Paint supply system

A coating supply and coating technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve problems such as paint clogging, complicated cleaning operations, and increased equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described below based on the drawings.

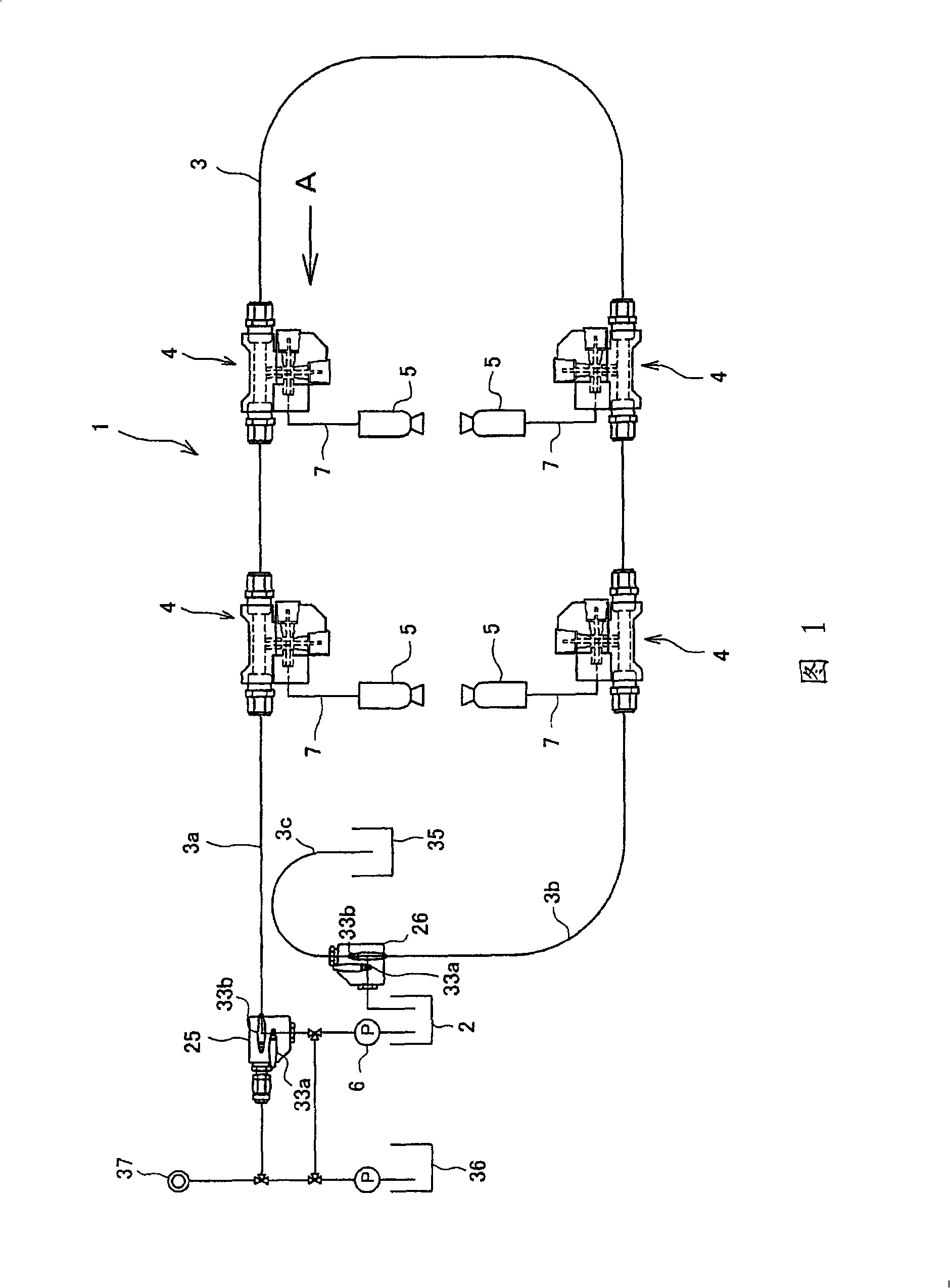

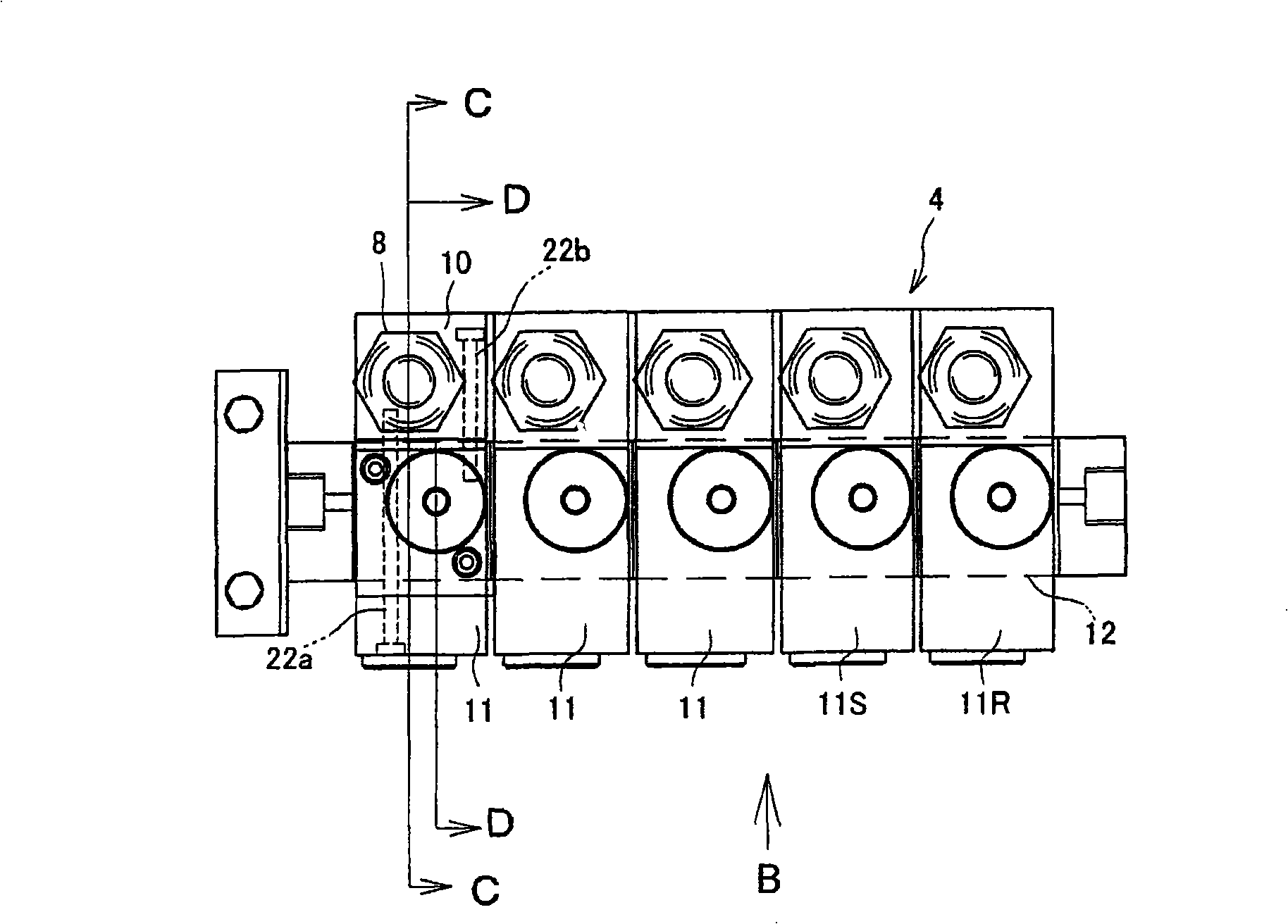

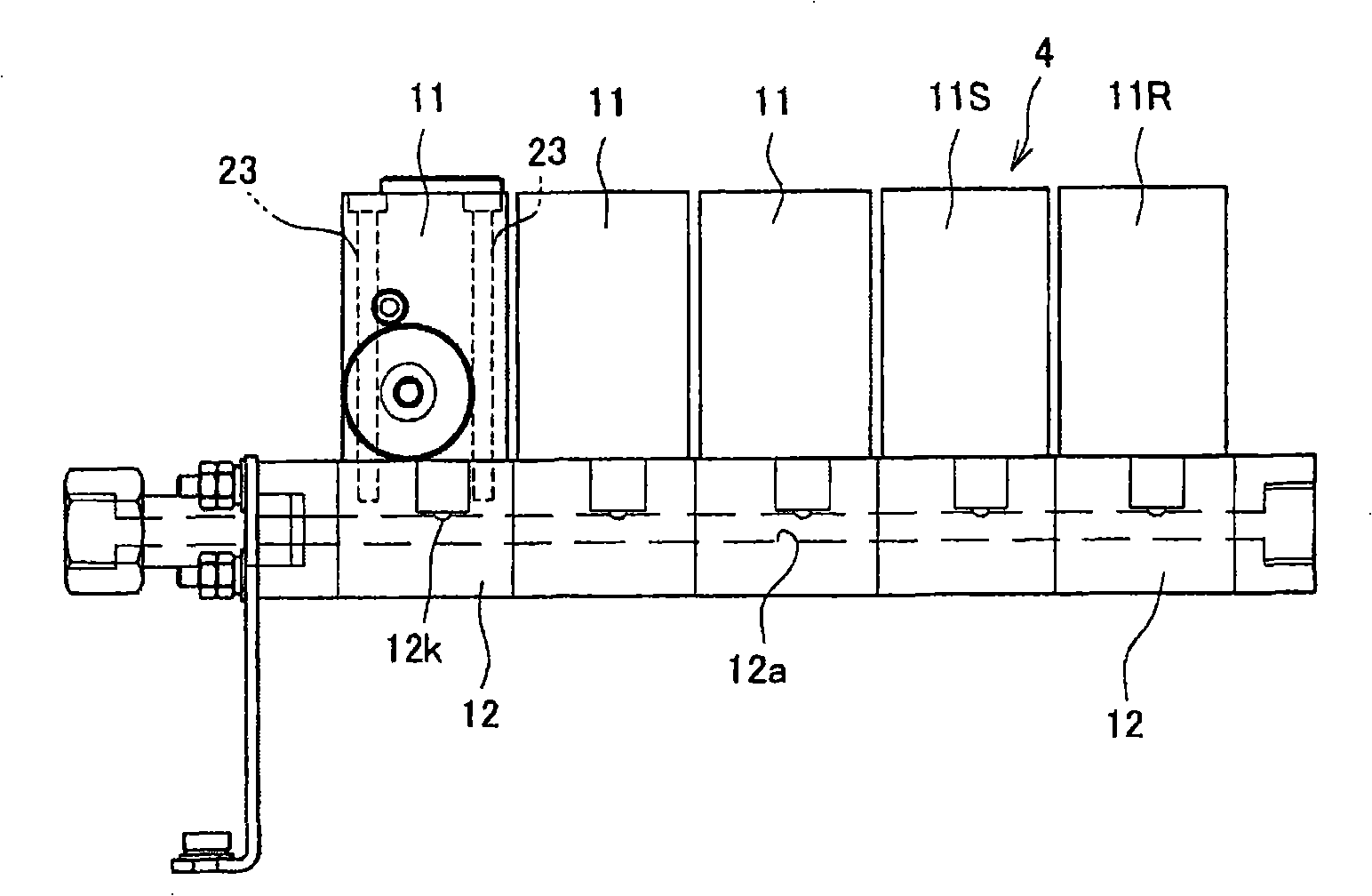

[0025] Here, Fig. 1 is a schematic structural view showing the circulation piping of a certain color paint of the paint supply device of the present invention, figure 2 It is an explanatory diagram of the color change valve viewed from the direction A of Fig. 1, image 3 From figure 2 The explanatory diagram viewed in the direction of B, Figure 4 is figure 2 The C-C line profile, Figure 5 is figure 2 Figure 6 and Figure 7 are explanatory diagrams for putting the pig into the valve.

[0026] The paint supply device of the present invention is constituted, for example, as a device for supplying paint to a spray gun in a spray booth used in an automobile body spray process, so that a plurality of paint cycles installed from the paint mixing room to the spray booth are cleaned with a pig. During piping, it is difficult to clog the paint passage with peeled deposits, and it is possible ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap