Manufacturing process of wiring convenient road lamp wiring box

A manufacturing process, junction box technology, applied in the direction of clamping/spring connection, electrical components, etc., to achieve the effect of large voltage creepage distance, clever idea, and overcoming cumbersome wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

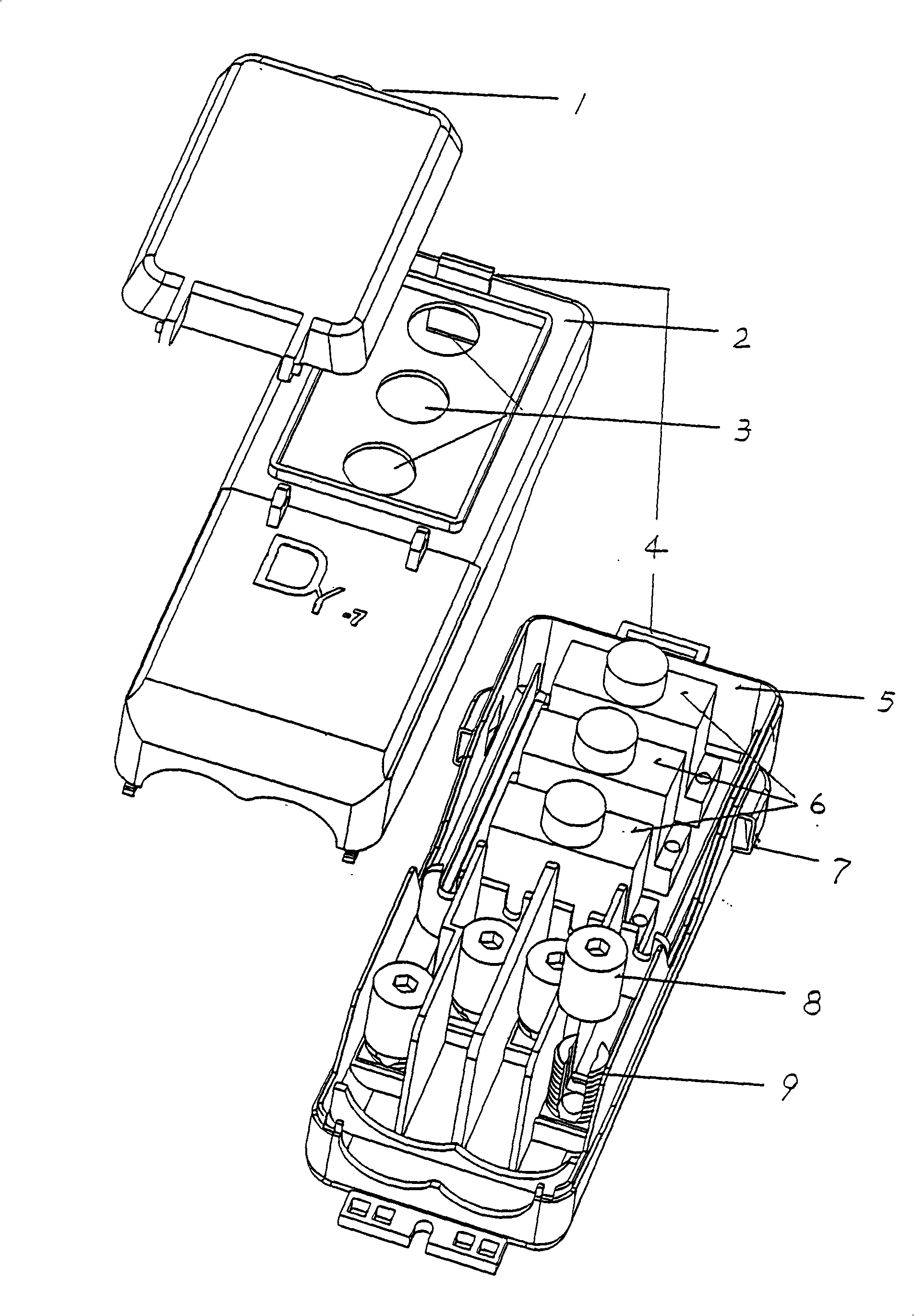

[0008] A manufacturing process of a street lamp junction box with convenient wiring mainly includes the following steps: a matching open-type terminal nut and an open-type terminal are provided in the base. The structure of the street lamp junction box with convenient connection manufactured by the present invention will be further described in detail below in conjunction with the accompanying drawings. Referring to the accompanying drawings, a street light junction box with convenient wiring is mainly composed of an upper cover 2 and a base 5 with a fuse box 6. The upper cover 2 is provided with a fuse nut hole 3 and a transparent cover 1 for viewing the fuse. Matching snap buttons 4 are provided at corresponding positions of the upper cover 2 and the base 5 . The base 5 is provided with an open terminal post 9 and an open terminal post nut 8 . The side end of the base 5 is provided with a rain-shielding ear type outlet hole 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com