Ferromagnetic powder for magnetic recording and magnetic recording medium

A ferromagnetic technology for magnetic recording, applied in the direction of the magnetic material of the record carrier, etc., can solve the problem of difficult running durability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

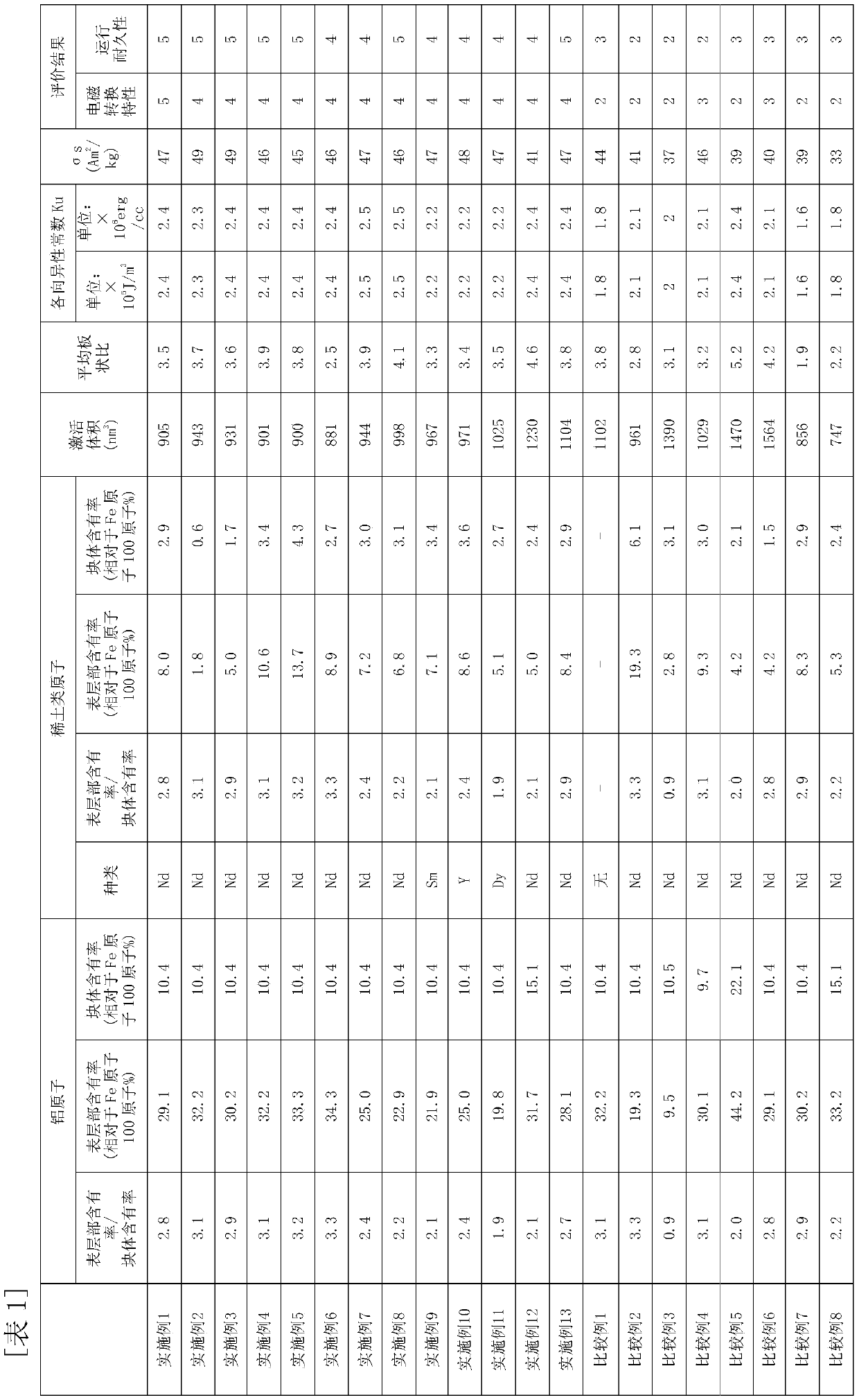

Embodiment 1

[0120] Weigh SrCO 3 1610g, H 3 BO 3 635g, Fe 2 o 3 1097g, Al(OH) 3 108g, BaCO 3 23g, CaCO 3 34g and Nd 2 o 3 231 g and mixed with a mixer to obtain a raw material mixture.

[0121] The obtained raw material mixture was melted at a melting temperature of 1390° C. in a platinum crucible, and the outlet provided at the bottom of the crucible was heated while stirring the melt, so that the melt flowed out in rod form at about 6 g / sec. The effluent was rolled and quenched with water-cooled twin rolls to produce an amorphous body.

[0122] The produced amorphous body 280g is charged into an electric furnace, heated up to 635°C (crystallization temperature) at a heating rate of 3.5°C / min, and kept at this temperature for 5 hours to precipitate hexagonal strontium ferrite particles ( crystallization).

[0123] Next, coarsely pulverize the crystallized product obtained above containing hexagonal strontium ferrite particles with a mortar, put 1000 g of zirconia beads w...

Embodiment 2

[0125] In addition to the Nd used in the preparation of the raw material mixture 2 o 3 Hexagonal strontium ferrite powder was obtained in the same manner as in Example 1 except that the amount was 47 g.

Embodiment 3

[0127] In addition to the Nd used in the preparation of the raw material mixture 2 o 3 Hexagonal strontium ferrite powder was obtained in the same manner as in Example 1 except that the amount was 142 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Step size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com