Wall surface cleaning robot based on positive-negative pressure adsorption principle

A cleaning robot, positive and negative pressure technology, applied in the direction of cleaning machinery, cleaning equipment, carpet cleaning, etc., can solve the problems of poor adsorption effect on the wall, poor obstacle surmounting ability, complex structure, etc., to achieve good obstacle surmounting ability, simple structure, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

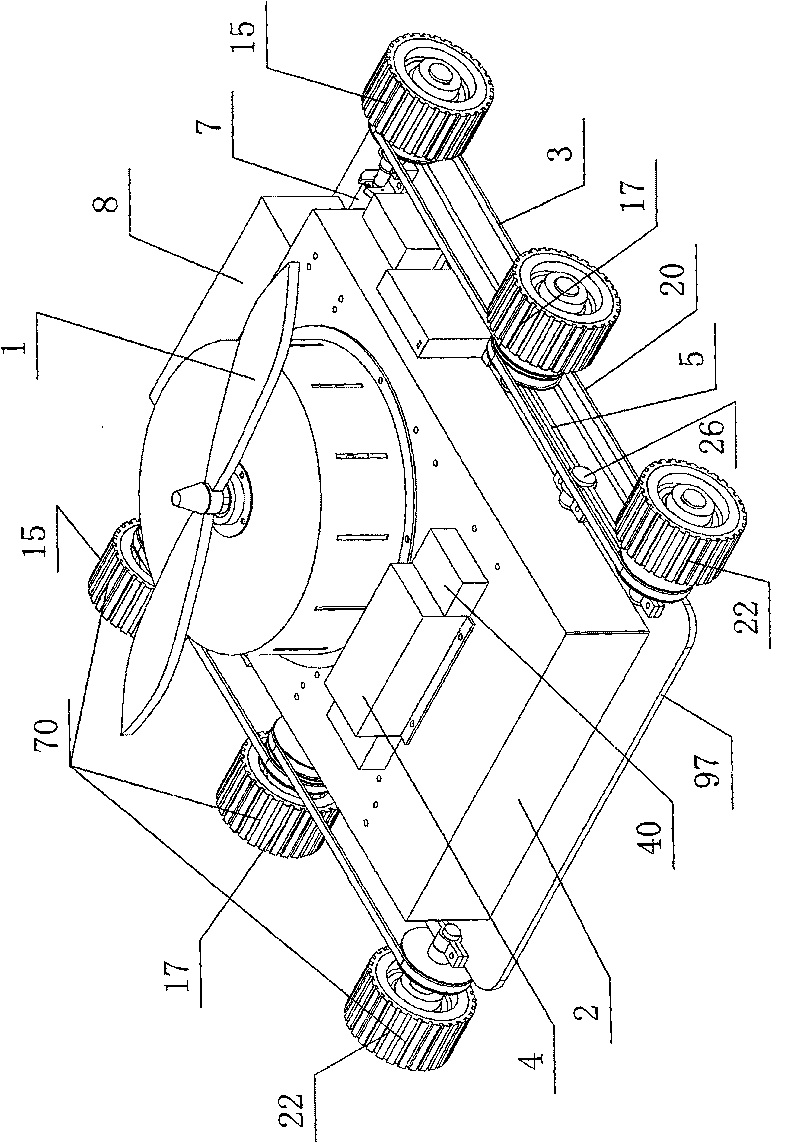

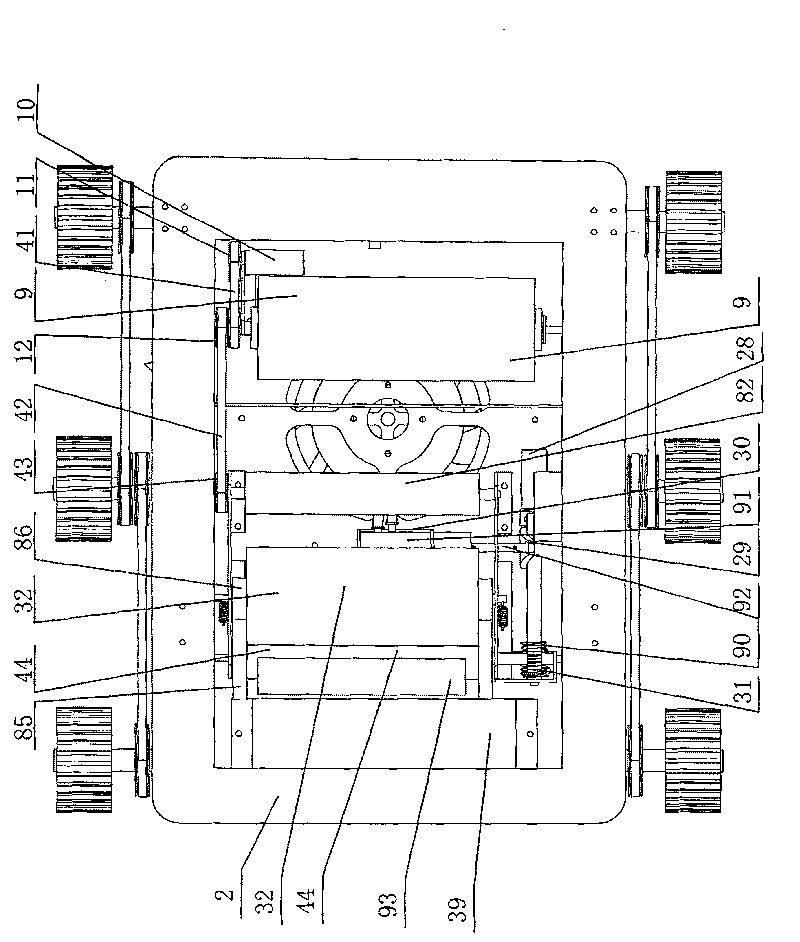

[0008] Specific implementation mode one: as Figure 1-7 As shown, the wall cleaning robot based on the principle of positive and negative pressure adsorption in this embodiment includes a housing 2, a three-phase motor 13, a propeller 1, a centrifugal blade 23, a wheeled walking system 70, a cleaning mechanism 71 and a water inlet and outlet mechanism 72. The cleaning mechanism 71 and the water inlet and outlet mechanism 72 are all installed in the housing 2, and the wheeled walking system 70 is installed in the lower part of the housing 2. The cleaning mechanism 71 includes a dry brush 9, a wet brush 27, a water suction roller 32, and a squeezer. Water roller 44, dry brush shaft 81, wet brush shaft 82, water suction roller shaft 83, squeeze water roller shaft 84, two driving wheels 85, two driven wheels 86, sewage collection box 39, sewage collection container 93, motor 10, The first pulley 11, the second pulley 12, the third pulley 43, the first transmission belt 41 and the ...

specific Embodiment approach 2

[0009] Specific implementation mode two: as Figure 1~2 As shown, the wheeled walking system 70 in this embodiment is composed of two sets of wheeled walking assemblies, and the two sets of wheeled walking assemblies are respectively installed on the outer edge of the housing 2, and each set of wheeled walking assemblies All are composed of adjustable motor 7, front wheel 15, middle wheel 17, rear wheel 22, support bar 5, pin 26, first synchronous belt 3 and second synchronous belt 20, and the adjustable motor 7 is installed in the housing 2, the middle part of the support bar 5 is rotationally connected with the outer edge of the housing 2 through a pin 26, the output shaft of the adjustable motor 7 is rotationally connected with the front wheel 15, and the front wheel 15 is connected with the middle wheel 17 through the first synchronous belt 3 Connect, the middle wheel 17 is connected with the rear wheel 22 by the second synchronous belt 20, the middle wheel 17 is installed...

specific Embodiment approach 3

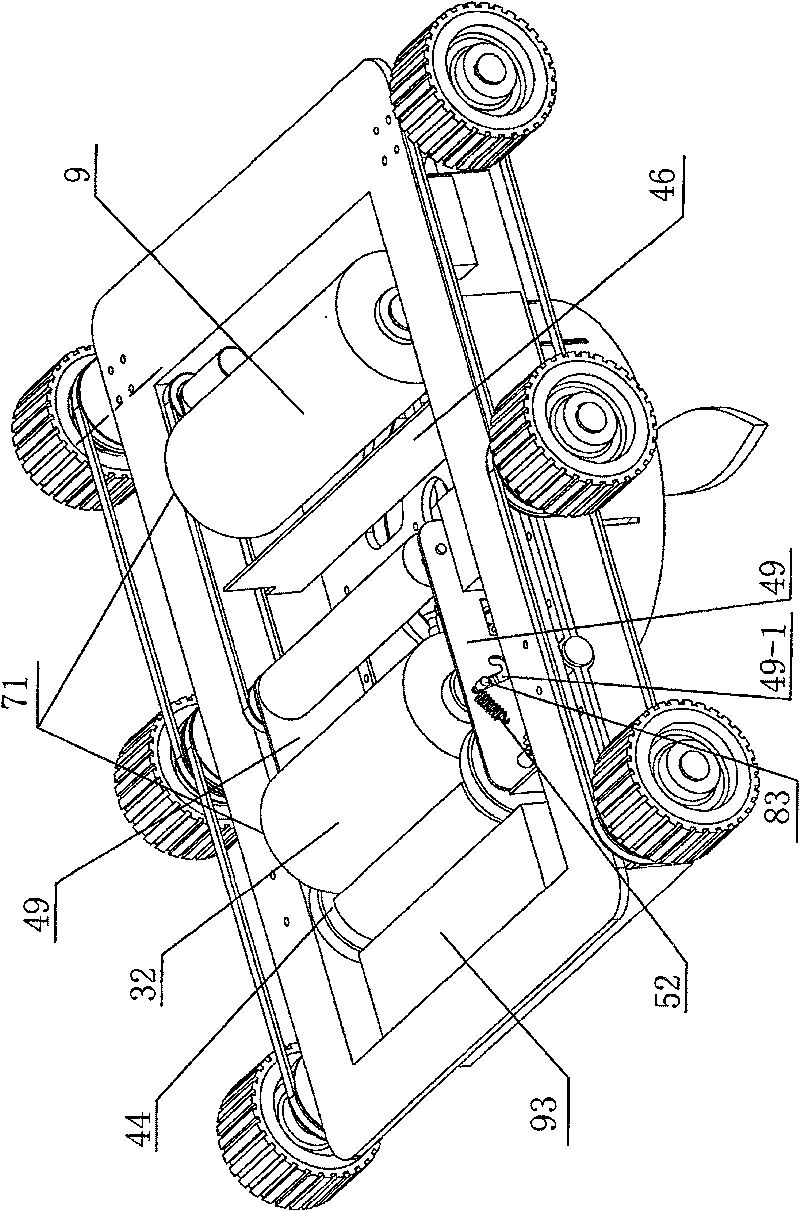

[0010] Specific implementation mode three: as figure 1 and Figure 9 As shown, the wheeled walking system 70 in this embodiment is composed of two front driving wheels 45, two rear driven wheels 50, two synchronous belts 51, and two reduction motors 47, and the two reduction motors 47 are respectively installed On the two side walls of the front end in the housing 2, the two front driving wheels 45 are respectively connected in rotation with the output shafts of the two reduction motors 47, and the two rear driven wheels 50 are installed on the two side walls of the rear end in the housing 2 respectively. Above, the two front driving wheels 45 and the two rear driven wheels 50 are respectively connected by two synchronous belts 51 . This embodiment is a four-wheel drive, and the four wheels are all installed inside the housing 2 and driven by two reduction motors 47, which can realize forward, backward and turning. This embodiment can make the structure simpler and more comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com