Reciprocating stroke apparatus

A technology of reciprocating stroke and housing, applied in the field of reciprocating stroke device, can solve the problems of large volume, noisy working environment, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above and other objects, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention, together with the accompanying drawings, are described in detail as follows:

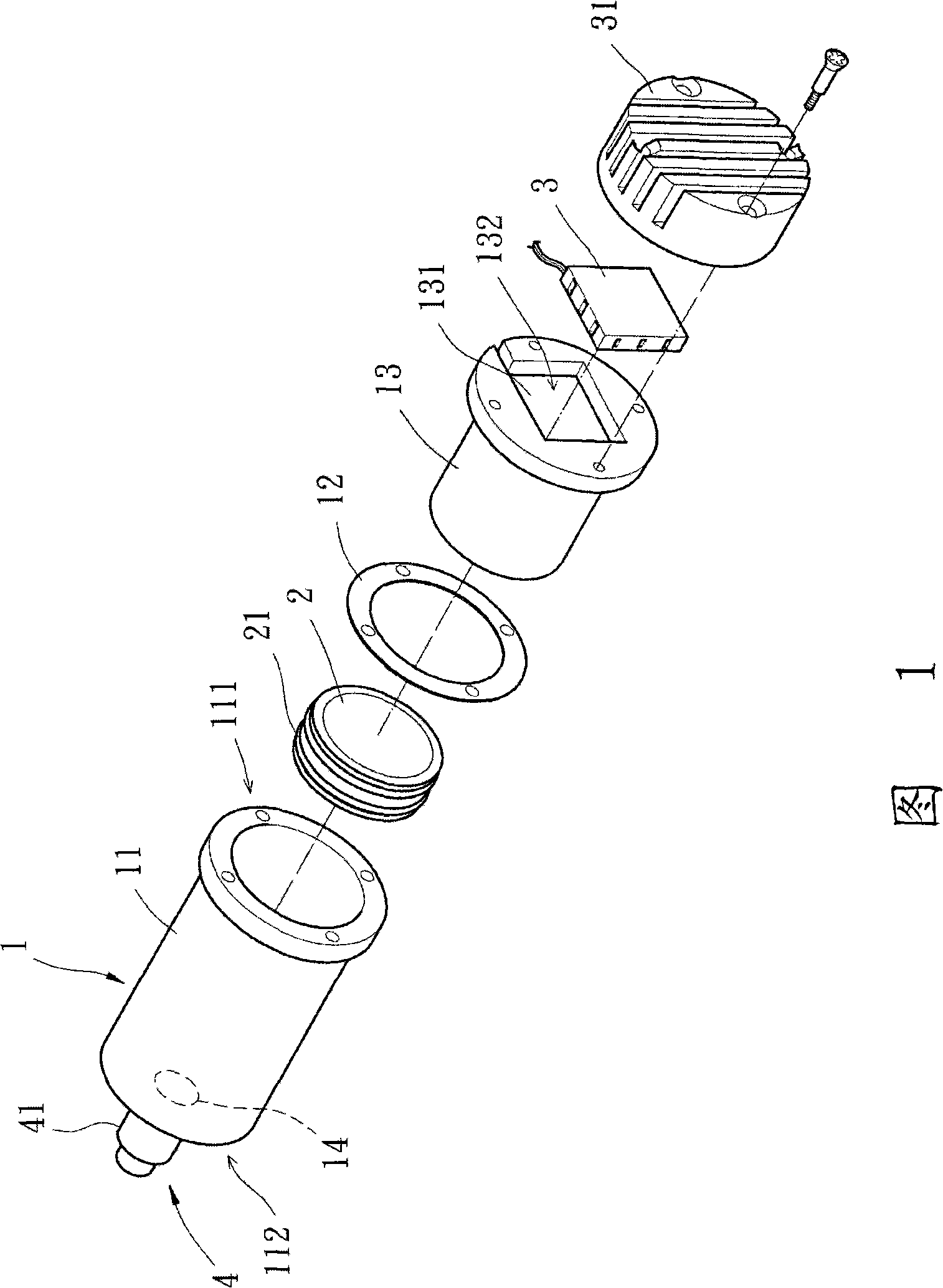

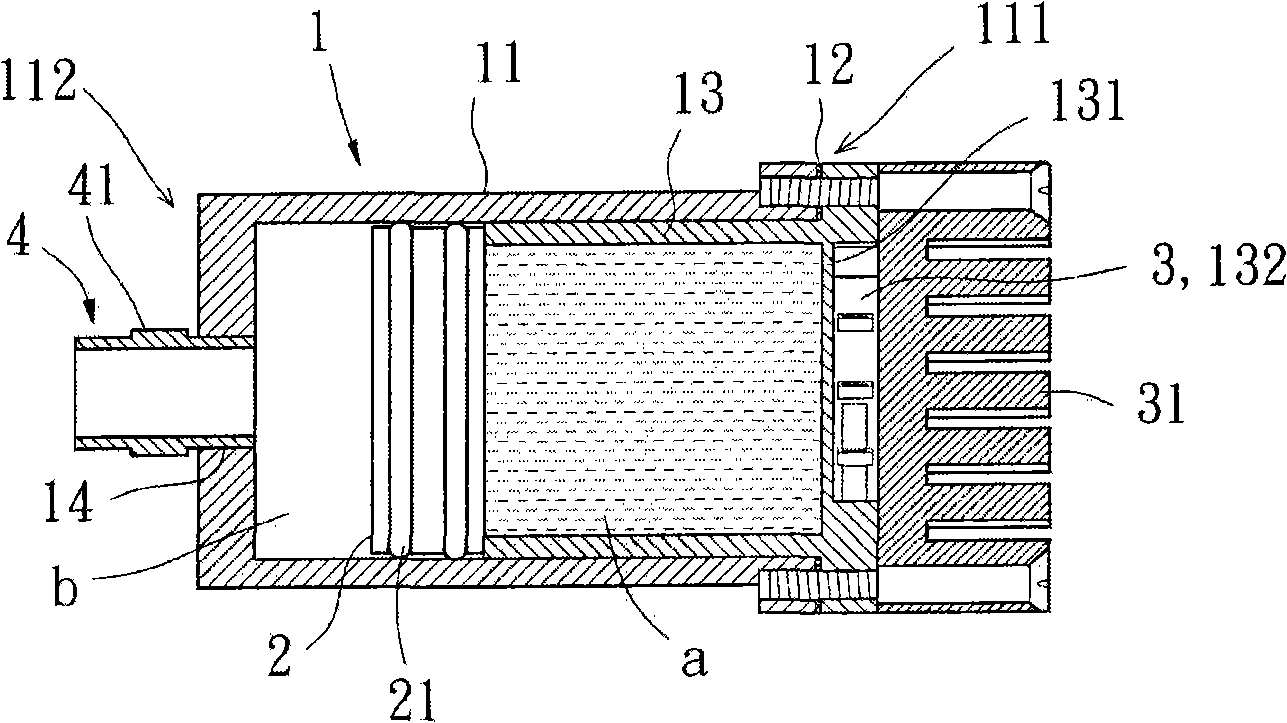

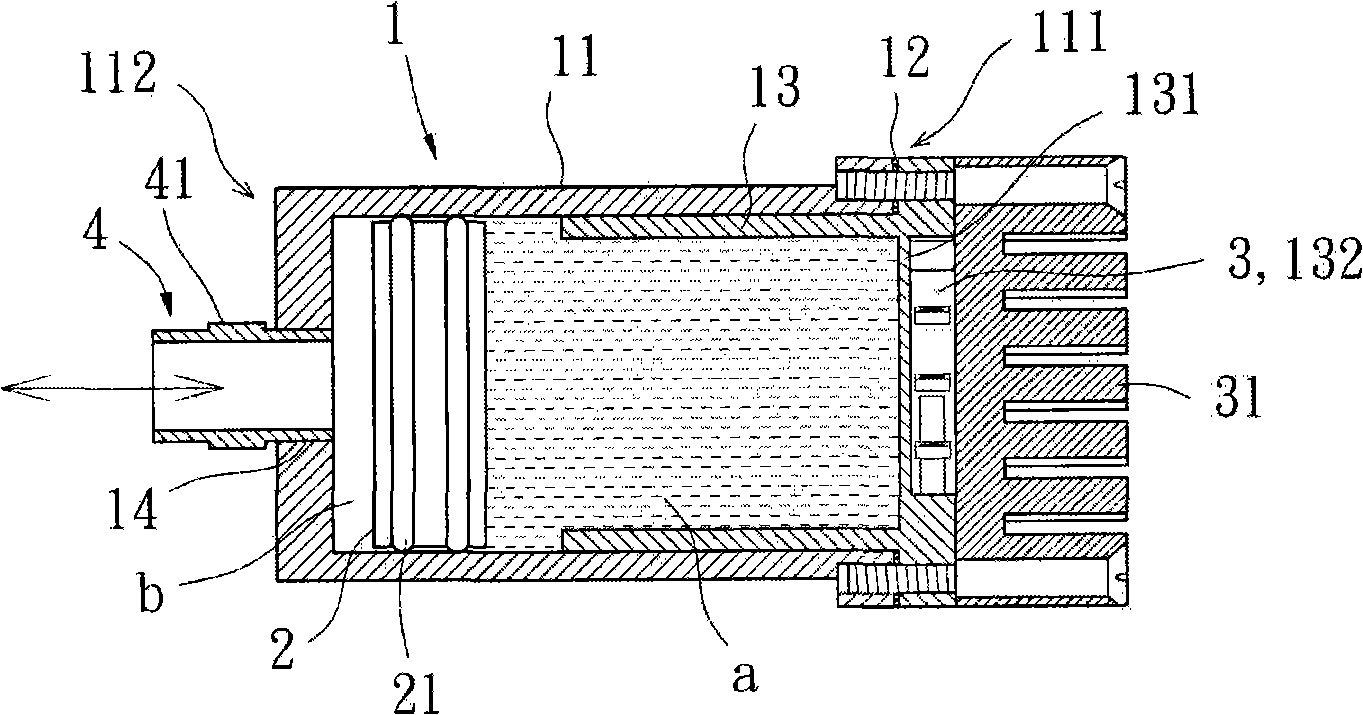

[0030] Please refer to FIG. 1 , the reciprocating stroke device according to the first embodiment of the present invention includes a casing 1 , a piston 2 , a temperature control unit 3 and a transmission component 4 . The inside of the casing 1 can accommodate the piston 2, and the inside of the casing 1 is filled with a gas on the side opposite to the piston 2, and the temperature control unit 3 is arranged on one side of the casing 1 for controlling The gas inside the casing 1 is repeatedly heated and cooled, so as to control the reciprocating action of the piston 2 by using the principle of thermal expansion and contraction of the gas, and then cooperate with the transmission component 4 to realize a predetermin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com