Epicyclic transmission type straw block making machine

A technology of straw briquetting machine and planetary transmission, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of small agricultural machines that cannot be driven and are not suitable, and achieve small power, improve extrusion efficiency, and manufacture low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

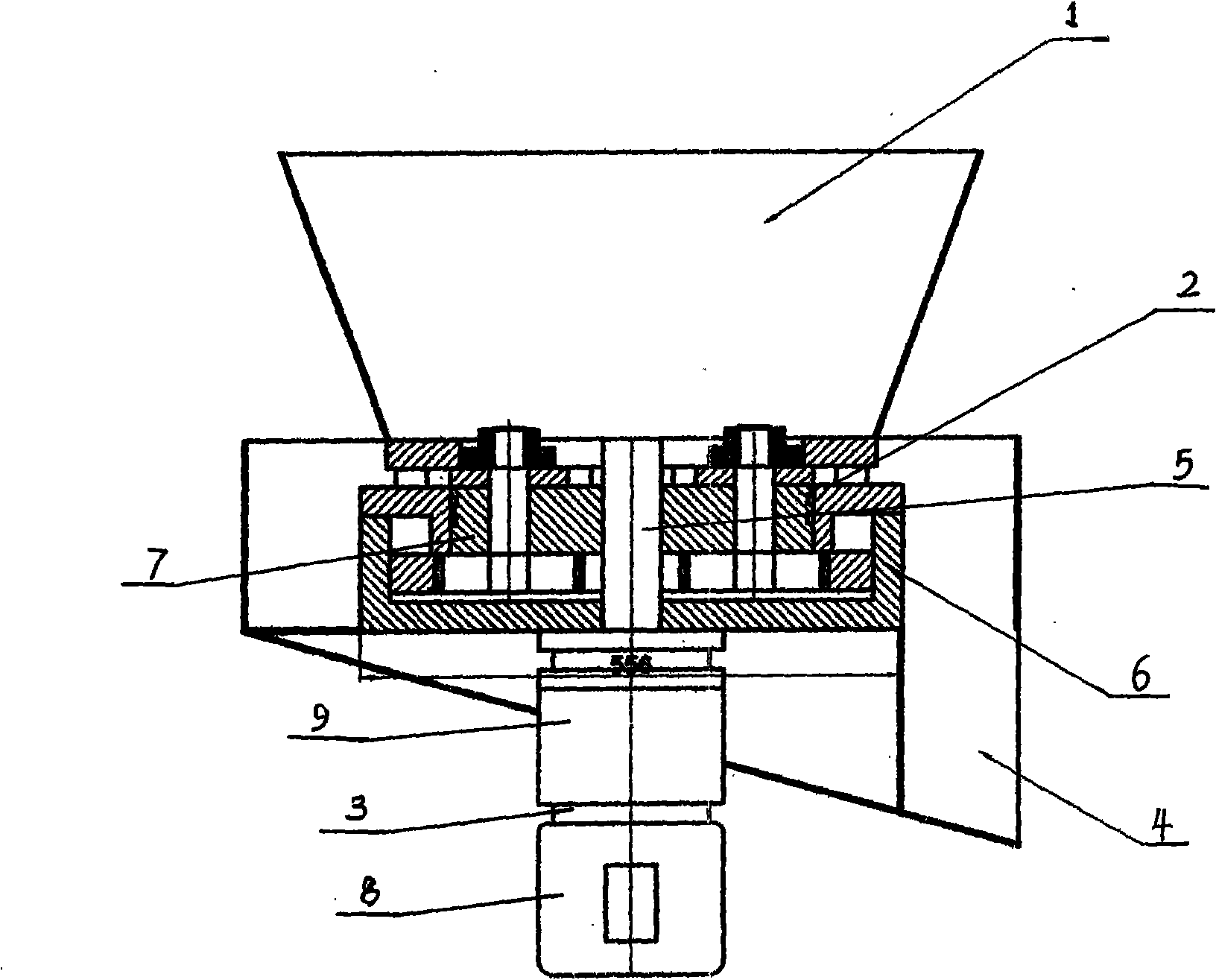

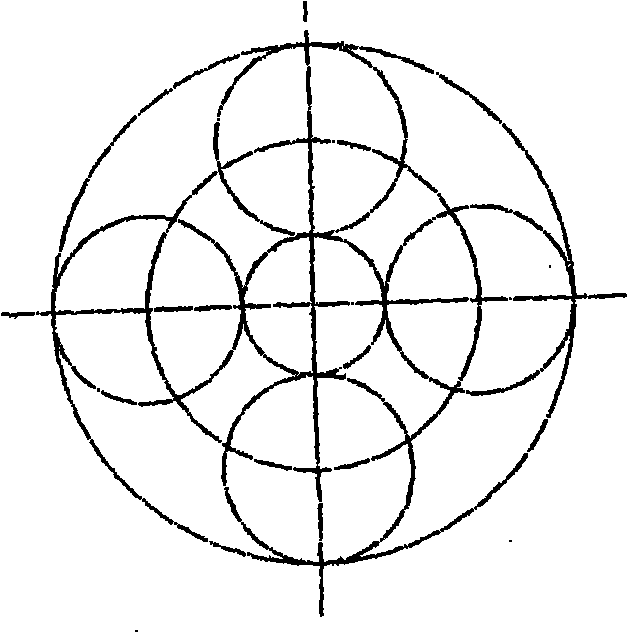

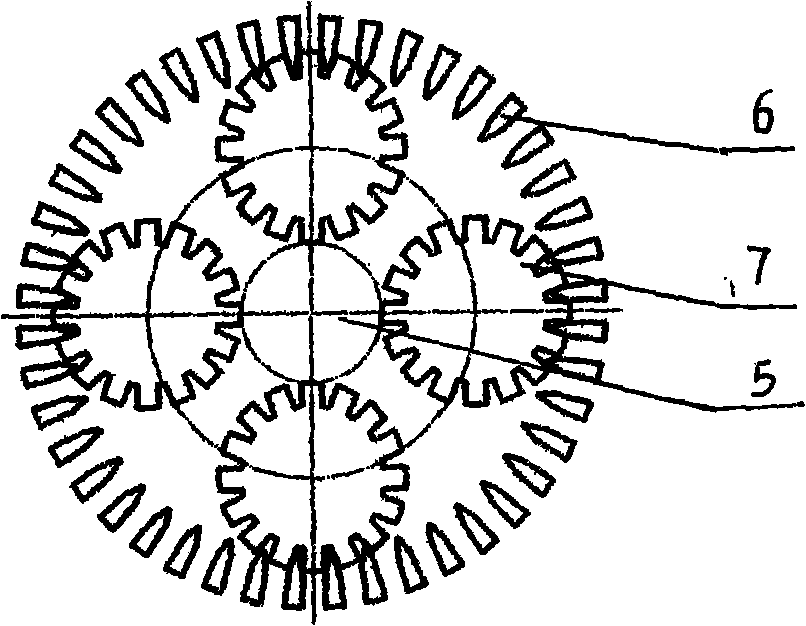

[0018] Embodiment 1: as figure 1 -4. The planetary transmission straw briquetting machine is composed of a feed hopper 1, an extrusion mechanism 2, a power input mechanism 3 and a discharge port 4. The feed hopper 1 is connected to the extrusion mechanism 2, and the discharge port 4 is connected to the extrusion The mechanism 2 is connected, and the extruding mechanism 2 is connected with the power input mechanism 3. The extruding mechanism 2 includes a gear shaft 5 and a forming die 6. The gear shaft 5 is located in the middle of the forming die 6 and is connected with the power output shaft of the power input mechanism 3. Concavo-convex meshing teeth are formed on the inner ring of the forming die 6 circumference, and paired gears 7 are housed between the gear shaft 5 and the forming die 6 and the paired gears 7 are meshed with the gear shaft 5 and the forming die 6 . Paired gears 7 are 1-3 pairs. The power input mechanism 3 includes a power machine 8 and a speed reducer 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com