Dust collection structure

A technology of dust collection bucket and dust collection chamber, which is applied in the direction of suction filter, etc., can solve the problems of increased air turbidity and increased filter workload, and achieve the effect of increased workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

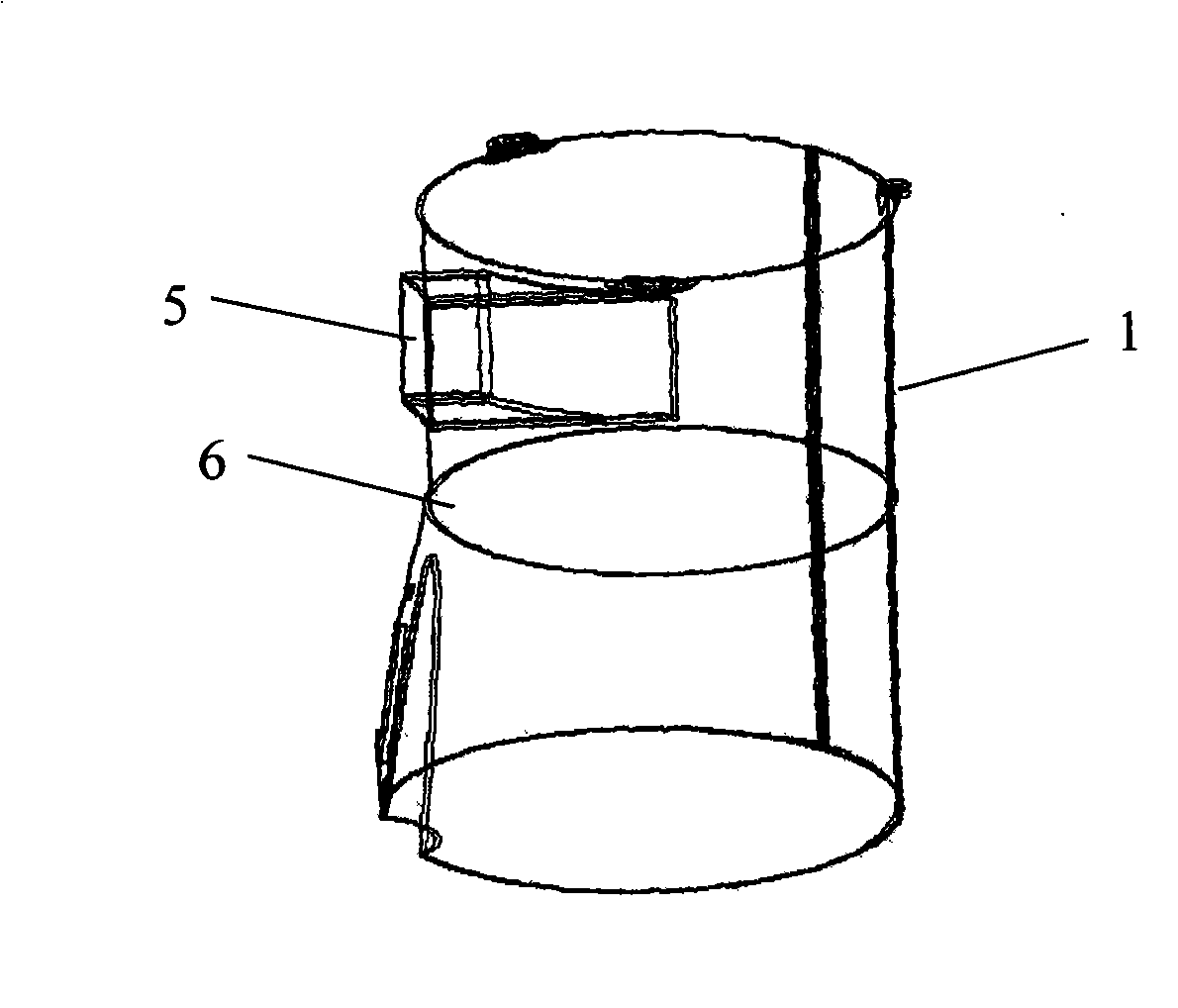

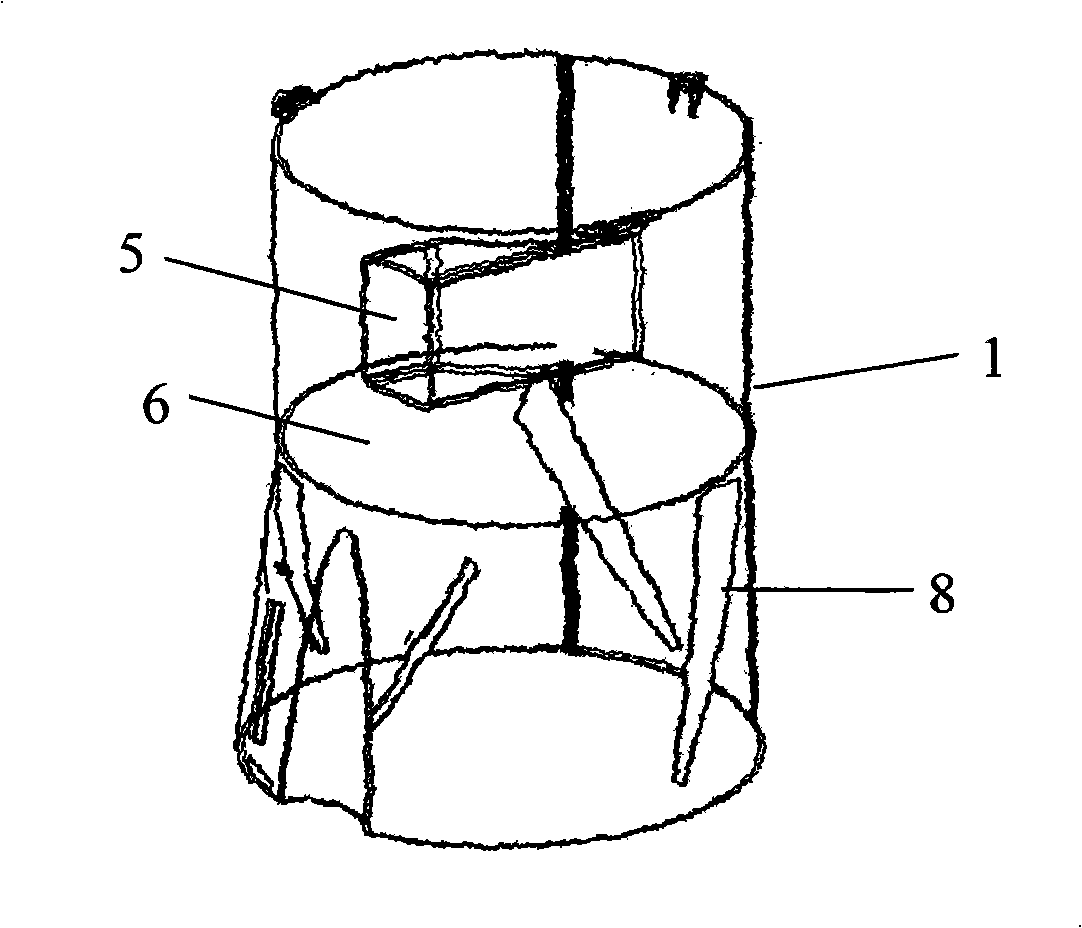

[0023] image 3 It is a three-dimensional schematic diagram of the bucket body of the dust collecting bucket of the present invention.

[0024] In the drawings, the same symbols are used for the same components.

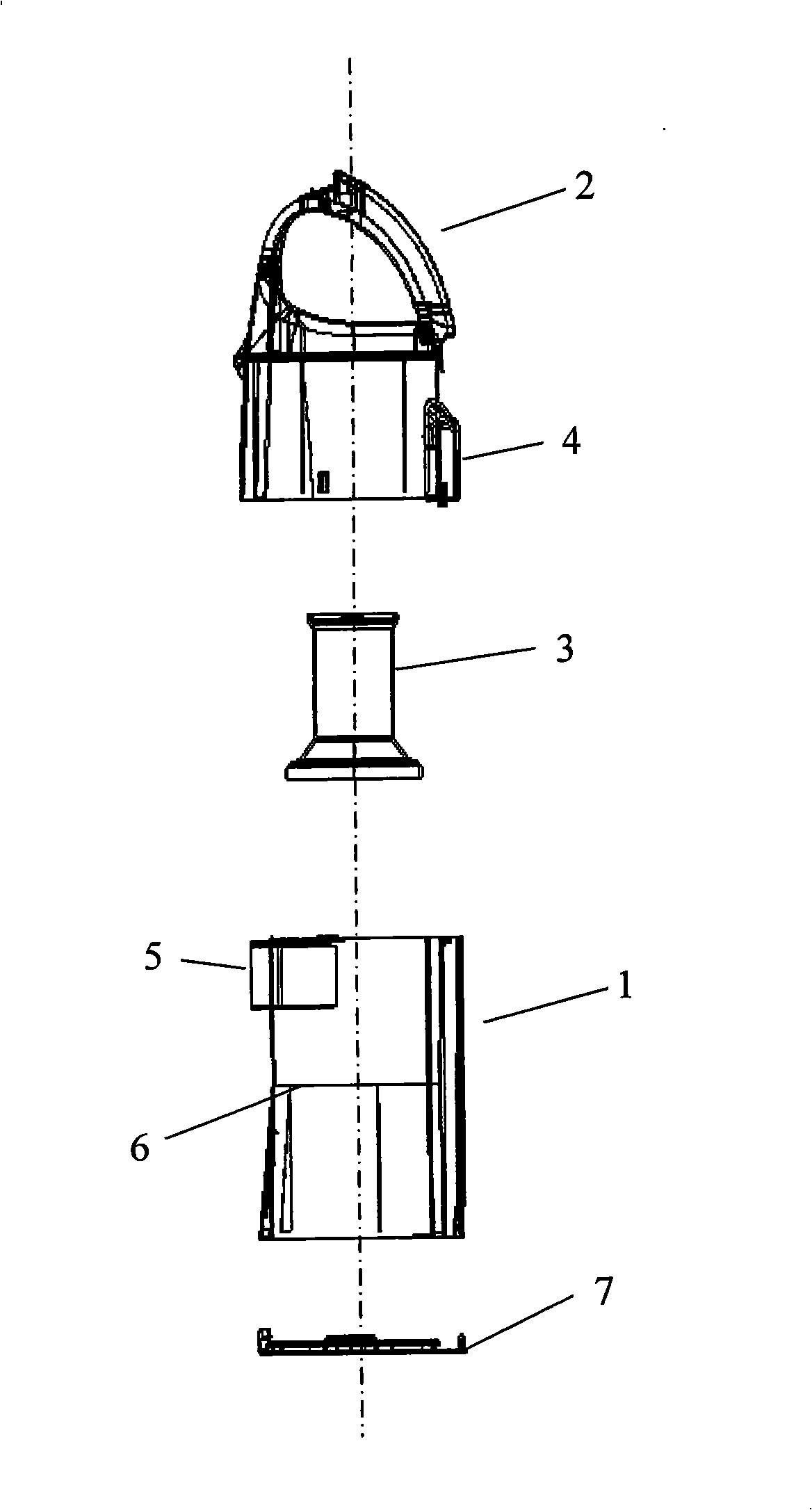

[0025] Such as image 3 As shown, a dust collecting barrel structure, the dust collecting barrel includes a barrel body 1; an upper cover 2; and a filter 3 including a filter cover and a filter element; a bottom cover 7 hingedly formed at the bottom of the barrel; the dust collecting barrel barrel 1 A plurality of windshields 8 that can change the direction of the airflow are formed in the lower dust collection chamber; a plurality of windshields 8 that can change the direction of the airflow are formed in the dust collection cham...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap