Feed supply working vehicle

A feed supply and working vehicle technology, applied in the field of trucks, can solve the problems of cumbersome unloading process, low level of mechanization, low unloading efficiency, etc., and achieve the effect of reducing labor intensity, improving mechanization level, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

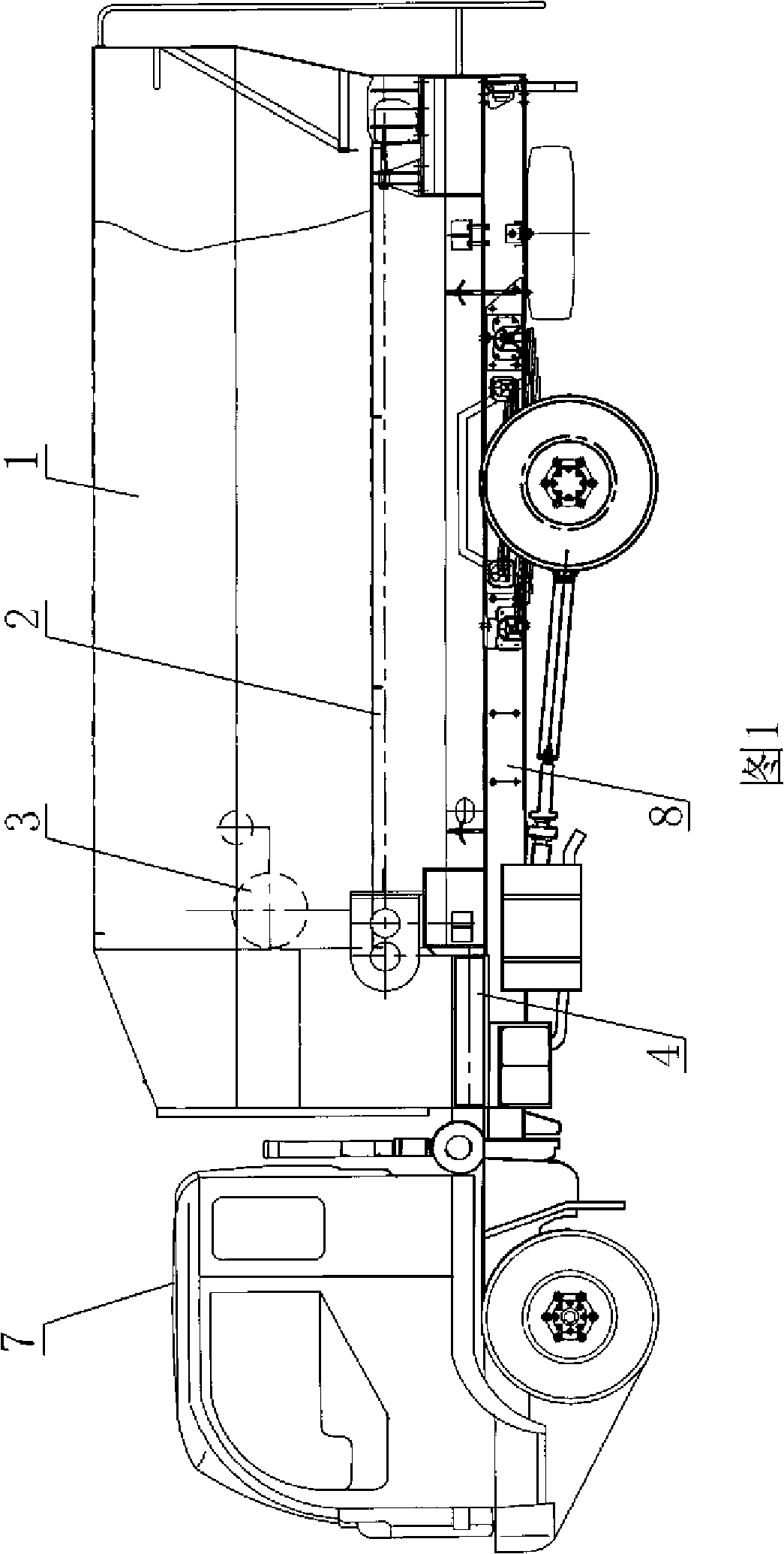

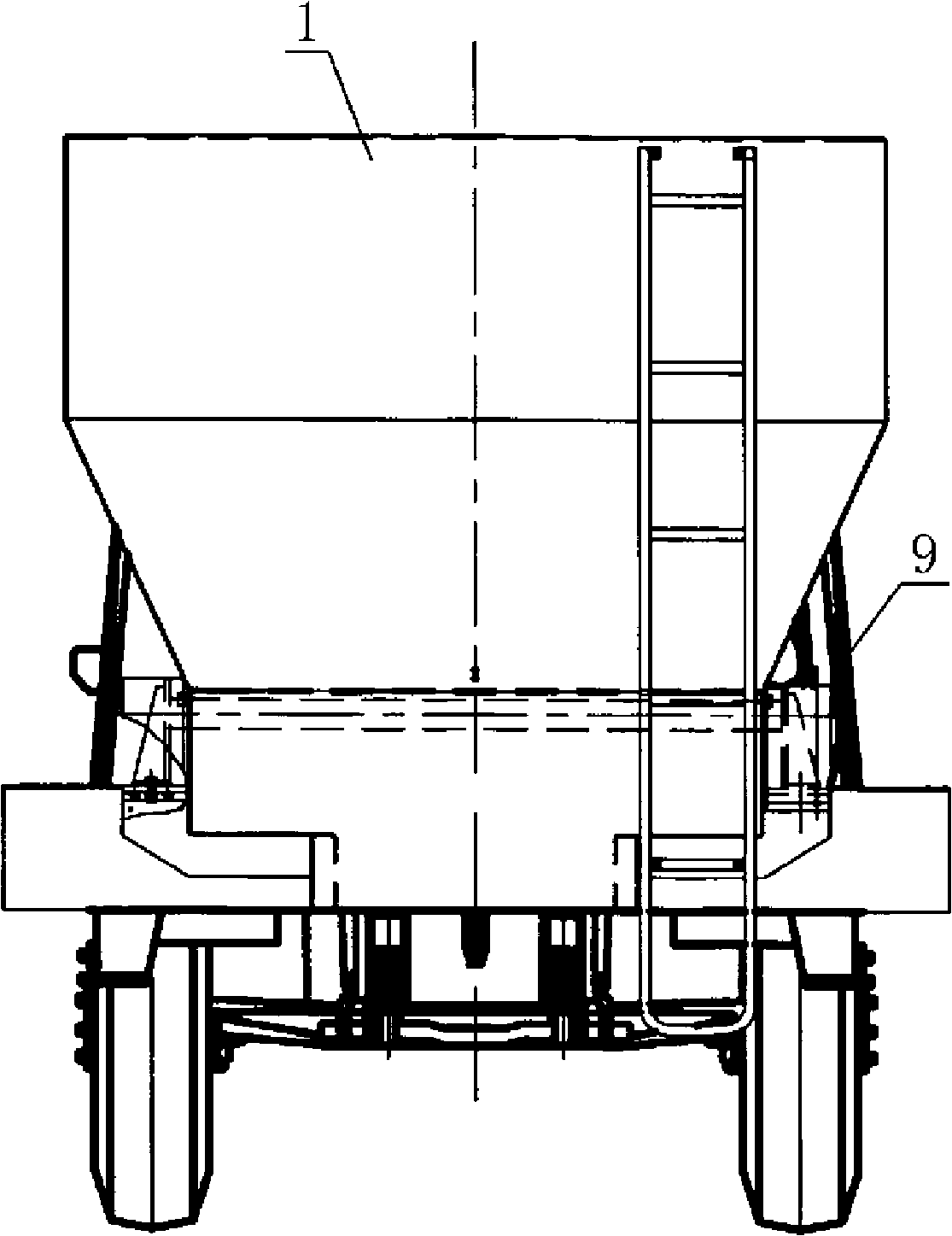

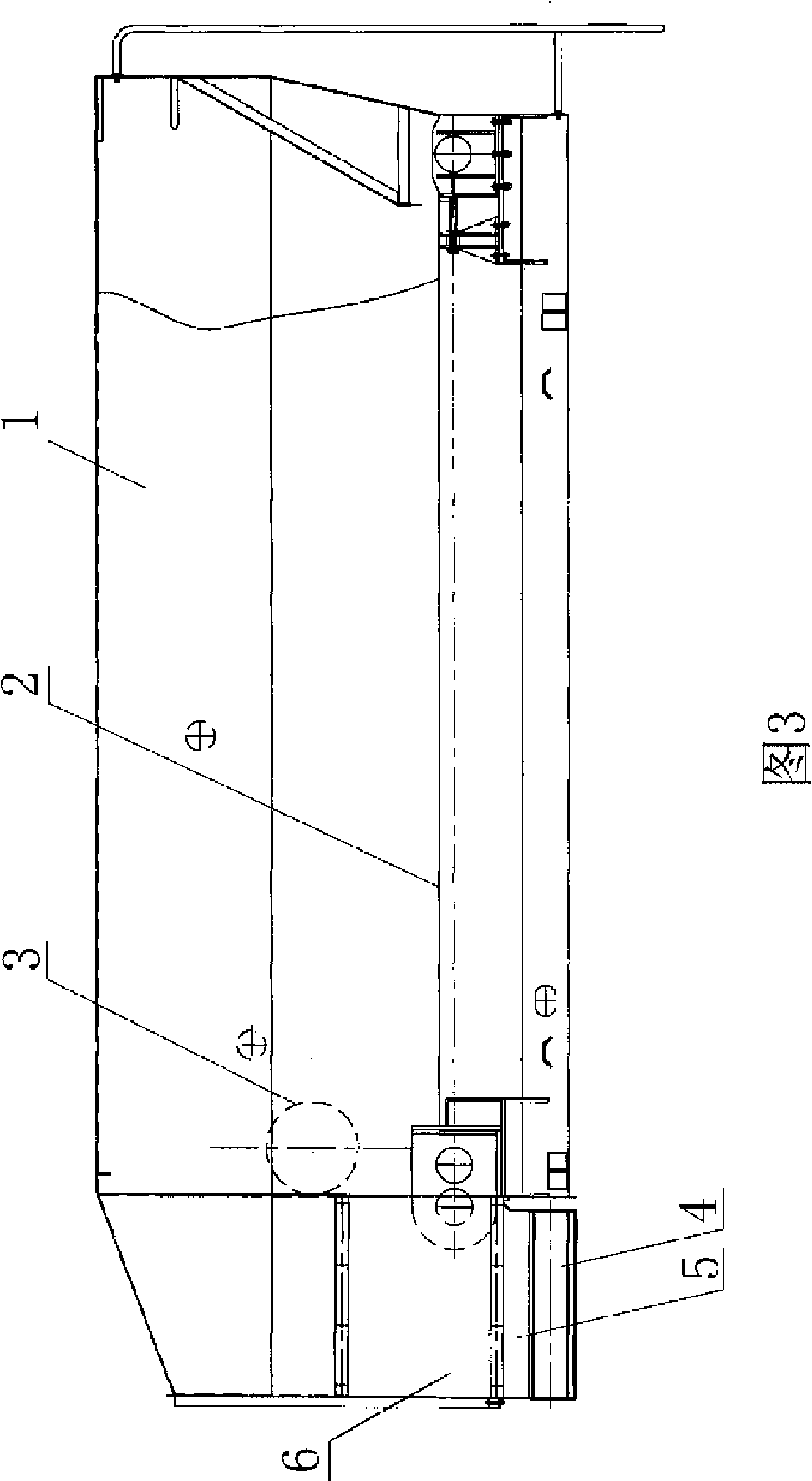

[0033] Referring to the embodiment shown in Figures 1-4, this feed supply vehicle includes a chassis 8, a compartment 1 and a driver's cab 7, and a longitudinal conveying device 2 is provided from the rear of the compartment bottom to the abdomen, and the head of the compartment bottom It is lower than the rear part of the bottom of the car to the abdomen, and a horizontal conveying device 4 is arranged along the width direction of the car in the depression. Have a discharge port 5 on the side wall of the compartment at the end, and a flashboard 6 is housed on the discharge port 5.

[0034] The carriage 1 is small at the bottom and large at the top, and is in an inverted trapezoidal shape. The shaft support 2.6 of the longitudinal conveying device 2, the longitudinal conveying reduction box 2.7 and the longitudinal conveying motor 2.9 are located outside the side wall of the carriage and covered by a cover plate 9.

[0035] Referring to Fig. 5, the longitudinal conveying devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com