Image checking device and image checking mehtod

A technology for inspection devices and graphics, which can be used in measurement devices, optical devices, and material analysis by optical means, and can solve problems that have not yet been established.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

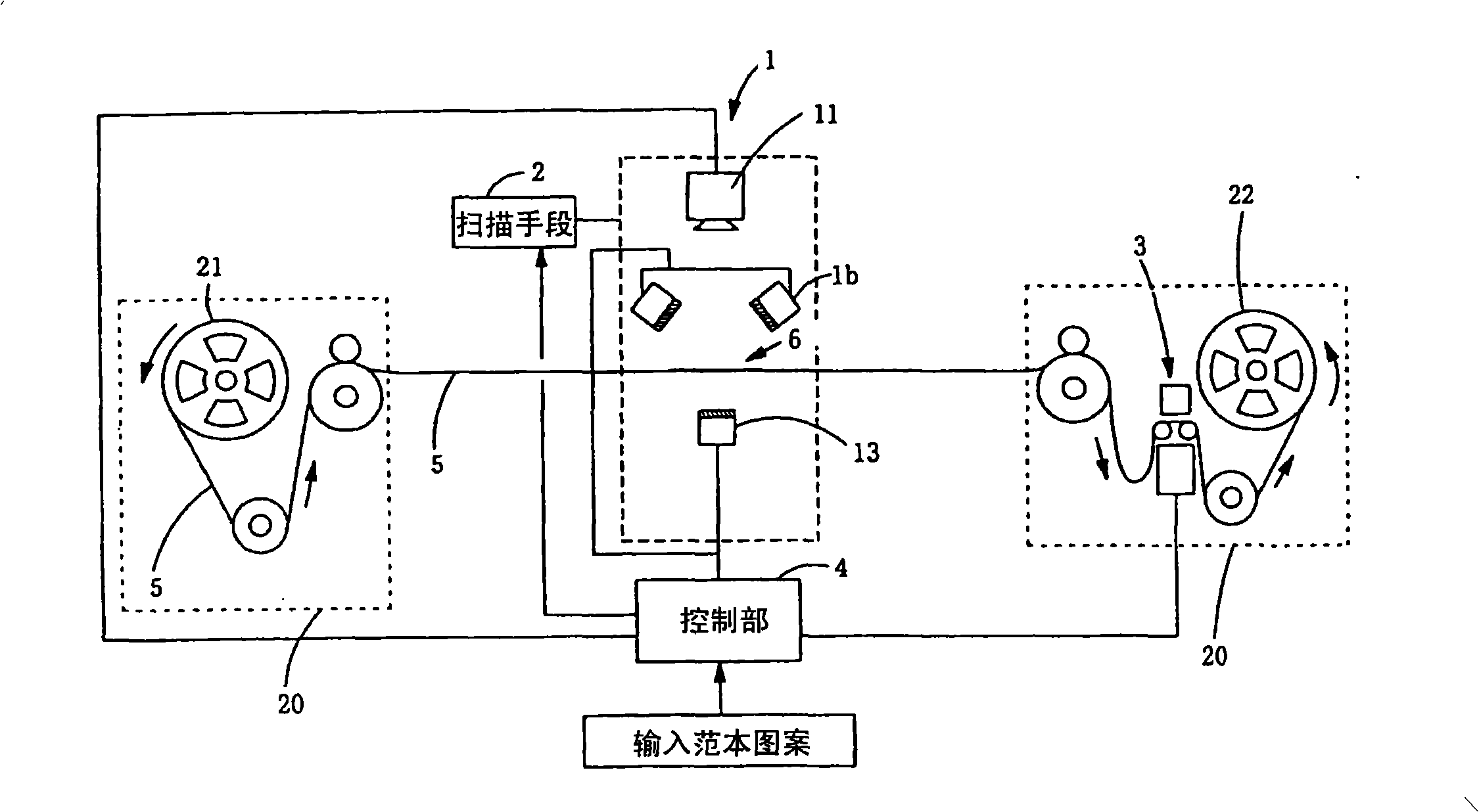

[0056] figure 1 is a block diagram of a wiring pattern inspection device according to an embodiment of the present invention. In addition, although the following embodiments are described for the case where the substrate is a thin-film workpiece such as TAB tape or COF, the present invention can also be applied to pattern inspection of other substrates.

[0057] The pattern inspection device of the present embodiment, as shown in the figure, is equipped with: the tape conveying mechanism 20 that is constituted by sending out reel 21 or take-up reel 22 etc. that TAB tape 5 is conveyed; The inspection unit 1 that irradiates the transmitted illumination light and reflected illumination light on the TAB tape 5 and takes an image of the inspection pattern 6, the scanning unit 2 that makes the inspection unit 1 scan the inspection pattern 6 on the TAB tape 5, and attaches to the unqualified pattern. Marking part 3 of the mark.

[0058] In the marking part 3, the pattern judged to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com