Cooling system of motorboat engine

An engine cooling and cooling system technology, which is applied to the propulsion engine, motor-driven engine, ships, etc., can solve the problem that the cooling system cannot meet the cooling requirements of the motorboat engine, and achieve the effect of satisfying the requirements and reliable cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

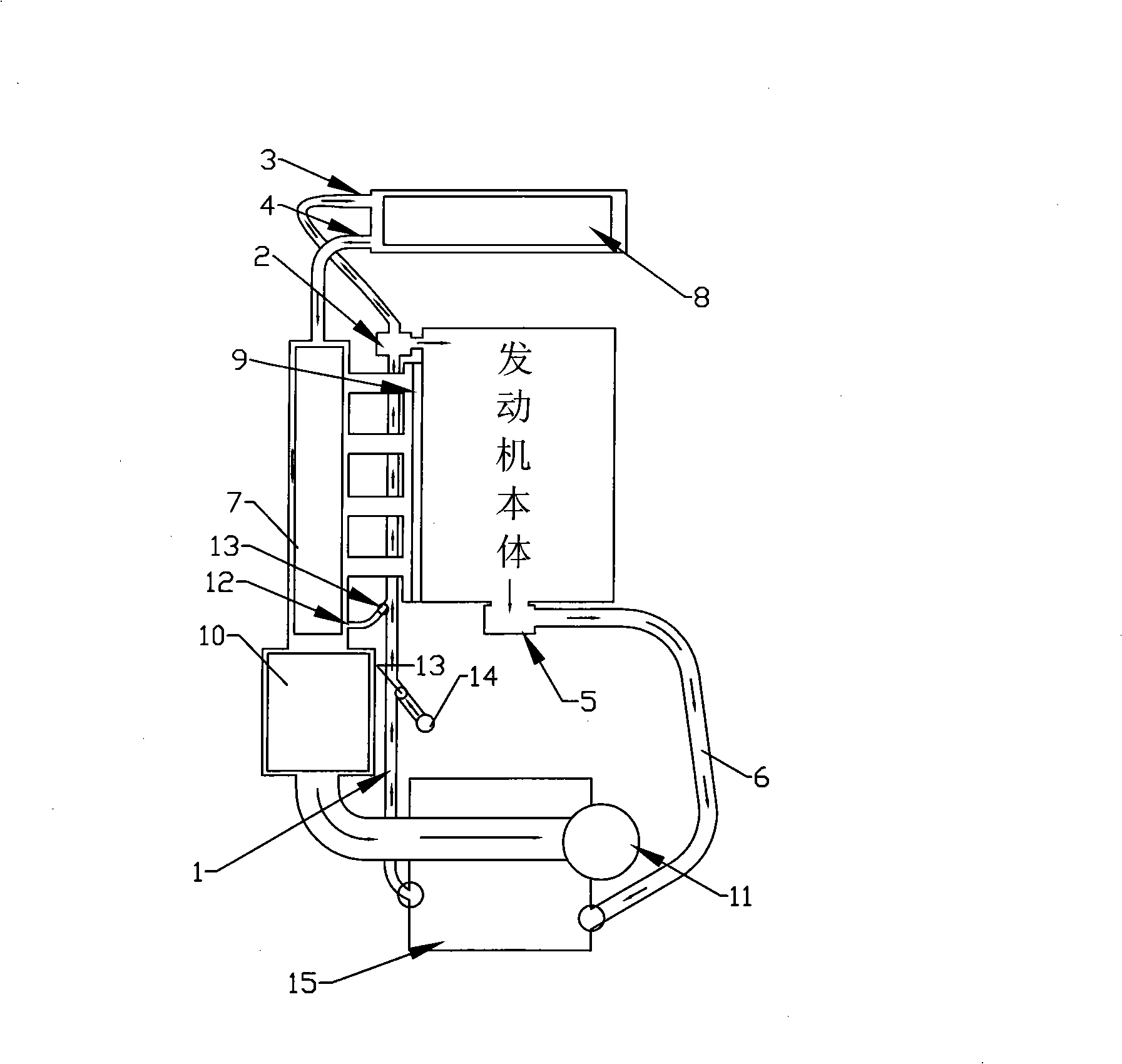

[0020] As shown in the drawings, the cooling system of the present invention includes an engine body cooling channel water chamber, a water pump assembly 15, a generalized oil pan 8, an exhaust pipe 7, an exhaust flange 9, an inlet pipe joint 2, a muffler 10 and a plastic muffler 11. Thermostat 5 and two one-way valves 13; the exhaust pipe 7 is a water-cooled exhaust pipe; the water pump assembly 15 is connected to the water inlet pipe joint 2 by the water inlet hose 1, and the water inlet pipe joint 2 is connected to the The water inlet joint 3 of the generalized oil pan 8 is connected by a hose, and the water outlet joint 4 of the generalized oil pan 8 is also connected with the exhaust pipe 7 by a hose; the thermostat seat 5 is arranged at the water outlet of the engine cylinder head , which is connected with the water pump assembly 15 by the outlet main pipe 6; the muffler 10 is connected with the exhaust pipe 7, and the plastic muffler 11 is connected with the muffler 10; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com