 11 respectively. Each main c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com