Cleaning structure of industry parts washer

A technology for cleaning warehouses and washing machines, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., which can solve the problems of unsafe working conditions, increase labor intensity, flammability, etc., and improve cleaning efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

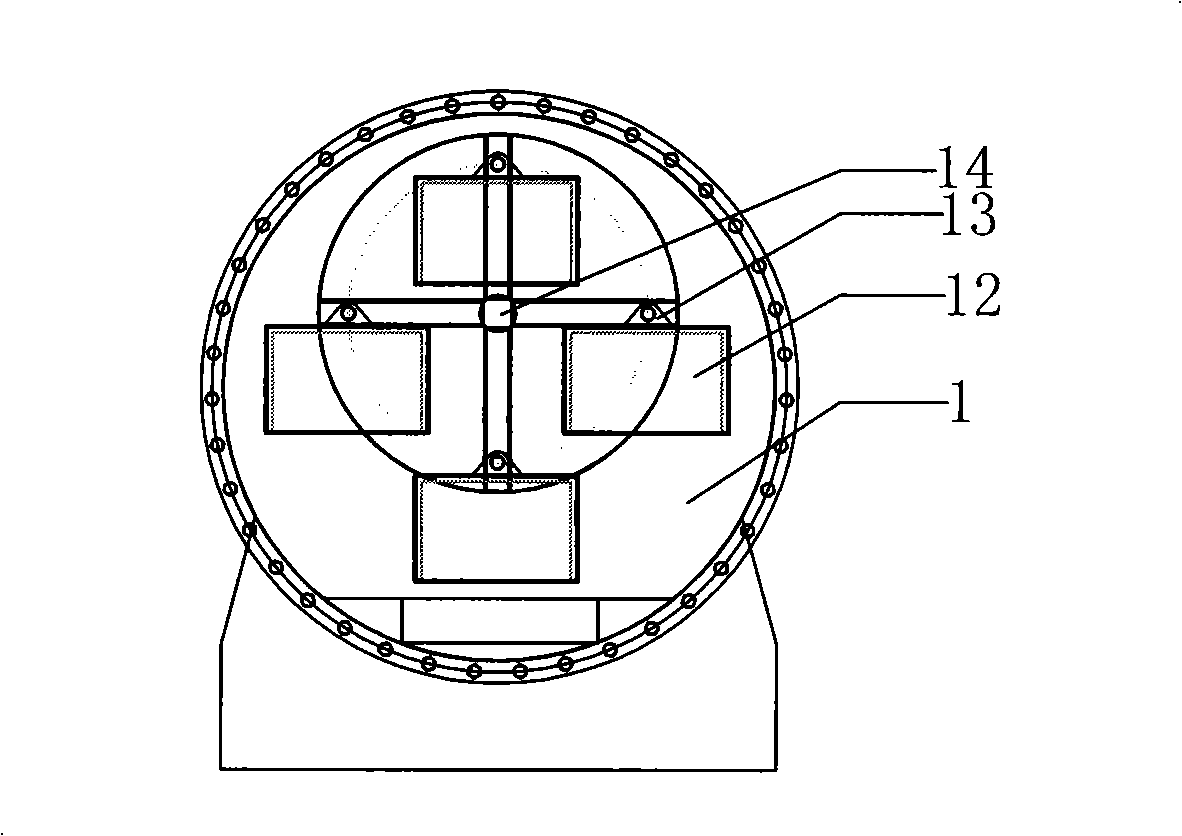

[0012] like figure 1 As shown, the cleaning chamber structure of the industrial parts cleaning machine described in the utility model is a cleaning chamber structure of an industrial parts cleaning machine. The cleaning chamber 1 is a cylinder, and several hanging baskets 12 for loading parts are installed in the cleaning chamber 1. The hanging basket 12 is hung on the hanging basket support 13, and the hanging basket support 13 is equipped with an eccentric main shaft 14 relative to the cylindrical cleaning chamber 1, which is driven to rotate by the main transmission system 2 with a reducer; the hanging basket support 13 can be rotated clockwise or Turn counterclockwise.

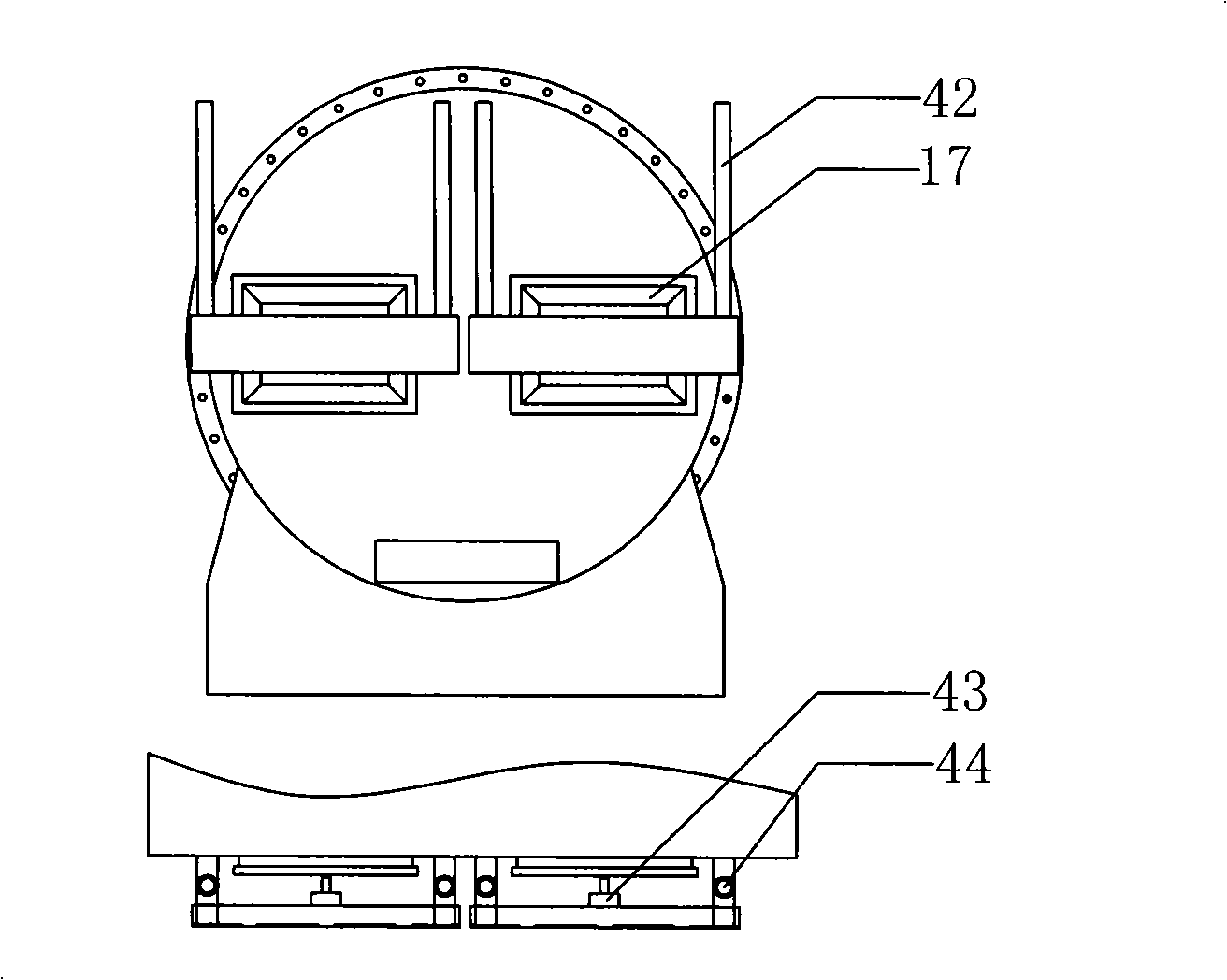

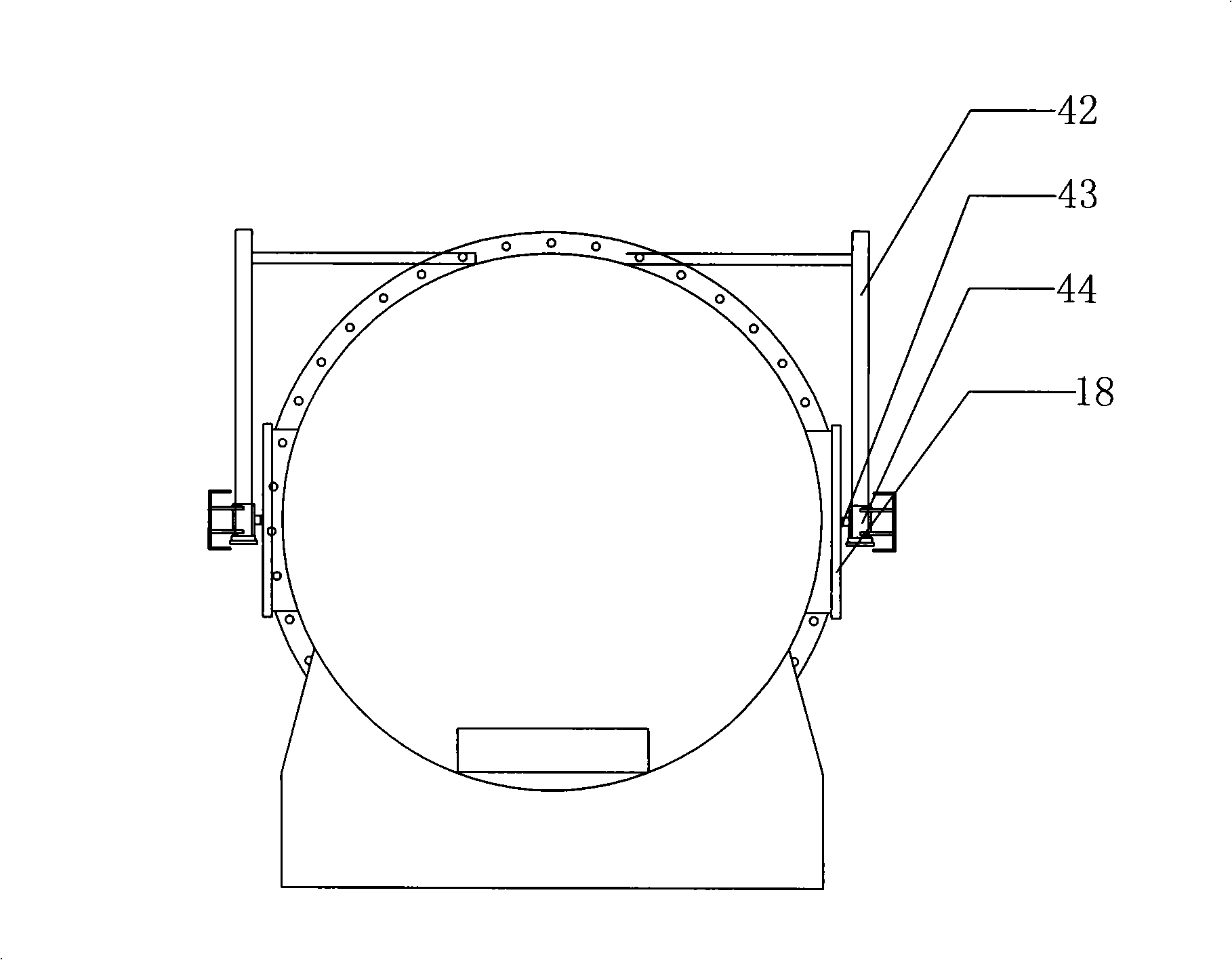

[0013] like Figure 2-3 As shown, there are two ways to open the door of the cleaning chamber of the industrial parts cleaning machine described in the utility model: one is to open two door 17 horizontally on the cylindrical end surface of the cleaning chamber 1, and the door 17 is opened by the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com