Method for removing rudder blades of floating production

A technology of unloading device and floating production, which is applied in the direction of warships, etc., can solve the problems of long docking period and high cost, and achieve the effect of saving docking cost, simple method and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

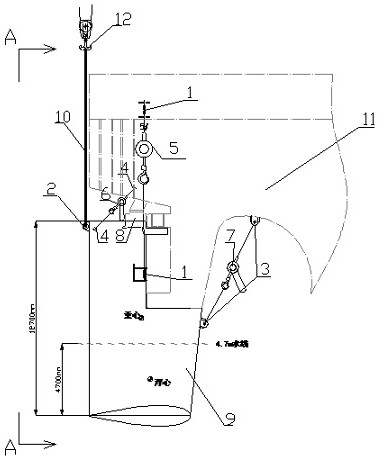

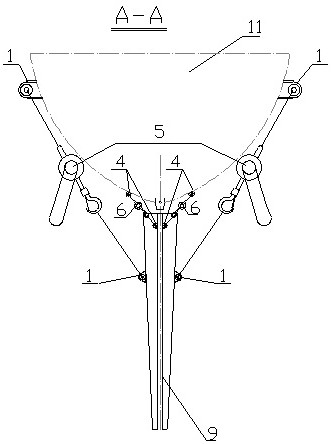

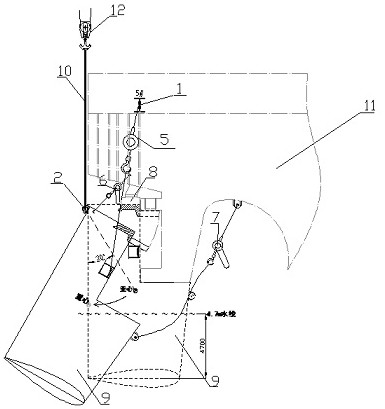

[0016] Such as Figure 1 to Figure 4 As shown, the floating production, storage and unloading device rudder blade removal method in water, the rudder blade 9 is located at the tail of the floating production, storage and unloading device ship 11, and is submerged 4.7m below the water surface in the ship's own floating state. The entire installation process is on the water Carry out, the specific dismantling method includes the following steps: A. First, prepare four 100-ton main suspension lugs 1 to respectively weld the FPSO ship stern 11 on the upper side of the outer plate and the designated positions on both sides of the rudder blade 9, and place one 100-ton hoist Transport lifting lug 2 is welded at the specified position on the upper end of rudder blade 9, and then prepare four 20-ton rear adjustment lifting lugs 4, respectively weld the lower side of the outer plate of the stern 11 of the floating production, storage and unloading device, and the specified position on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com