Packing case

A packing box and box body technology, which is applied in the directions of packaging, transportation, packaging, display stands, etc., can solve the problems of increased work load, obstruction of hooks, complicated work of packing boxes, etc., and achieve the effect of reducing the work load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

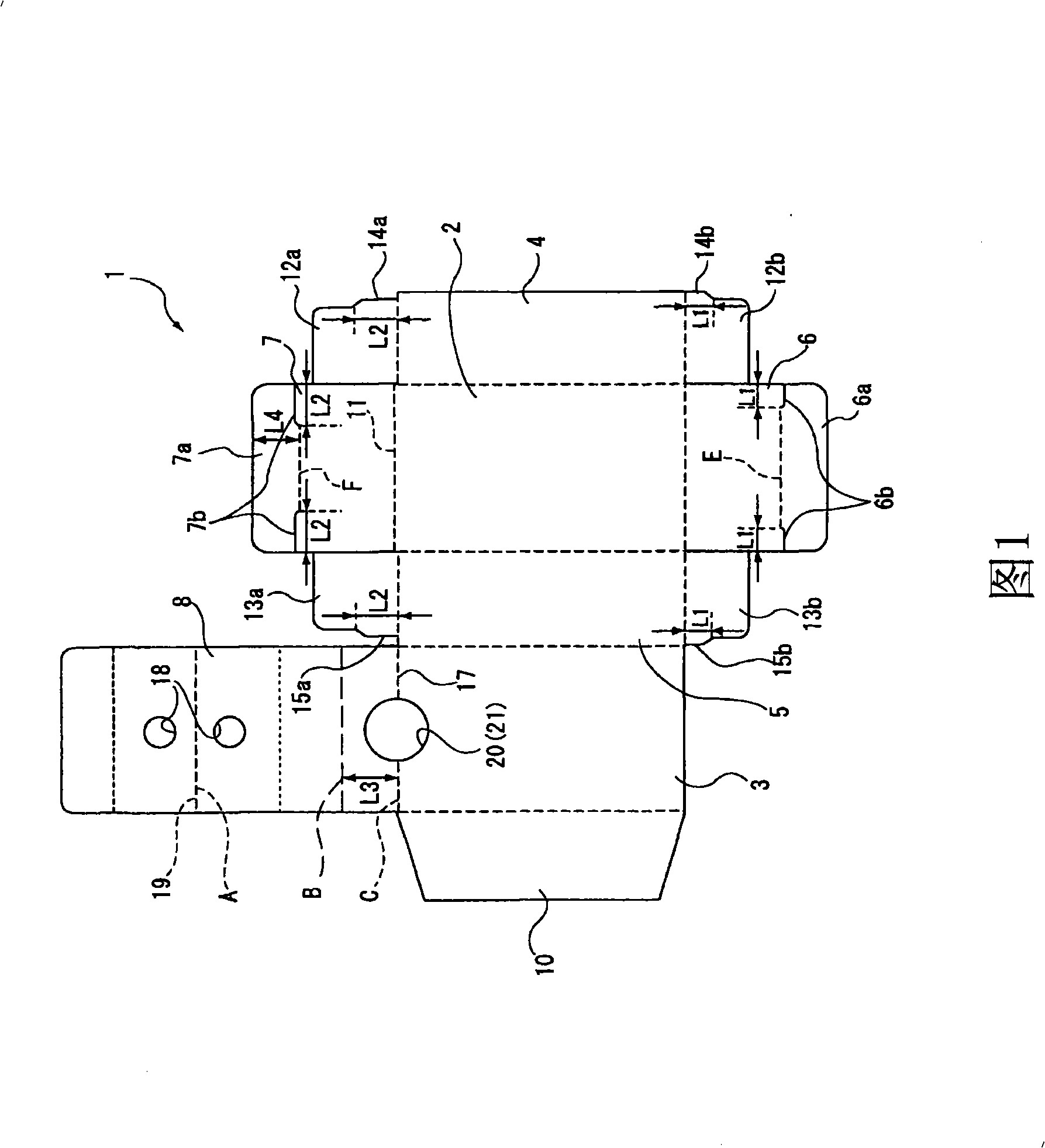

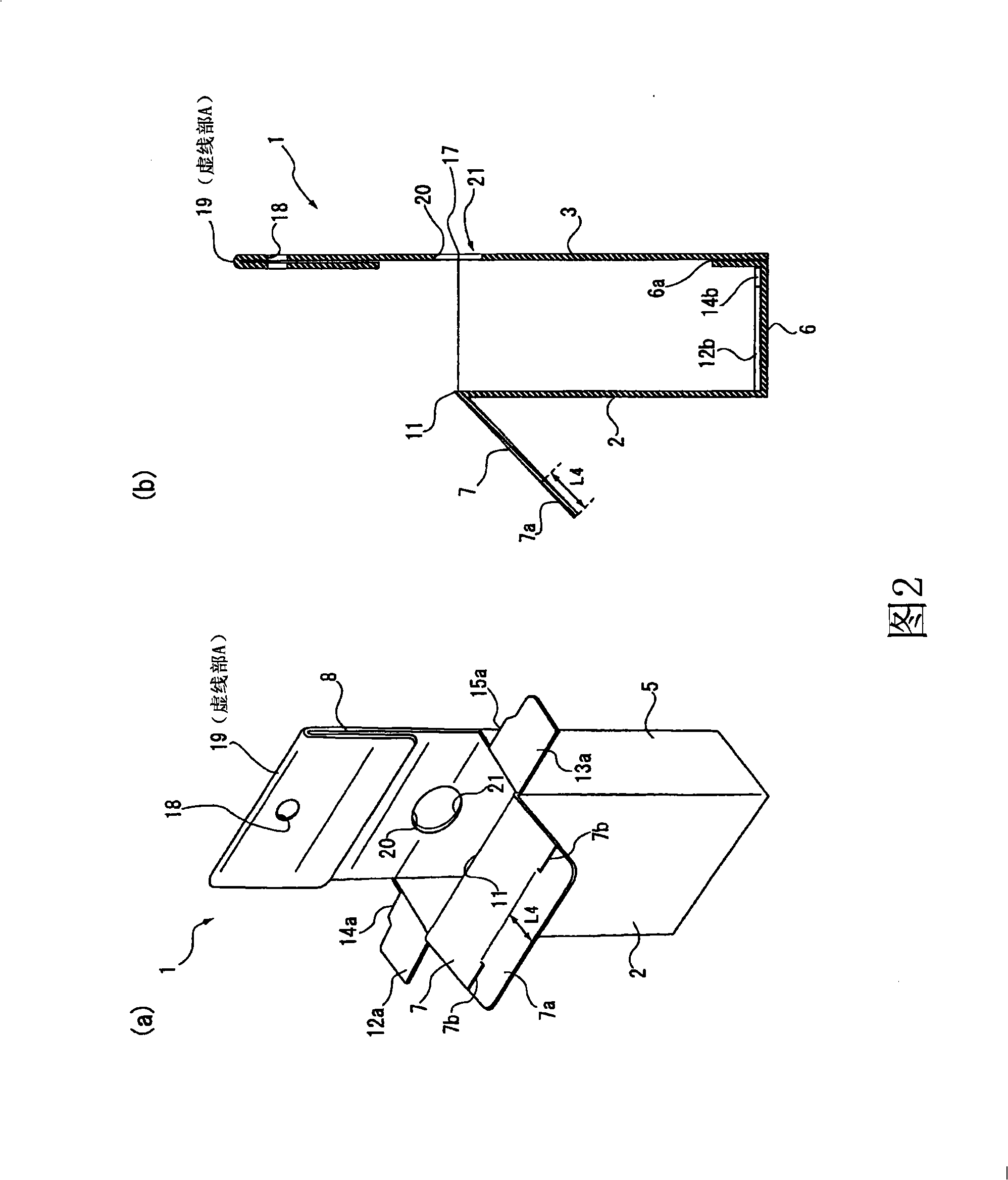

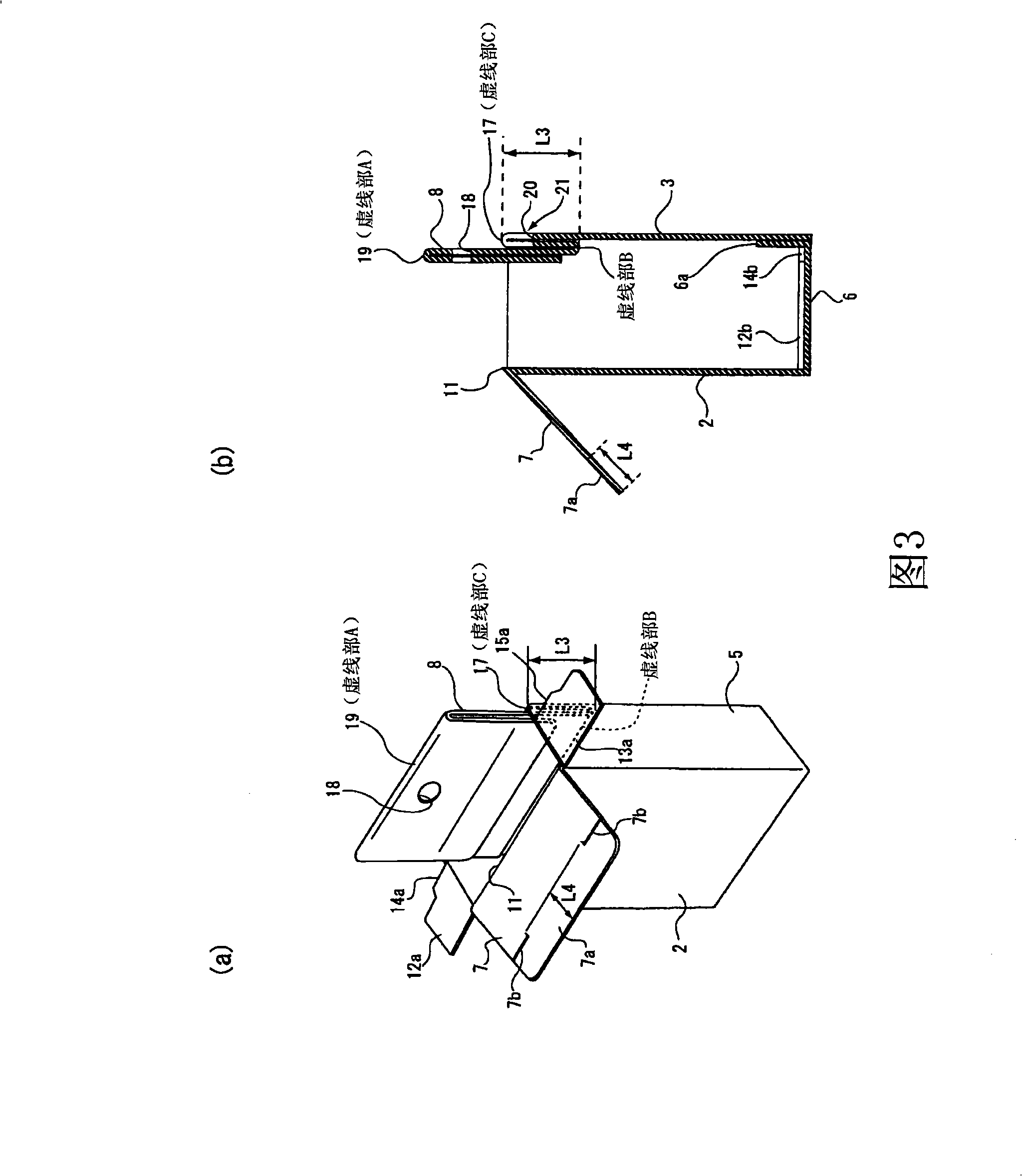

[0027] The packaging box of the present invention will be described in detail below with reference to the accompanying drawings. Fig. 1 shows a developed view of the packaging box of the present invention. Fig. 2(a) shows a front perspective view showing a state in which the packing box is formed into a rectangular cylindrical shape with a bottom by assembling the expanded view shown in Fig. 1 , and Fig. 2(b) shows a side sectional view thereof.

[0028] The packing box 1 roughly includes four rectangular side portions 2 to 5 , a bottom portion 6 , an upper surface portion (lid portion) 7 , and a hook portion 8 . As shown in FIG. 1 , the packing box 1 is formed of a sheet of paper, and the above-mentioned four side parts 2 to 5, the bottom part 6, the upper surface part 7, and the hook part 8 are integrally formed.

[0029] The four side parts 2 to 5 are composed of a front part 2 and a back part 3 in a wide rectangular shape, and a right side part 4 and a left side part 5 in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap