Method for analyzing and detecting free carbon in chromium carbide

A detection method and technology for free carbon, which can be used in the preparation of test samples, and by removing certain components for weighing, etc., which can solve the problem of low accuracy of free carbon and achieve good precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Determination of free carbon in chromium carbide (sample S-1)

[0025] Weigh 0.5000g (grams) of chromium carbide sample in a polytetrafluoroethylene sample-dissolving crucible, rinse the crucible wall with 1mL (milliliters) of deionized water, and then add in order the purity to be analytically pure and the mass concentration to be 1.14g / mL (grams) 10 mL of hydrofluoric acid (the same as in the following examples) and 1 mL of nitric acid with a purity of 1.42 g / mL (the same in the following examples) as analytically pure, and mix well, cover the crucible lid, and dissolve the sample in the crucible Put it into a stainless steel autoclave, tighten the lid of the autoclave, and heat the autoclave in a graphite furnace. When the temperature rises to 195-205°C, use a voltage regulator to adjust the voltage and keep it decomposed at this temperature for 120min (minutes). After the decomposition time is up, cool down and take out the autoclave, open the tank in...

Embodiment 2

[0028] Embodiment 2: Determination of free carbon in chromium carbide (sample S-2)

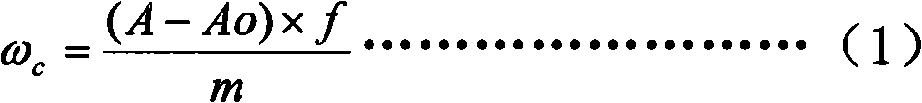

[0029] Weigh 0.5000g chromium carbide sample into a polytetrafluoroethylene crucible, add 1.5mL deionized water to rinse the crucible wall, then add 9mL hydrofluoric acid and 1.5mL nitric acid in sequence, mix well, cover the crucible lid, and put it into an autoclave , tightened, and the autoclave was placed in a graphite furnace for heating. When the temperature rises to 205-215°C, keep it at this temperature for 90 minutes to decompose. Then put the porcelain boat in an oven and bake at 120°C for 1.5h. After drying, measure the free carbon content in the sample with a 101-type carbon tester and calculate the free carbon content in the sample according to the above formula (1). The measurement results (X), mean value (x), standard deviation (S), and relative standard deviation (RSD) are shown in Table 2.

[0030] Table 2%

[0031] sample name

Embodiment 3

[0032] Embodiment 3: Determination of free carbon in chromium carbide (sample S-3)

[0033] Weigh 0.5000g of chromium carbide sample into a polytetrafluoroethylene crucible, add 2.0mL of deionized water to rinse the crucible wall, then add 7mL of hydrofluoric acid and 2mL of nitric acid in sequence, mix well, cover the crucible lid, and put it into an autoclave. Tighten, place the autoclave in a graphite furnace for heating. When the temperature rises to 215-225°C, keep it at this temperature for 70 minutes to decompose. Then put the porcelain boat in an oven, bake it at 150°C for 1 hour, measure it with a carbon analyzer after drying, and calculate the free carbon content in the sample according to the above formula (1). The measurement results (X), mean value (x), standard deviation (S), and relative standard deviation (RSD) are shown in Table 3.

[0034] table 3%

[0035] sample name

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap