Preparation method of electrochemical sensor based on magnetic nanocomposite

A technology of nanocomposite materials and composite materials, which is applied in the field of preparation of electrochemical sensors, can solve the problems of easy aggregation and instability of spinel ferromagnetic particles, and achieve the effects of improving electron transfer speed, convenient qualitative and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

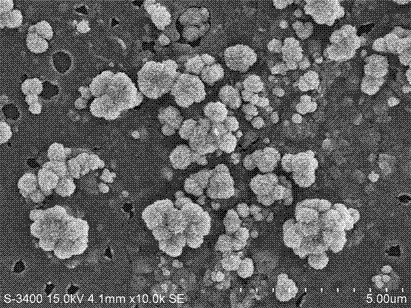

[0035] Example 1 Fe 3 o 4 Preparation of / rGO nanocomposites

[0036] (1) Preparation of graphene oxide

[0037] Use the improved Hummers method to prepare graphene oxide, the specific method is as follows: First, weigh 0.75g of graphite powder and add it to a 250mL round bottom flask, then add 100mL of sulfuric acid / phosphoric acid mixed liquid (volume ratio: 9:1); After stirring evenly, slowly add 4.5g of potassium permanganate; subsequently, the mixture was heated and stirred at 50°C for 12h; Neutralize the unreacted potassium permanganate with hydrogen peroxide; let it settle for half a day, pour off the supernatant, and centrifuge to precipitate in a high-speed centrifuge; finally wash the precipitate with deionized water and 5% hydrogen peroxide until neutral.

[0038] (2) Add 0.2g of sodium hydroxide (NaOH) to 20mL of diethylene glycol (DEG), heat and stir at 120-150°C under nitrogen protection for 1-2h, then cool to 70°C to make NaOH / DEG stock liquid;

[0039] (3)...

Embodiment 2

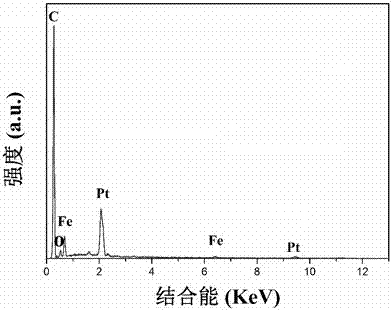

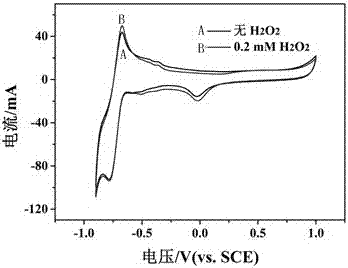

[0042] Example 2 Pt / Fe 3 o 4 Preparation of / rGO New Nanocomposite Modified Electrode

[0043] (1) Pretreatment of glassy carbon electrodes

[0044] Clean the glassy carbon electrode with deionized water for 3-5 times, and polish the surface with alumina polishing powder. Ultrasonic cleaning is performed on the electrode surface. Then with freshly prepared 1 mol / L H 2 SO 4 As the bottom liquid, scan 15 cycles with cyclic voltammetry, the voltage range is -0.25V-1.25V, and the scanning speed is 0.05V / s. After the electrode is dried, it is washed with ultrapure water and dried for use.

[0045] (2) Fe 3 o 4 Preparation of / rGO nanocomposite modified electrode

[0046] Get the Fe prepared in 1 mg embodiment 1 3 o 4 / rGO nanocomposites were added to 1:1 ethanol aqueous solution and ultrasonically oscillated for 30-90 min to obtain evenly dispersed Fe 3 o 4 / rGO nanocomposite suspension. Then take 10-20 μL of the dispersion suspension and add it dropwise on the pretrea...

Embodiment 3

[0051] Example 3 MnFe 2 o 4 Preparation of / rGO nanocomposites

[0052] In the step (4) of embodiment 1, except soluble iron salt FeCl 3 In addition, add Mn-containing divalent ferromagnetic metal salts, including MnCl 2 , MnSO 4 , Mn(NO 3 ) 2 or Mn(CH 3 COO) 2 One of them, other steps and conditions are all the same as in Example 1, and the specific conditions are changed and adjusted accordingly within the scope of the content of the invention to obtain MnFe 2 o 4 / rGO nanocomposites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com