Non-contact measurement-based screw propeller taper hole fitting method

A non-contact, propeller technology, applied in the direction of measuring devices, image data processing, instruments, etc., can solve the problems of long time in the dock, long preparation period, low efficiency, etc., and achieve strong versatility of equipment, low cost, and improved operation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] A method for matching propeller cone holes based on non-contact measurement, specifically comprising the following steps:

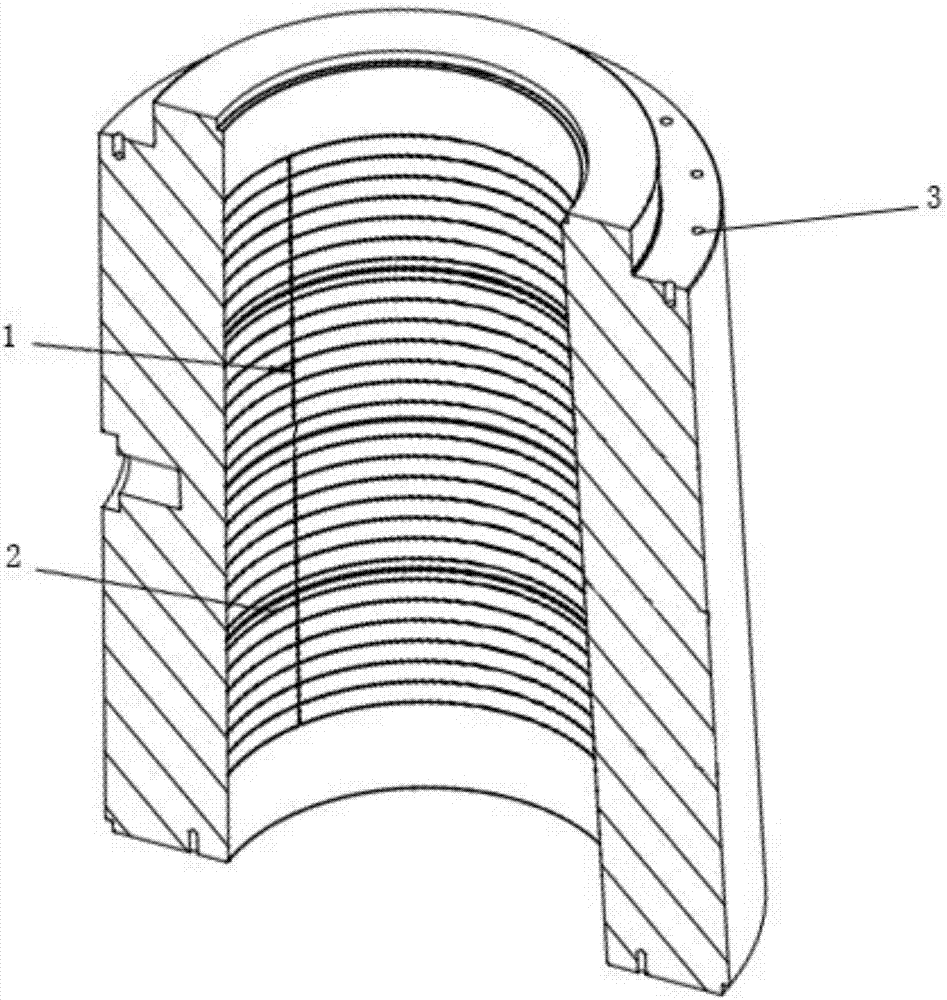

[0028] Step 1: If figure 1 As shown, the taper hole of the propeller has a 0.2-0.3 mm stroke allowance during machining, and the inner wall is provided with 3-4 linear oil grooves 1 and 20-30 annular oil grooves 2. An elevator is erected on a horizontal plane, and the propeller cone hole is placed on the horizontal plane, with either end of the hole facing upwards, and the construction personnel use the elevator to lift and operate in the propeller cone hole. Clean the linear oil tank 1 and the annular oil tank 2, and mark several azimuth marks 3 equidistantly on the surface of the large end of the upward facing hole, and each linear oil tank corresponds to a position mark, and some azimuth marks are not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com