Steel tape

A steel tape measure and ruler wheel technology, applied in the direction of a bendable ruler, can solve the problems of high noise, high production cost, easy wear, etc., and achieve the effects of slow speed, low cost, and reduced wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

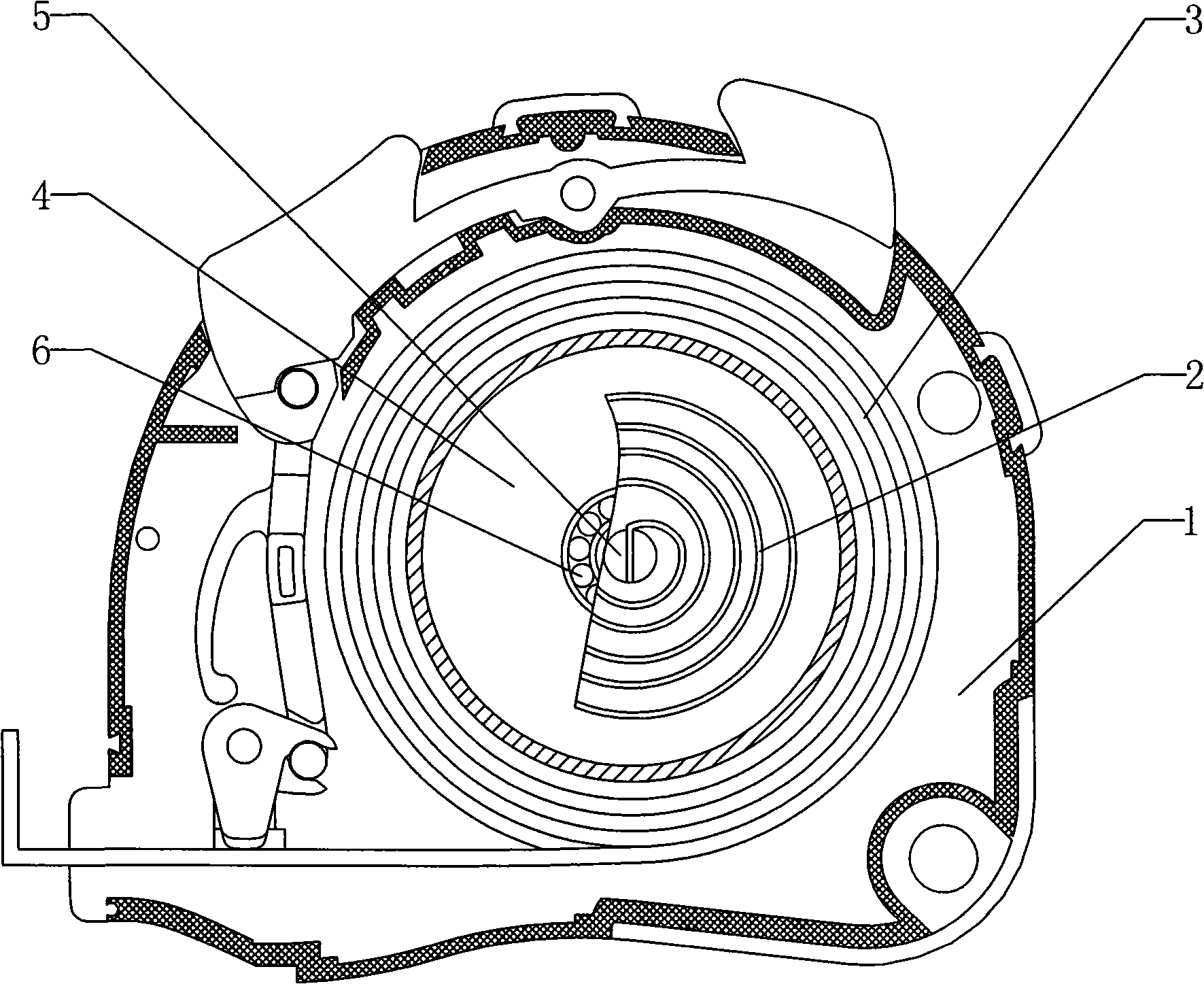

[0011] Such as figure 1 As shown, the steel tape measure of the present invention mainly includes a housing 1, a reverse spring 2, a ruler belt 3 and a ruler wheel 4. The center of the housing 1 is provided with a central column 5, and the described ruler wheel 4 is installed on the central column 5, the center of the scale wheel 4 is provided with a bearing 6, and the scale wheel 4 is fixed on the center column 5 through the bearing 6; the reverse spring 2 is fixed on the center column 5, and the reverse spring 2 is located inside the scale wheel 4; The ruler tape 3 mentioned above is wound on the outside of the ruler wheel 4 . When in use, no noise will be generated when the ruler tape 3 is pulled, the wear of the ruler wheel 4 is reduced, and the service life of the steel tape is prolonged; at the same time, the requirement for the amount of the counter spring 2 is reduced, and the production cost is saved.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap