Substrate for magnetic disk and magnetic recording medium

A magnetic recording medium and magnetic disk technology, applied in the direction of the magnetic recording layer, the base layer of the recording layer, different recording carrier forms, etc., can solve the problems that cannot fully meet the high recording density, and achieve the effect of excellent electromagnetic conversion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1 to 12

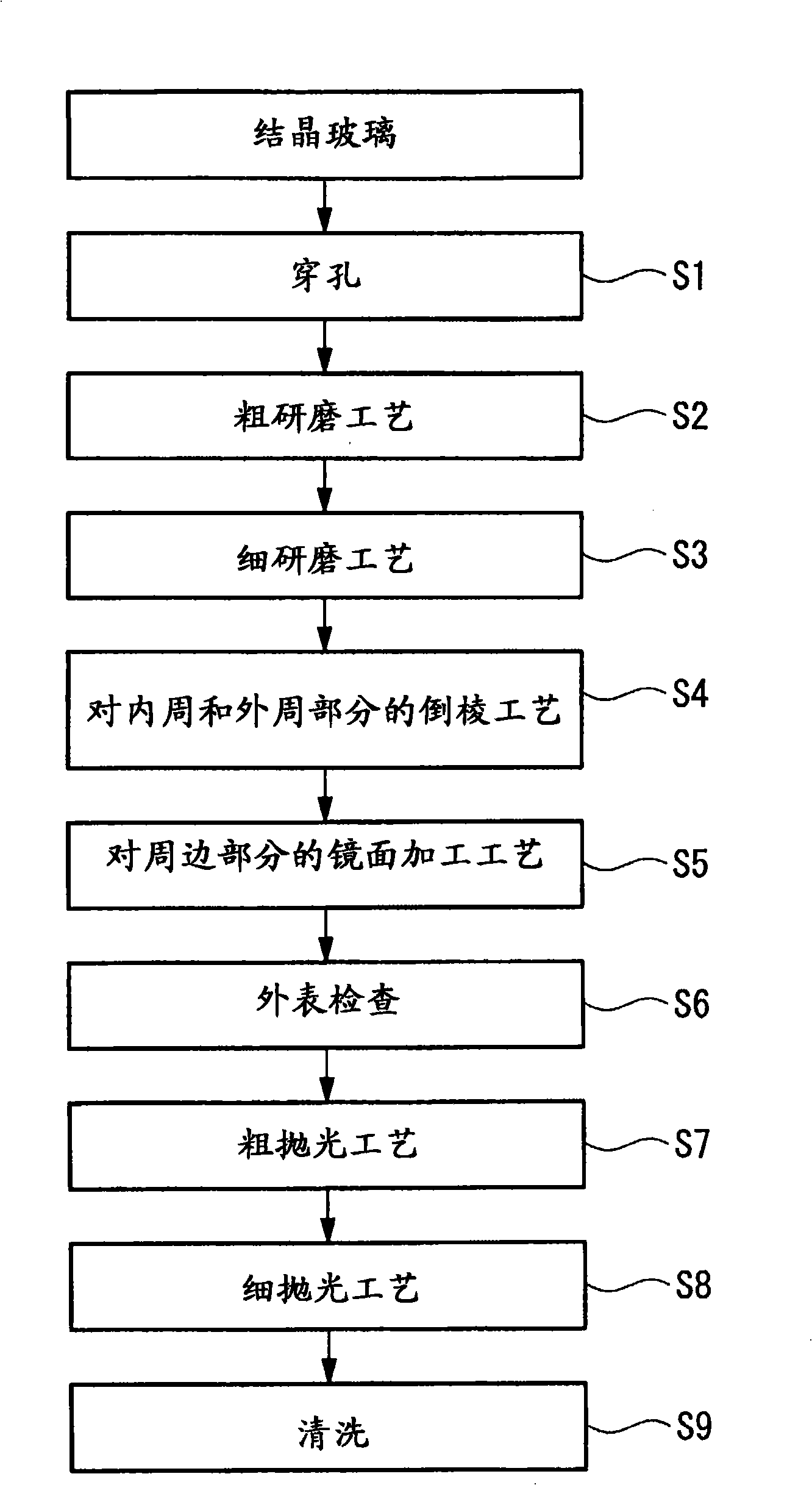

[0047] Preparation mainly consists of 77% SiO 2 , 11% Li 2 O, 4% Al 2 o 3 and 3% MgO raw material glass, as the material for each disk substrate. By using a melting device, the raw material glass was melted at about 1350° C. to 1500° C., and the raw material glass was mixed, pressed, and cooled, thereby obtaining a disk-shaped glass plate having a diameter of 66 mm and a thickness of about 1 mm. The obtained glass plate was then heat-treated at 540° C. for about five hours to form crystal nuclei and at 780° C. for two hours to form crystals, thereby forming a crystallized glass in which the crystalline phases were lithium disilicate and alpha quartz, And aggregated particles of alpha quartz are dispersed on the glass.

[0048] Next, a base was prepared by forming a center hole in the center portion of the crystallized glass plate using a cylindrical grinding stone. Then, by using a polishing device capable of polishing both sides of the substrate and using diamond particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com