Heat-assisted magnetic recording medium and magnetic storage device

A recording medium and auxiliary magnetic technology, which is applied in the fields of recording information storage, magnetic recording, data recording, etc., can solve the problems of increasing Curie temperature variance of magnetic particles, decreasing temperature, and decreasing electromagnetic conversion characteristics of thermally assisted magnetic recording media. , to achieve the effect of excellent electromagnetic conversion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~1-8

[0090] (Examples 1-1 to 1-8 and Comparative Example 1-1)

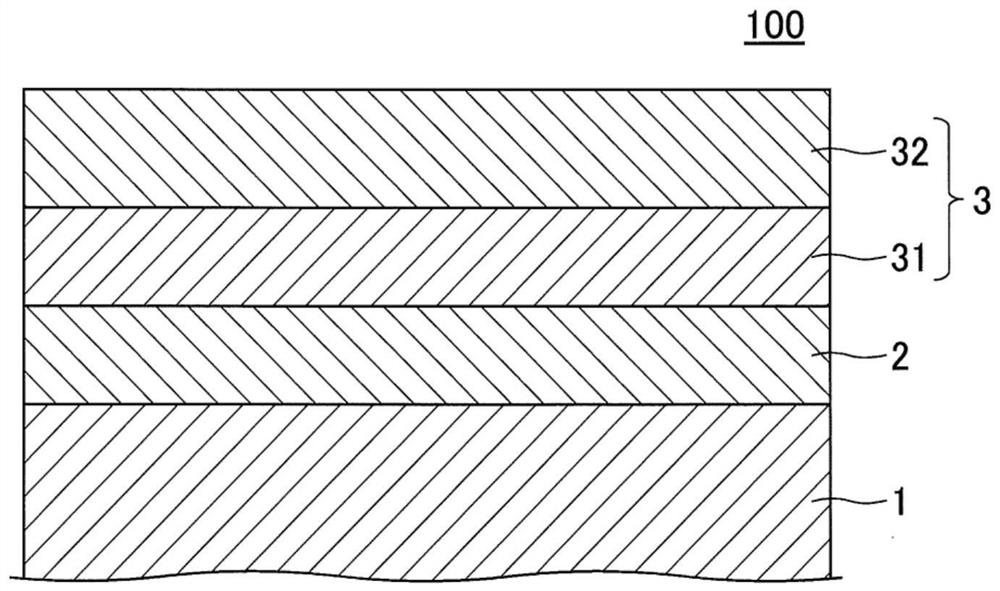

[0091] Form a Cr-50at%Ti (Cr content is 50at%, Ti content is 50at%) alloy layer (underlayer) with a thickness of 50nm and a Co-20at%Ta-5at%B with a thickness of 25nm on a heat-resistant glass substrate alloy layer (soft magnetic underlayer), which is then heated to 250°C. Next, a Cr layer (underlayer) with a thickness of 10 nm and an MgO layer (underlayer) with a thickness of 10 nm were formed, which were then heated to 520°C. Next, a first magnetic layer with a thickness of 0.5 nm and a second magnetic layer with a thickness of 6.0 nm were formed, and then a carbon layer (protective layer) with a thickness of 3 nm was formed. Finally, a lubricant layer was formed by coating a perfluoropolyether-based lubricant on the protective layer, whereby a heat-assisted magnetic recording medium was obtained.

[0092] Here, the materials constituting the first magnetic layer and the second magnetic layer are shown in Table 1.

...

Embodiment 2-1~2-9

[0101] (Examples 2-1 to 2-9 and Comparative Example 2-1)

[0102] Except that the thickness of the first magnetic layer was changed to 1.0 nm, and the materials constituting the first magnetic layer and the second magnetic layer were changed (see Table 2), compared with Examples 1-1 to 1-8 and In Example 1-1, a heat-assisted magnetic recording medium was obtained in the same manner.

[0103] Table 2 shows the measurement results of the electromagnetic conversion characteristics of the heat-assisted magnetic recording media.

[0104] 【Table 2】

[0105]

[0106] It can be seen from Table 2 that the electromagnetic conversion characteristics of the heat-assisted magnetic recording media of Examples 2-1 to 2-9 are relatively high.

[0107] However, in the heat-assisted magnetic recording media of Comparative Examples 2-1 and 2-2, since the second magnetic layer does not contain ferrite, the electromagnetic conversion characteristics are low.

[0108] Based on the above, it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com